Patents

Literature

50results about How to "No coking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing crisp-fried barking walnut kernel

The invention relates to the food processing field, specifically a processing method of a crispy peel free walnut kernel, which solves the problem that color, taste and nutritional components of walnut kernel are damaged in prior art of walnut kernel processing method, comprising the steps of (1) peeling off the walnut kernel; (2) drying: adjusting temperature of the microwave oven at 75 deg C to 85 deg C, baking 2min to 3min; (3) coating: coating the surface of the walnut kernel evenly by constant temperature liquid flavoring; (4) roasting: adjusting temperature of the microwave oven at 115 deg C to 125 deg C, baking 1.5min to 3.5min; it is appropriate when the walnut kernel observed is golden, then cooling the walnut kernel at constant temperature to prepare the crispy peel free walnut kernel. The walnut kernel is processed respectively before and after coating by microwave oven at low temperature, which enables the walnut kernel to be crispy in mouthfeel, bright in color and great preservation of the nutritional components. The peel off of the walnut kernel is dipped by low temperature, low concentration sodium hydroxide solution that is changed always, then neutralized by citric acid, finally washed to remove the peel of the walnut kernel.

Owner:王晶平

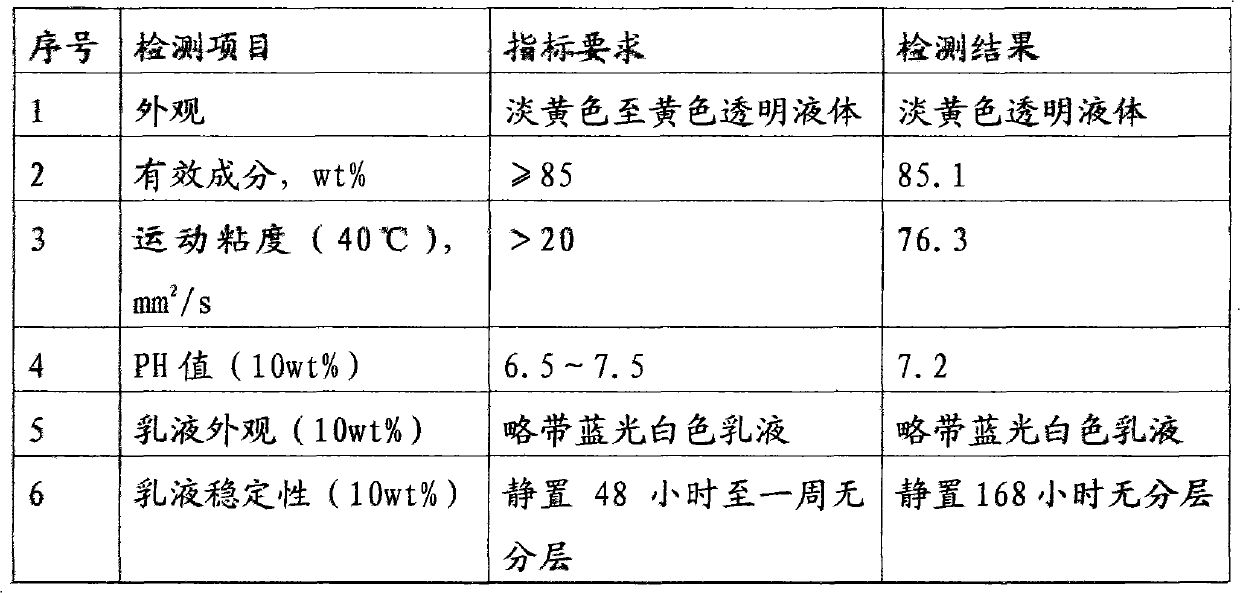

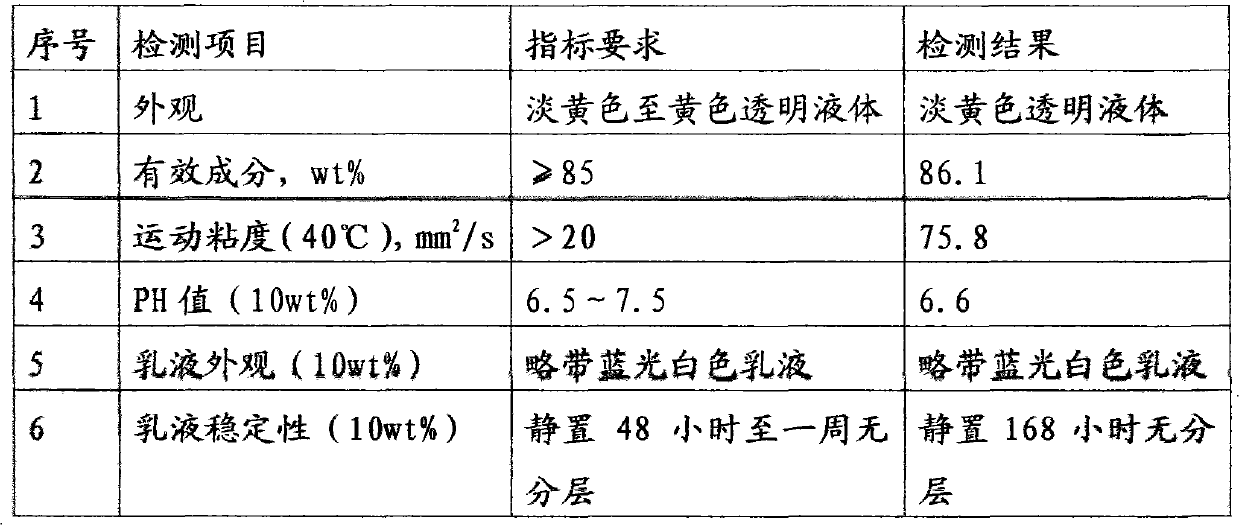

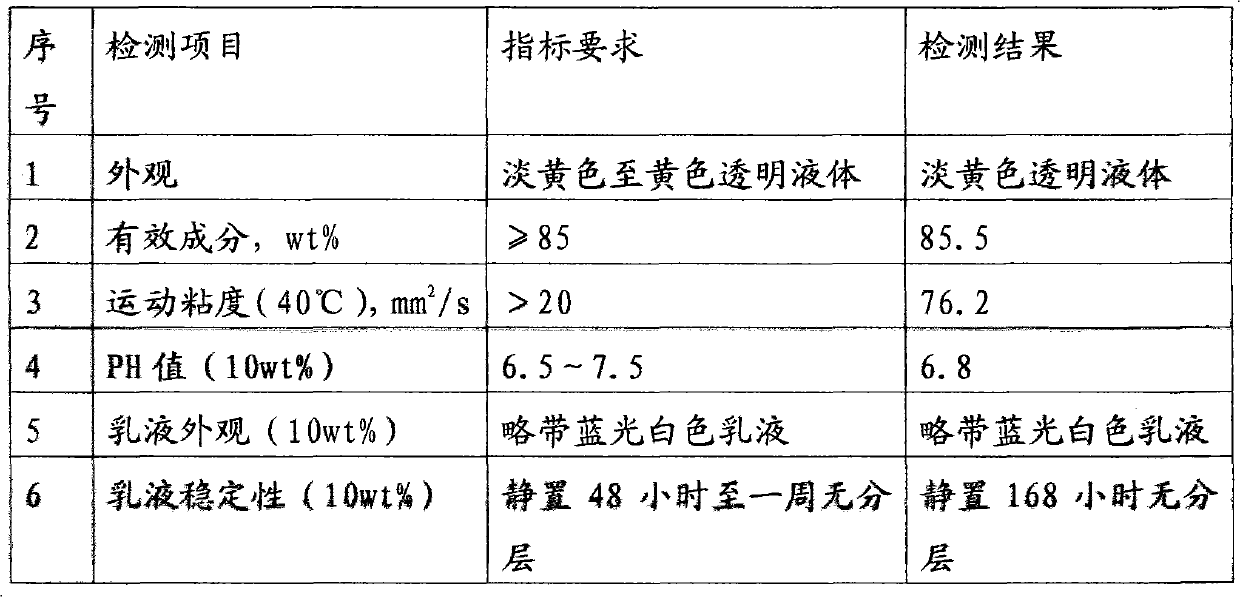

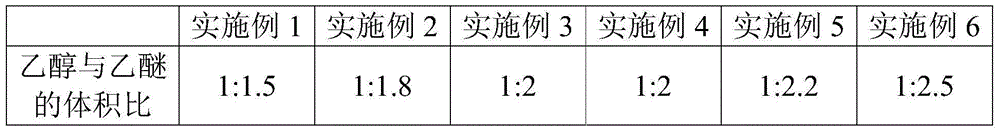

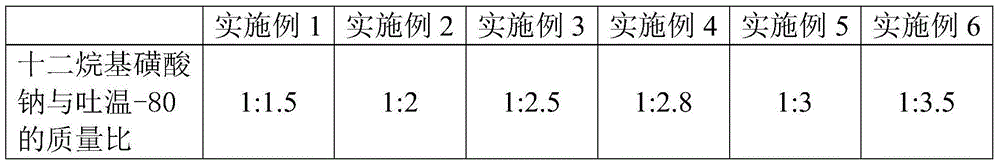

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

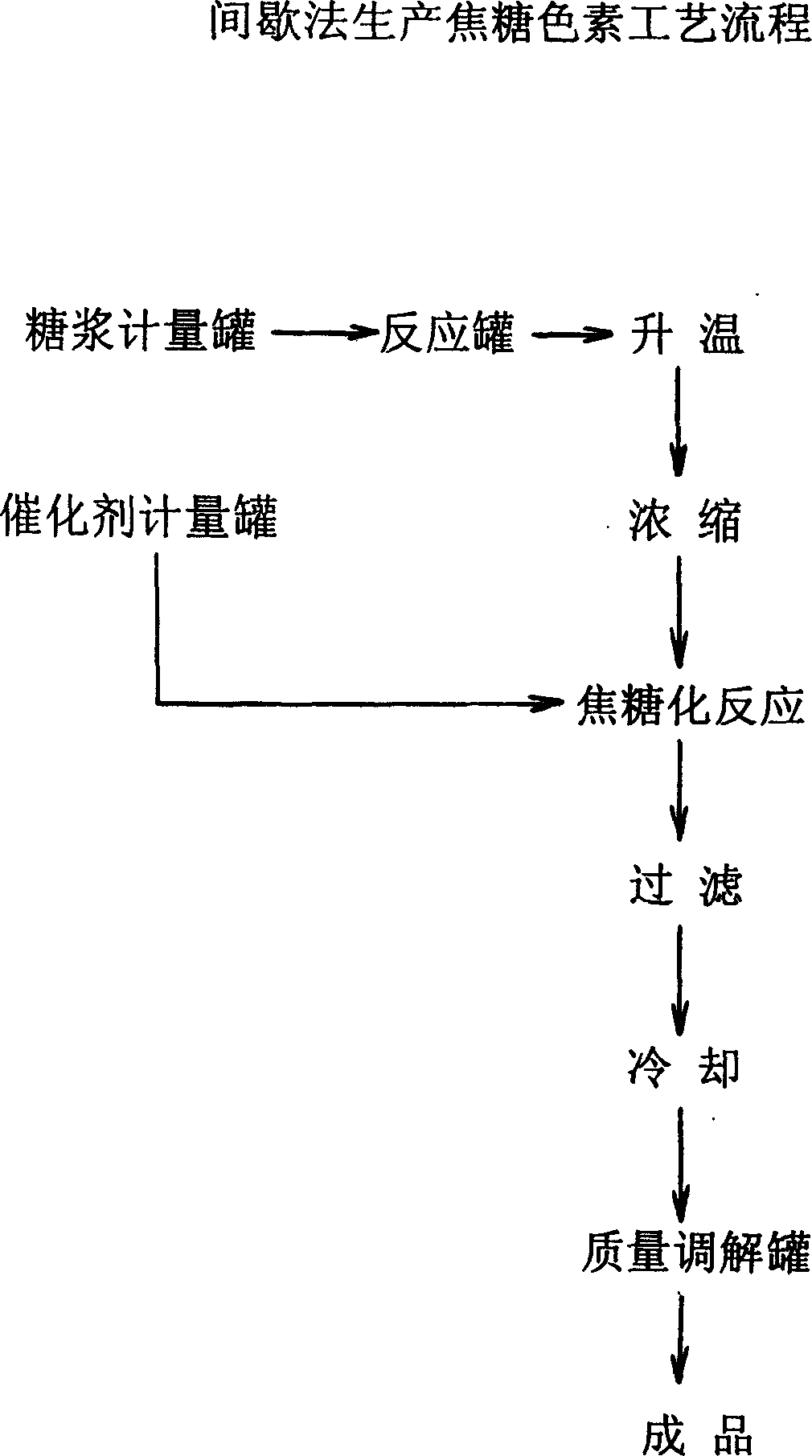

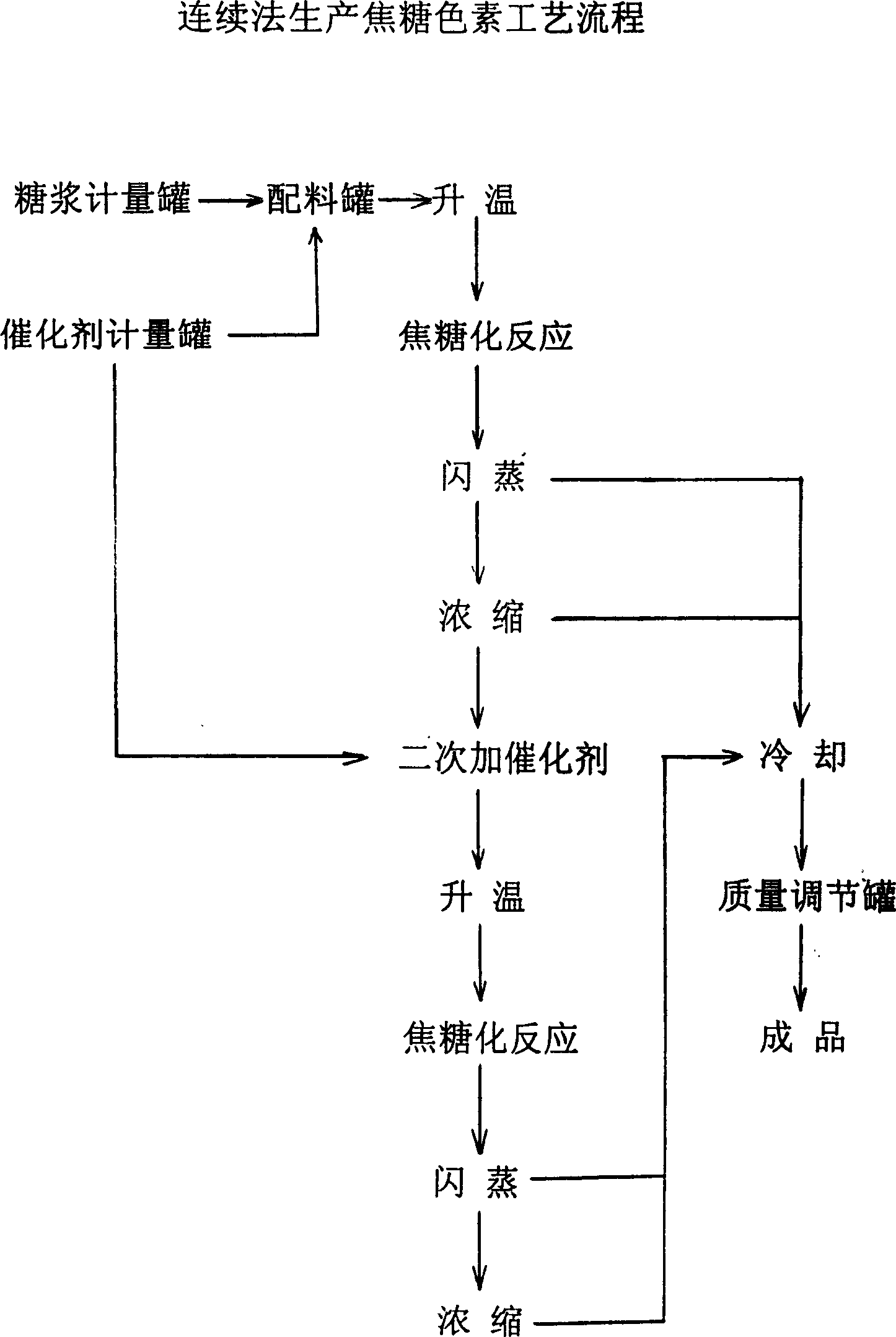

Process and apparatus for continuous manufacturing burnt sugar colouring matter

A process for continuous production of caramel pigment includes such steps as proportionally mixing catalyst with syrup, heating by heat exchanger for indirect heating and steam sprayer for direct heating, caramelizing reacting in reactor, cooling by flash evaporator, concentrating by evaporator, cooling by cooler, regulating quality in quality regulating tank, and storing in tank. Its advantages are high quality and output rate and low cost.

