In-furnace denitrification method and device

A technology for denitrification and furnace, which is applied in the direction of combustion method, combustion with various fuels, combustion with block fuel and liquid fuel, etc., which can solve the problem of furnace slagging, desulfurization efficiency, combustion efficiency and burnout rate, which are difficult to guarantee and cannot Extensive promotion and use and other issues to achieve the effect of high denitrification rate, high efficiency and low cost denitrification, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

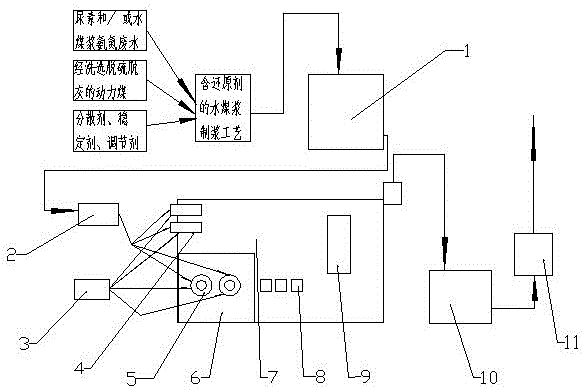

[0044] From attached figure 1 It can be seen that the present invention relates to a kind of coal-water slurry pulping and combustion system integrated equipment for denitrification in the furnace, including a coal-water slurry combustion boiler, which is divided into a main combustion chamber 7 and a secondary combustion chamber 6; , the upper side of the head of the main combustion chamber 7 is equipped with an axial swirling main burner 4, the lower side is a secondary combustion chamber 6, and the side of the secondary combustion chamber 6 is equipped with a secondary burner 5, and the axial swirling main burner 4 It is perpendicular to the auxiliary burner 5 in the axial direction; the axial swirl main burner 4 and the auxiliary burner 5 are respectively connected to the coal-water slurry tank 1 through the screw pump 2 through pipelines, and at the same time, the axial swirl main burner 4 and the The auxiliary burner 5 is connected to the air compressor 3 through pipes a...

Embodiment 2

[0052] The principle of the second embodiment is the same as that of the first embodiment, but the structure is different; a coal-water slurry slurry and combustion system integrated equipment for denitrification in the furnace, including a coal-water slurry combustion boiler, a coal-water slurry combustion boiler Divided into a main combustion chamber 7 and an auxiliary combustion chamber 6; wherein, the main combustion chamber 7 is equipped with an axial swirl main burner 4 on the upper side of the head, and an auxiliary combustion chamber 6 on the lower side, and an auxiliary combustion chamber 6 is arranged on the side. The burner 5, and the axial swirling main burner 4 and the auxiliary burner 5 are perpendicular to each other in the axial direction; the axial swirling main burner 4 and the auxiliary burner 5 pass through the screw pump 2 and the coal-water slurry tank 1 respectively through pipelines At the same time, the axial swirling main burner 4 and the auxiliary bur...

Embodiment 3

[0058] The principle of the second embodiment is the same as that of the first embodiment, but the structure is different; a coal-water slurry slurry and combustion system integrated equipment for denitrification in the furnace, including a coal-water slurry combustion boiler, a coal-water slurry combustion boiler Divided into a main combustion chamber 7 and an auxiliary combustion chamber 6; wherein, the main combustion chamber 7 is equipped with an axial swirling main burner 4 on the upper side of the head, and an auxiliary combustion chamber 6 on the lower side, and an auxiliary combustion chamber 6 is arranged on the side. The burner 5, and the axial swirling main burner 4 and the auxiliary burner 5 are perpendicular to each other in the axial direction; the axial swirling main burner 4 and the auxiliary burner 5 pass through the screw pump 2 and the coal-water slurry tank 1 respectively through pipelines At the same time, the axial swirling main burner 4 and the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com