Patents

Literature

30results about How to "High color ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

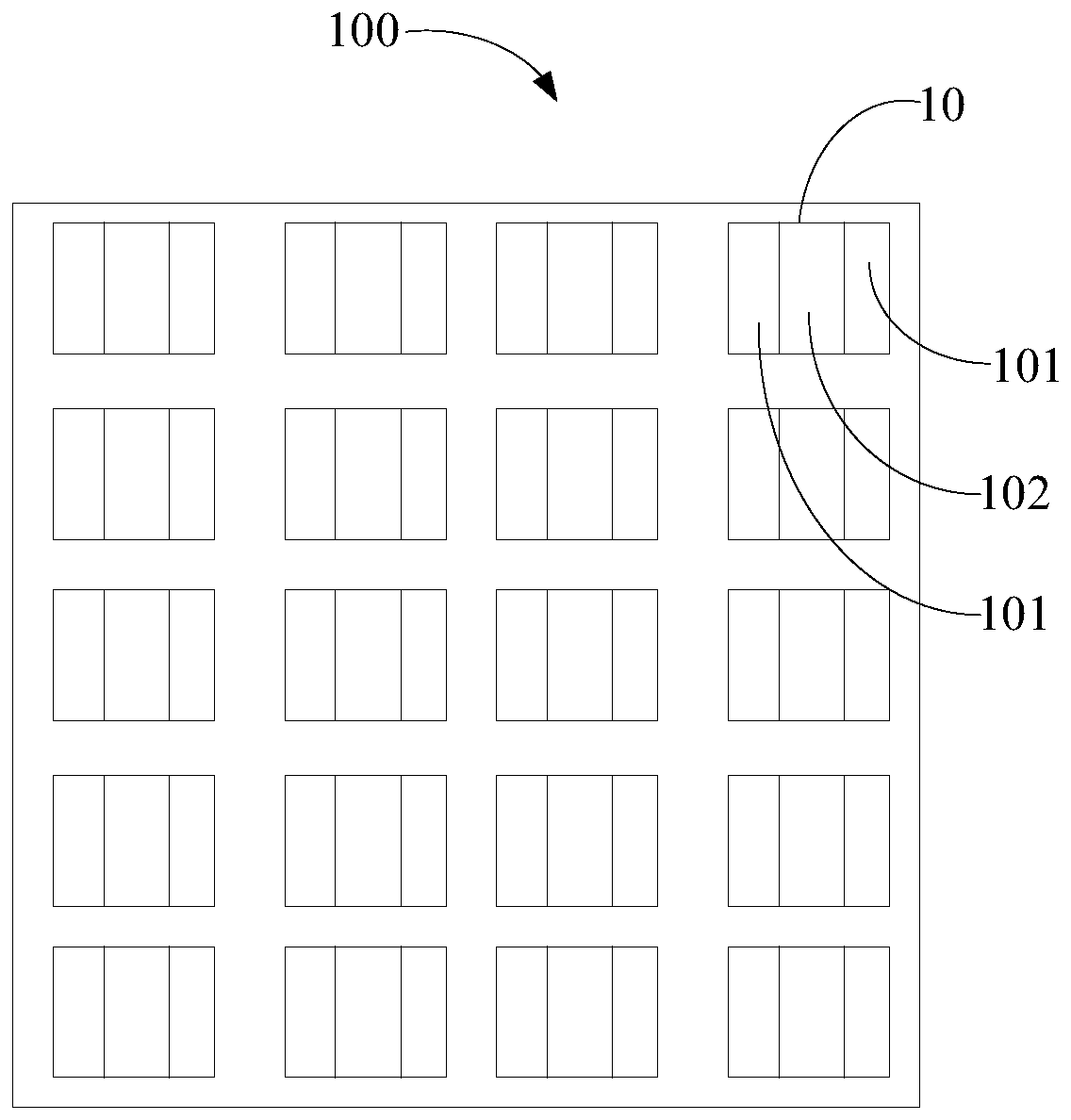

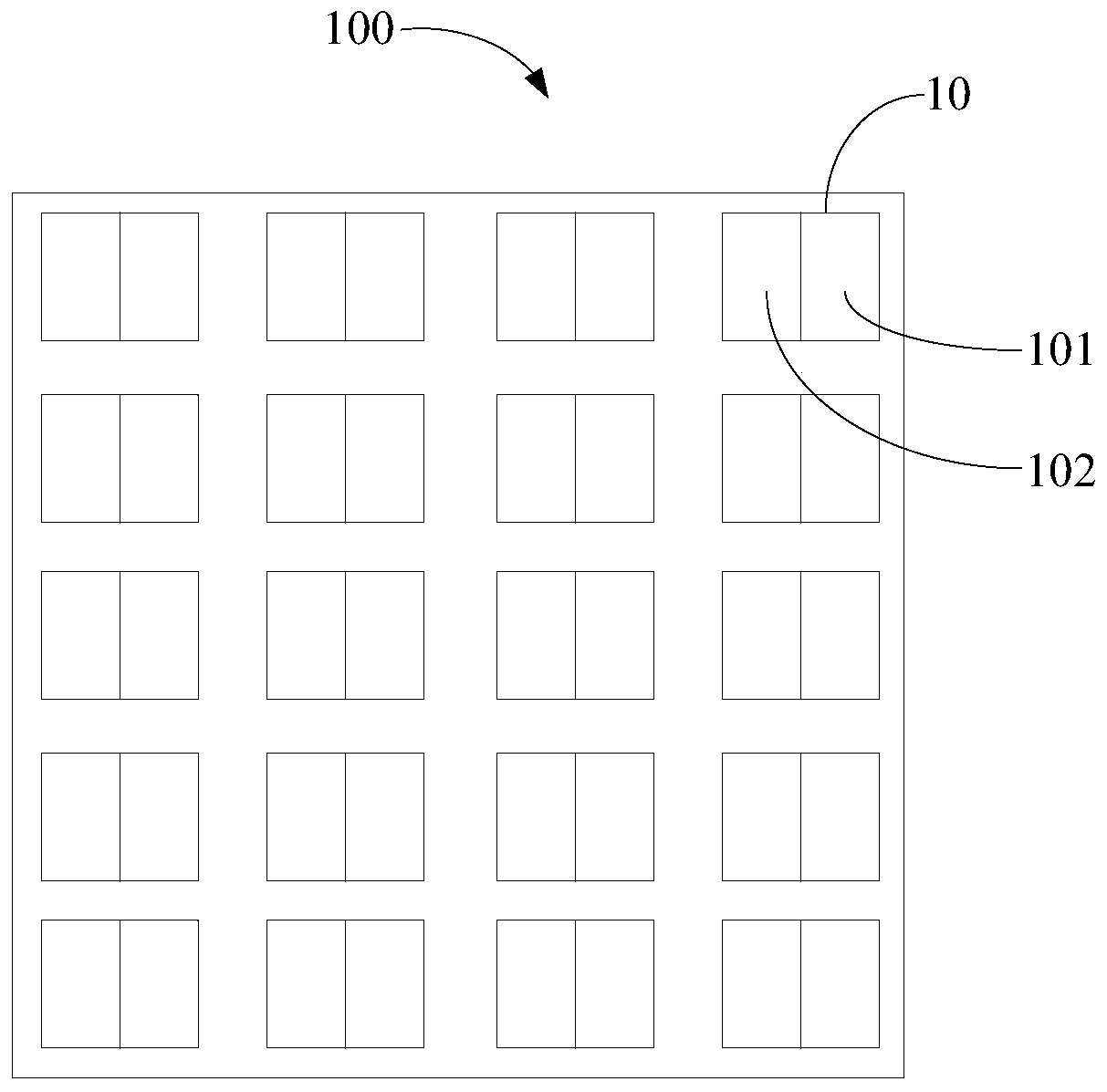

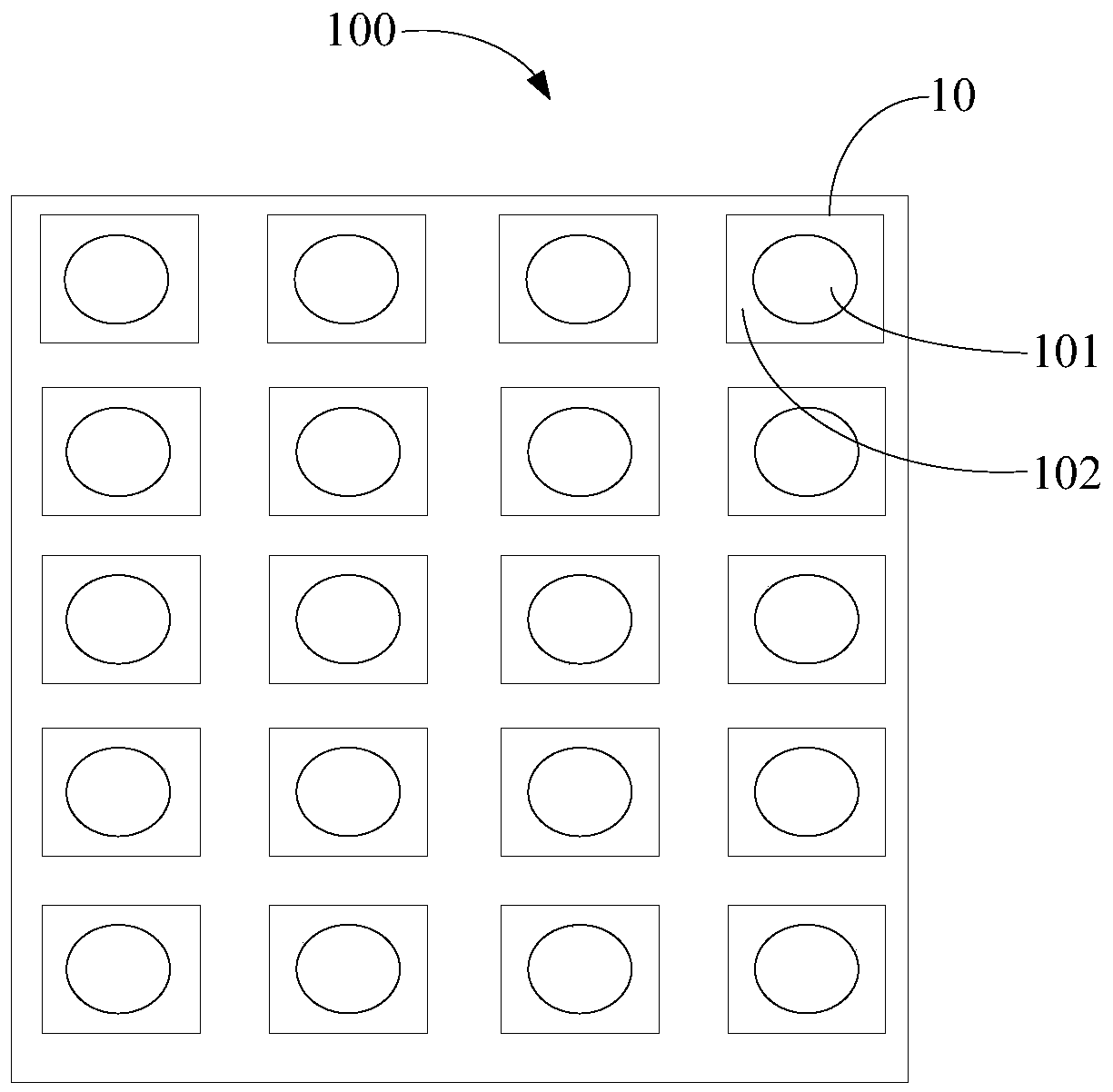

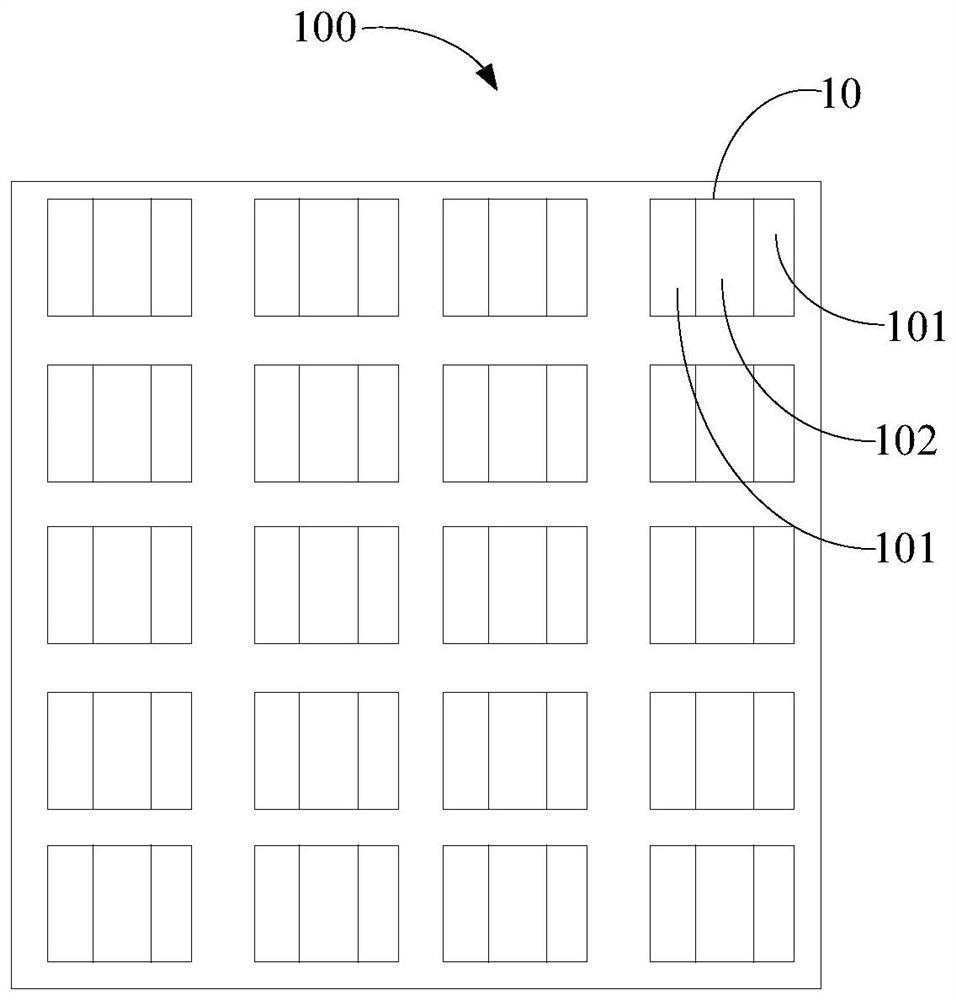

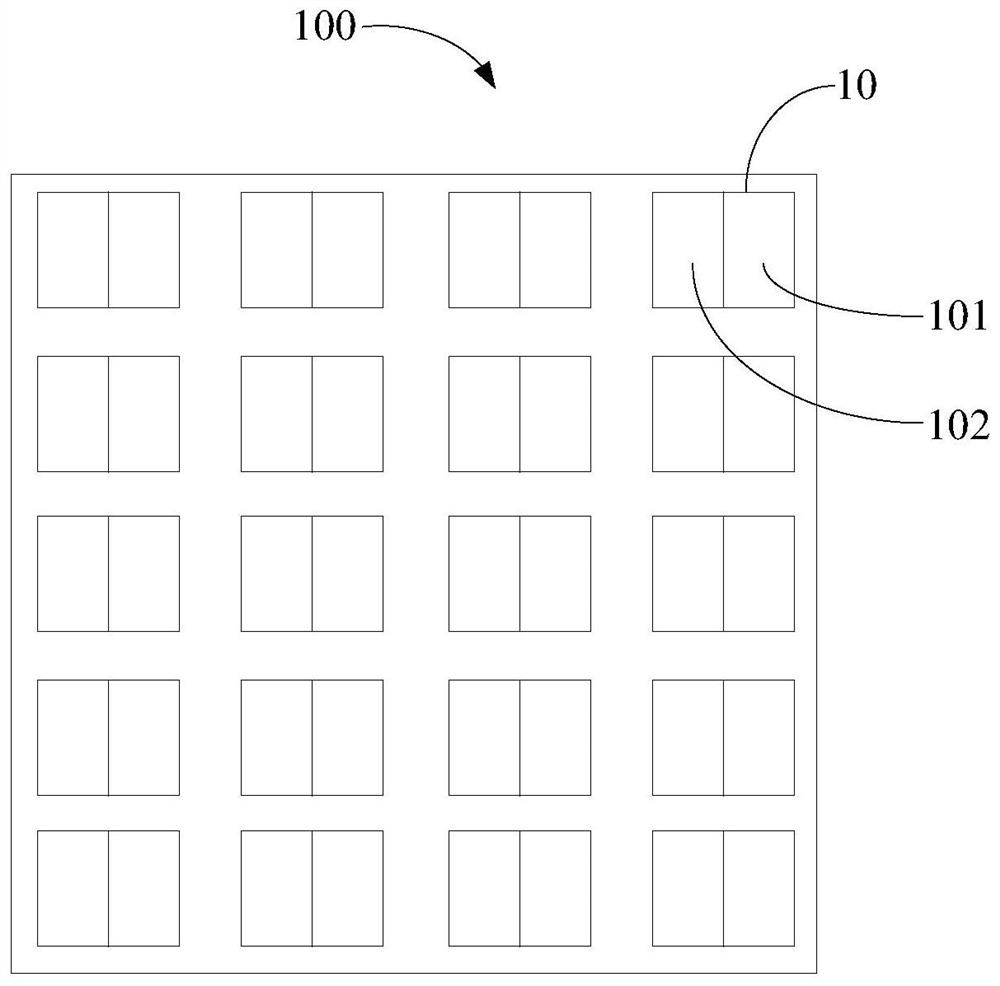

Transparent display substrate, array substrate, display panel and display device

ActiveCN110148621AHigh color ratioStrong brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTransmittance

The invention provides a transparent display substrate, an array substrate, a display panel and a display device. A plurality of first sub-pixels are arranged in a display area of the transparent display substrate, wherein each first sub-pixel comprises a first light-emitting area and a second light-emitting area, and the light transmittance of the first light-emitting areas is larger than that ofthe second light-emitting areas. Each first sub-pixel comprises a first electrode, a light-emitting structure located on the first electrode and a second electrode located on the light-emitting structure, wherein the first electrode comprises a first conductive layer and a second conductive layer located on the first conductive layer, and the first conductive layer is in contact with the second