High-quality high-efficiency water-gas shift method and device

A water-gas, high-efficiency technology, applied in the field of high-quality and high-efficiency water-gas shift methods and devices, can solve the problems of high and only 40-50vol, difficult to apply to hydrogen production or water gas, water gas quality is unstable, etc. The effect of a wide range, a wide range of applications, and a short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

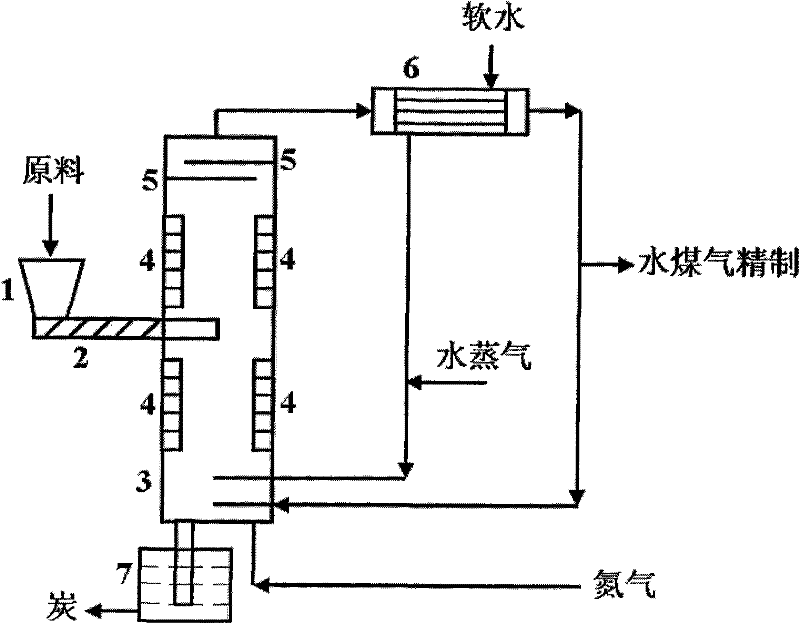

[0017] The first step is to replace the air in the gasifier 3 with steam.

[0018] In the second step, wheat straw is used as raw material, dried until the water content is less than 20 wt%, crushed to a size less than 2 cm, and sent to the gasifier 3 through the raw material hopper 1 and the screw conveyor 2.

[0019] The third step is microwave-induced heating, and the water-gas shift reaction occurs at 980°C.

[0020] H in the generated water gas 2 : 61.8vol%, CO: 30.1vol%, others (mainly CO 2 、CH 4 etc.): 8.1 vol%. Solid residue production rate (dry mass percentage of solid residue and raw material input): 1.8%.

Embodiment 2

[0022] The first step is to replace the air in the gasifier 3 with water gas.

[0023] In the second step, apple branches are used as raw materials, dried until the water content is less than 15 wt%, crushed to a size less than 1 cm, and sent to the gasifier 3 through the raw material hopper 1 and the screw conveyor 2.

[0024] The third step is microwave-induced heating, and the water-gas shift reaction occurs at 1100°C.

[0025] H in the generated water gas 2 : 62.6vol%, CO: 29.7vol%, others: 7.7vol%. Solid residue yield: 4.6%.

Embodiment 3

[0027] The first step is to replace the air in the gasifier 3 with nitrogen.

[0028] In the second step, rice straw is used as a raw material, dried until the water content is less than 25 wt%, crushed to a size less than 2 cm, and sent to the gasifier 3 through the raw material hopper 1 and the screw conveyor 2.

[0029] The third step is microwave-induced heating, and the water-gas shift reaction occurs at 790°C.

[0030] H in the generated water gas 2 : 52.4vol%, CO: 24.9vol%, others: 22.7vol%. Solid residue yield: 3.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com