Cylindrical granular fuel, preparation method thereof and equipment used for preparation method

A pellet fuel and cylinder technology, applied in the field of pellet fuel and its preparation, can solve the problems of inability to normally burn coal-straw mixed fuel, unusable straw stove, unable to form fuel, etc., and achieves high production efficiency and easy transportation. , does not produce the effect of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

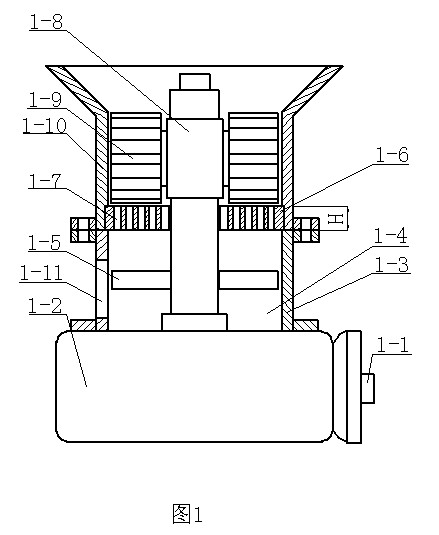

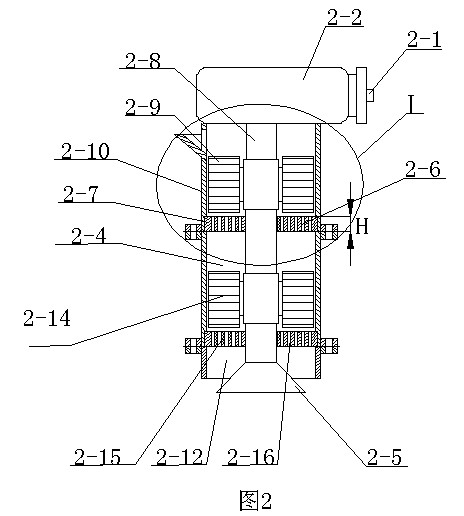

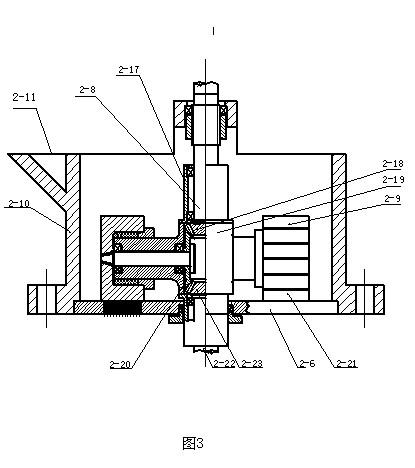

[0014] The present invention will be further described with reference to the accompanying drawings.

[0015] A kind of column particle fuel of the present invention is made by mixing crushed coal and straw column particles, the weight ratio of crushed coal to straw column particles is 1:0.15-0.7, and the column particle fuel The shape is a solid cylinder. The straw cylinder particles refer to that the harvested straw is chopped and extruded into cylinders by a straw roller extrusion machine. The ratio range of crushed coal to straw cylinder particles is better: 1:0.2-0.5, when the weight ratio of crushed coal to straw is 1:0.15, 1:0.2, 1:0.25, 1:0.3, 1 : 0.4, 1: 0.45, 1: 0.5 or 1: 0.6, 1: 0.7 and many other different ratios are available. When the amount of stalk column particles added is less and the pulverized coal is more, the cost of fuel is relatively high, but the gasification effect of fuel is relatively low when burned. When the amount of straw column particles is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com