Baking-resistant chocolate beans and production method thereof

The technology of a chocolate bean and a production method is applied in the field of food processing, and can solve the problems of burning taste, deterioration of chocolate sauce flavor, complicated preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

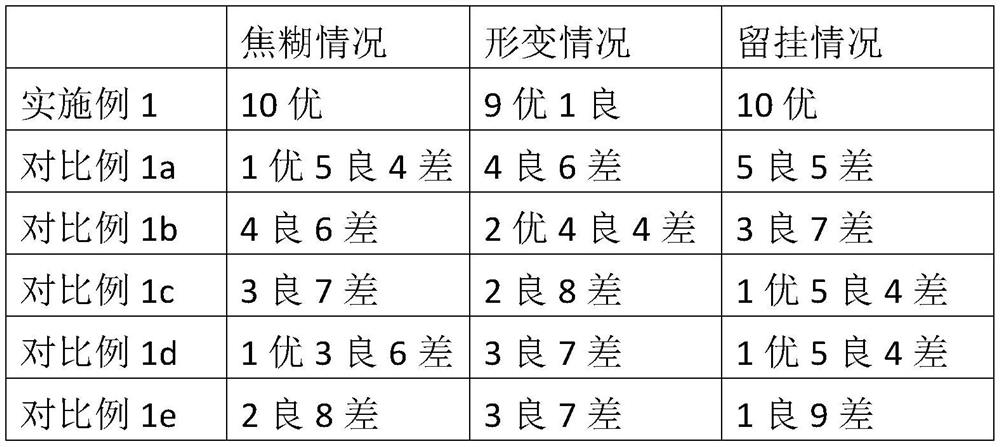

Examples

Embodiment 1-4

[0045] The formula of the baking-resistant chocolate bean of embodiment 1-4, wherein basic component (mass part) is as follows:

[0046] 25 parts cocoa butter substitute

[0047] 17 parts cocoa powder

[0048] 58 parts white sugar

[0049] After a lot of attempts, the inventor found that the cocoa butter substitute must meet specific parameters, 1) need to use hydrogenated refined palm kernel oil; 2) the solid fat content at 20°C is 88-96%wt. For those skilled in the art, you can choose a suitable hydrogenated refined palm kernel oil (single oil), or you can choose hydrogenated refined palm kernel oils with different degrees of saturation to mix, as long as the mixed oil meets the requirements of "at 20 ℃ The condition that the solid fat content at temperature is 88-96%wt" gets final product.

[0050] In the formula of Examples 1-4, cocoa butter substitute is the mixed oil of hydrogenated refined palm kernel oil of two different degrees of saturation, the iodine value of th...

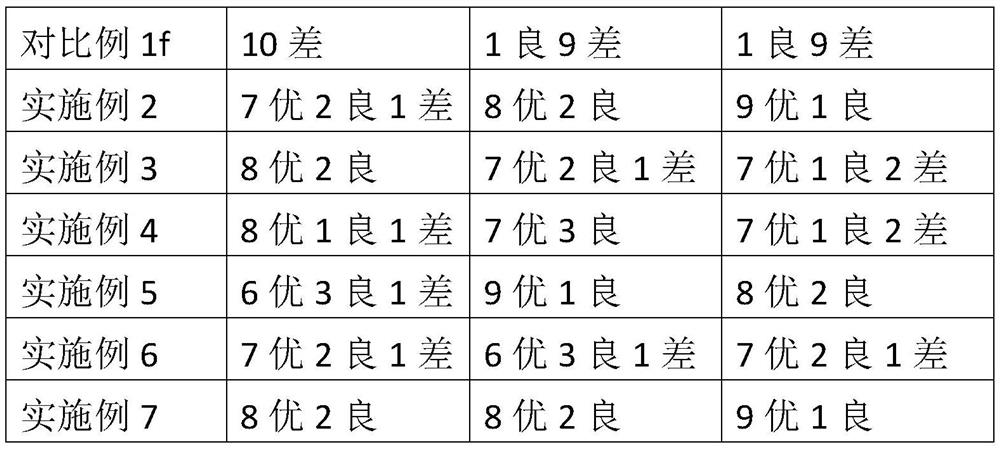

Embodiment 5-7

[0063] The formula of the baking-resistant chocolate bean of embodiment 5-7, wherein basic component (mass part) is as follows:

[0064] Cocoa butter substitute 28 parts

[0065] 20 parts cocoa powder

[0066] 52 parts white sugar

[0067] In Example 5, the cocoa butter substitute is a mixed oil of hydrogenated refined palm kernel oil with two different degrees of saturation, the iodine value of the first hydrogenated refined palm kernel oil is about 4.0, and the iodine value of the second hydrogenated refined palm kernel oil is about 4.0. 0.7, the mixing ratio of the former and the latter is 1:2.5; the solid fat content of the mixed cocoa butter substitute is about 92.499% at a temperature of 20°C.

[0068] In Example 6, the cocoa butter substitute is a mixed oil of hydrogenated refined palm kernel oil of two different degrees of saturation, the iodine value of the first hydrogenated refined palm kernel oil is about 6.0, and the iodine value of the second hydrogenated refin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com