conductive layer. One of the first conducting layer and the second conducting layer comprises a reflecting film layer, and the other one of the first conducting layer and the second conducting layer isa transparent conducting film layer, wherein the reflecting film layer is only arranged in the second light-emitting area, and the transparent conducting film layer at least covers the first light-emitting area.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

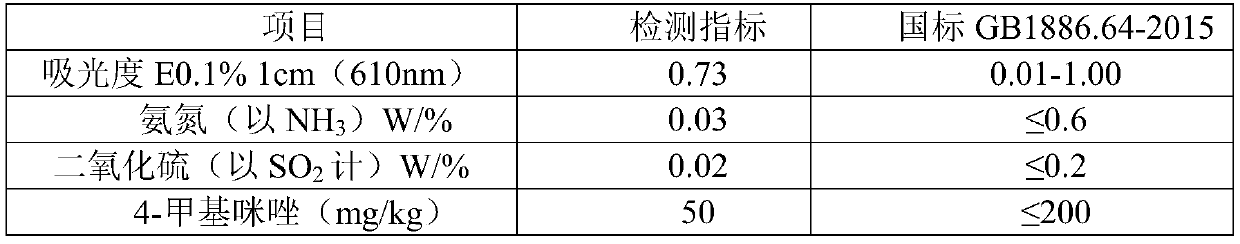

Process for producing pheomelanine by Maillard reaction of amino-acid with glucose

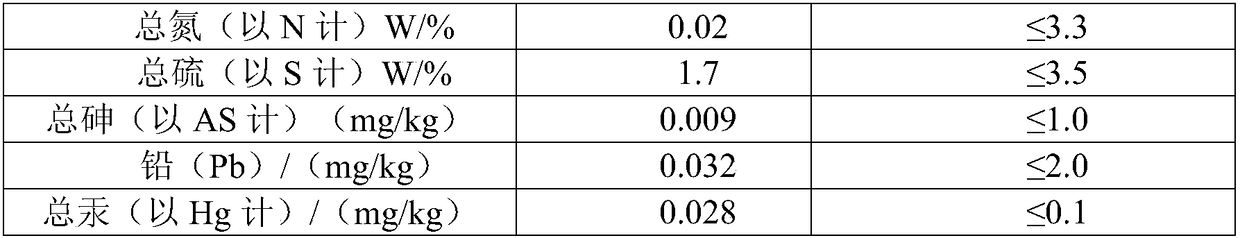

InactiveCN1450122AGreat tasteHigh color ratioArtificial dyesFermentationMaillard reactionHazardous substance

The method for producing melanoid by using amino acid and glucose Maillard reaction includes the following steps: adding 90%-99% of glucose and 1-10% of amino acid or amino acid composite in a reactor, heating to 120-150 deg.C, after 2-3 hr. the melanoid used in food, beverage and medicine can be obtained. Said invention has no need of adding NH4Cl, (NH4)2SO4, urea or ammonia water, its taste is good, colour intensity is high, it contains no carcinogenic harmful substances of 4-methyl imidazole. Its preparation process is simple and operation is convenient.