Owner:马荣昌

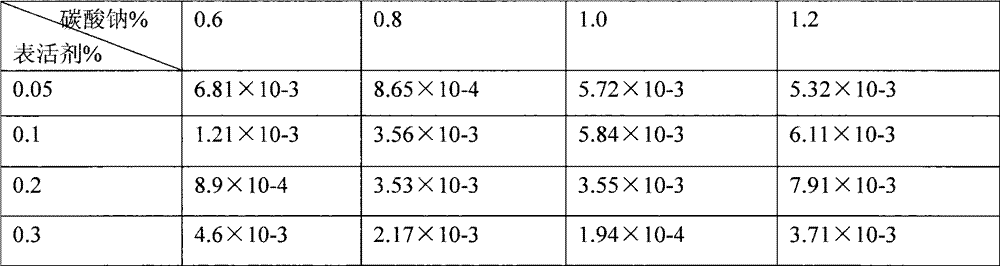

Method for preparing petroleum sulfonate oil displacement agent

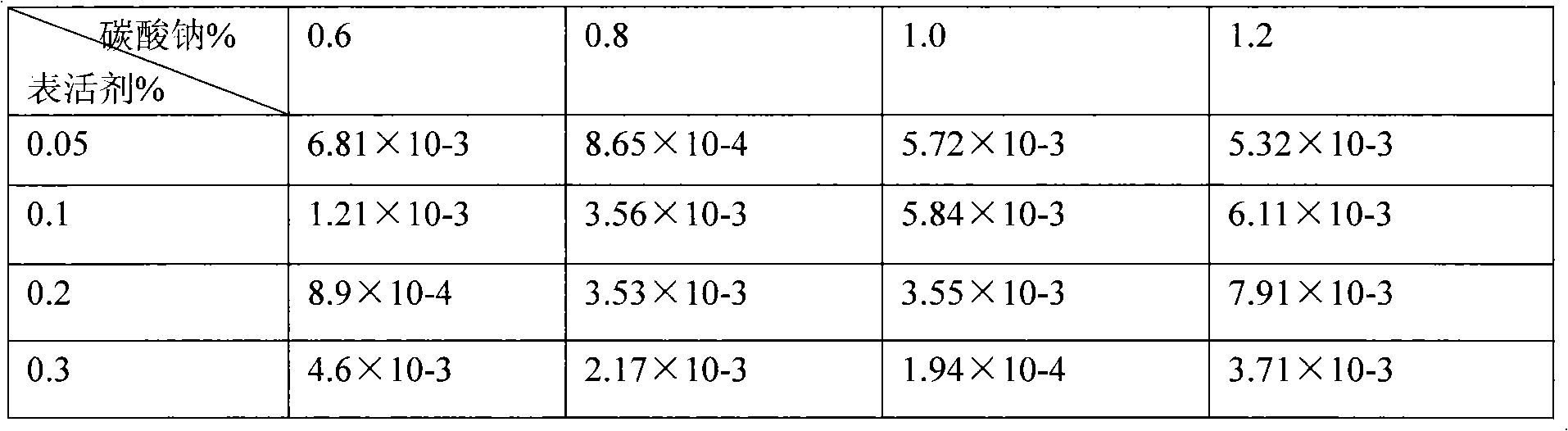

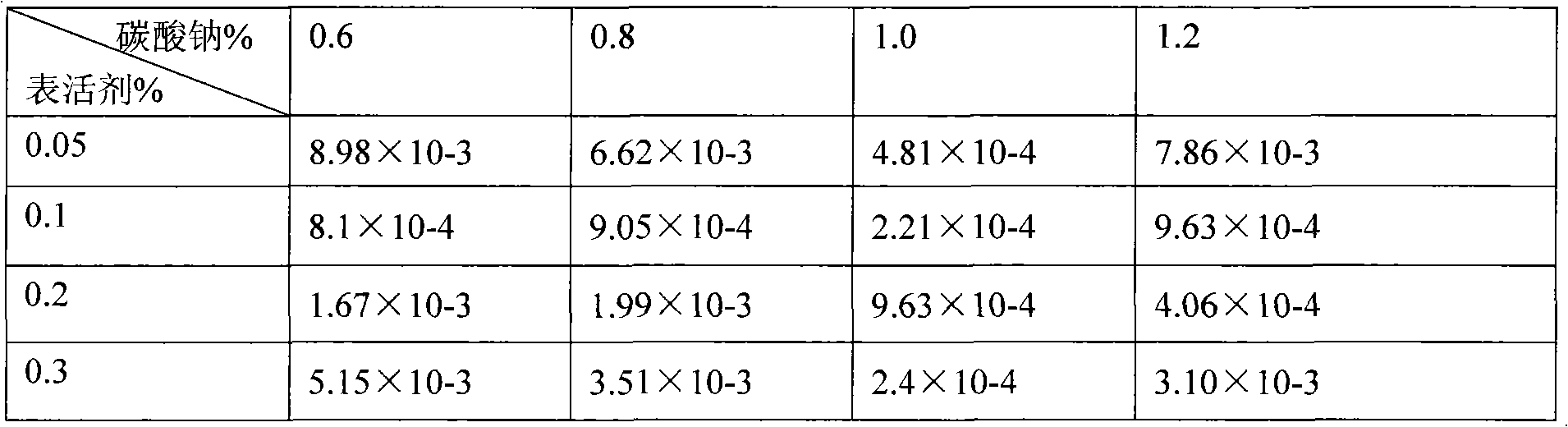

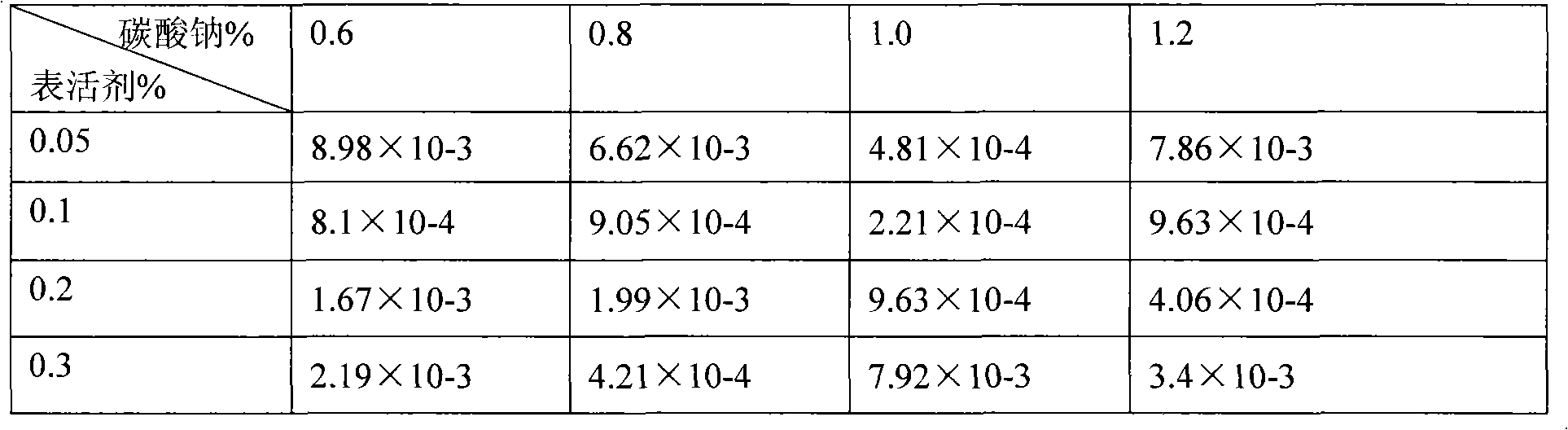

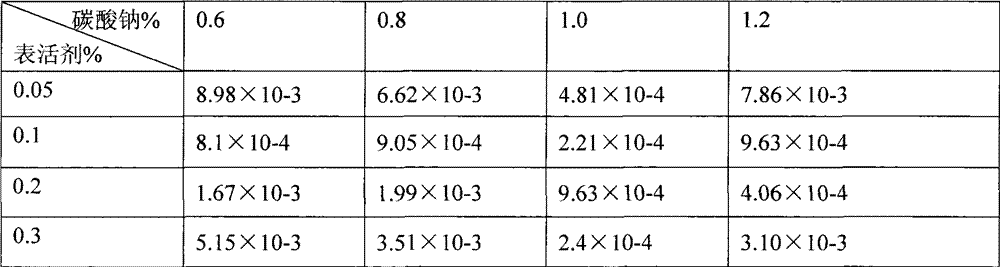

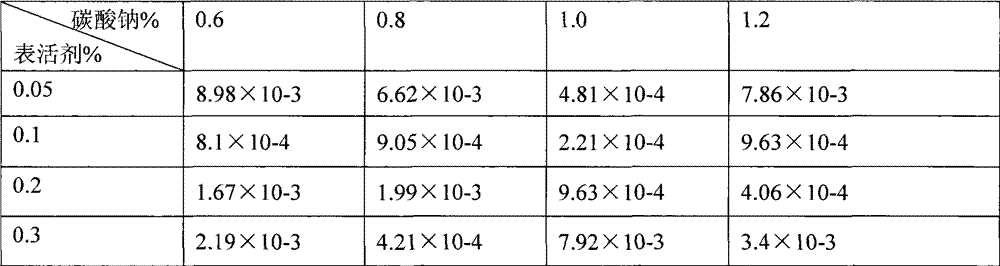

The invention relates to a method for preparing a petroleum sulfonate oil displacement agent. Benzol-ketone dewaxing oil and furfural extract oil are mixed in a weight ratio of 1:0.01-1:0.5, and the mixture enters a film or tank reactor for sulfonation reaction; a sulfonating agent is SO3 gas, the concentration is diluted to between 1.5 and 3.0 percent in a volume ratio by dry air or inert gas of which the dew point is lower than 60 DEG C, the temperature of the sulfonation reaction is between 30 and 85DEG C, the acid value of sulfonatedbodies is controlled to between 30 and 90mgNaOH / g, and the sulfonatedbodies are neutralized by NaOH or KOH solution; and the raw materials have the advantages of high content of arene capable of being sulfonated and no coking phenomenon in the reaction process; after neutralization, and the sulfonatedbodies do not need extraction separation; the active matter content reaches 25 to 40 percent; a weak alkali / surfactant / polymer system configured by adopting Na2CO3 or a non-alkali binary system configured by salts such as NaCL and the like has the interfacial tension less than 10<-3>mN / m.

Owner:PETROCHINA CO LTD

Method for preparing glucosamine hydrochloride

InactiveCN101775045AShort reaction timeInhibit side effectsSugar derivativesSugar derivatives preparationGas explosionChemistry

The invention relates to a method for preparing glucosamine hydrochloride, which is characterized by comprising the following steps: 1) treatment of chitin in a gas explosion expanding method: feeding chitin as a raw material into a gas explosion expanding tank, and injecting a gas explosion expanding medium into the gas explosion expanding tank, wherein the gas explosion expanding medium is one of the four substances, namely, steam, water, ammonium hydroxide and ethanol; and instantly releasing the pressure of the gas explosion expanding tank, and discharging the raw material chitin into an atmospheric vessel, thereby obtaining chitin concentrate; 2) hydrolysis with hydrochloric acid; 3) decolorization; 4) filtration; 5) concentration and crystallization; and 6) secondary crystallization. Compared with the prior art, the invention has the following advantages that: 1) the chitin pretreated in the gas explosion expanding method is used as the raw material, and due to the high chemical activity thereof, the invention can achieve a higher product yield; 2) almost no 'coking' can be caused in the process of hydrolysis; 3) the extraction of GAH can be completed at one step during the technological process of technology, thereby simplifying the preparation of GAH; and 4) the hydrochloric acid can be recycled, thereby realizing the clean production of GAH.

