New process for preparing prepared white spirit

A preparation process and liquor technology, applied in the field of preparation technology for preparing liquor, can solve the problems of flavor, monotony of varieties, insignificant nutritional effect, etc., and achieve the effect of refreshing wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

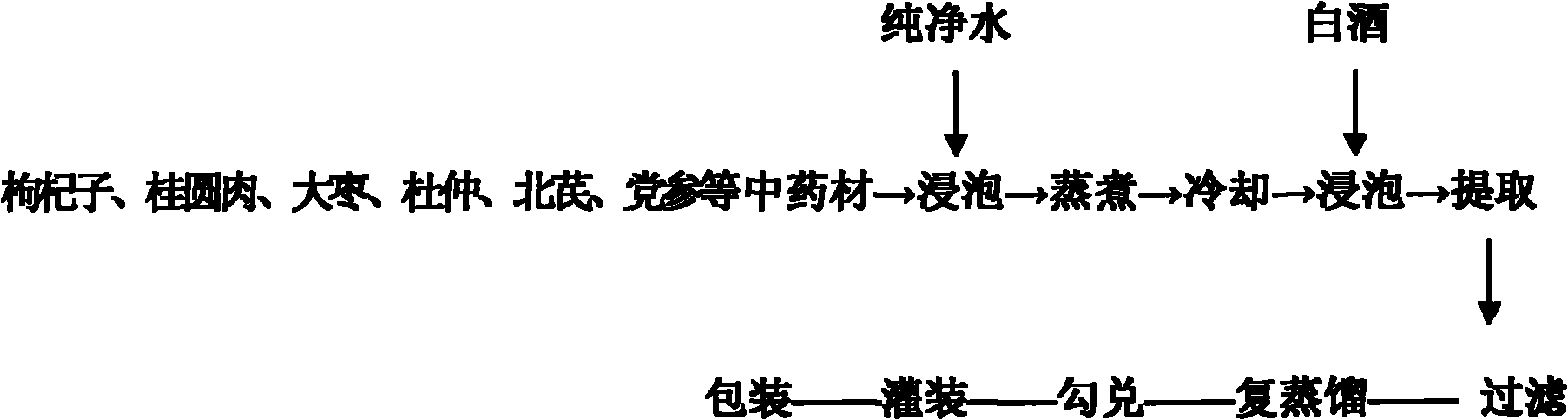

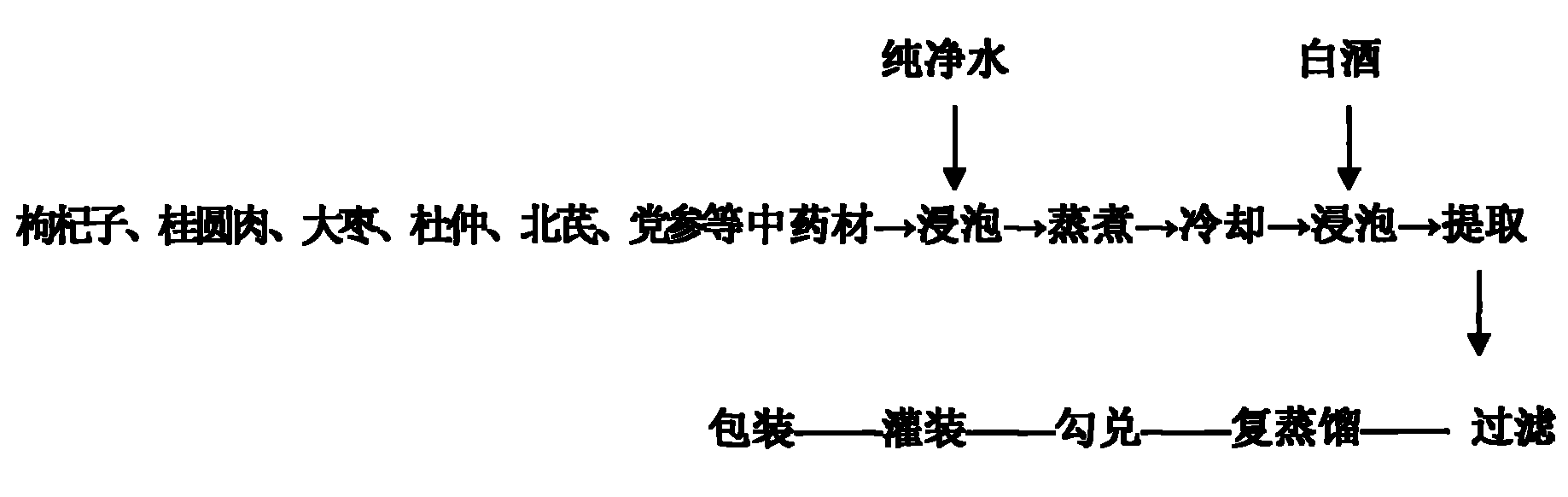

[0012] As shown in the attached figure, the process sequence is as follows:

[0013] 1. Take 100 kg of 40% Vol rice-flavored liquor and put it into a ceramic jar.

[0014] 2. Take 2 kg of medlar, 1 kg of longan meat, 1 kg of jujube, 0.5 kg of Eucommia ulmoides, 0.5 kg of astragalus, and 0.3 kg of Codonopsis pilosula, wash them, add 8 kg of pure water to soak for 2 hours, cook for 20 minutes, cool, add In the wine jar, stir evenly and then seal the lid.

[0015] 3. After soaking for 100 days, extract the wine liquid, filter it with a 100-mesh sieve, and then redistill the wine liquid at 100°C to extract distilled wine. Distilled wine is divided into front, middle and back sections to extract a total of 100 kg of distilled wine. The distilled liquors extracted at different stages are blended to reach the calibrated alcohol content, and the wines with different alcohol content are blended to the calibrated alcohol content, and finally filled, packaged and finished.

[0016] The...

Embodiment 2

[0018] As shown in the attached figure, the process sequence is as follows:

[0019] 1. Take 100 kg of 50% Vol rice-flavored liquor and put it into a ceramic jar.

[0020] 2. Take 3 kg of medlar, 2 kg of longan meat, 2 kg of jujube, 1 kg of Eucommia ulmoides, 1 kg of astragalus, and 0.6 kg of Codonopsis pilosula, wash them, add 8 kg of pure water to soak for 2 hours, cook for 20 minutes, cool, add In the wine jar, stir evenly and then seal the lid.

[0021] 3. After soaking for 180 days, extract the wine liquid, filter it with a 100-mesh sieve, and then redistill the wine liquid at 100°C to extract the distilled wine. The distilled wine is divided into front, middle and back sections to extract a total of 100 kg, and then the front The distilled liquors extracted at different stages are blended to reach the calibrated alcohol content, and the wines with different alcohol content are blended to the calibrated alcohol content, and finally filled, packaged and finished.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com