Owner:HUBEI UNIV

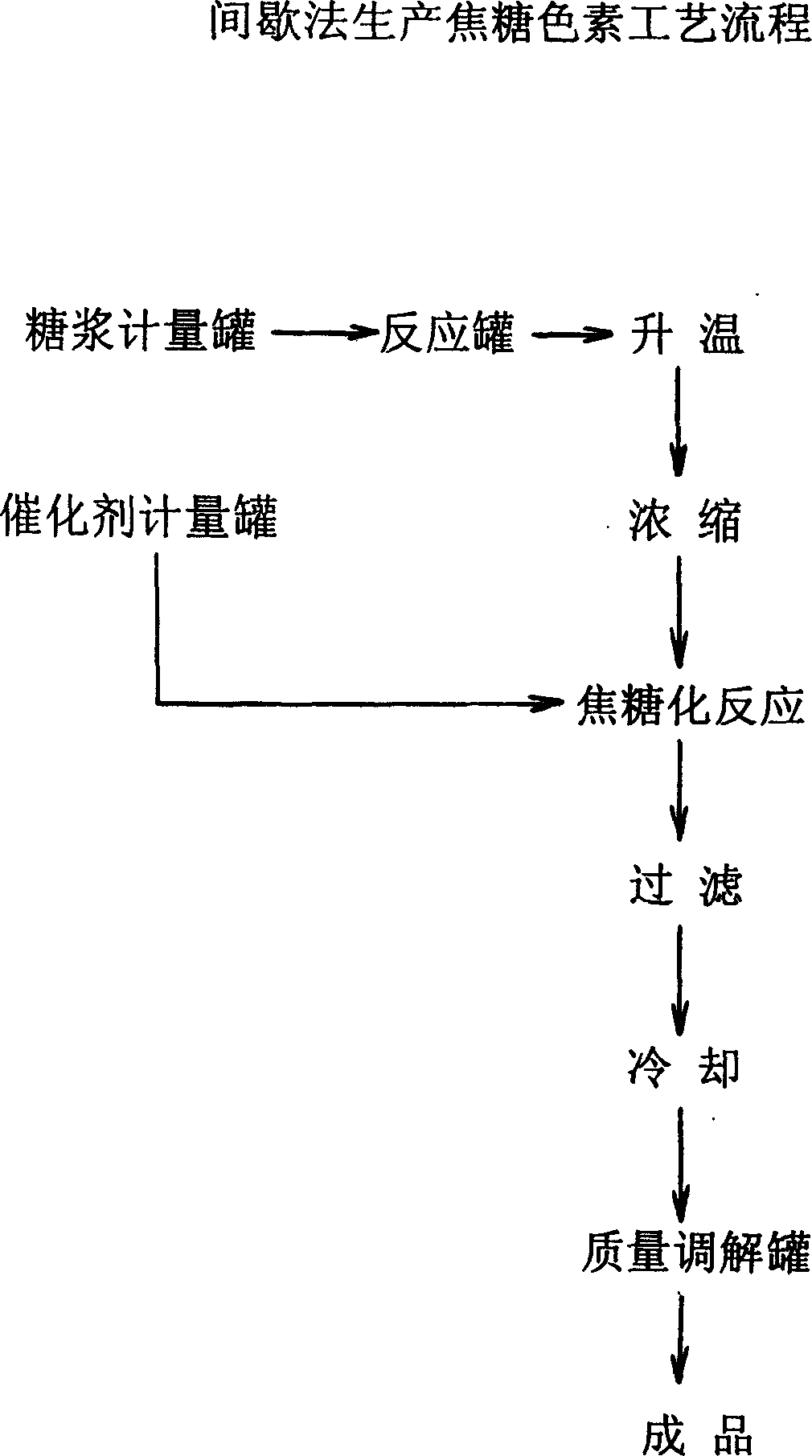

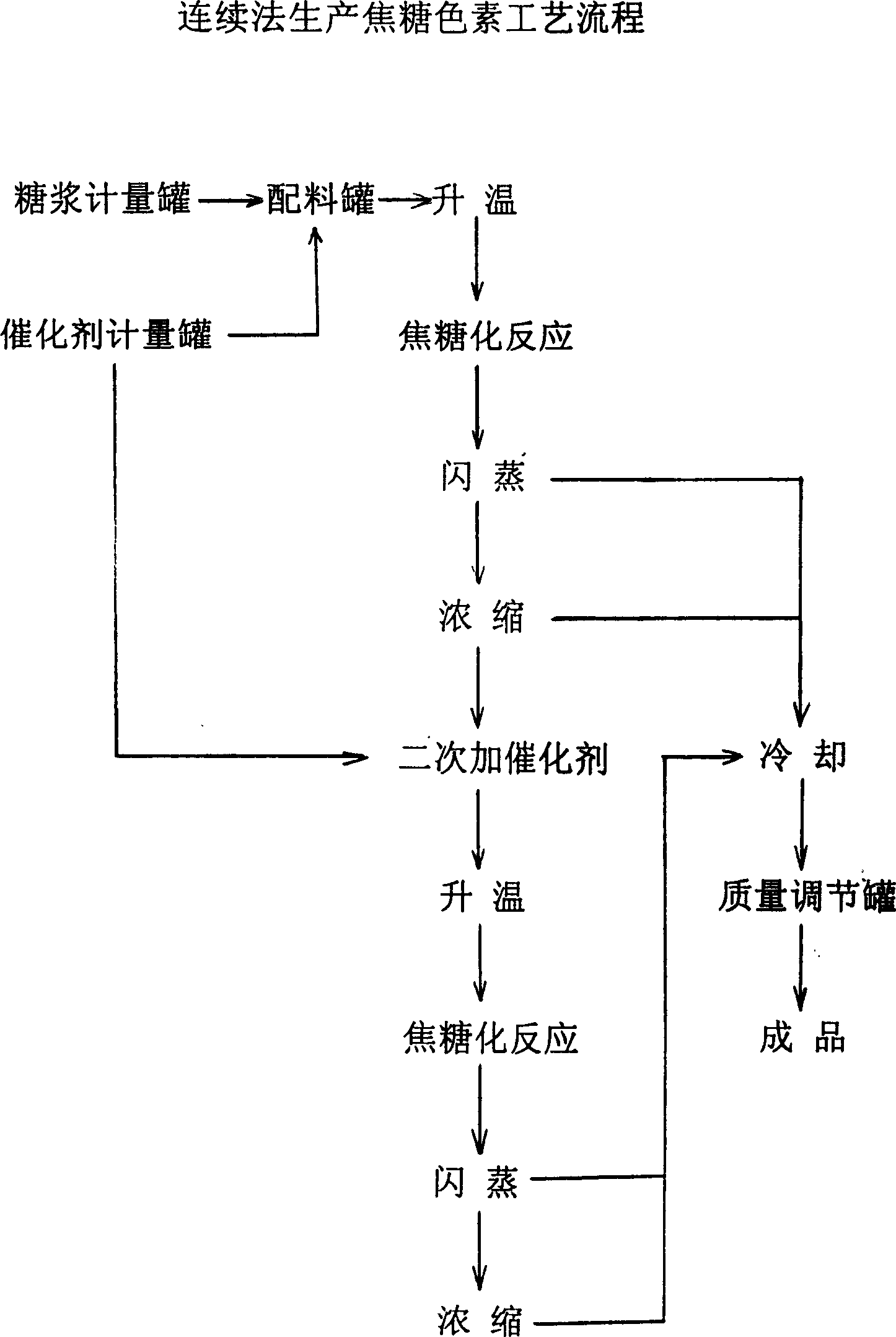

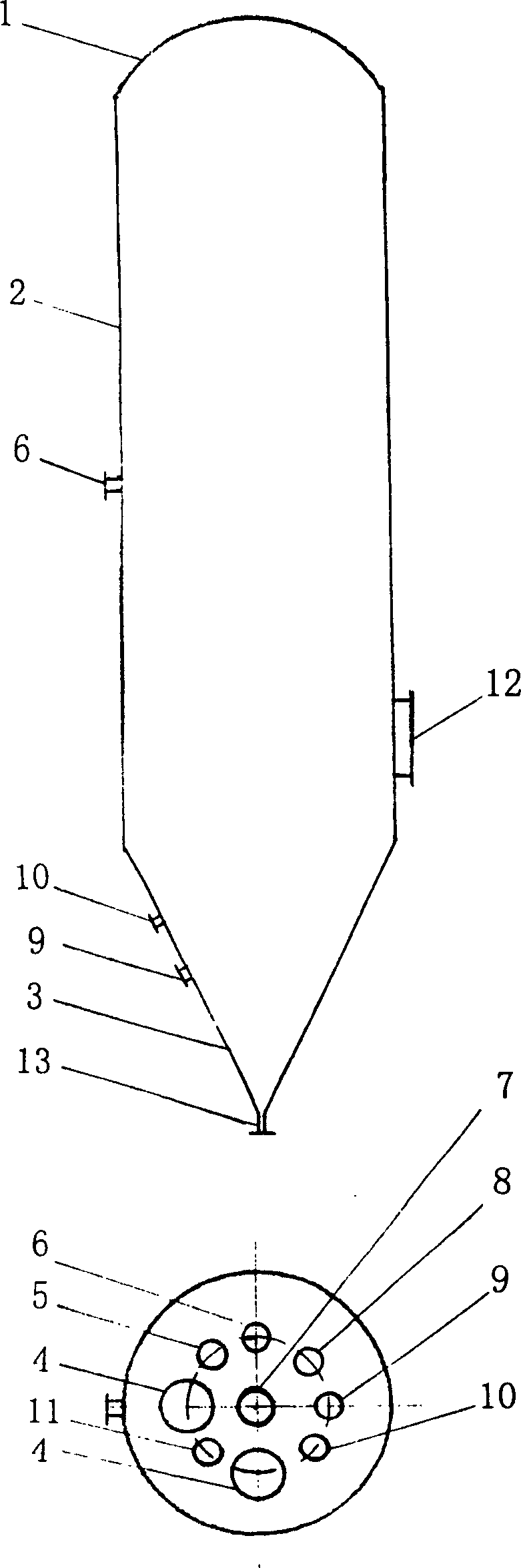

Process and apparatus for continuous manufacturing burnt sugar colouring matter

A process for continuous production of caramel pigment includes such steps as proportionally mixing catalyst with syrup, heating by heat exchanger for indirect heating and steam sprayer for direct heating, caramelizing reacting in reactor, cooling by flash evaporator, concentrating by evaporator, cooling by cooler, regulating quality in quality regulating tank, and storing in tank. Its advantages are high quality and output rate and low cost.

Owner:马荣昌

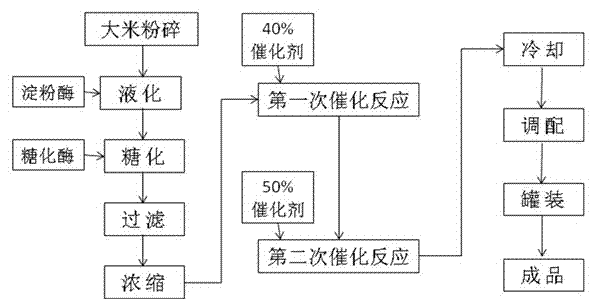

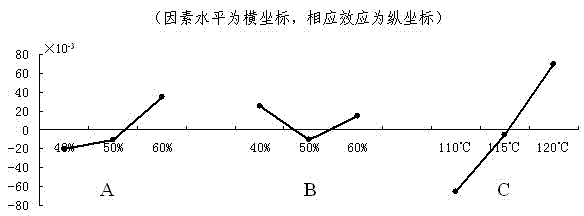

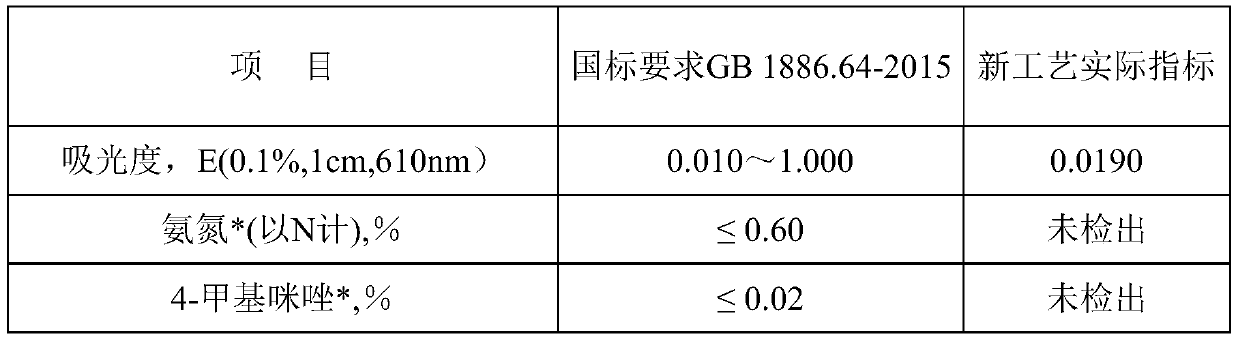

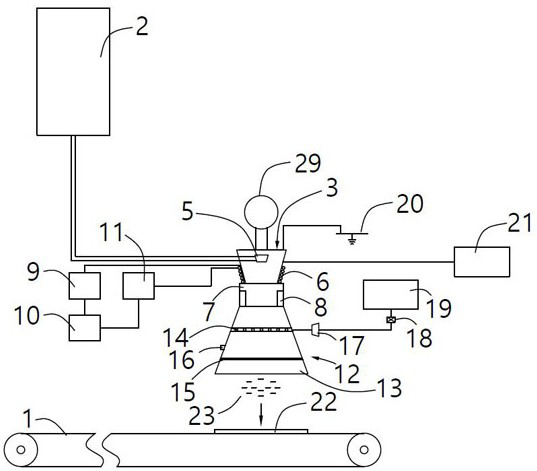

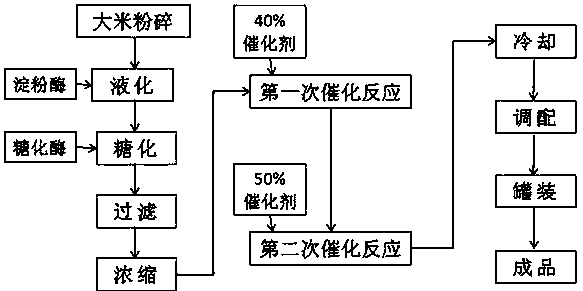

Method for producing high-safety caramel color through twice catalytic reaction

ActiveCN102643862AReduce unit consumptionReduce the temperatureNatural dyesFermentationReaction temperatureDry basis

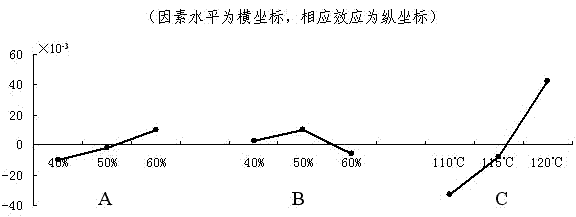

The invention relates to a method for producing high-safety caramel color through twice catalytic reaction. The method comprises the following steps of: a, rice pulverization; b, spraying liquefaction; c, diastatic enzyme addition into liquefied rice for saccharification; d, filtering; e, concentration; f, primary catalytic reaction: through being metered by the mass percentage content of dry basis, catalysts accounting for 40 percent of the catalyst consumption are adopted and added in the primary catalytic reaction, then, through the pressurization and temperature rise reaction, the reaction pressure is controlled to a value being smaller than or equal to 0.1 MPa, the temperature is smaller than or equal to 110 DEG C, and the primary catalytic reaction is stopped when the reaction is carried out to reach 60 percent of the total required color rate; g, secondary catalytic reaction: the secondary catalytic reaction is stopped when the reaction is carried out to reach the required color rate; h, cooling; and i, finished product blending. Through the twice catalytic reaction, the reaction temperature and the reaction pressure are reduced, the reaction conditions are milder, the single consumption of steam is reduced, the reaction process and the control are easier and more stable, each ton of products can save 100kg of steam, and the method is favorable for improving the market competitiveness of products.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Manufacturing method of crimson brown granulated sugar

InactiveCN102703611AHigh color ratioColoring effect is stableSugar productsFood preparationSucroseCaramel Flavor

The invention discloses a manufacturing method of crimson brown granulated sugar, which comprises the steps of: raw material juicing in white granulated sugar manufacturing process, sugar juice defecation, evaporation, sugar cooking, assisted crystallization, purging and drying, and is characterized in that edible caramel pigment is added during the growth period of granulated sugar crystal sucrose-absorption crystal from the triose cooking working procedure to the assisted crystallization working procedure in the later-stage working procedure of three-stage sugar cooking, so that the granulated sugar crystal sugar and the caramel pigment are synchronously absorbed; and the edible caramel pigment is at least one of double caramel pigment or single caramel pigment. Compared with the prior art, the crimson brown granulated sugar obtained by the manufacturing method of the crimson brown granulated sugar has the advantages of high color ratio, stable and controllable color ratio, reliable quality and longer shelf life.

Owner:广西柳州中嘉知识产权服务有限公司 +1

6íõ-heterocycle substituted spirooxazine photochromic compound and method for preparing same

The invention discloses a 6íõ-heterocycle substituted spirooxazine photochromic compound and method for preparation, wherein the compound has the structural formula disclosed in the specification, the advantages of the synthesized photochromic compound include bright color, better antifatigue property, thus can be widely applied to the field of optical information material, false proof identification material, textile printing and dyeing.

Owner:NANKAI UNIV

Process for producing liquid caramel

InactiveCN101798471ARaise the reaction temperatureHigh Yield Caramel ColorNatural dyesCaramel FlavorAmmonia

The invention relates to a process for producing liquid caramel under low pressure. The process comprises the following steps: heating a sugar material to 130-140 DEG C (ammonia process) / 160-180 DEG C ( ammonia-free process) by utilizing a closed reaction kettle, and carrying out pyrogenetic reaction under the pressure of 0.08 Mpa; and after the reaction finishes, opening a bleed valve, adding water to dilute, and concentrating to the commercial-grade color ratio. The invention has the advantage of high product color ratio, and can increase the color ratio to more than 55000 (EBC) by the ammonia process and more than 15000 (EBC) by the ammonia-free process. The dehydrated and concentrated product does not have the burned taste, thereby widening the application range of the product.

Owner:李松 +1

Method for producing caramel

InactiveCN101798470AReduce heat lossSave energyNatural dyesEnergy based chemical/physical/physico-chemical processesMicrowaveCaramel Flavor

The invention relates to a method for producing ammonium-free caramel. Sugar materials are heated in a microwave heating mode, so that the sugar materials are subjected to pyrogenic reaction in an internal heating mode under the condition of atmospheric pressure or heating, thereby obtaining the product. The invention has the advantages of good repetitiveness, low energy consumption, short response time and high color ratio.

Owner:李松 +1

Caramel color production process

ActiveCN108948784AHigh color ratioSave energyNatural dyesFood scienceMaillard reactionPositive pressure

The invention discloses a caramel color production process and belongs to the technical field of caramel color production. According to the process disclosed by the invention, by improving the ordinary process, on the basis of not adding any other chemical substance, high fructose corn syrup is adopted as the raw material, the content of reducing sugar in the raw material is more than or equal to95%, the content of fructose is more than or equal to 42%, the pH value is 4.5-.0, and the concentration of the high fructose corn syrup is 74-75%. A reaction kettle pressurization condition or a microwave heating manner is adopted; when the checked color index is more than 16000EBC, the reaction is terminated, so that the final color rate of the produced caramel color can reach 16000EBC, and thered index is high; furthermore, under the pressurization condition of the reaction kettle, trace dietary alkali is added, the pH value is regulated by edible citric acid, the positive reaction (Maillard reaction and caramel reaction as required) is completely carried out, and the color rate of the produced caramel is further improved. Compared with positive pressure and normal pressure methods, the method disclosed by the invention has the advantages that external odor or vapor is avoided, the energy is saved, and the environment is protected.