Owner:汪昔奇 +1

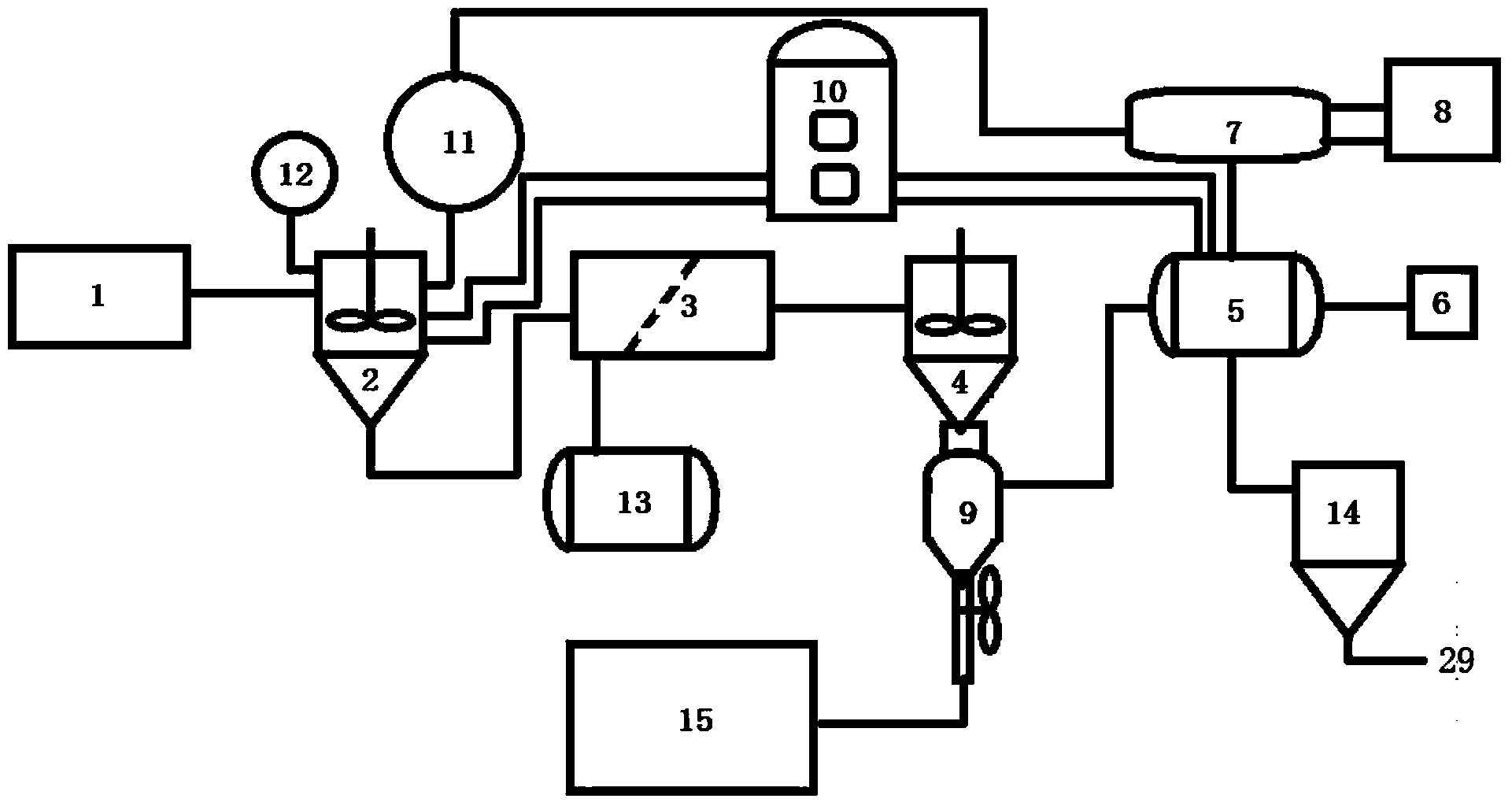

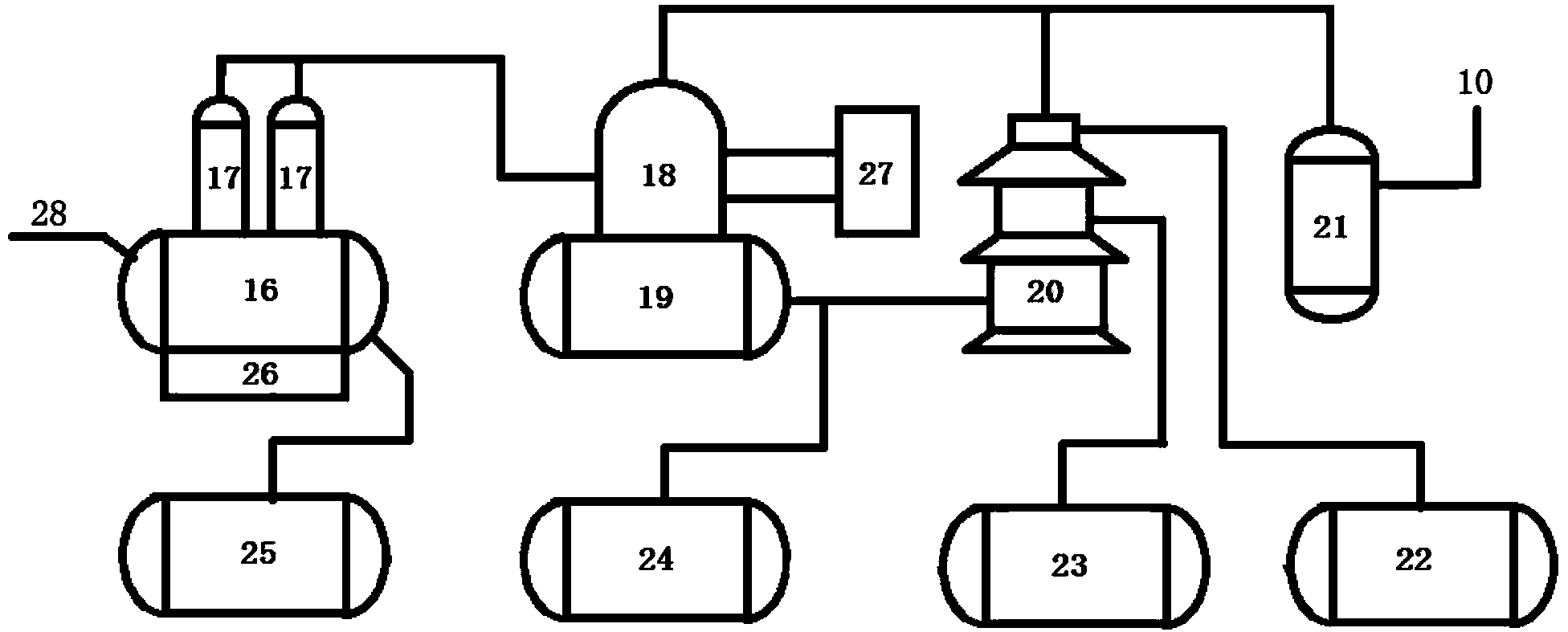

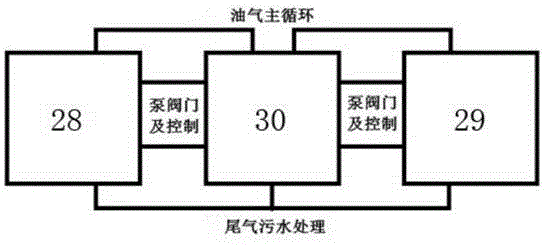

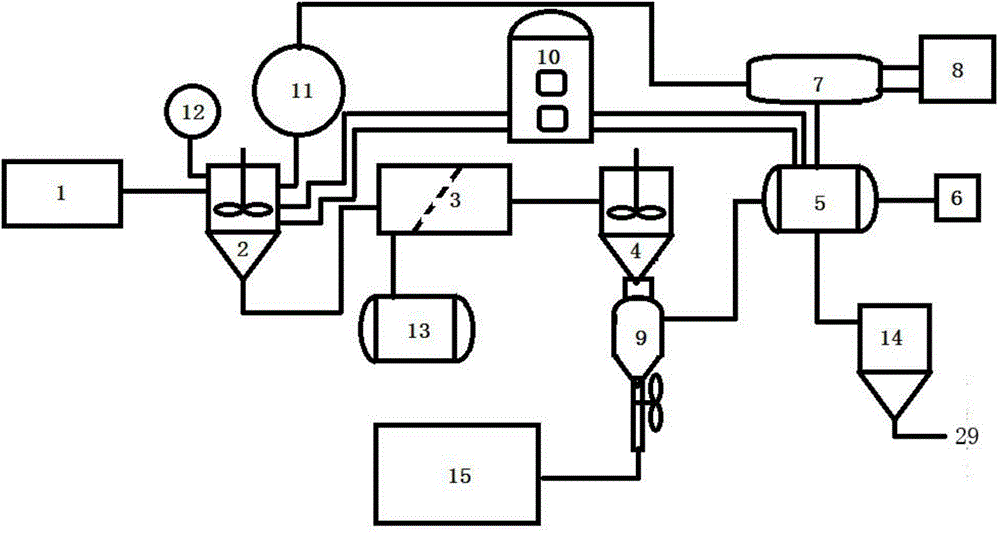

Method for refining oil through depolymerizing and liquifying waste plastics and device used in method

InactiveCN103555354ARealize depolymerization and liquefactionQuality assuranceHydrocarbon distillationPlastic recyclingFiberCeramic sintering

The invention relates to a method for refining oil through depolymerizing and liquifying waste plastics and a device used in the method. The method comprises the following steps of (1) crushing the waste plastics; (2) carrying out depolymerization reaction on the crushed waste plastics; (3) neutralizing a depolymerized acidic product by using a sodium hydroxide solution; (4) further washing to obtain a plastic depolymerization chlorobenzene dissolved liquid; (5) carrying out reduced pressure distillation on the plastic depolymerization chlorobenzene dissolved liquid; (6) carrying out cracking reaction and condensing to obtain a cracked fuel oil mixture; (7) rectifying and catalyzing the cracked fuel oil. The method has the beneficial effects that the depolymerization and liquidation of the plastics are realized by using a solvent and acid catalysis technology on the basis of a liquifying technology for plastics such as polyurethane, polyester and the like used in the chemical fiber industry; the cracking temperature is controlled within 360 DEG C in heating and cracking, so that the coking phenomenon is avoided; a porous nickel and chromium salt loaded catalyst is used, and the catalyst is prepared by using a ceramic sintering method, so that the quality of a refined oil product is ensured.

Owner:HUIZHOU SHENZHOU CHUANGYU LOW CARBON TECH DEV

Soybean drawing protein and production technology thereof

InactiveCN107006676AImprove organizational structureNot easy to looseProteins working-up by texturisingVegetable proteins working-upGlutenSoybean meal

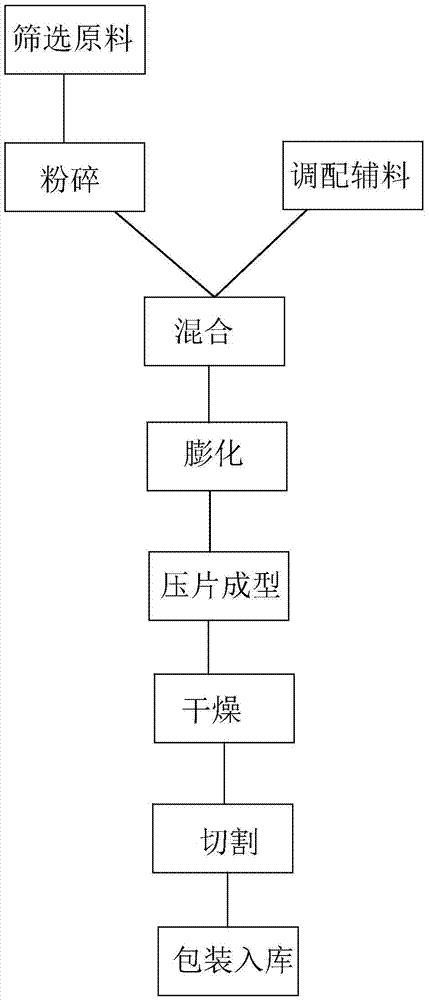

The invention discloses soybean drawing protein and a production technology thereof. The soybean drawing protein is technically characterized by being prepared from the following components of 80% of soybean meal, 10% of separation protein, 5% of vital gluten, and 5% of wheat flour; or, 10% of soybean meal, 80% of separation protein, 5% of vital gluten, and 5% of wheat flour. The production technology comprises the following steps of S1, screening; S2, crushing; S3, blending of auxiliary materials; S4, mixing; S5, swelling; S6, tabletting and forming; S7, drying; S8, cutting; S9, packaging and sending into a warehouse. The soybean drawing protein and the production technology thereof have the advantages that the forming effect is good, the coking is avoided, the sticking is avoided in cutting, the mouth feel is good, and the nutritional value is high.

Owner:ZHEJIANG BAICHUAN FOOD

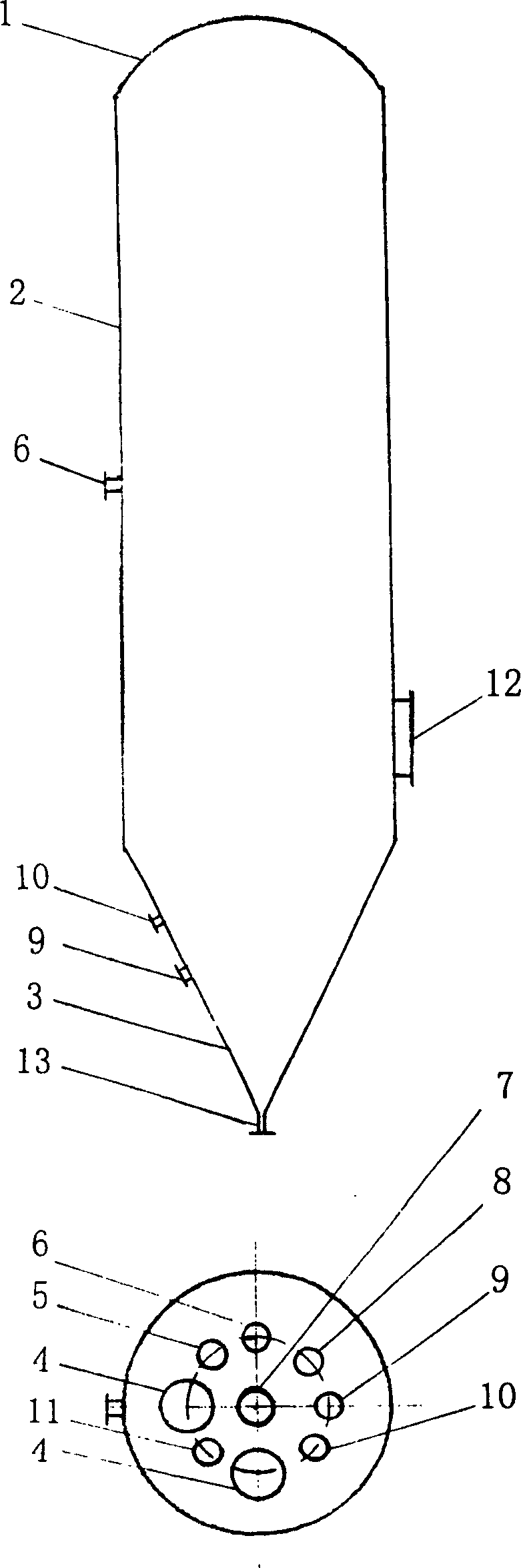

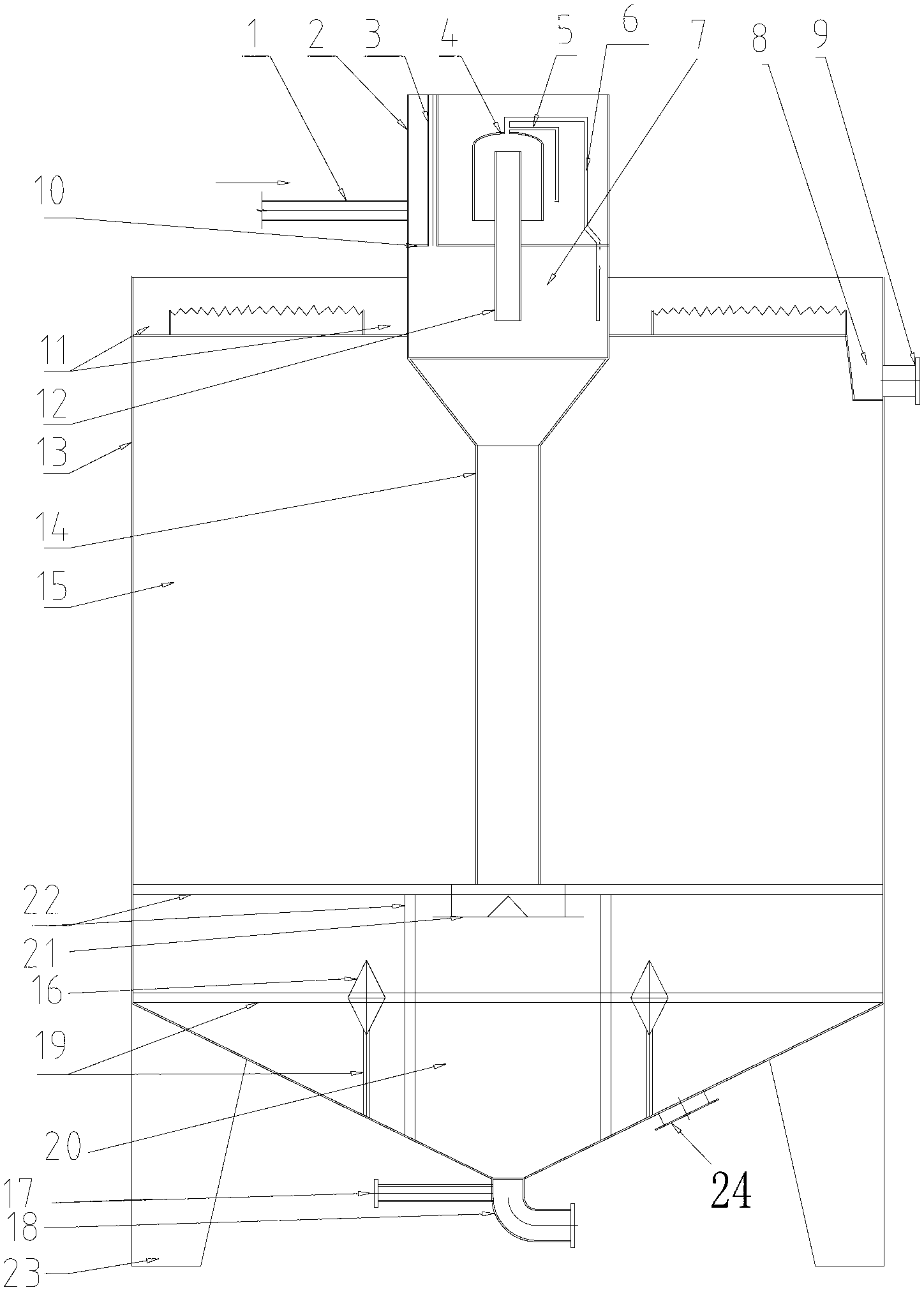

Alcohol waste pulse quick precipitator

ActiveCN103272414AEasy to operateLow running costSedimentation settling tanksWater pipeHigh concentration

