Technique for extracting rose essential oil

A technology of rose essential oil and extraction method, which is applied in the direction of essential oil/fragrance, fat production, etc. It can solve the problems affecting the yield and purity of rose oil, the incomplete separation of oil and water, and the quality of rose oil, and achieves easy cleaning and heating The effect of fast speed and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

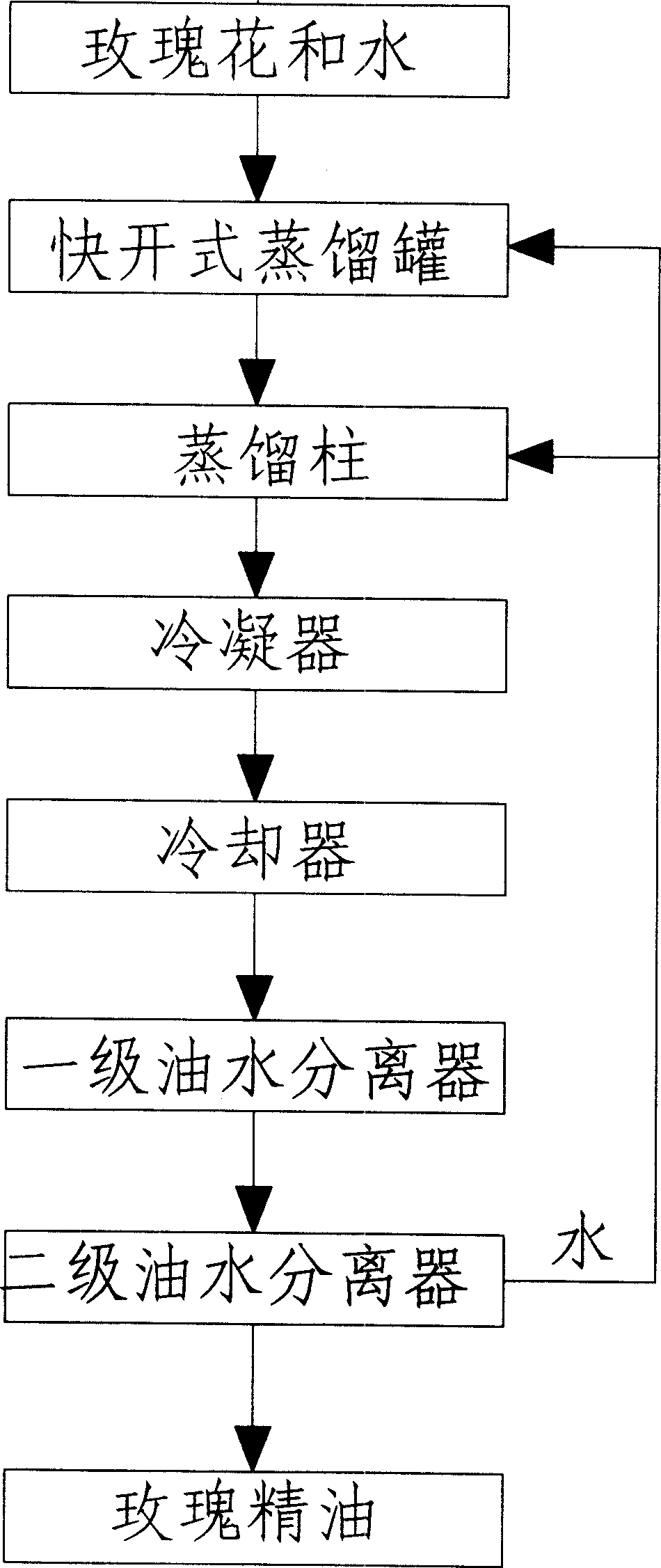

[0007] The accompanying drawings show the implementation process of the method of the present invention, and further describe the relevant details of its embodiments below in conjunction with the accompanying drawings. The extraction method of the rose essential oil is firstly to mix roses and water into a pneumatic open and close distillation tank, then pass steam into the jacket of the pneumatic open and close distillation tank, and use a stirring device to distill in the pneumatic open and close The tank is heated while stirring, and the steam generated in the pneumatic open-close distillation tank is subjected to secondary distillation of the distillation column, condensed by the condenser, cooled by the cooler, and then subjected to secondary oil-water separation, and finally the rose essential oil product is obtained; During the heating process, the temperature should be controlled at 100-120°C; the water after secondary separation flows back into the distillation tank an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com