Owner:湖南金代科技发展有限公司

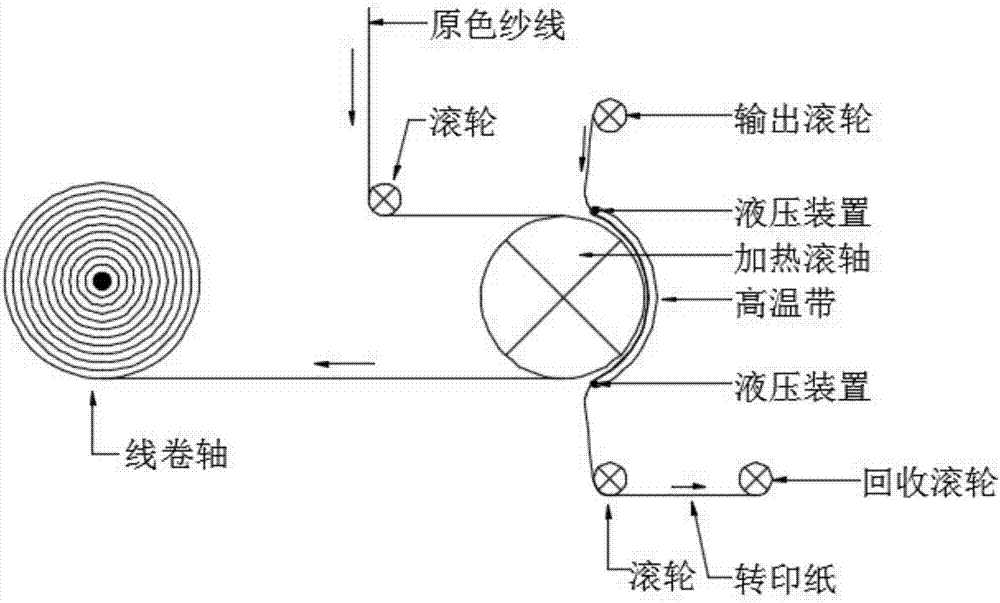

Dyeing technology

The invention discloses a dyeing technology which specifically comprises the following steps: 1) mounting a primary color yarn and a transfer paper and starting a machine; 2) bending a high-temperature tape and the transfer paper toward a heating roller and keeping a certain distance by hydraulic devices at the two ends of the high-temperature tape; 3) heating the transfer paper and the primary color yarn by the high-temperature tape and the heating roller, heating and subliming the ink on the transfer paper and attaching to the primary color yarn and then recovering the dyed yarn by a yarn reel. According to the technology, the heated subliming dye is adopted for directly transferring on the yarn, the ink is automatically blended on a printer so that the yarn color can be realized; the color is accurate and repeated color change is not required; the color index is higher and can reach above level-4; the technology is simple and convenient in operation; the production efficiency is increased; the dyeing technology also can be directly used for dyeing the warp yarns in a textile machinery plant, can increase the economic benefit and can reduce resource waste and environmental pollution; one yarn can be dyed in different colors and different lengths according to the technology.

Owner:广州市富元服装辅料有限公司

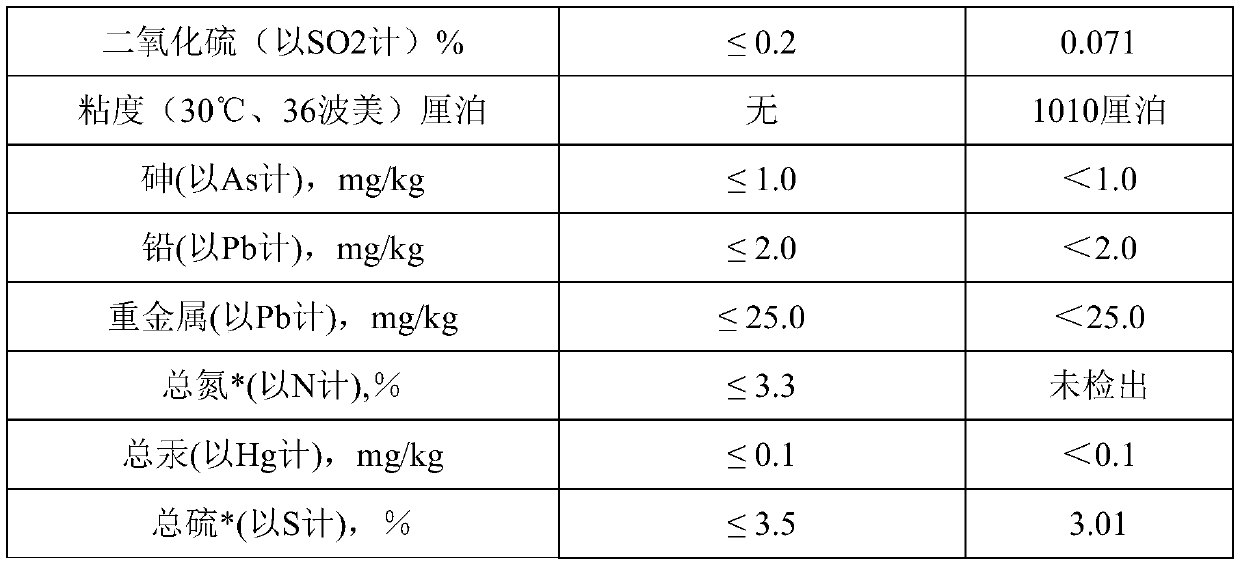

Preparation process of caramel pigment

InactiveCN107652707ADoes not affect flavorWide variety of sourcesNatural dyesFood ingredient functionsSucroseHydrolysate

The invention discloses a preparation process of caramel pigment. The preparation process is characterized by including the steps of firstly, crushing corn and potatoes, and hydrolyzing under 85-95 DEG C for 5-8 hours; secondly, regulating the pH of hydrolysate to be 6-8, and filtering to obtain filtrate; thirdly, adding 1-3% of amino acid into the filtrate obtained in the second step, heating to190-200 DEG C, and keeping the temperature for 50-85 minutes; fourthly, cooling the liquid obtained in the third step to room temperature within 3-5 minutes. The preparation process has the advantagesthat non-sucrose crops are used as the raw materials to extract natural pigment, and non-sucrose crops are wide in source; extraction is simple and short in flow; 4-methylimidazole content in the caramel pigment can be lowered, the red index or color index of the caramel pigment can be increased, the original flavor of the caramel pigment is unaffected, and the eating safety and quality of caramel pigment can be increased greatly.

Owner:广西顶俏食品科技集团有限公司

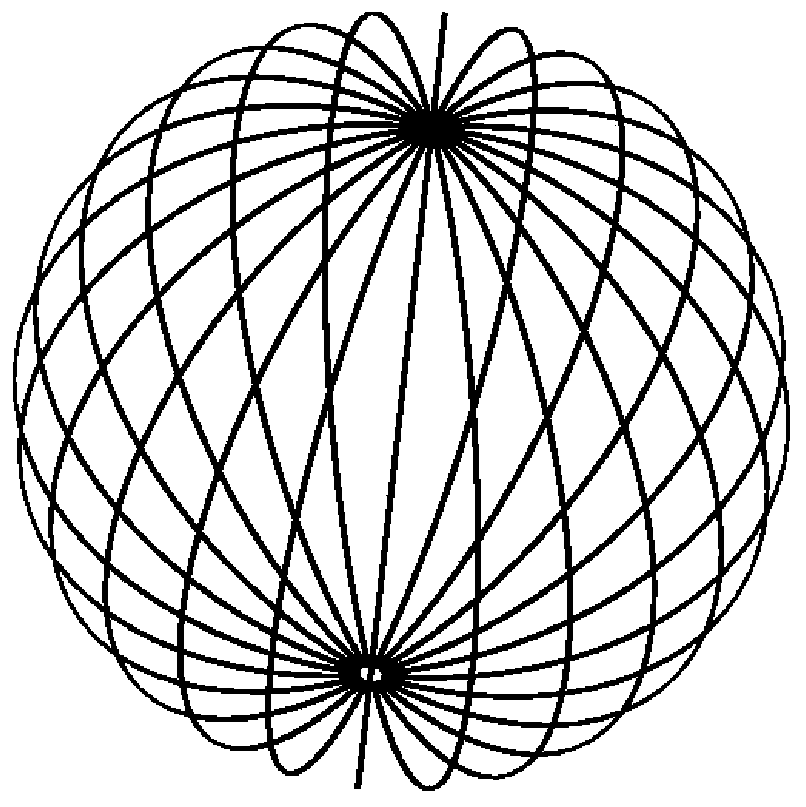

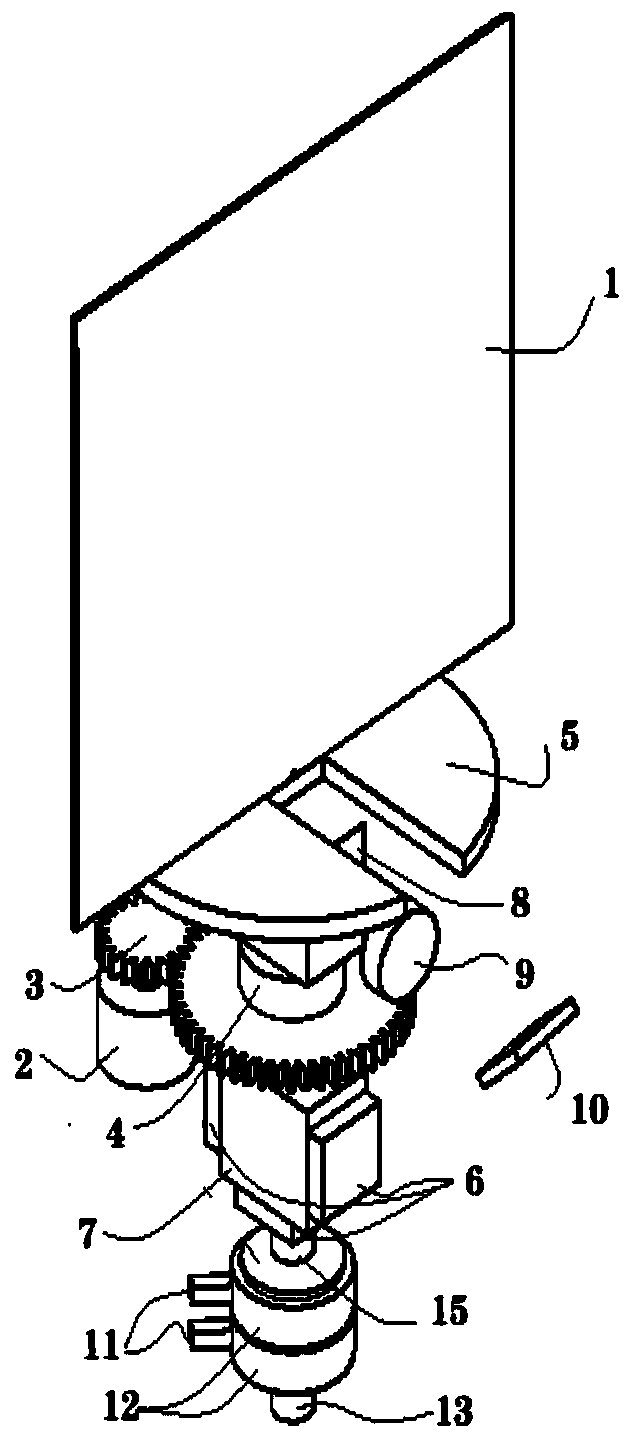

Three-dimensional imaging display instrument

InactiveCN110989196AHigh resolutionHigh color ratioStatic indicating devicesStereoscopic imaging3d image

The invention provides a three-dimensional imaging display instrument. The three-dimensional imaging display instrument comprises a projection display screen rotating at a high speed, a mechanical unit driving the projection display screen to rotate; an MICROLED display chip, a projection light path synthesis unit and a control unit. The control unit receives the displayed three-dimensional imagedata, decomposes the displayed three-dimensional image into a plurality of high-resolution and high-color-rate two-dimensional plane images, and projects the two-dimensional plane images onto the projection display screen in sequence through the MICROLED display chip; meanwhile, the control unit outputs a motor driving signal synchronous with the two-dimensional projection image according to theposition of the projection display screen detected by the position sensor, and drives the motor to drive the projection display screen and the two-dimensional projection image to be projected to synchronously rotate, so that the two-dimensional plane image is projected to the projection display screen which synchronously rotates at a high speed with the projection display screen; and the multiple-effect two-dimensional plane images projected to the projection display screen are rapidly superposed to form a three-dimensional image.

Owner:杨军

Caramel color and preparation method thereof

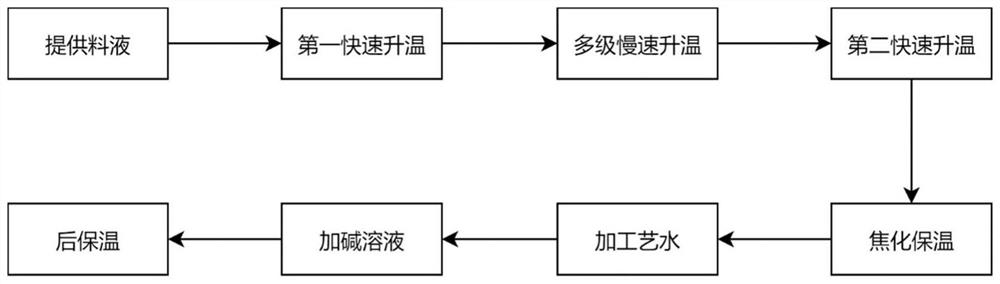

ActiveCN113383893AHigh color ratioRaise the red indexFood ingredient as colourSulfite saltPhysical chemistry

The invention provides a caramel color and a preparation method thereof. The preparation method of the caramel color comprises the steps that 1, providing material liquid, which contains m1 parts by weight of sulfite, m2 parts by weight of ammonium salt and m3 parts by weight of glucose; 2) rapidly heating the product obtained in the previous step from room temperature to T1 DEG C under positive pressure; 3) slowly heating the product obtained in the previous step to T2 DEG C under positive pressure; 4) rapidly heating the product obtained in the previous step to T3 DEG C under positive pressure; 5) preserving the heat of the product obtained in the previous step at T3 DEG C until the color rate reaches 26000-36000; 6) adding m4 parts of process water into the product in the previous step, and cooling the product to T4 DEG C; 7) heating the product obtained in the previous step to T5 DEG C under positive pressure, and adding an alkali solution into the product in the heating process; 8) preserving the heat of the product obtained in the previous step at 80-100 DEG C under positive pressure for 30-100 minutes; and 9) cooling the product obtained in the previous step to below 60 DEG C.