The invention discloses an alcohol waste pulse quick precipitator; a water supply chamber, a pulse region, a water distribution downcomer, a buffering plate and a sludge collecting region are sequentially arranged at the center part of a cylinder body from the top down, a water inlet pipe is connected to the side edge of the water supply chamber, a pulse deep is arranged inside the water supply chamber, a center siphon pipe extending to the pulse region is arranged below the pulse deep, the top of the pulse deep is in pipe connection with an extraction pipe and a siphonic damage pipe which are communicated with each other, and an exhaust pipe communicated with the pulse region is arranged inside the water supply room; the bottom of the pulse region is connected with the water distribution downcomer, a settling zone is arranged on the outer side of the water distribution downcomer, the buffering plate is arranged at the bottom of the water distribution downcomer, the sludge collecting region is arranged below the buffering plate, and a blow-off pipe is arranged at the bottom of the sludge collecting region; and a water outlet slot, a water outlet header tank and a water outlet which are communicated with one another are arranged at the top of the cylinder body. The alcohol waste pulse quick precipitator provided by the invention has the advantages that the settling effect is excellent, the problem of solid-liquid separation of high-concentration alcohol sediment is solved, and the phenomenon of coking is avoided.

Owner:NANNING HUIXIAN ENVIRONMENTAL PROTECTION ENG

Puffed flower crisp chips and processing method thereof

InactiveCN103478602ABright and beautiful colorGood colorFood preparationMonosodium glutamateCorn meal

The invention in particular relates to a processing method and a product of flower crisp chips. The product is characterized by comprising the following raw materials in percentage by weight: 5%-60% of flower powder, 20%-60% of maize powder, 10%-50% of sticky rice powder, 4%-10% of white granulated sugar, 1.5%-3% of mycose, 0.5%-1.5% of salt and 0.06%-0.15% of composite monosodium glutamate. The product is bright and attractive in color and luster, crispy in mouth feel, salty, sweet and delicious, has specific fragrances of flower varieties, and is suitable for public taste. The flower crisp chips are easy to prepare, easy for industrial production and low in cost, can be used for providing cheap leisure foods for people to meet the healthy consumption requirements of the people, and have a good market prospect.

Owner:徐州绿之野生物食品有限公司

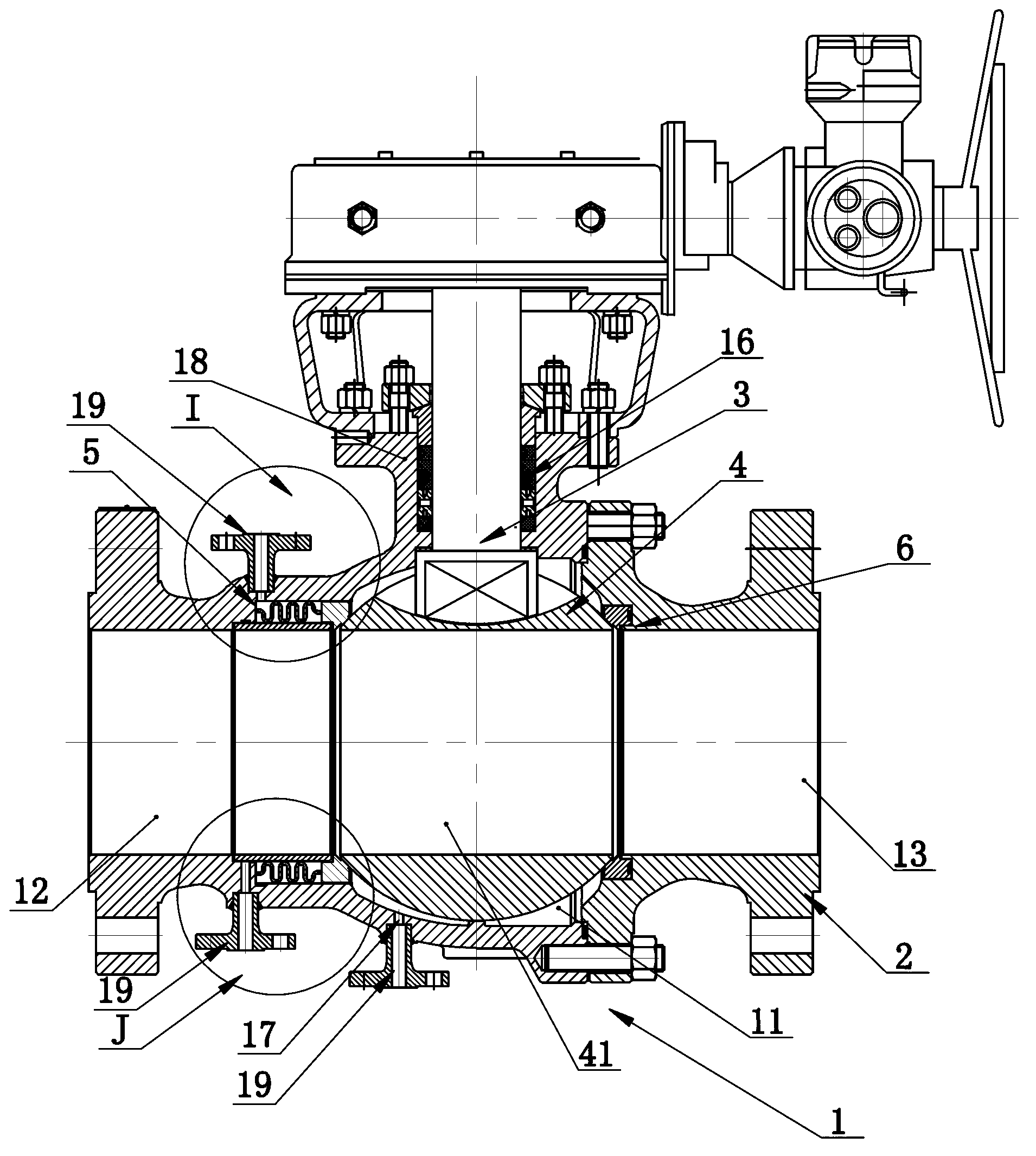

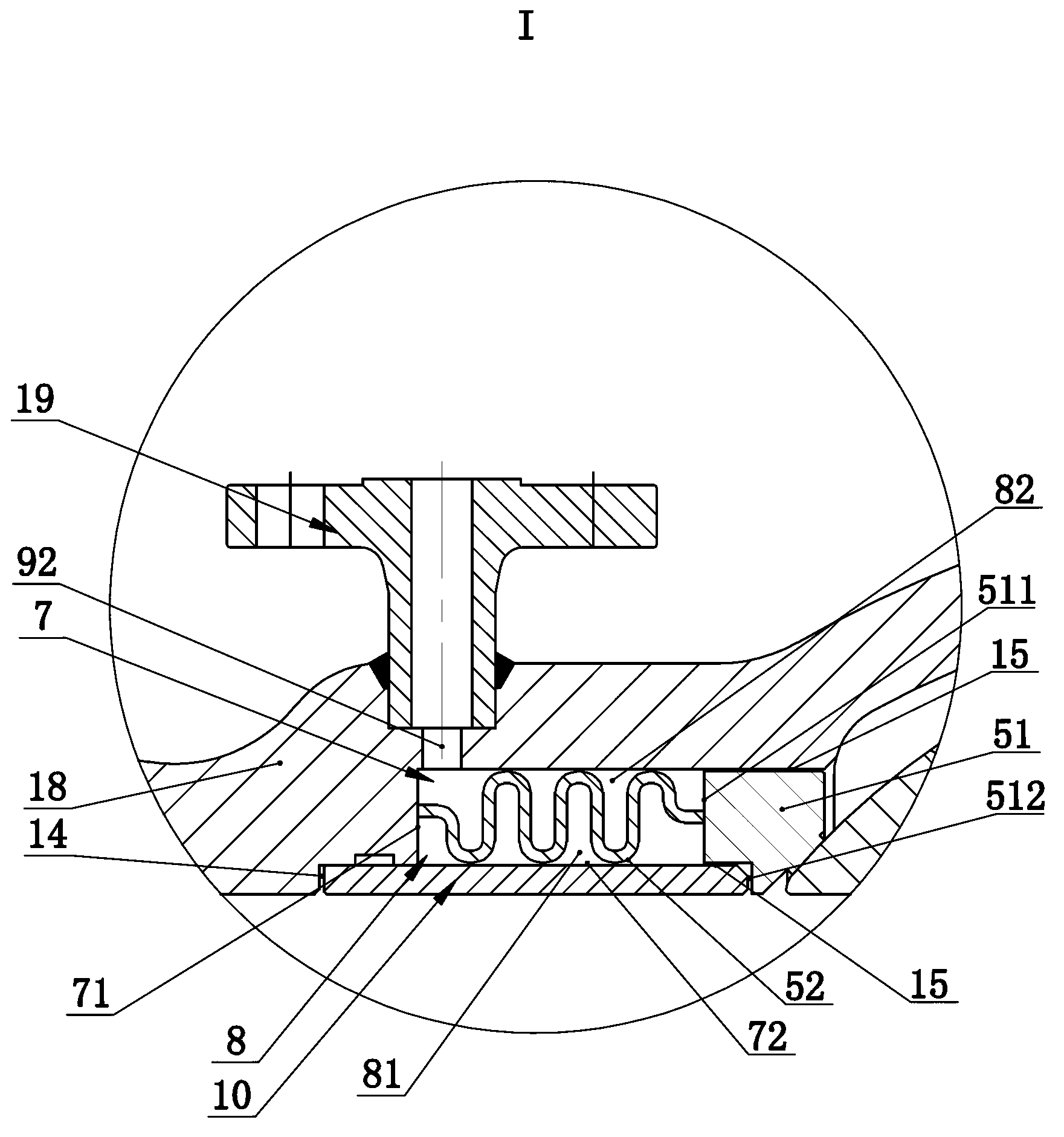

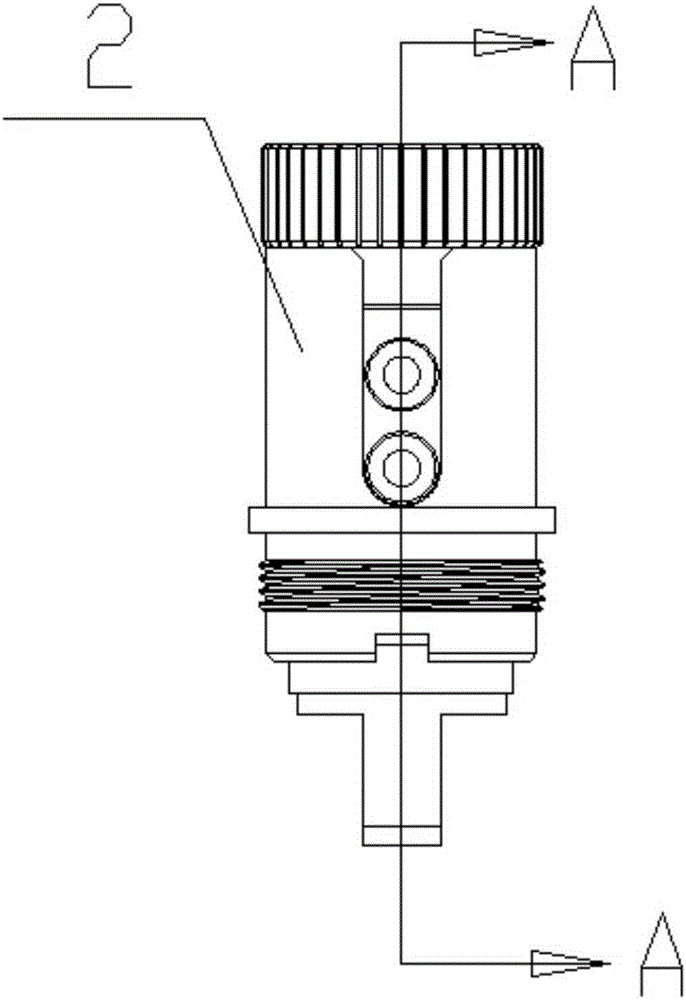

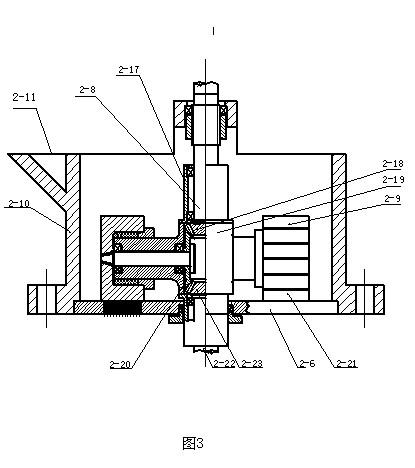

Ball valve used for high-temperature easily-coking medium

InactiveCN102840359ANo coking phenomenonImprove work performanceSpindle sealingsPlug valvesWork performanceEngineering

The invention relates to a ball valve used for a high-temperature easily-coking medium. The ball valve used for the high-temperature easily-coking medium comprises a valve body, a valve rod and a ball core. A valve cavity is arranged inside the valve body, and an inflow channel and an outflow channel are arranged on the valve body. An inlet side valve seat assembly is arranged between the ball core and the inflow channel and comprises a valve seat body and an elastic piece. The valve body arranged between the inflow channel and the valve cavity is provided with an annular groove, the outer side end of the valve seat body extends to the inside of the annular groove, and a pressure-storage cavity is formed by enclosure of the outer side end of the valve seat body and the annular groove. An expansion clearance is reserved between the valve seat body and the valve body. One end of the elastic piece is abutted against the outer side end of the valve seat body, and the other end of the elastic piece is abutted against the bottom of the annular groove. The valve body is provided with a first inflation channel communicated with the pressure-storage cavity. With the technical scheme, the ball valve used for the high-temperature easily-coking medium can prevent the high-temperature easily-coking medium from influencing the inlet side valve seat assembly, and guarantee that a coking phenomenon of the valve seat body can not occur and working performance of the valve is stable.

