Electric heating non-combustion cigarette core and preparation method thereof

A non-combustion cigarette, electric heating technology, applied in the direction of tobacco, tobacco treatment, smoker's products, etc., can solve the problems of uneven dispersion and poor fluidity, achieve uniform smoke, ensure smoking quality, and improve thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

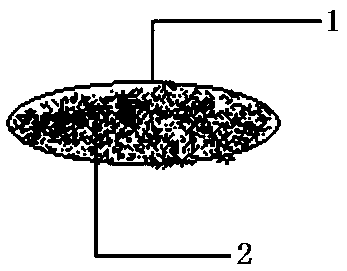

Image

Examples

Embodiment 1

[0033] Spray the tobacco extract with a mass percentage of 1% on the shredded tobacco, and process the rest according to the traditional shredded tobacco production process, disperse the shredded tobacco through the groove plate, adjust the pressure to -0.04Mpa to -0.02Mpa, and fill it to the purchased No. 00 The empty shell capsules are sealed and cleaned to obtain the product. After sensory evaluation, compared with the new cigarette cartridges purchased in the market, it is found that the smoke is more uniform.

Embodiment 2

[0035] Spray the tobacco extract on the shredded tobacco at a dose of 3% by mass, and process the rest according to the traditional shredded tobacco production process, disperse the shredded tobacco through a groove plate, adjust the pressure to -0.02Mpa to -0.01Mpa, and fill it to the purchased 000 No. empty shell capsules are sealed and cleaned to obtain the product. After thermal efficiency verification, compared with the new type of cigarette core purchased in the market, the capsule type cigarette core of the present invention has higher efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com