Owner:佛山市海盛食品有限公司 +2

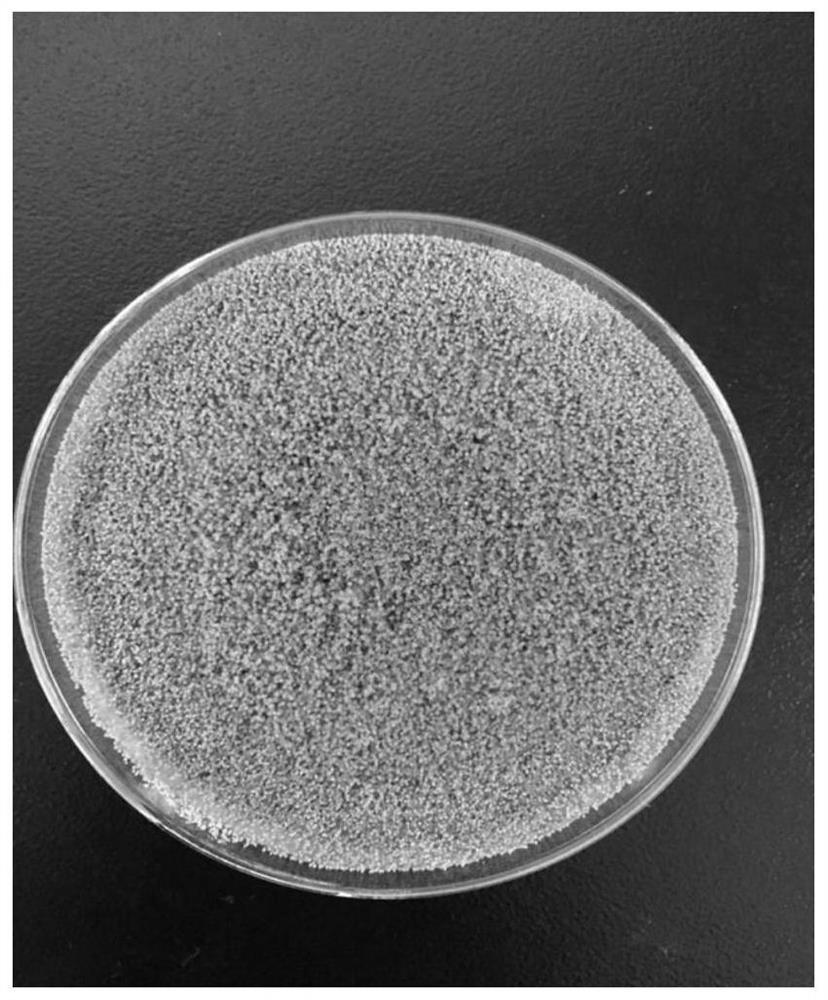

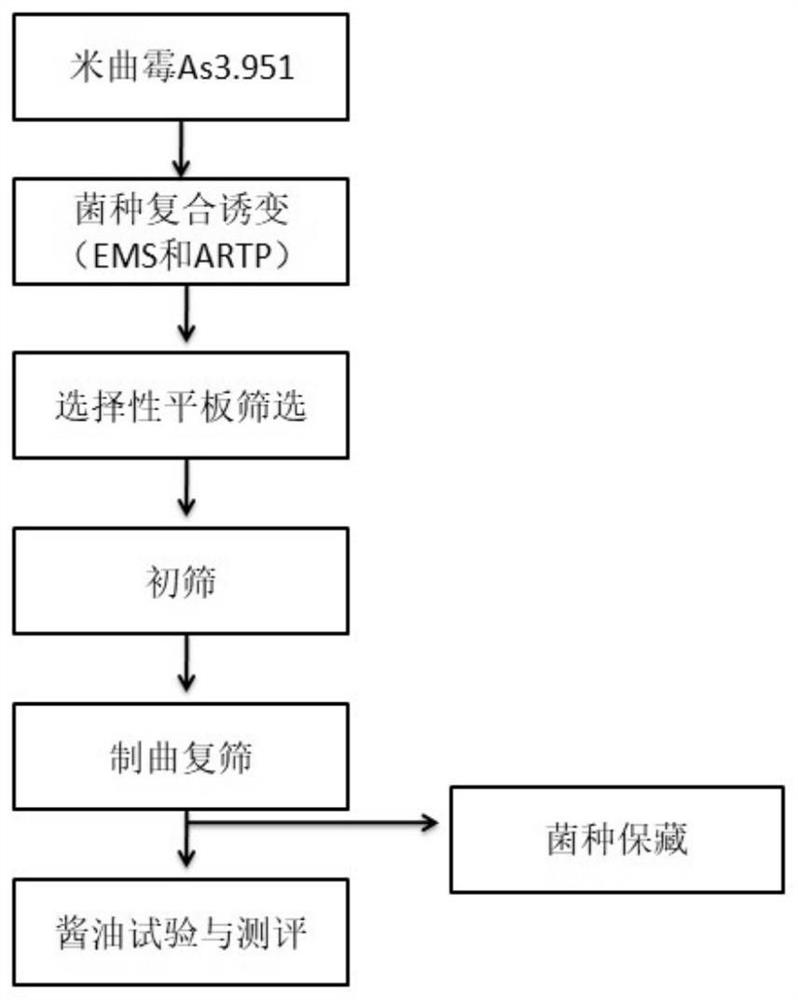

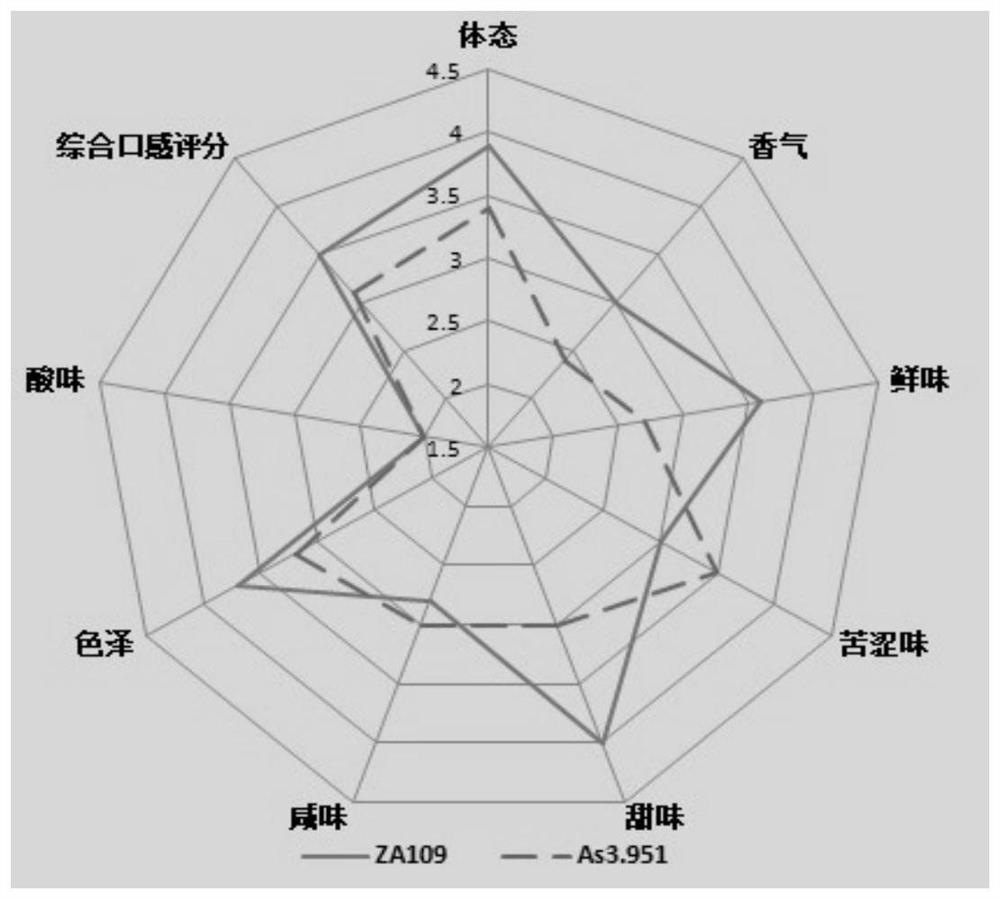

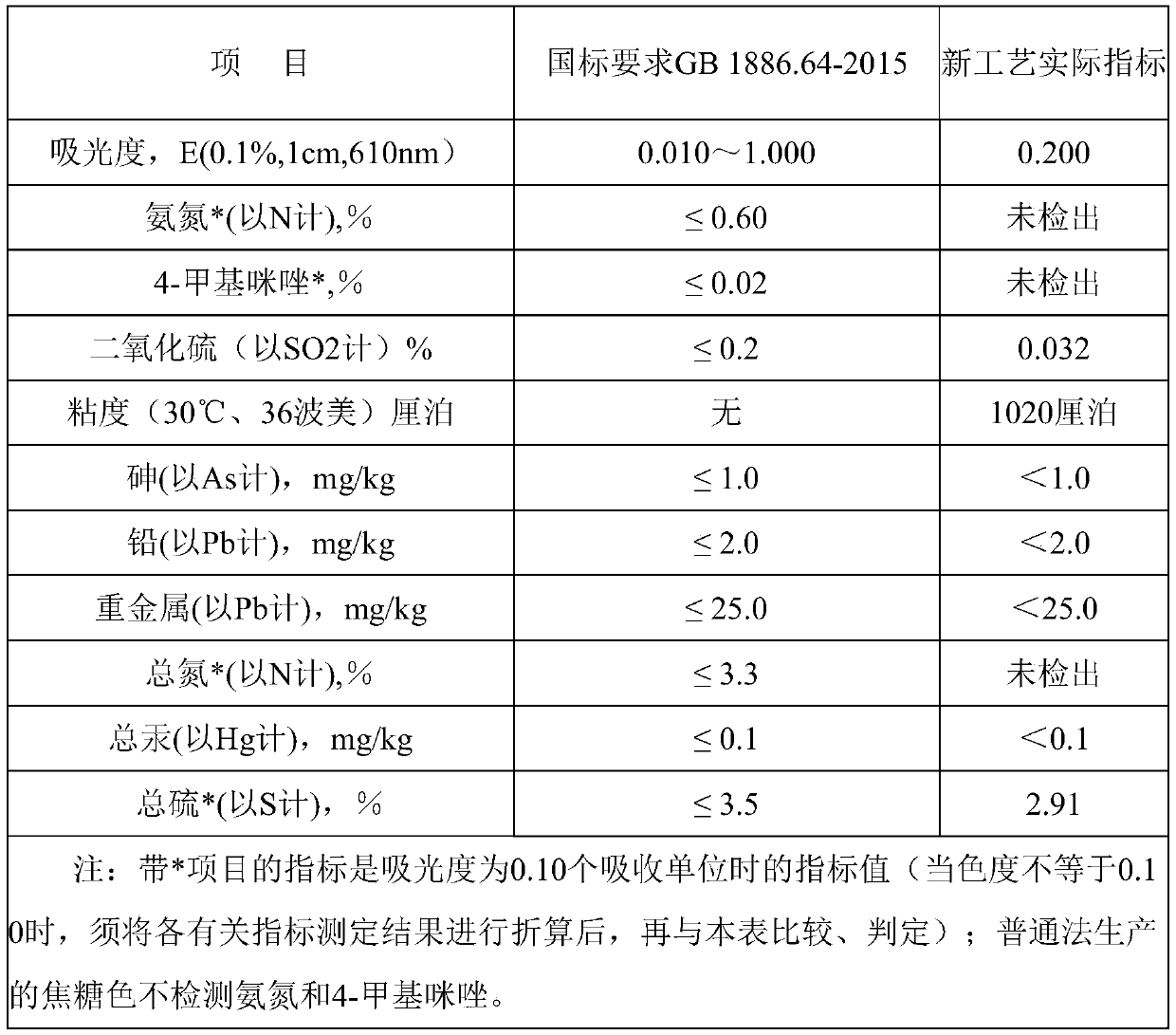

A kind of aspergillus oryzae za109 and application thereof

ActiveCN109706088BStrong growth and reproductionBright green colorFungiMicroorganism based processesBiotechnologyMicrobiological culture

The invention provides an Aspergillus oryzae ZA109 which has been deposited in the Guangdong Microbiological Culture Collection Center on November 15, 2018, wherein the preservation number is GDMCC NO: 60478 and the preservation address is Building 59, No.100 courtyard, Xianlie Middle Road, Guangzhou. The Aspergillus oryzae ZA109 strain of the present invention takes Aspergillus oryzae As3.951 asa starting strain and is obtained by mutation breeding. The Aspergillus oryzae ZA109 of the invention has high proline aminopeptidase activity, and the proline aminopeptidase produced by fermentationdestroys the N-terminal proline residue of a bitter peptide, thereby achieving the purpose of removing bitterness of a soy sauce. At the same time, on the basis of maintaining the integrity of an original enzyme system of Aspergillus oryzae, the high-activity proline aminopeptidase can also promote the deep hydrolysis of protein, and is beneficial to reducing the raw material consumption rate in the koji-making stage. When applied in the preparation of a soy sauce or a sauce, the strain can further improve the utilization rate of the raw materials, and produce a seasoning which is fresher, sweeter and more palatable in taste.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +2

A method for preparing chestnut shell brown pigment by ultrafine pulverization and pulsed electric field

The invention provides a method of preparing chestnut shell brown pigment by ultra-micronization in cooperation with pulsed electric field, comprising the steps of (1), cleaning, washing and drying chestnut shells and then primarily crushing the chestnut shells; (2), adding coarse chestnut shell powder into an ultra-micronization apparatus for wall breaking to obtain chestnut shell superfine powder; (3), using ethanol solution as an extracting solvent to extract the chestnut shell superfine powder by the aid of a pulsed electric field treating device, filtering, and combining double extracts to obtain pigment extract; (4), concentrating the pigment extract under reduced pressure to 1 / 3 of the original size, and carrying out alcohol precipitation, solid-liquid separation, concentration and drying to obtain the chestnut shell brown pigment that is powdery. The ultra-micronization and pulsed electric field treating techniques are combined, no heating is required to provide quick and complete dissolution of the chestnut shell pigment, extracting time and energy can be greatly saved, and the method has the advantages of rich material sources, low extracting temperature, high product yield is high, short treatment time, good operational simplicity and the like; the obtained chestnut shell brown pigment has high color intensity, good water-solubility, stable quality, safety with no toxicity and is worthy of practical production and conversion and practical popularization and application.