Owner:CHAODA VALVE GRP

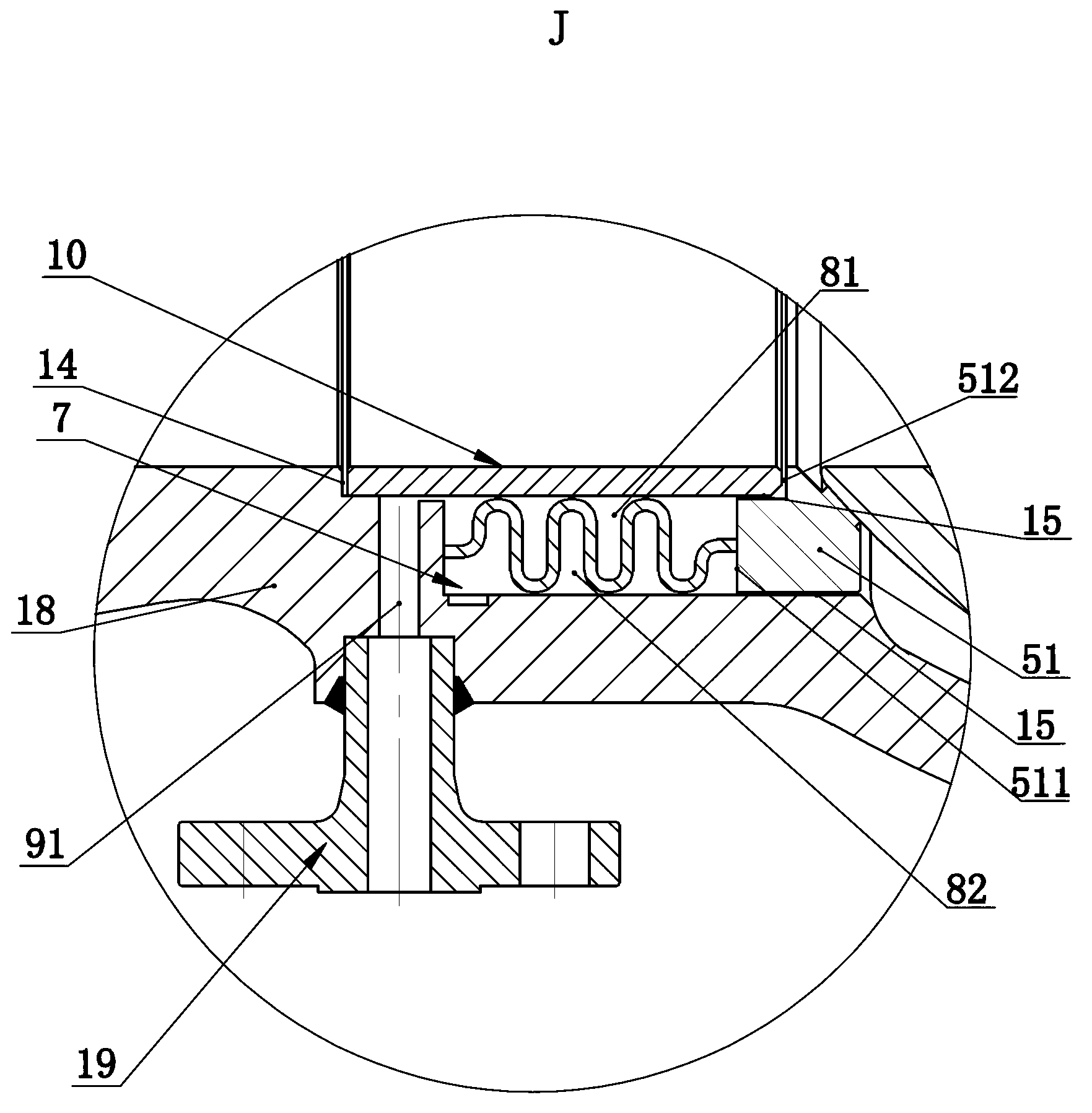

High-quality high-efficiency water-gas shift method and device

InactiveCN102408918AHeating evenlyReduce energy consumptionBulk chemical productionFixed-bed gasificationMicrowaveWater-gas shift reaction

The invention discloses a high-quality high-efficiency water-gas shift method and a device. The invention adopts domestic wastes, kitchen wastes, municipal sludge, biomass and other carbon-containing substances or carbon-containing wastes as raw materials, and realizes a high-quality high-efficiency water-gas shift reaction by introducing water vapor under an air-isolated (oxygen-free) condition and performing microwave induction. The invention has a simple process, convenient operations, low running cost, short reaction time, low energy consumption, a high conversion rate, and widely-applicable raw materials; no catalyst is required; no coking phenomenon occurs; the prepared water gas has high quality, that is, a high H2 content; the H2 / CO (volume ratio) is almost maintained to be about 2:1, which greatly reduces the purification and refining cost in subsequent procedures; biological fuel oil with low cost and high quality is prepared through FT (Fischer-Tropsch) synthesis, which can substitute scarce petroleum resources.

Owner:XIAN BAORUN IND DEV

Preparation of stabilizing brain for curing apoplexy and migraine and producing method

ActiveCN1539461ALow toxicityEnhanced inhibitory effectNervous disorderHydroxy compound active ingredientsCarthamusBorneol

A Chinese medicine for treating apoplexy and hemicrania is prepared from Chuan-xiong rhizome, Chinese angelica root, ginseng safflower and borneol. Its preparing process is also disclosed. Its advantages are low dosage and high curative effect.

Owner:安徽雷允上药业有限公司

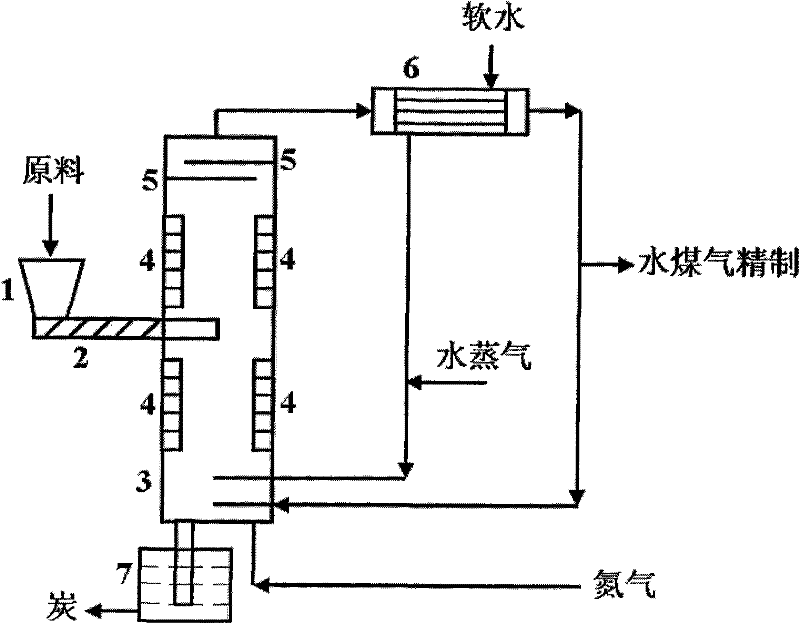

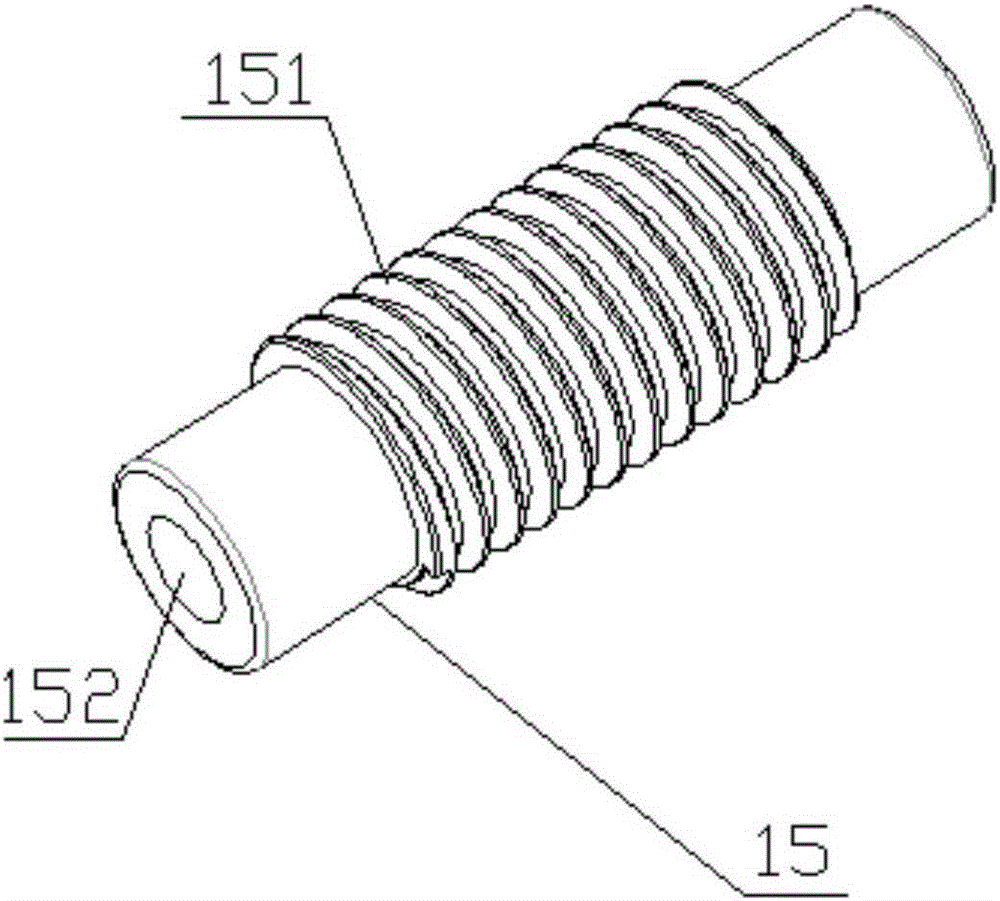

Electronic cigarette atomizer heating device, electronic cigarette atomizer head and electronic cigarette thereof

ActiveCN105192894AAvoid mutual interferenceNo coking phenomenonTobacco devicesGlass fiberElectronic cigarette

The invention provides an electronic cigarette atomizer heating device, which comprises at least two groups of heating components. Each heating component comprises a heating coil and a liquid absorption device arranged in mutual cooperation; two adjacent heating components are distributed at an interval; multiple heating coils are electrically connected by adopting a parallel connection mode; each liquid absorption device is a ceramic rod made of a multi-micropore ceramic material; each ceramic rod is provided with a drainage passageway; smoke juice permeates and penetrates the micropores in each ceramic rod via each drainage passageway to contact the heating coils. By distributing the heating components formed by the multiple heating coils and the liquid absorption devices at intervals, mutual interference among the heating components is avoided, a heating area is effectively enabled to be maximized, and the liquid absorption devices are ceramic rods made of the multi-micropore ceramic material, so even the smoke juice in an atomizer is less, a phenomenon similar to the phenomenon of coking of a fiberglass strand cannot occur, and the mouthfeel of a user smoking the electronic cigarette is guaranteed.

Owner:JOYETECH EURO HLDG

Environment-friendly coal-saving agent

InactiveCN104877730ASignificant coal saving effectReduce consumptionSolid fuelsSocial benefitsCombustion

The invention relates to the field of fire coal additive, in particular to environment-friendly coal-saving agent. The environment-friendly coal-saving agent includes 10 to 20 parts of combustion improver, 10 to 20 parts of oxygen supplier, 5 to 15 parts of catalyst, 0.8 to 1.6 parts of penetrating agent, 0.5 to 1.2 parts of dispersing agent, 1.6 to 3.2 parts of purificant and 0.8 to 3.2 parts of sulfur-fixing agent by weight. The environment-friendly coal-saving agent is obvious in coal saving effect, the coal saving effect can arrive at 24.35%, the coal consumption is reduced, the emission of carbon dioxide and the like harmful gas is greatly reduced, and the economical benefit and social benefit are high; the harmful gas is reduced by more than 70%, and the Greenman blackness is less than 1 grade.

Owner:ZHANGJIAGANG WUHU NEW MATERIAL TECH DEV

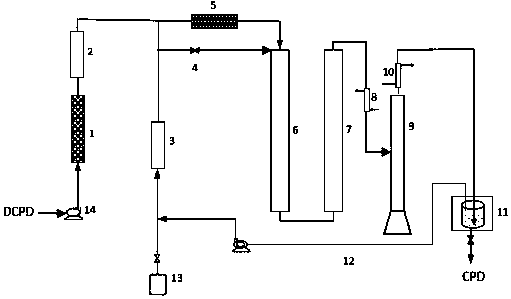

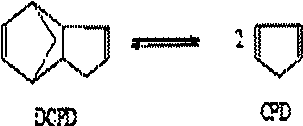

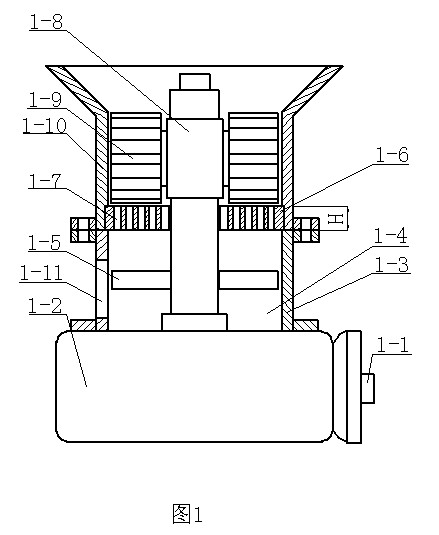

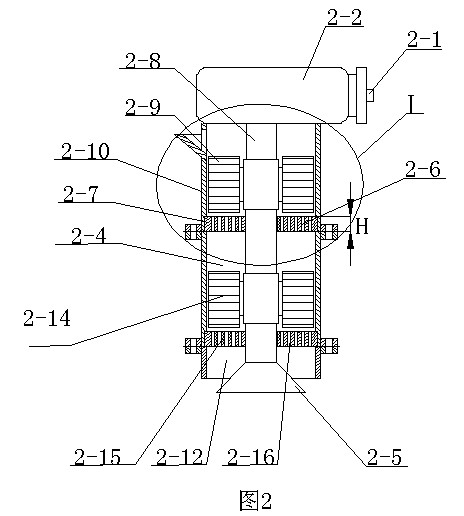

Method for preparing cyclopentadiene through gas-phase depolymerization of dicyclopentadiene

ActiveCN106699497AReduce entrainment lossReduce pollutionHydrocarbon by depolymerisationTemperature controlDepolymerization

The invention provides a method for preparing cyclopentadiene through gas-phase depolymerization of dicyclopentadiene. According to the method, a depolymerizing device is in subsection series connection design and subjected to subsection temperature control; on one hand, the depolymerization time is shortened, and the coking possibility is reduced, so that the service life of the depolymerizing device is prolonged to the maximum, and the depolymerization energy consumption is also reduced by adopting the method provided by the invention; and on the other hand, the DCPD depolymerization rate and CPD yield are further improved by adopting the method provided by the invention and respectively reach 99.9% and 99.5%, especially the CPD yield is also improved by 5% under the condition that the life is prolonged compared with the prior art, and the service life of the depolymerizing device is prolonged to be more than 1200h.

