Method for preparing petroleum sulfonate oil displacement agent

A technology of petroleum sulfonate and oil displacement agent, which is applied in the field of preparation of petroleum sulfonate oil displacement agent, can solve the problems of increasing equipment investment, increasing energy consumption and production cost, etc., and achieves strong adaptability and product quality control Smooth, good interfacial tension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The optimized molecular weight is about 510, and the carbon number distribution is at C 22 ~C 36 The mixed raw materials are heated and stirred evenly, and then poured into a tank reactor for sulfonation reaction. The jacket temperature of the reactor is controlled to be 65-70° C., and 7% SO3 (volume) is passed through to carry out the sulfonation reaction. Stop reaction when acid value reaches 65mgNaOH / g, adopt 35% (weight) NaOH solution to carry out neutralization, control neutralization terminal pH value to be 8-11. The test results of raw materials and products are shown in Table 1 and Table 2.

[0020] Mixed raw material composition analysis Table 1

[0021] name Saturated hydrocarbon% Aromatics % Non-hydrocarbon % Asphaltene% mixed ingredients 55.95 39.25 3.95 0.85

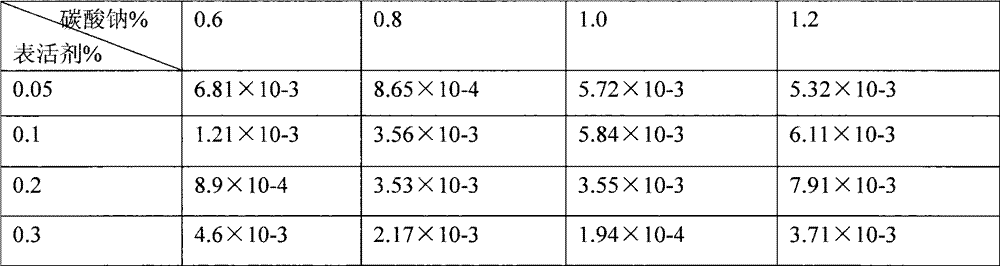

[0022] Interfacial Tension Test Table 2

[0023] Daqing No. 4 Oil Extraction Plant, Xing No. 5 Middle School Combined Station Containing Polymer Sewage Daqing No. 4...

Embodiment 2

[0026] The optimized molecular weight is about 538, and the carbon number is distributed in C 22 ~C 36 The mixed raw materials are heated and stirred evenly, and then enter the membrane reactor for sulfonation reaction. Its reaction temperature is controlled to be 55-60 DEG C, and the SO3 (volume) that feeds gas concentration 4.5% carries out sulfonation reaction, and gas volume is 2.5m3 / h. After the reaction, the acid value of the sulfonic acid is 70 mgNaOH / g, and it is neutralized with a 35% (weight) NaOH solution, and the pH value at the end point of the neutralization is controlled at 8-11. The test results of raw materials and products are shown in Table 3 and Table 4.

[0027] Mixed raw material composition analysis Table 3

[0028] name Saturated hydrocarbon% Aromatics % Non-hydrocarbon % Asphaltene% mixed ingredients 51.52 43.7 4.43 0.35

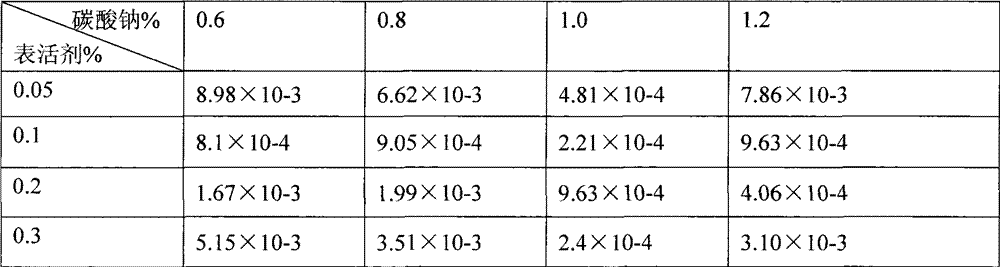

[0029] Interfacial Tension Test Table 4

[0030] Daqing No. 4 Oil Production Plant Xing No. 5 M...

Embodiment 3

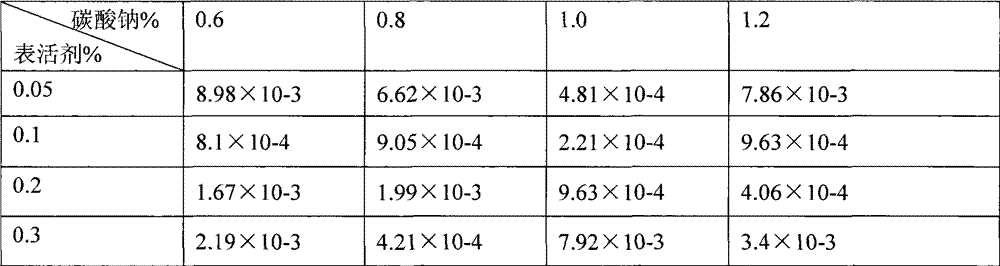

[0033] The product of embodiment 2 is configured into a sodium carbonate weak base ternary system by adopting the crude oil and sewage of the third oil production plant in Daqing, and the detection results are as follows:

[0034] Daqing No. 3 Oil Production Plant North Erxi Combined Station Containing Polymer Wastewater Daqing No. 3 Plant Crude Oil Daqing Refining and Chemical Company Salt-resistant Polymer 1200ppm

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com