Owner:WUHAN YELLOW CRANE TOWER NEW MATERIAL TECH DEV

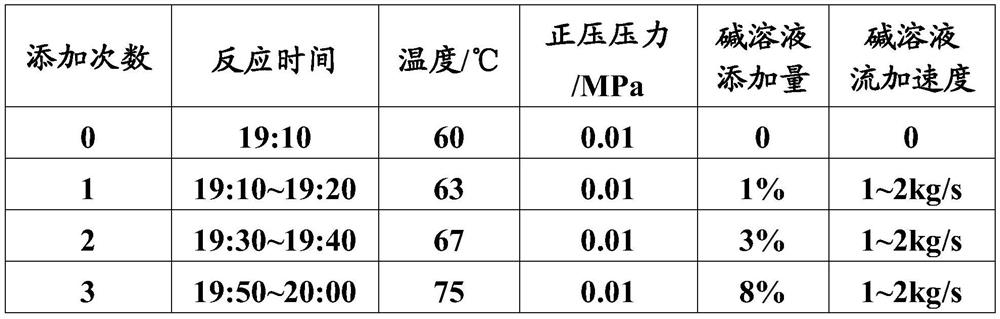

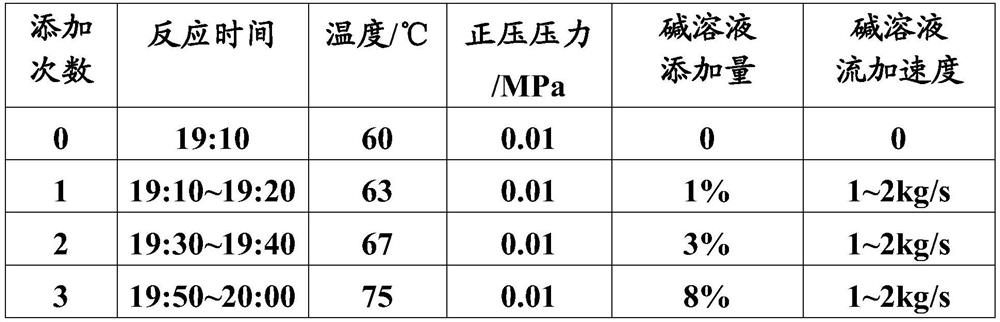

Preparation method for improving color rate of caramel by caustic sulfite method

InactiveCN111410849AHigh color ratioResolve inhibitionNatural dyesFood sciencePtru catalystSulfite salt

The invention discloses a preparation method for improving the caramel color rate of a caustic sulfite method. According to the catalytic reaction, different catalysts are added for three times underthe condition of normal pressure or pressurization to carry out three times of staged reaction. According to the preparation method of the caramel color, the problem that the caramel color rate is difficult to increase by the caustic sulfite method can be solved, the color rate of the product can be increased to 50000 EBC or above, and the product has the advantages of being good in quality, low in sulfur dioxide residue, stable in coloring and good in wine resistance.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Process for producing caramel pigment

InactiveCN101693903BIncrease concentrationHigh color ratioNatural dyesFermentationAlpha-amylaseHigh pressure

The invention discloses a process for producing caramel pigment, comprising the following procedures of a) gelatinization procedure, b) liquefaction and saccharification procedure, c) hydrolysis procedure and d) ammonification procedure, wherein the b) liquefaction and saccharification procedure comprises the following steps: adding alpha-amylase and saccharifying enzyme to the gelatinized purplesweet potato with the pH of 4.5-6.0 and the temperature of 70-95 DEG C, and reacting for 30-60min, wherein the weight proportion of the purple sweet potato, the alpha-amylase and saccharifying enzymeis 1:0.01-0.04:0.01-0.04. Compared with the prior art, in the invention, the purple sweet potato is taken as the raw material, therefore the extraction procedure of starch is saved and the process flow is simplified; furthermore, the purple sweet potato contains natural pigment and has good acid resistance, salt resistance and good stability; the caramel pigment produced by taking the sweet potato as the raw material has high color ratio and good stability, generates no pollutants during the hydrolysis process, shortens the production period and saves the cost; and the caramel pigment prepared by utilizing the sugar solution through a high-pressure ammonia method has good color ratio and good product quality.

Owner:ANHUI POLYTECHNIC UNIV

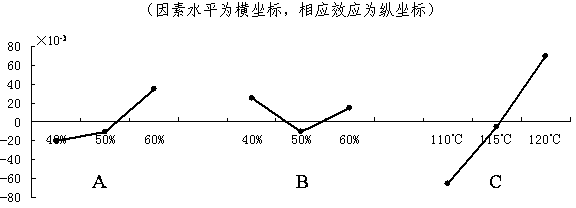

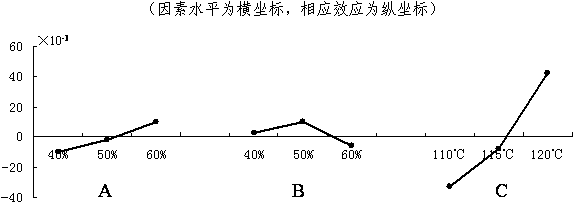

Method for reducing 4-methylimidazole in caramel pigment

InactiveCN108559303AReduce dosagePromote hydrolysisNatural dyesFood scienceGlycineAmmonium carbonate

The invention discloses a method for reducing 4-methylimidazole in caramel pigment, and belongs to the technical field of edible colorants. The caramel pigment is prepared from, by weight, 20%-60% ofwheat B-flour, 1%-8% of ammonium carbonate, 4%-7% of glycine, 0.1%-0.6% of a hydrochloric acid water solution, 10%-18% of sodium chloride, 8%-10% of sodium hydroxide and 30%-40% of deionized water. Forming of 4-methylimidazole in a reaction system is controlled with the method of adding glycine. By optimizing the production technology, a caramel pigment product with the low 4-methylimidazole content, the high color rate and the high quality is obtained; process operation is easy, production efficiency is high, and the method is economical and practical and suitable for popularization.

Owner:肇庆焕发生物科技有限公司

Process for producing pheomelanine by Maillard reaction of amino-acid with glucose

InactiveCN1204204CGreat tasteHigh color ratioArtificial dyesFermentationMaillard reactionHazardous substance

The method for producing melanoid by using amino acid and glucose Maillard reaction includes the following steps: adding 90%-99% of glucose and 1-10% of amino acid or amino acid composite in a reactor, heating to 120-150 deg.C, after 2-3 hr. the melanoid used in food, beverage and medicine can be obtained. Said invention has no need of adding NH4Cl, (NH4)2SO4, urea or ammonia water, its taste is good, colour intensity is high, it contains no carcinogenic harmful substances of 4-methyl imidazole. Its preparation process is simple and operation is convenient.

Owner:HUBEI UNIV

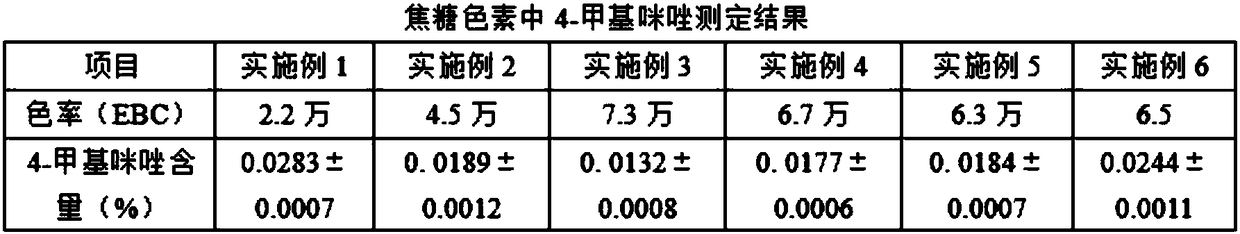

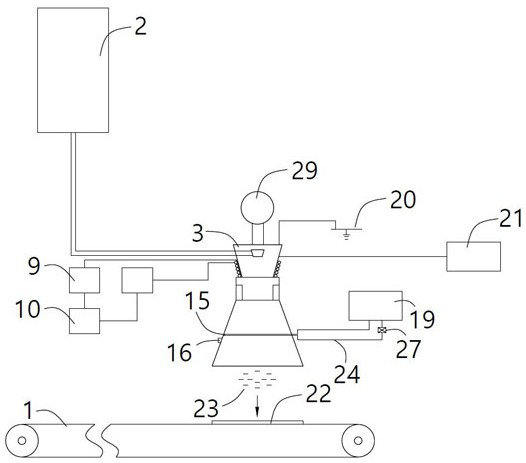

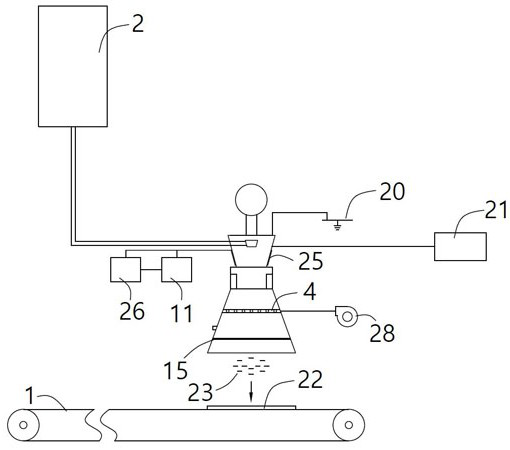

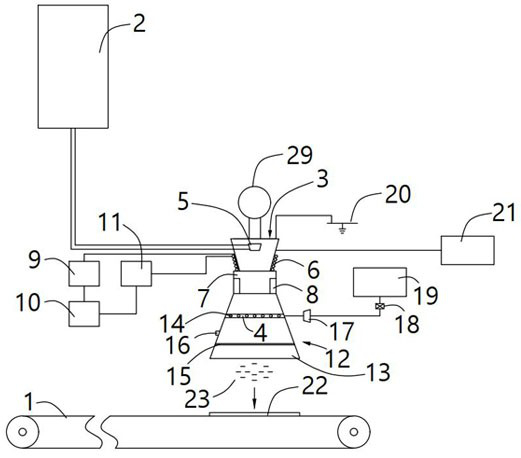

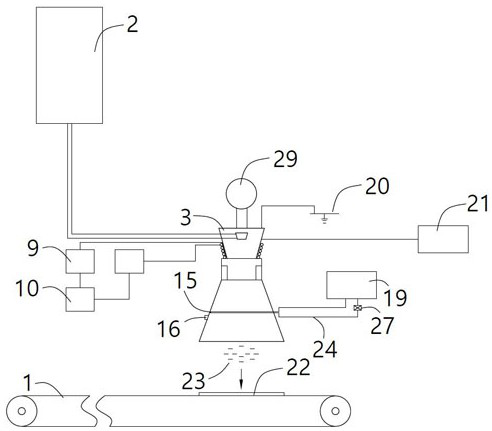

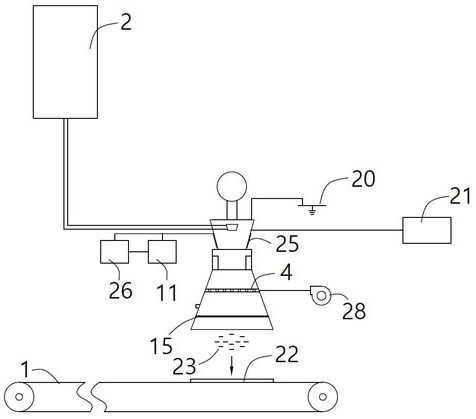

Spraying processing method for fabric dyeing and finishing and spraying machine

ActiveCN114561757AReduce the difficulty of sprayingReduce wasteTextile treatment machine arrangementsTextile/flexible product manufactureProcess engineeringDyeing

The invention provides a spraying processing method for fabric dyeing and finishing and a spraying machine. The spraying processing method comprises the following steps: crushing a dyeing and finishing auxiliary agent into first micro-scale liquid drops with static electricity by adopting air-assisted electrostatic atomization; under the combined action of airflow, gravity and electric field force, enabling the first liquid drops to pass through a cold-hot alternating environment to become second liquid drops, spraying the second liquid drops onto the fabric, and enabling the second liquid drops to form a micro-scale dyeing and finishing area on the fabric; wherein an induction electric field is formed between the electrostatic second liquid drop and the fabric, so that the electric field force is provided. According to the invention, the spraying difficulty is reduced, and the waste of dyeing and finishing auxiliaries is also reduced, so that the dyeing and finishing thickness, the color rate and the dyeing and finishing efficiency are improved within the same time. On the basis of improving the dyeing and finishing uniformity, the deposition rate and the dyeing and finishing efficiency and reducing the energy consumption and the dyeing and finishing processing, the dyeing and finishing thickness, the dyeing and finishing color rate and the dyeing and finishing efficiency are improved in an auxiliary mode by arranging the cold and hot alternating environment area.

Owner:南通云花色织有限公司

Transparent display substrate, array substrate, display panel and display device

ActiveCN110148621BHigh color ratioStrong brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTransmittance

The present application provides a transparent display substrate, an array substrate, a display panel and a display device. A plurality of first sub-pixels are arranged in the display area of the transparent display substrate, the first sub-pixels include a first light-emitting area and a second light-emitting area, and the light transmittance of the first light-emitting area is greater than that of the second light-emitting area. Light-emitting area; the first sub-pixel includes a first electrode, a light-emitting structure on the first electrode, and a second electrode on the light-emitting structure, the first electrode includes a first conductive layer and a light-emitting structure on the first electrode A second conductive layer on the first conductive layer, the first conductive layer is in contact with the second conductive layer. One of the first conductive layer and the second conductive layer includes a reflective film layer, the other is a transparent conductive film layer, and the reflective film layer is only arranged in the second light-emitting area, and the transparent The conductive film layer at least covers the first light emitting area.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

A kind of production process of caramel color

The invention discloses a caramel color production process and belongs to the technical field of caramel color production. According to the process disclosed by the invention, by improving the ordinary process, on the basis of not adding any other chemical substance, high fructose corn syrup is adopted as the raw material, the content of reducing sugar in the raw material is more than or equal to95%, the content of fructose is more than or equal to 42%, the pH value is 4.5-.0, and the concentration of the high fructose corn syrup is 74-75%. A reaction kettle pressurization condition or a microwave heating manner is adopted; when the checked color index is more than 16000EBC, the reaction is terminated, so that the final color rate of the produced caramel color can reach 16000EBC, and thered index is high; furthermore, under the pressurization condition of the reaction kettle, trace dietary alkali is added, the pH value is regulated by edible citric acid, the positive reaction (Maillard reaction and caramel reaction as required) is completely carried out, and the color rate of the produced caramel is further improved. Compared with positive pressure and normal pressure methods, the method disclosed by the invention has the advantages that external odor or vapor is avoided, the energy is saved, and the environment is protected.