Owner:抚顺华兴石油化工有限公司

Cylindrical granular fuel, preparation method thereof and equipment used for preparation method

The invention discloses cylindrical granular fuel, a preparation method thereof and equipment used for the preparation method. The cylindrical granular fuel is prepared by mixing crushed coal and straw cylindrical particles in the weight ratio of 1:0.15-0.7, and the cylindrical granular fuel is in the shape of a solid cylinder. The preparation method of the cylindrical granular fuel includes the following steps of firstly, preparing crushed coal for standby application; secondly, crushing straws; thirdly, disposing crushed straws into a straw wheel extruder to extrude straw cylindrical grains; and fourthly, uniformly mixing the crushed coal and the straw cylindrical grains and then disposing the coal and straw mixture into the wheel extruder and extruding the cylindrical granular fuel. The equipment used for the preparation method includes the straw wheel extruder and a coal and straw mixing wheel extruder. The cylindrical granular fuel is high in rigidity, convenient in storage and transport and easy to burn continuously, can be used as industrial fuel and overcomes the defects in the prior art thoroughly since the crushed coal and the straws are mixed to be extruded into cylindrical grains.

Owner:孔令增

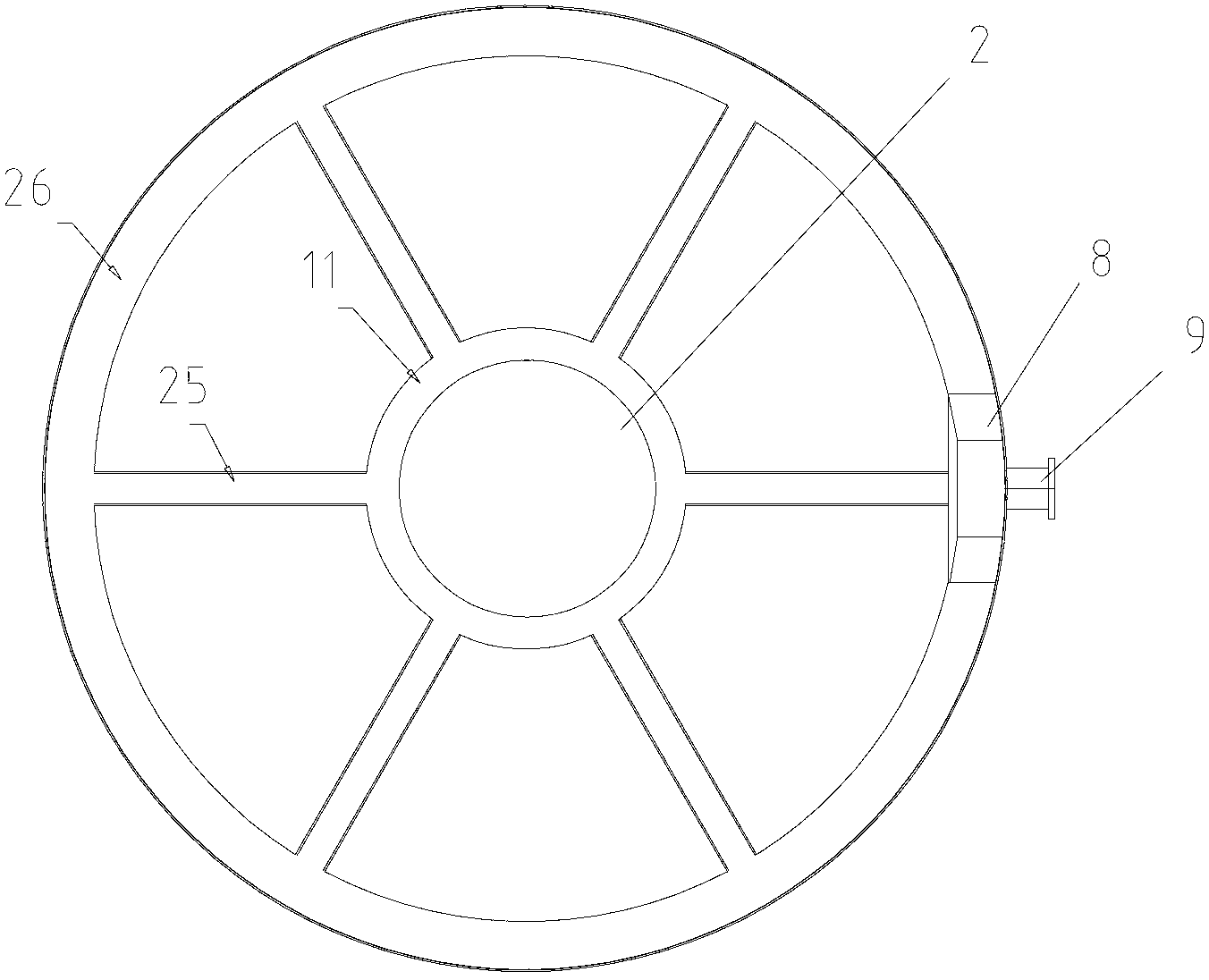

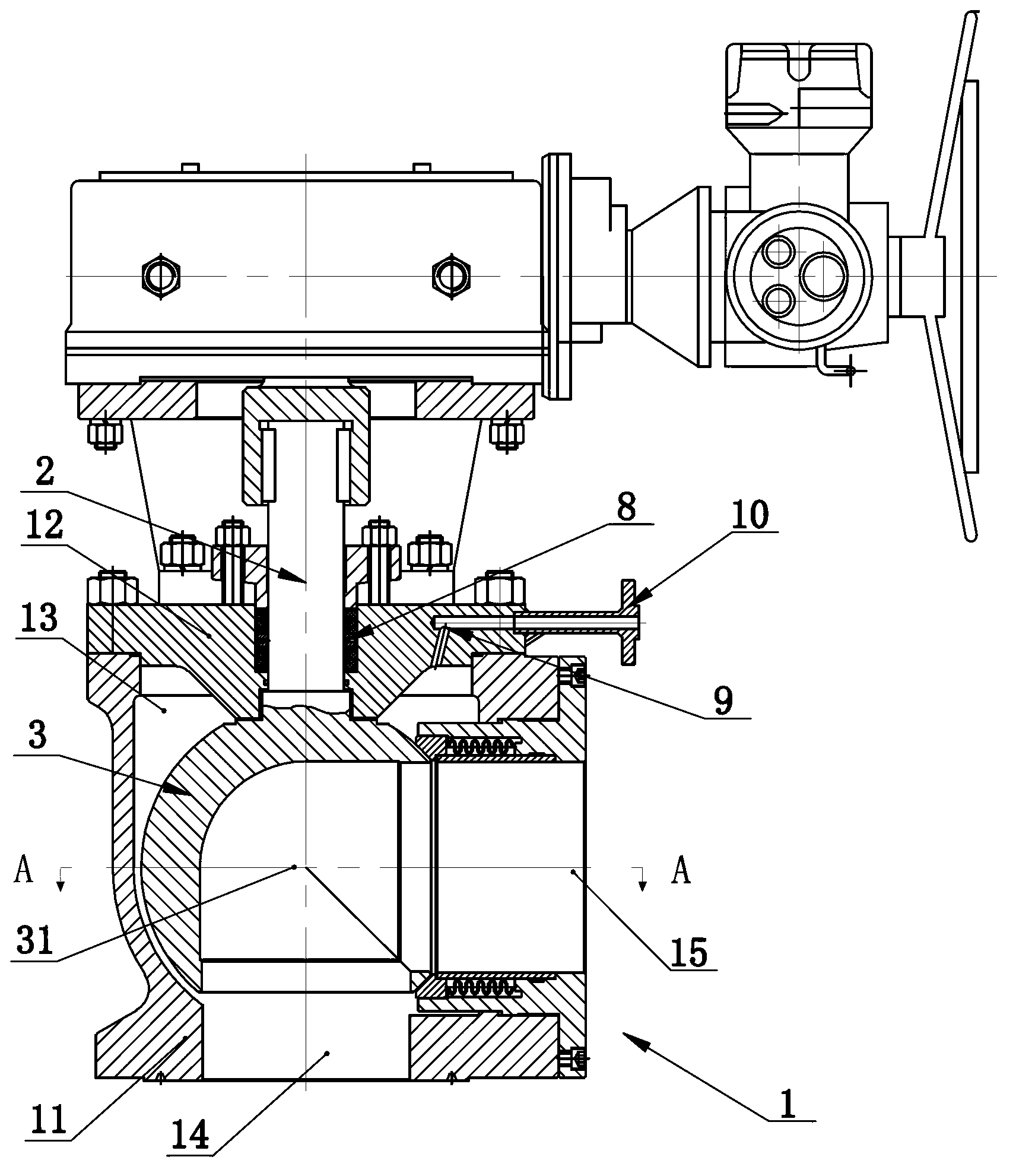

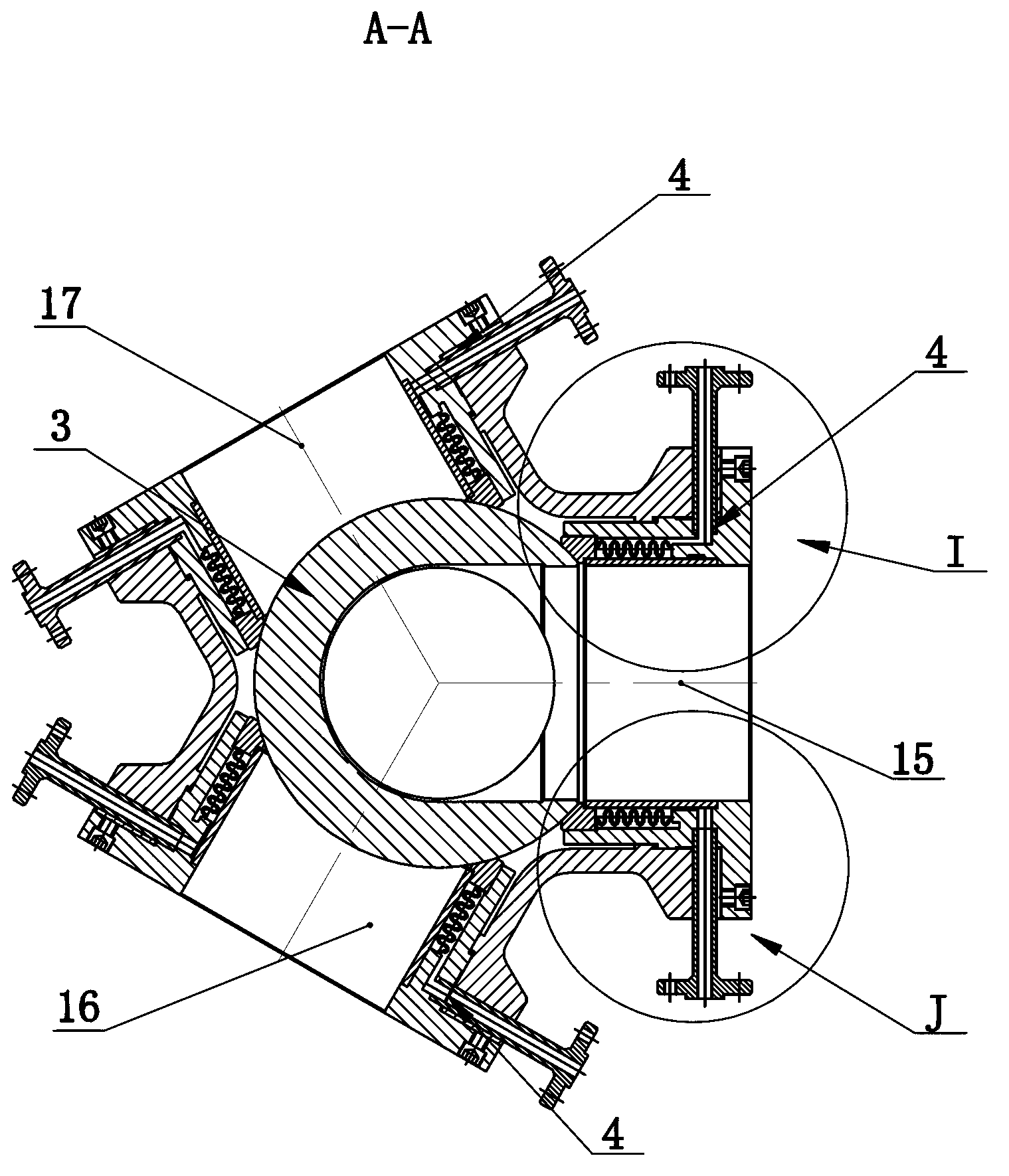

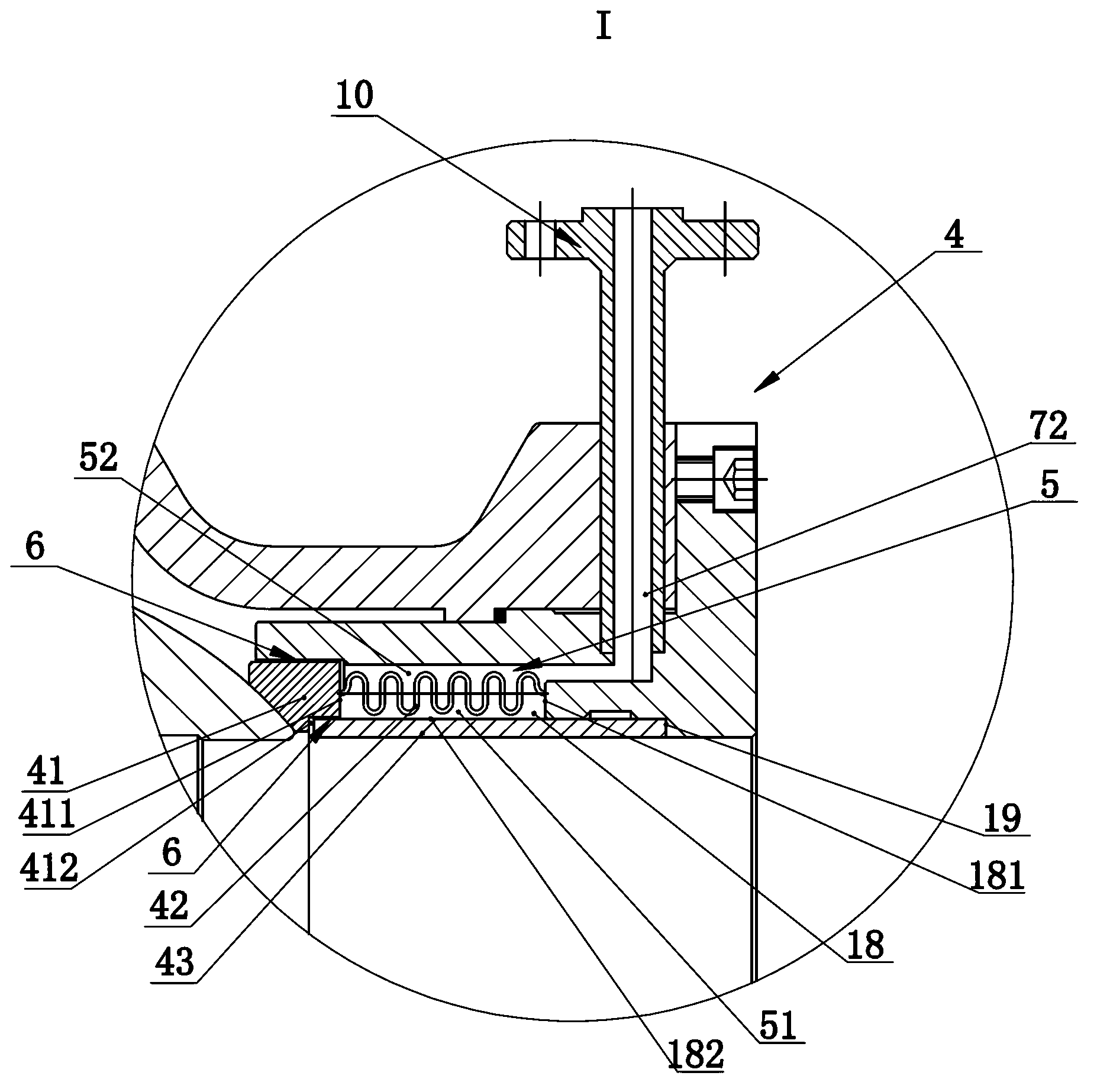

Four-way ball valve used for high-temperature easily-coking medium

InactiveCN102840363ANo coking phenomenonImprove work performanceSpindle sealingsMultiple way valvesWork performanceMain channel

