Alcohol waste pulse quick precipitator

A technology of rapid pulse and alcohol waste liquid, which is applied in the direction of settling tanks, etc., can solve the problems of waste of heat energy loss, concentration tank cost, secondary environmental pollution, etc., and achieve the effects of low operating cost, reduced environmental pollution emissions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

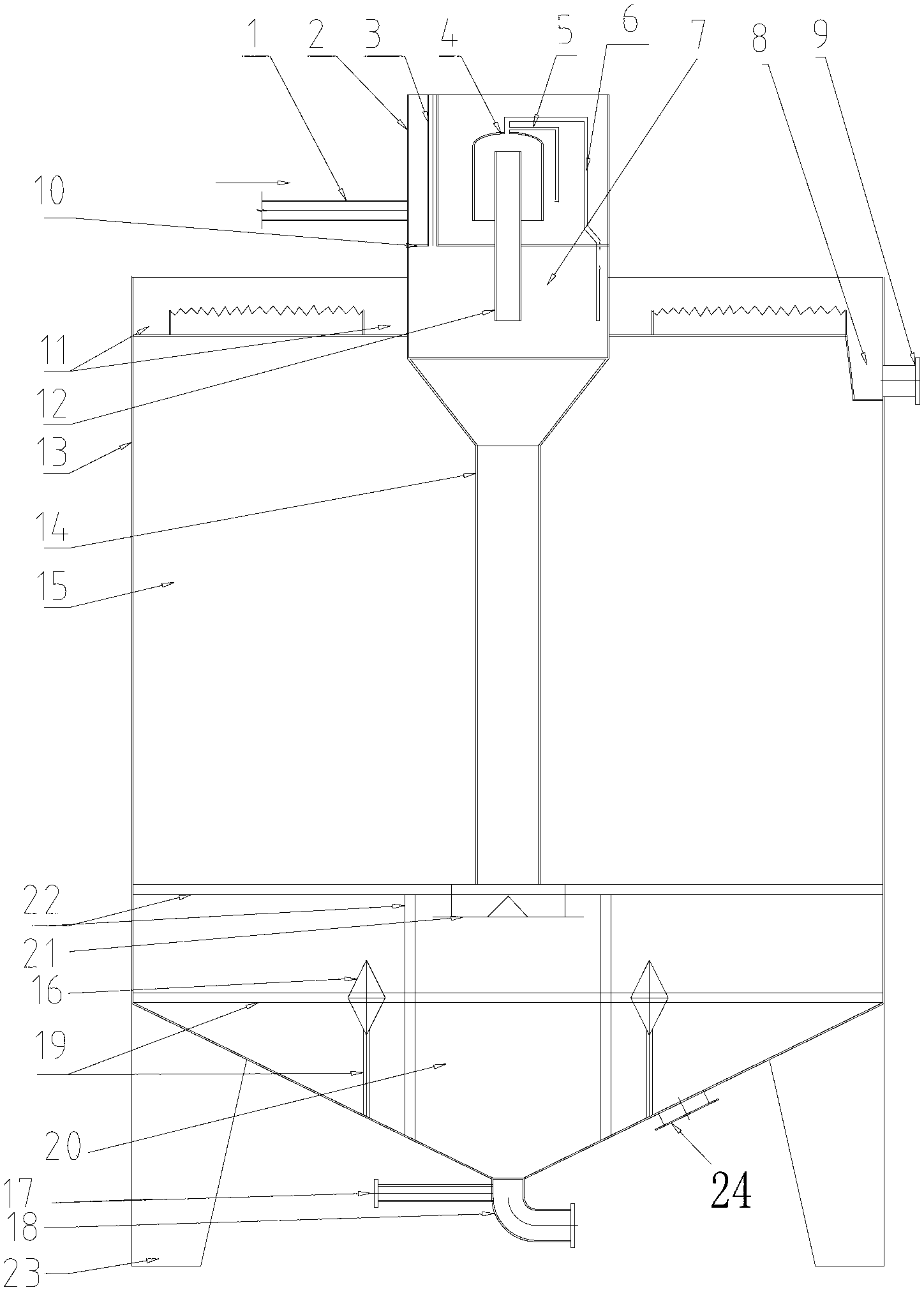

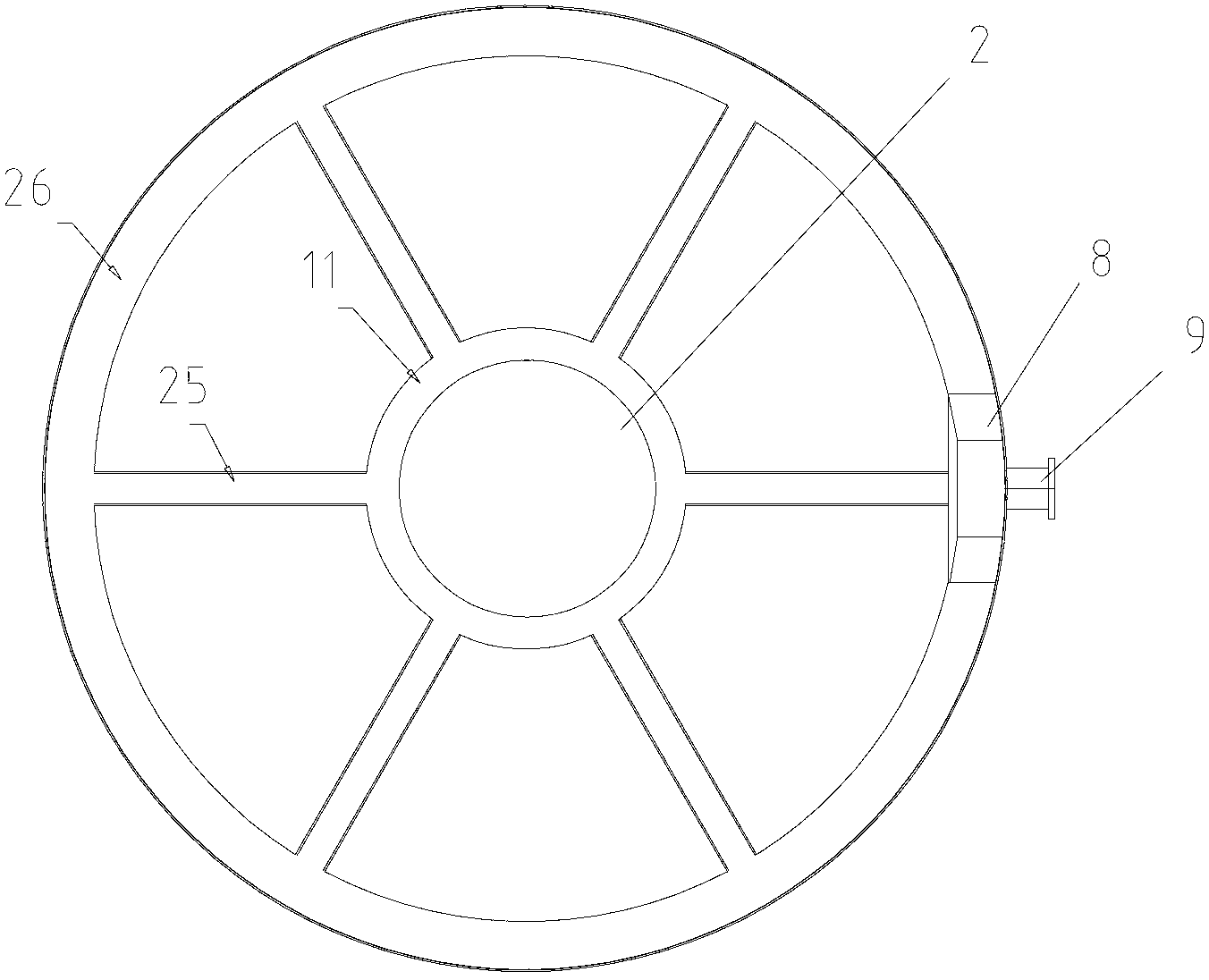

[0019] As shown in the drawings; the alcohol waste liquid pulse fast settler of the present invention is mainly composed of a pulse area 7, a sedimentation area 15 and a sludge collection area 20, and the central part of the cylindrical body 13 is provided with a water supply chamber from top to bottom. 2. Pulse area 7, water distribution drop pipe 14, buffer baffle 21, sludge collection area 20, the bottom of water supply chamber 2 is separated from pulse area 7 by partition plate 10, the side of water supply chamber 2 is connected to water inlet pipe 1, water supply Chamber 2 is provided with a pulse valve 4 with an inverted U-shaped longitudinal section, and a central siphon pipe 12 extending into the pulse area 7 is provided below the pulse valve 4. The top of the pulse valve 4 is connected to a connected exhaust pipe 6 and a siphon breaker through a pipeline. Pipe 5, the length of air extraction pipe 6 is greater than the length of siphon breaking pipe 5 and stretches into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com