Owner:湖南金代科技发展有限公司

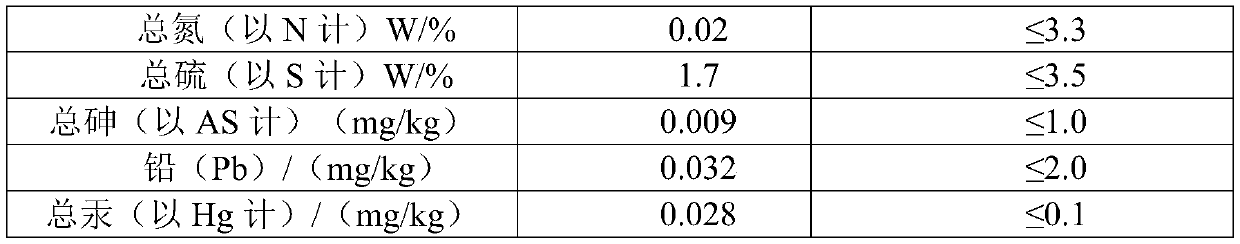

A digital active cold transfer printing non-steaming and non-cleaning water additive and method

ActiveCN110886102BPrint fineFine print transferTransfer printing processDyeing processTextile printerComputer printing

The invention discloses a non-steaming and non-cleaning water additive for the first time, the main component of which is the polycondensation product of polyfunctional cross-linking reactive polycondensate and cationic quaternary ammonium salt polymer, including diethylenetriamine and epichlorohydrin Polycondensate, a polymer of dimethyldiallyl ammonium chloride and a crosslinking agent, and a polycondensate of a low-temperature self-crosslinking accelerator. The use of this additive can realize the combination of digital cold transfer printing and non-steaming and non-washing water additives, which is flexible, fast-reversing, energy-saving and environmentally friendly waterless printing production, that is, the number of meters of printing transfer film required for flexible printing by digital printers , high-precision and high-uniformity transfer printing technology, and quick-reverse production with a short process of no-steaming and no-cleaning water, realizing the rapid production process of reactive dye waterless printing. This printing process is the first printing method in the printing industry.

Owner:广州希音国际进出口有限公司

Spray processing method and spray machine for fabric dyeing and finishing

ActiveCN114561757BReduces fluttering off the fabricReduce wasteTextile treatment machine arrangementsTextile/flexible product manufactureProcess engineeringIndustrial engineering

Owner:南通云花色织有限公司

Method for preparing caramel pigment from cane molasses

The invention relates to the technical field of caramel pigment processing, and particularly discloses a method for preparing caramel pigment from cane molasses. The method comprises the following steps of preparing a cane molasses solution from the cane molasses, regulating a pH value to 4-6, adding a complex enzyme agent, and keeping the temperature at 40-55 DEG C for 1-1.5 hours; heating to 60-65 DEG C, adding sucrase, and keeping the temperature for 2-3 hours; raising the temperature to 85-95 DEG C and keeping the temperature for 10-15 minutes to obtain a pretreated cane molasses solution;adding chitosan and sodium carboxymethylcellulose into the pretreated cane molasses solution, stirring for 30-40 minutes, and centrifugally collecting supernate; and adding amino acid into the supernate, heating to 140-150 DEG C, keeping the temperature to react for 1-2 hours, cooling to obtain a reaction product, concentrating and drying to obtain the caramel pigment. According to the method disclosed by the invention, colloid, protein, ash and other substances in the cane molasses are removed, and the prepared caramel pigment is high in color index and good in clarity.

Owner:南宁雄晋生物科技有限公司

Preparation and application of a tobacco sheet additive with both flavoring and coloring effects

ActiveCN106213576BPromote dissolutionBright colorTobacco preparationTobacco treatmentBiotechnologyMaillard reaction

The invention provides preparation and application of a tobacco slice additive having an aroma-enhancing effect and a coloring effect. The preparation method of the additive includes: (1) removing impurities from chestnut shells, cleaning the chestnut shells, drying the chestnut shells, and crushing the chestnut shells; (2) mixing the chestnut power in an aqueous solution to perform enzymolysis treatment by using cellulase; and (3) adding a certain mass of glucose and compound amino acid into the enzymatic hydrolysate of the step (2), controlling a process condition, extracting pigment of the chestnut shells in an alkaline condition, performing a Maillard reaction, filtering and concentrating the reaction solution to obtain the tobacco slice additive. The obtained tobacco slice additive has the aroma-enhancing effect and the coloring effect, can be used as a spice additive to perform aroma-enhancing treatment on tobacco slices, and can be used as a coloring agent to dye the tobacco slices; and the obtained tobacco slice additive is low in preparation cost, is simple in process, is remarkable in scorch aroma, is good in aroma quality, is high in color index, is excellent in water solubility, is stable in quality, is safe and non-toxic, and has actual production conversion and promotion application value.

Owner:WUHAN HUANGHELOU FLAVOR & SPICES

Method for producing high-safety caramel color through twice catalytic reaction

ActiveCN102643862BReduce unit consumptionReduce the temperatureNatural dyesFermentationReaction temperatureDry basis

The invention relates to a method for producing high-safety caramel color through twice catalytic reaction. The method comprises the following steps of: a, rice pulverization; b, spraying liquefaction; c, diastatic enzyme addition into liquefied rice for saccharification; d, filtering; e, concentration; f, primary catalytic reaction: through being metered by the mass percentage content of dry basis, catalysts accounting for 40 percent of the catalyst consumption are adopted and added in the primary catalytic reaction, then, through the pressurization and temperature rise reaction, the reaction pressure is controlled to a value being smaller than or equal to 0.1 MPa, the temperature is smaller than or equal to 110 DEG C, and the primary catalytic reaction is stopped when the reaction is carried out to reach 60 percent of the total required color rate; g, secondary catalytic reaction: the secondary catalytic reaction is stopped when the reaction is carried out to reach the required color rate; h, cooling; and i, finished product blending. Through the twice catalytic reaction, the reaction temperature and the reaction pressure are reduced, the reaction conditions are milder, the single consumption of steam is reduced, the reaction process and the control are easier and more stable, each ton of products can save 100kg of steam, and the method is favorable for improving the market competitiveness of products.

Owner:QIANHE CONDIMENT & FOOD CO LTD

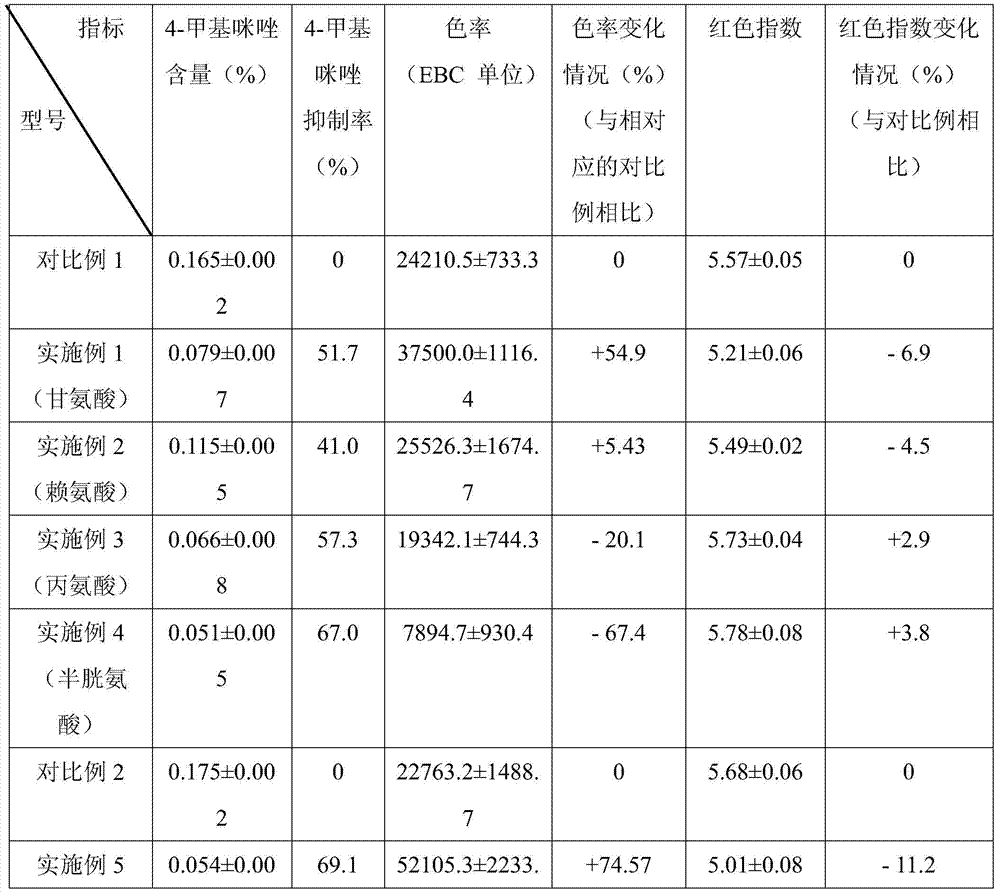

The preparation method of the caramel coloring that reduces 4-methylimidazole content

ActiveCN105368090BDoes not affect flavorReduce 4-methylimidazole contentNatural dyesPtru catalystProcess engineering

The invention discloses a preparation method of caramel pigment with a reduced 4-methylimidazole content. The method includes the steps of: firstly preparing raw material sugar into a sugar solution, then adding ammonia water serving as the catalyst and adding amino acid, stirring the substances evenly, then rapidly raising the temperature to 140+ / -2DEG C and carrying out heat preservation reaction for 55-65min; cooling the reaction product to lower than or equal to 50DEG C rapidly, and concentrating the cooled reaction product to obtain a concentrated caramel pigment solution; and further drying the concentrated caramel pigment solution to a water content of less than or equal to 5% so as to obtain solid caramel pigment. According to the invention, the level of 4-methylimidazole in caramel pigment is significantly lowered by means of adding amino acid in the production link, thereby realizing production of high quality and safe edible caramel pigment with low 4-methylimidazole content without changing the existing production process and facilities.

Owner:ZHEJIANG UNIV

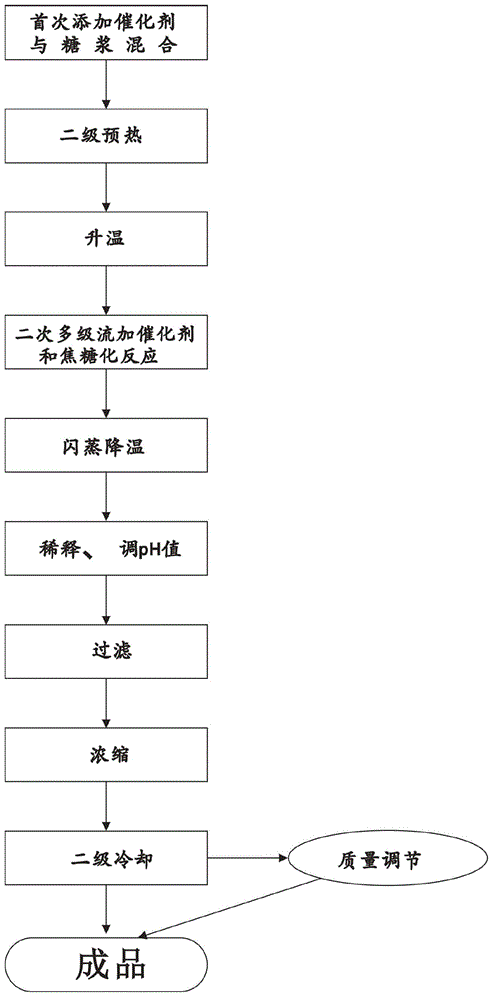

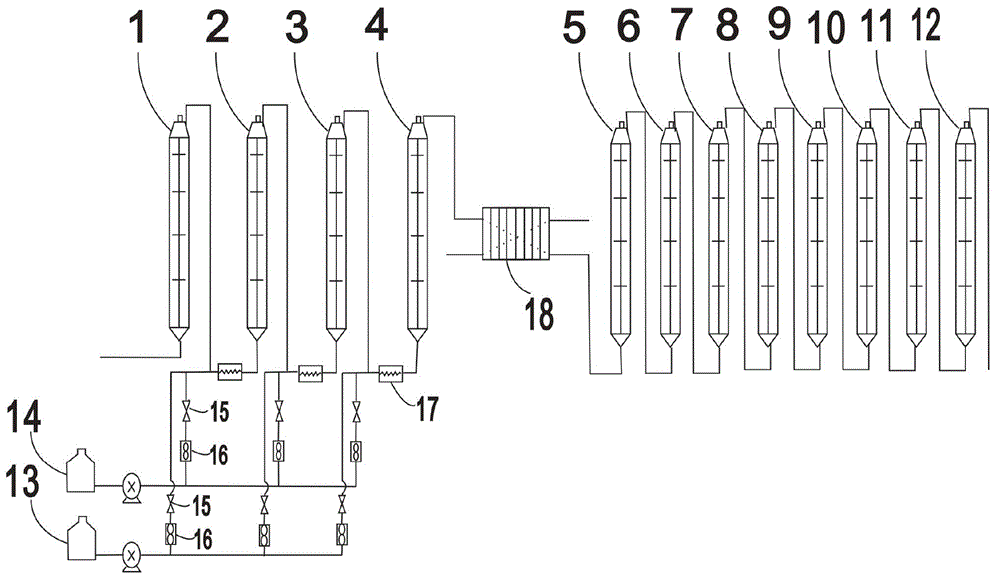

Process for continuous preparation of caramel pigment by ammonium sulfite method

The invention discloses a process for continuous preparation of caramel pigment by an ammonium sulfite method, which comprises the following steps of: (1) adding a catalyst for the first time, and mixing with syrup; (2) performing two-stage pre-heating; (3) increasing temperature; (4) performing secondary multi-stage catalyst feeding and caramelization; (5) flashing and reducing temperature; (6) diluting and regulating pH value; (7) filtering; (8) condensing; (9) performing two-stage cooling, and (10) quality regulating which can be further comprised. The process for continuous preparation of the caramel pigment by the ammonium sulfite method disclosed by the invention can realize continuous and sealed preparation of the caramel pigment by the ammonium sulfite method, improve production efficiency and output, improve safety of the product and reduce the energy consumption; the produced caramel pigment is stable in quality, and is capable of simultaneously meeting high color index and high red index, being ideal caramel pigment in many fields, particularly in soy sauce.