The invention relates to a ball valve used for a high-temperature easily-coking medium, in particular to a four-way ball valve used for the high-temperature easily-coking medium. The four-way ball valve used for the high-temperature easily-coking medium comprises a valve body, a valve rod and a ball core. A valve cavity is arranged inside the valve body, and the ball core is arranged inside the valve cavity. The valve body is provided with a main channel and three side channels, and an L-shaped connection channel is arranged inside the ball core. A valve seat assembly is respectively arranged between the three side channels and the valve cavity, and each valve seat assembly comprises a valve seat body and an elastic piece. The valve body arranged between the three side channels and the valve cavity is provided with an annular groove, the outer side end of the valve seat body extends to the inside of the annular groove, and a pressure-storage cavity is formed by enclosure of the outer side end of the valve seat body and the annular groove. An expansion clearance is reserved between the valve seat body and the valve body. The valve body is provided with a first inflation channel communicated with the pressure-storage cavity. With the technical scheme, the four-way ball valve used for the high-temperature easily-coking medium can prevent the high-temperature easily-coking medium from influencing the valve seat assembly, and guarantee that a coking phenomenon of the valve seat body can not occur and working performance of the valve is stable.

Owner:CHAODA VALVE GRP

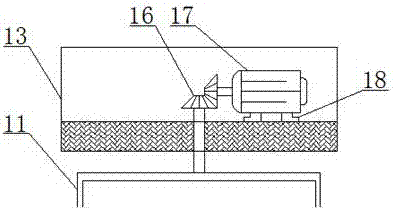

Sausage casing drying device

PendingCN107014186AQuality assuranceFully dryMeat/sausage hanging-upFood processingBiochemical engineeringCopper

The invention discloses a sausage casing drying device which comprises a box body; a moisture removing fan is arranged on the right surface of the box body; a fan shaft is arranged in the moisture removing fan; fan blades are arranged on the fan shaft; a ventilating duct is arranged on the right sides of the fan blades; a heat pump drying external unit is arranged below the ventilating duct; exhaust outlets are formed in the right surface of the heat pump drying external unit; and a copper tube connector is formed in the middle of the left end of the heat pump drying external unit. The sausage casing drying device is scientific and reasonable in structure and safe and convenient to use; eight rotatable sausage casing carrying racks are arranged in a drying box, are connected with top motors through shafts and can keep rotating all the time, sausage casings are heated uniformly, the drying time required is shortened, the surfaces of the sausage casings are fully dried, but no coking is caused due to too long drying time, so that the problem of microbe multiplication due to the fact that the interiors of the sausage casings are not breathable owing to sausage casing surface coking is solved, and the quality of the sausage casings is guaranteed.

Owner:南通天龙畜产品有限公司

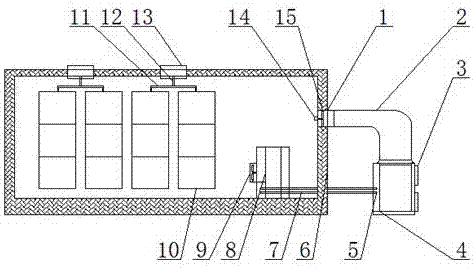

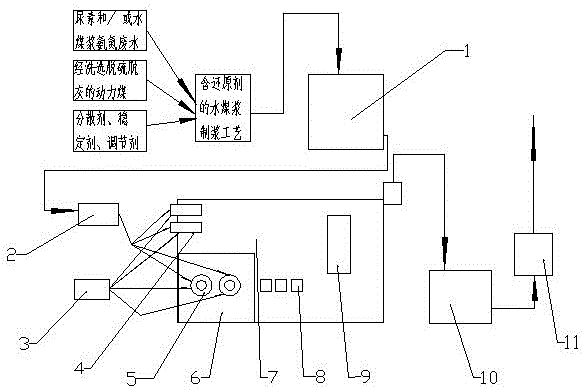

In-furnace denitrification method and device

InactiveCN106318515ARealize resource utilizationNo coking phenomenonCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustion chamber

The invention discloses an in-furnace denitrification coal water slurry making and combusting system integrated method and equipment. The method comprises the following steps: on the basis of the traditional slurry making process, adding a denitrification reducing agent, and preparing coal water slurry fuel containing the denitrification reducing agent; spraying the coal water slurry fuel into a boiler for burning, controlling the combustion temperature of the hearth to be stabilized in an optima reduction reaction temperature range and controlling the oxygen content of the flue gas, so that high-efficiency low-cost in-furnace SNCR denitrification of the coal water slurry is realized. The whole device comprises a coal water slurry combustion boiler, wherein the coal water slurry combustion boiler adopts the design of a primary combustion chamber and a secondary combustion chamber and is respectively provided with an axial cyclone primary combustor and a secondary combustor; a fire barrier is arranged at the tail of the primary combustion chamber, an air door is arranged below the primary combustion chamber, the rear upper part of the primary combustion chamber is connected with a dust remover through a pipeline, and the combusted smoke dust is discharged through an induced draft fan connected with the dust remover; and the axial cyclone primary combustor and the secondary combustor are respectively connected with a coal water slurry tank through a screw pump via pipelines, and are also respectively connected with an air compressor at the coal water slurry inlet through pipelines.

Owner:HUNAN UNIV OF TECH +1

Method for preparing petroleum sulfonate oil displacement agent

ActiveCN101659861BHigh content of sulfonatable aromaticsNo coking phenomenonDrilling compositionActive matterAcid value

The invention relates to a method for preparing a petroleum sulfonate oil displacement agent. Benzol-ketone dewaxing oil and furfural extract oil are mixed in a weight ratio of 1:0.01-1:0.5, and the mixture enters a film or tank reactor for sulfonation reaction; a sulfonating agent is SO3 gas, the concentration is diluted to between 1.5 and 3.0 percent in a volume ratio by dry air or inert gas of which the dew point is lower than 60 DEG C, the temperature of the sulfonation reaction is between 30 and 85DEG C, the acid value of sulfonatedbodies is controlled to between 30 and 90mgNaOH / g, and the sulfonatedbodies are neutralized by NaOH or KOH solution; and the raw materials have the advantages of high content of arene capable of being sulfonated and no coking phenomenon in the reaction process; after neutralization, and the sulfonatedbodies do not need extraction separation; the active matter content reaches 25 to 40 percent; a weak alkali / surfactant / polymer system configured by adopting Na2CO3 or a non-alkali binary system configured by salts such as NaCL and the like has the interfacial tension less than 10<-3>mN / m.

Owner:PETROCHINA CO LTD

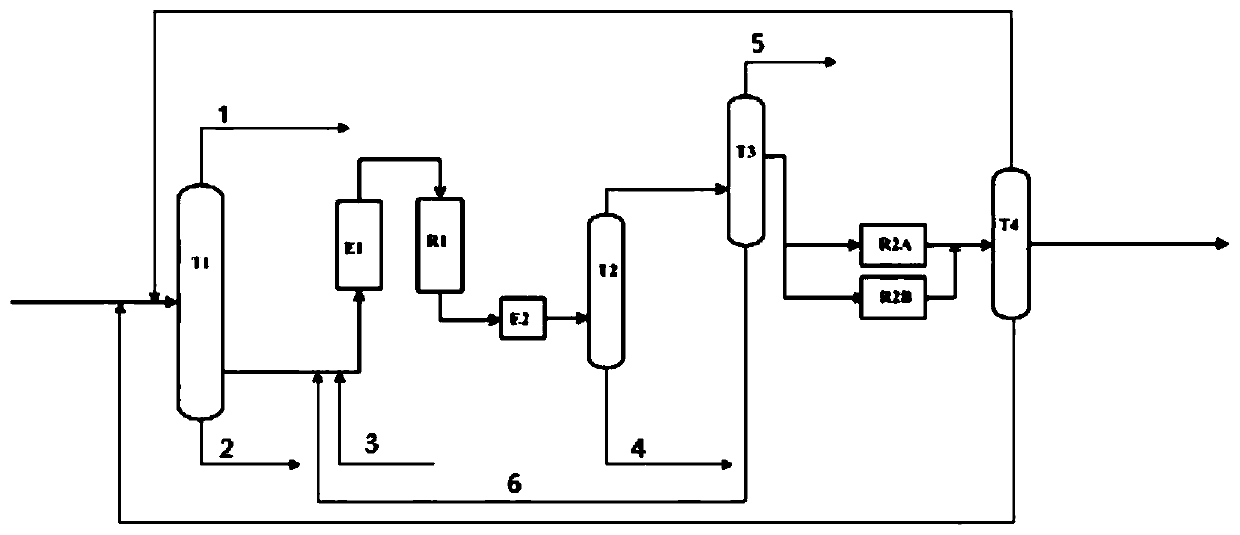

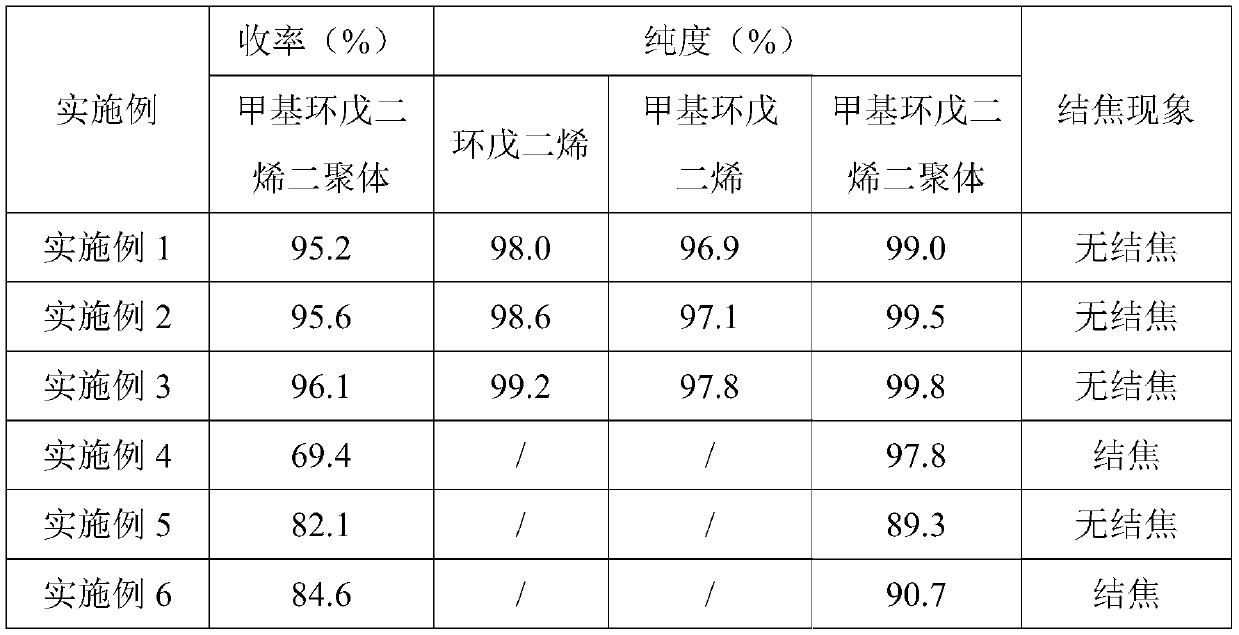

Method for preparing methylcyclopentadiene dimer from cracked C9 fraction

InactiveCN110563533AExtended service lifeThe method is safe and feasibleHydrocarbons from unsaturated hydrocarbon additionGas phaseDimmer

The invention relates to the field of preparation of methylcyclopentadiene dimmers, and concretely relates to a method for preparing a methylcyclopentadiene dimer from a cracked C9 fraction. The method for preparing the methylcyclopentadiene dimer from the cracked C9 fraction comprises the following steps: (1) the cracked C9 fraction is input into a rectifying tower T1, a material extracted from alateral line and an inert solvent go through a preheater E1, then enter a reactor R1 and are cracked; (2) a cracked material obtained in step (1) is quenched by a condenser E2, then enters a rectifying tower T2, and is rectified to obtain gaseous cyclopentadiene and methylcyclopentadiene at the tower top; (3) the tower top materials obtained in step (2) are input into a rectifying tower T3, and liquid-phase methylcyclopentadiene is extracted from the lateral line; (4) the lateral line extracted material obtained in step (3) enters a dimerization reaction kettle R2, and undergoes a dimerization reaction; and (5) the methylcyclopentadiene dimer reaction product obtained in step (4) enters a T4 rectifying tower, and is purified to obtain the high-purity methylcyclopentadiene dimer.

Owner:广东新华粤石化集团股份公司

Preparation method for PH-nano steel and iron corrosion inhibitor

The invention provides a preparation method for a PH-nano steel and iron corrosion inhibitor, which includes the following steps: (1) palm wax and sodium hydroxide are respectively prepared; the mixture of absolute ethyl alcohol and deionized water is prepared; first deionized water is then prepared; (2) the prepared palm wax is heated to melt until the palm wax is clear, and the liquid palm wax is poured into a first three-neck bottle; (3) the prepared sodium hydroxide is poured into the first deionized water until the sodium hydroxide is completely dissolved, and is then poured into the first three-neck bottle loaded with the liquid palm wax, and finally, the prepared mixture of absolute ethyl alcohol and deionized water is completely poured into the first three-neck bottle. The product prepared by the method has stable properties, good physicochemical properties and long anticorrosion time, and can resist high temperature, coating is thin, guns and cannons do not need to be cleaned before being used, and the product does not have adverse effects on the performance of the guns and the cannons after shooting.

