Multi-strain mixed fermentation process for soy sauce

A mixed fermentation and multi-strain technology, applied in the field of condiment processing, can solve the problems of difficult production of soy sauce, poor flavor of soy sauce, lack of competitiveness, etc., to improve amino acid nitrogen content and protein utilization, moderate saltiness, The effect of enhancing the luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

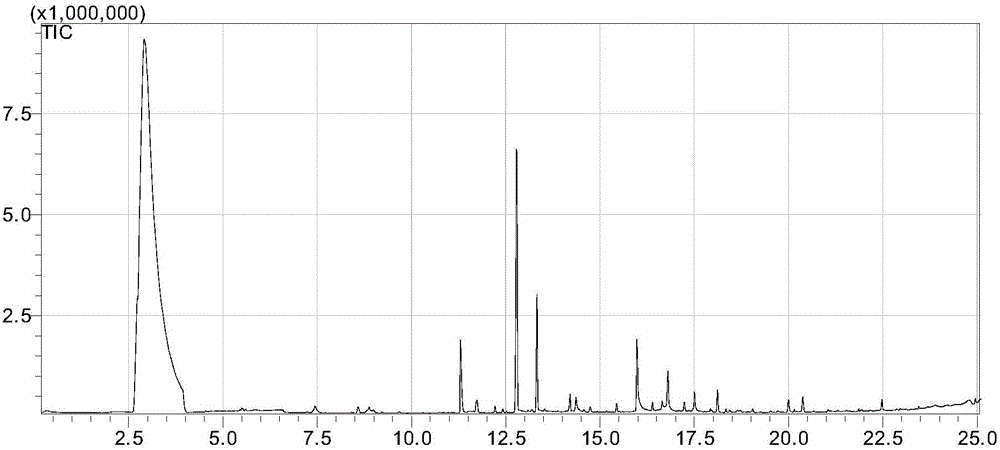

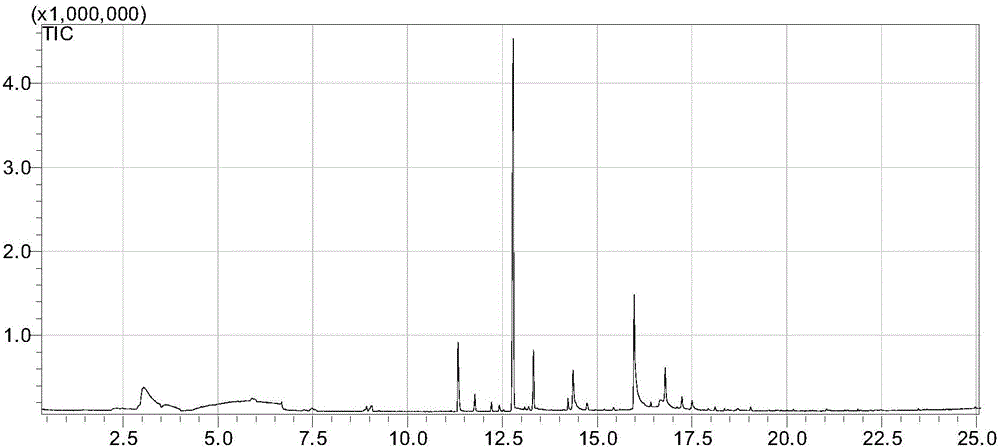

Image

Examples

Embodiment 1

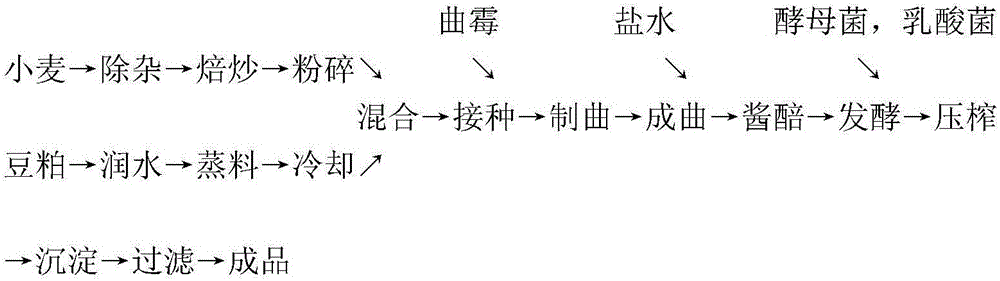

[0034] 1. a soy sauce multi-bacteria mixed fermentation process, its technological process is as follows:

[0035] S1 wheat selection: wheat impurities (stones, iron, metal lumps, dust, straw) are removed through the wheat screening machine.

[0036] S2 Roasted wheat, crushing: denature wheat protein, α-starch, sterilize and cool to produce the aroma of fried wheat. Put the wheat into the preheated wheat frying machine for roasting, the temperature of the wheat frying is 400°C, the outlet temperature is 180°C, cool to below 50°C and pulverize.

[0037] S3 cooking soybean meal: moderately denature the protein in the soybean meal, gelatinize the starch, and kill the microorganisms in the soybean meal. Run the steamer idly to preheat for 3 minutes, drain the condensed water. The temperature of the water tank is 80°C. According to the calculation, the flow rate of hot water matches the transportation of soybean meal, and the sprinkling amount is 125%.

[0038] S4 Seed Dressing...

Embodiment 2

[0046] The technical process of the present embodiment is basically the same as that of Example 1, the difference is: S5 is out of the song and mixed into the song: the song is mixed according to Aspergillus oryzae: Aspergillus sweetpotato is 4:1 and the red yeast rice of 2% of its weight is added and evenly mixed Add cold brine, and the amount of koji brine added is calculated as 12 water, and transported into the fermenter.

Embodiment 3

[0048] The technical process of the present embodiment is basically the same as that of Example 1, the difference being: S5 is produced and mixed into a song: the song is mixed according to Aspergillus oryzae: Aspergillus sweetpotato is 3:1 and the red yeast rice of 1% of its weight is added and evenly mixed Add cold brine, and the amount of koji brine added is calculated as 12 water, and transported into the fermenter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com