Owner:GUANGZHOU SHUANGQIAO

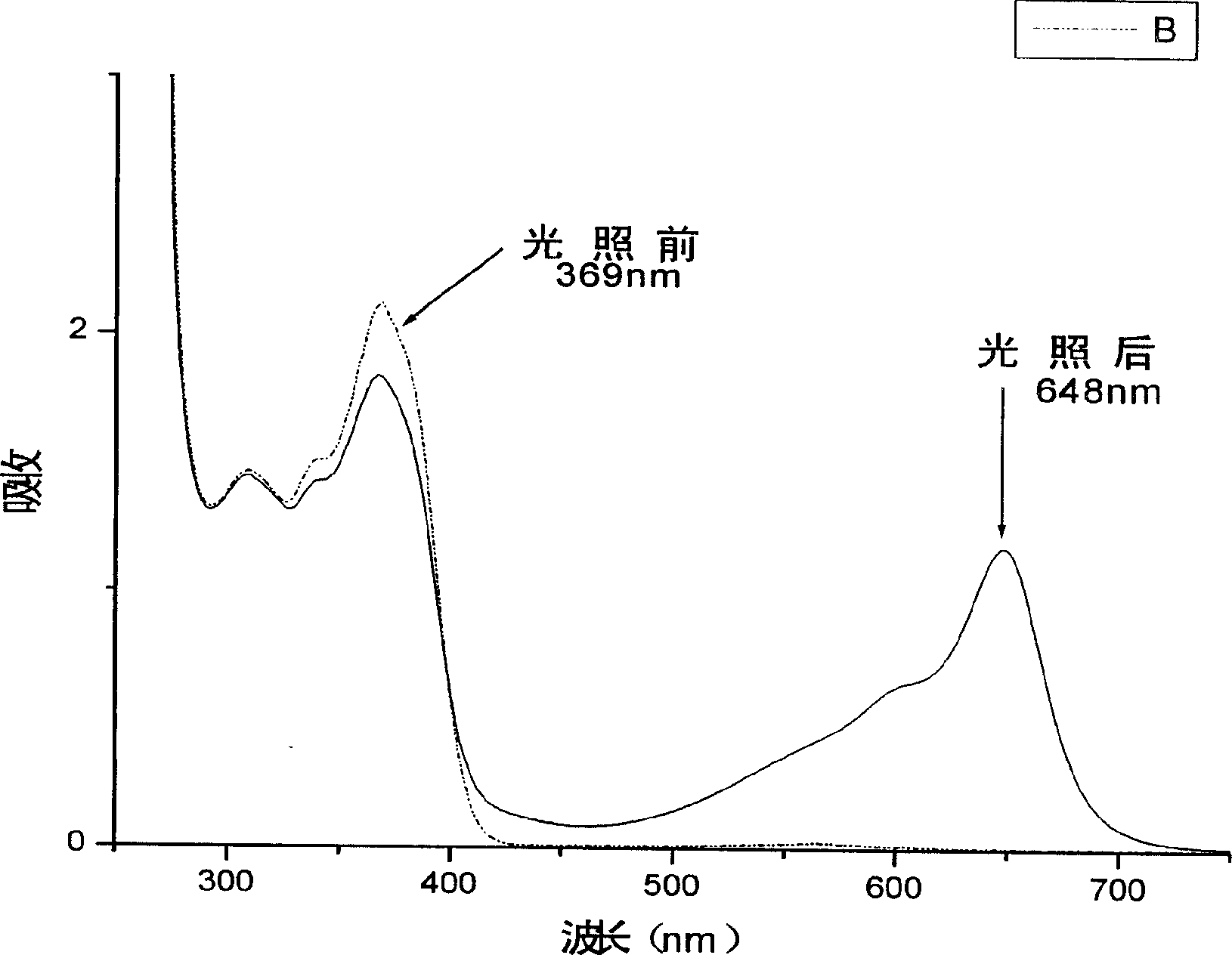

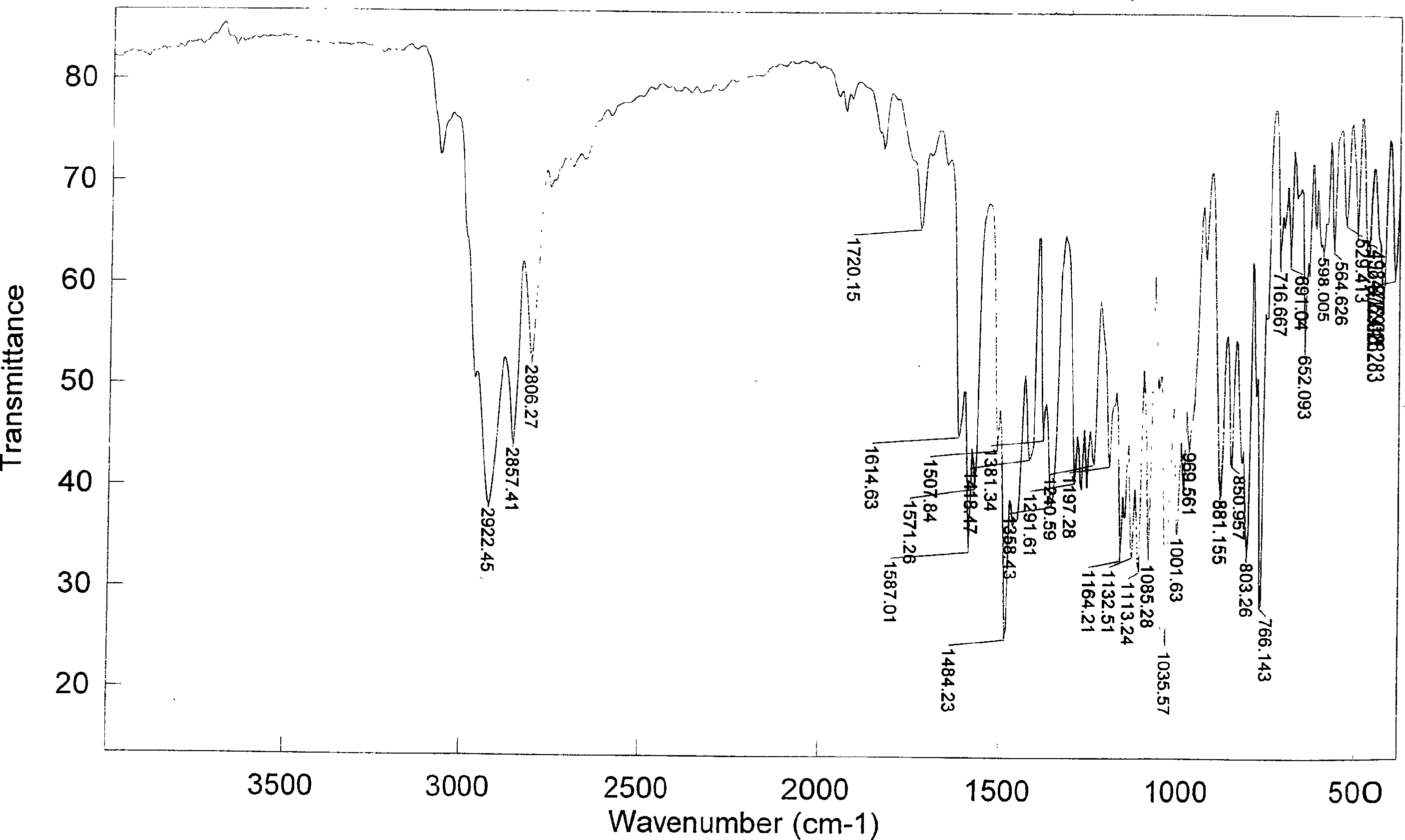

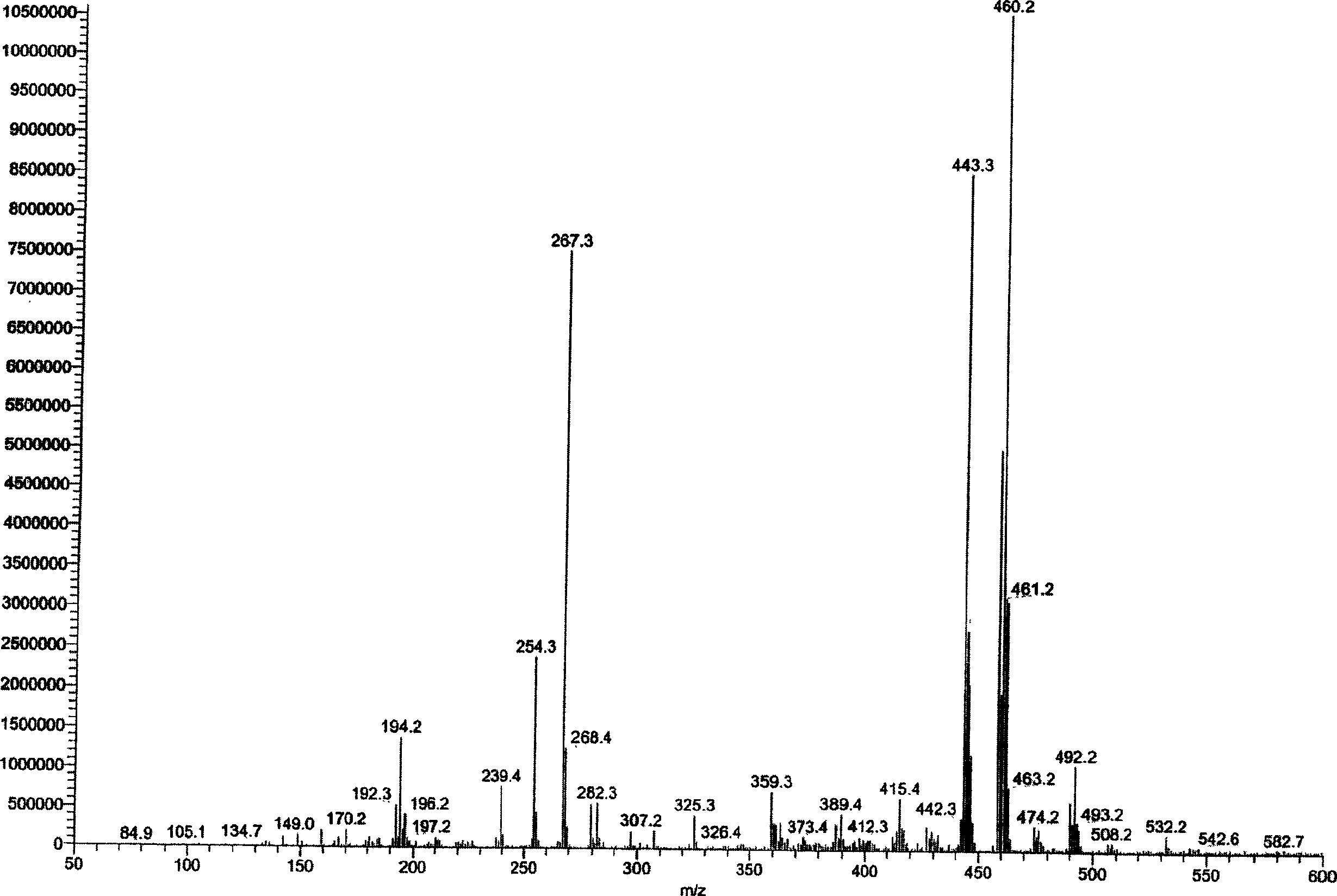

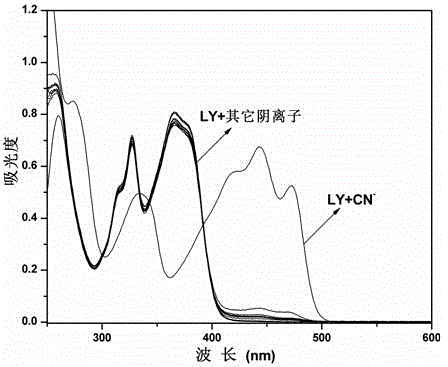

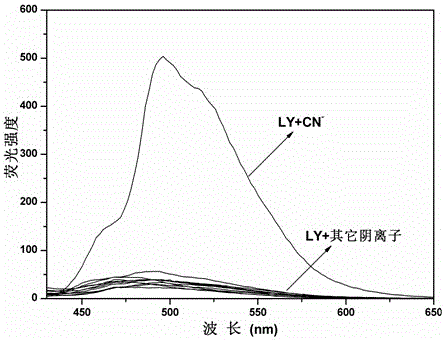

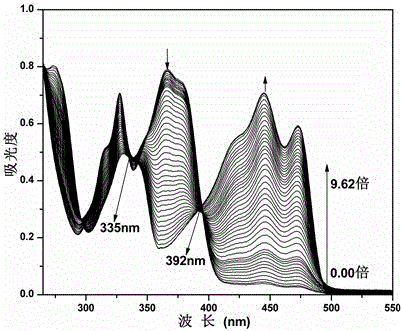

A kind of bisacylhydrazone compound and its synthesis and application of UV-fluorescence double pass to recognize cyanide ion in aqueous system

InactiveCN104961649BHigh sensitivityHigh selectivityMaterial analysis by observing effect on chemical indicatorHydrazone preparationChemical synthesisCyanide ion

The present invention discloses a diacylhydrazone compound capable of performing ultraviolet-fluorescent double-pass recognition of cyanide ions and synthesis thereof, and belongs to the technical field of chemical synthesis and anion detection. The diacylhydrazone compound is obtained by reflux reaction of ethanol as a solvent, acetic acid as a catalyst, and isophthaloyl hydrazine and 2-hydroxy-1-naphthaldehyde as substrates. Experimental results show that in a water-containing system of the diacylhydrazone compound, the solution changes from colorless to light yellow only by addition of CN<->; under ultraviolet lamp irradiation, fluorescence of the compound solution can open only by addition of the CN<->, so that the compound is capable of easily and quickly performing high sensitivity high selectivity colorimetric fluorescent double-pass recognition of the CN<-> in the aqueous solution, the synthesis process is simple, cost is low, and the diacylhydrazone compound as a simple and effective diacylhydrazone recognition receptor has broad application prospects.

Owner:NORTHWEST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com