Owner:长沙艾格防护新材料技术研发有限公司

Environment friendly coal-saving agent

InactiveCN101486939BReduce the frequency of dust removalImprove efficiencySolid fuelsFuel additivesSuppressorSulfur

The invention discloses an environmental-protection coal saving agent and relates to a coal saving agent, which solves the defects that the existing coal saving agent has large additive amount, pollutes the environment and does not meet the Greenman blackness. By weight percentage, the environmental-protection coal saving agent comprises 5 to 10 percent of activator, 30 to 40 percent of modifier,5 to 10 percent of smoke suppressor, 5 to 10 percent of purificant, 2 to 8 percent of oxidant, 30 to 35 percent of swelling agent and 5 to 10 percent of sulfur fixing agent. The environmental-protection coal saving agent has the advantages of small additive amount, environmental protection, wide application scope and simple use. The additive amount of the coal saving agent is only 3 permillage ofthe weight of coal, but the energy-saving rate reaches more than 10.81 percent; and the harmful gas is reduced more than 70 percent and the Greenman blackness is less than 1 class.

Owner:HEILONGJIANG WEIDE ENERGY SAVING TECH DEV

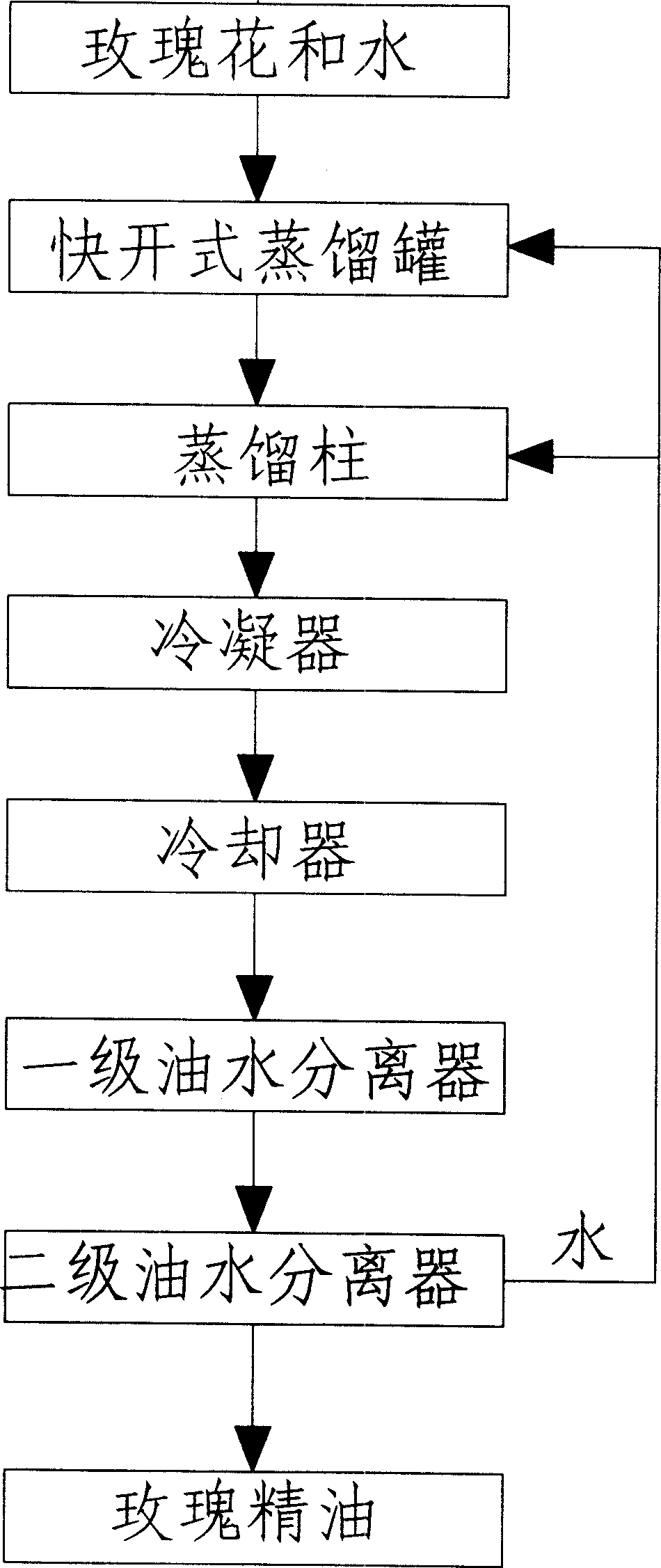

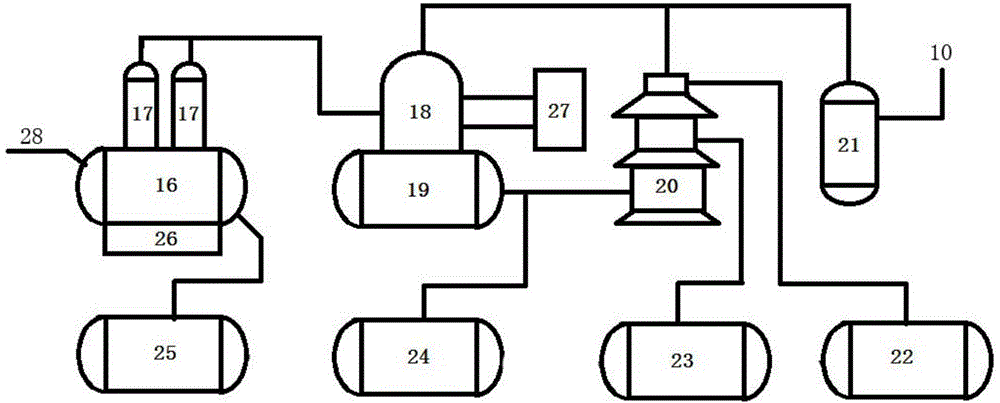

Technique for extracting rose essential oil

InactiveCN1232622CNo coking phenomenonQuality is not affectedEssential-oils/perfumesSteam distillationOil water

The invention discloses a method for extracting rose essential oil, which is characterized by mixing roses and water into a pneumatic opening and closing retort, then passing steam into the jacket of the pneumatic opening and closing retort, and using a stirring device Heating while stirring is carried out in the pneumatic open and closed distillation tank. After the steam generated in the pneumatic open and closed distillation tank is subjected to the secondary distillation of the distillation column, it is condensed by the condenser and cooled by the cooler, and then the secondary oil and water are separated. Get rose essential oil products. In the present invention, steam is introduced into the jacket of the distillation tank for heating. Due to the large heating area and fast heating speed, after the roses and water in the distillation tank are heated, the thermal reaction is carried out in a dynamic state under the stirring of the stirring device. , without affecting the internal quality of roses, maintaining the original properties and transparency of roses, using secondary oil-water separation, the oil and water are completely separated, and the quality, yield and purity of rose essential oil are improved.

Owner:ZHEJIANG KAIDI PHARMA CHEM MACHINERY

Coal saver as well as preparation method and application thereof

InactiveCN105779075AReduce carbon contentNo coking phenomenonSolid fuelsSodium acetateAluminium silicate

The invention discloses a coal saver as well as a preparation method and application thereof. The coal saver consists of the following raw materials in parts by weight: 9-18 parts of potassium ferrate, 20-30 parts of poly-aluminum ferric silicate, 2-8 parts of potassium nitrate, 1-5 parts of sodium acetate and 10-18 parts of borax. The preparation method for the coal saver comprises the following steps: mixing and crushing the borax and poly-aluminum ferric silicate, enabling the mixed and crushed borax and poly-aluminum ferric silicate to pass through a 200-mesh sieve, and adding triethanolamine to carry out stirring treatment, thereby obtaining a pre-treated mixture of the borax and poly-aluminum ferric silicate; and mixing and ball-milling potassium nitrate and sodium acetate, adding potassium ferrate to mix and ball-mill, stirring and mixing with the pre-treated mixture of the borax and poly-aluminum ferric silicate, irradiating the pre-treated mixture by use of an ultraviolet lamp, and cooling to the room temperature. The coal saver is non-toxic, is free from pungent smell, and is free of corrosivity and pollution; raw materials are cheap and easily available, the production cost is low, and the adding amount is less; and the coal saver has remarkable coal-saving, combustion-supporting and desulfuration effects, can remarkably reduce the carbon content of ash, can reduce emission of harmful gas, and can improve the thermal efficiency of coal.

Owner:张传业

Electric heating type non-combustion cigarette core and preparation method thereof

ActiveCN105411005AHigh thermal efficiencyUniform flue gasTobacco treatmentTobacco devicesCombustionEngineering

The invention discloses an electric heating type non-combustion cigarette core and a preparation method thereof. The electric heating type non-combustion cigarette core comprises a tobacco matrix and cigarette additives, which are packaged through a capsule shell. According to the non-combustion cigarette core, the tobacco matrix and the cigarette additives are covered with the capsule shell, so that thermal efficiency of the cigarette core is greatly improved, and mobility and uniformity of smoke are improved; besides, the preparation method is simple in technological process, and the cost is low.

Owner:CHINA TOBACCO HUNAN INDAL CORP

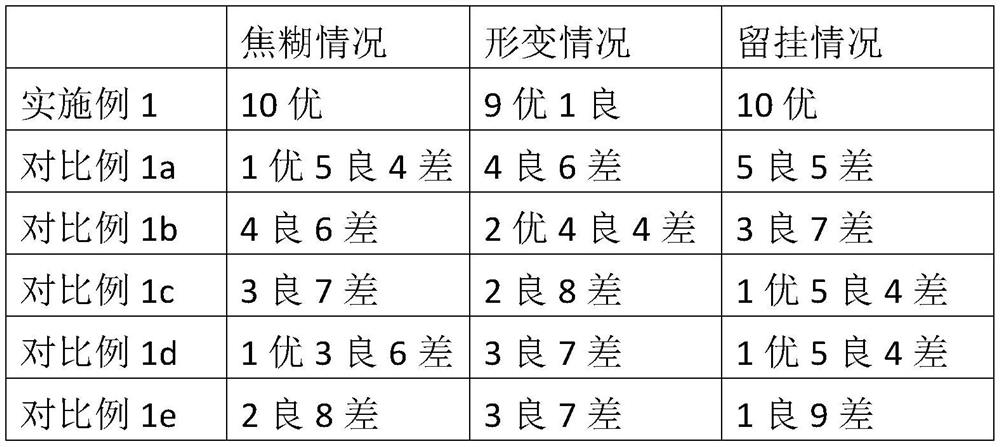

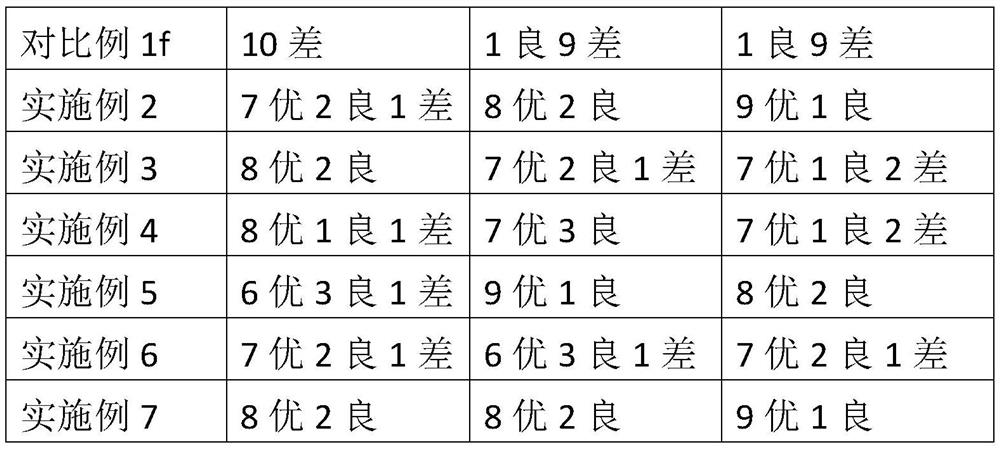

Baking-resistant chocolate beans and production method thereof

PendingCN112056441AGuaranteed flavorGuaranteed tasteCocoaSugar food ingredientsButter cocoaPalm kernel oil

The invention relates to a formula of baking-resistant chocolate beans, the baking-resistant chocolate beans adopting the formula and a production method of the baking-resistant chocolate beans. The formula disclosed by the present invention adopts a cocoa butter substitute (hydrogenated refined palm kernel oil with solid fat content of 88 to 96%wt at a temperature of 20 DEG C) meeting specific parameter conditions, and a specific amount of composition of anhydrous dextrose and inulin is added; the prepared chocolate beans can resist to baking and resist to roasting and have no coking phenomenon; the original chocolate flavor and taste can be guaranteed, and a case of deformation or collapse cannot be generated; and the chocolate beans can be hung on the surface of a baked product.

Owner:可可琳纳食品海门有限公司

Preparation method of ph-nanometer iron and steel corrosion inhibitor

ActiveCN104894567BSolving the Difficulty of CorrosionImprove performanceSodium hydroxideMaterials science

The present invention provides a kind of preparation method of PH-nanometer iron and steel corrosion inhibitor, comprises the following steps: (1) prepare palm wax, sodium hydroxide respectively; Prepare the mixed solution of dehydrated alcohol and deionized water; Prepare the second One part of deionized water; (2) heat and melt the prepared palm wax until clear, and pour it into the first three-neck bottle; (3) pour the prepared sodium hydroxide into the first part of deionized water until dissolved Completely, then pour into the first three-necked bottle equipped with liquid palm wax, and finally pour the mixed solution of absolute ethanol and deionized water into the first three-necked bottle. The product prepared by the method has stable performance, good physical and chemical properties, long anti-corrosion time, high temperature resistance, thin coating film, guns and cannons do not need to be cleaned before use, and have no adverse effect on the performance of the guns and cannons after shooting.

Owner:长沙艾格防护新材料技术研发有限公司

Method for refining oil through depolymerizing and liquifying waste plastics and device used in method

InactiveCN103555354BRealize depolymerization and liquefactionQuality assuranceHydrocarbon distillationPlastic recyclingCeramic sinteringFiber

The invention relates to a method for refining oil through depolymerizing and liquifying waste plastics and a device used in the method. The method comprises the following steps of (1) crushing the waste plastics; (2) carrying out depolymerization reaction on the crushed waste plastics; (3) neutralizing a depolymerized acidic product by using a sodium hydroxide solution; (4) further washing to obtain a plastic depolymerization chlorobenzene dissolved liquid; (5) carrying out reduced pressure distillation on the plastic depolymerization chlorobenzene dissolved liquid; (6) carrying out cracking reaction and condensing to obtain a cracked fuel oil mixture; (7) rectifying and catalyzing the cracked fuel oil. The method has the beneficial effects that the depolymerization and liquidation of the plastics are realized by using a solvent and acid catalysis technology on the basis of a liquifying technology for plastics such as polyurethane, polyester and the like used in the chemical fiber industry; the cracking temperature is controlled within 360 DEG C in heating and cracking, so that the coking phenomenon is avoided; a porous nickel and chromium salt loaded catalyst is used, and the catalyst is prepared by using a ceramic sintering method, so that the quality of a refined oil product is ensured.

Owner:HUIZHOU SHENZHOU CHUANGYU LOW CARBON TECH DEV

Electric heating non-combustion cigarette core and preparation method thereof

ActiveCN105411005BHigh thermal efficiencyUniform flue gasTobacco treatmentTobacco devicesCombustionBurn cigarette

The invention discloses an electric heating type non-combustion cigarette core and a preparation method thereof. The electric heating type non-combustion cigarette core comprises a tobacco matrix and cigarette additives, which are packaged through a capsule shell. According to the non-combustion cigarette core, the tobacco matrix and the cigarette additives are covered with the capsule shell, so that thermal efficiency of the cigarette core is greatly improved, and mobility and uniformity of smoke are improved; besides, the preparation method is simple in technological process, and the cost is low.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com