The preparation method of the caramel coloring that reduces 4-methylimidazole content

A caramel coloring, methylimidazole technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of complex caramel coloring production process, complicated physical removal method operation, difficult to control reaction conditions, etc. , to achieve the effect of inhibiting the formation of 4-methylimidazole, improving food safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

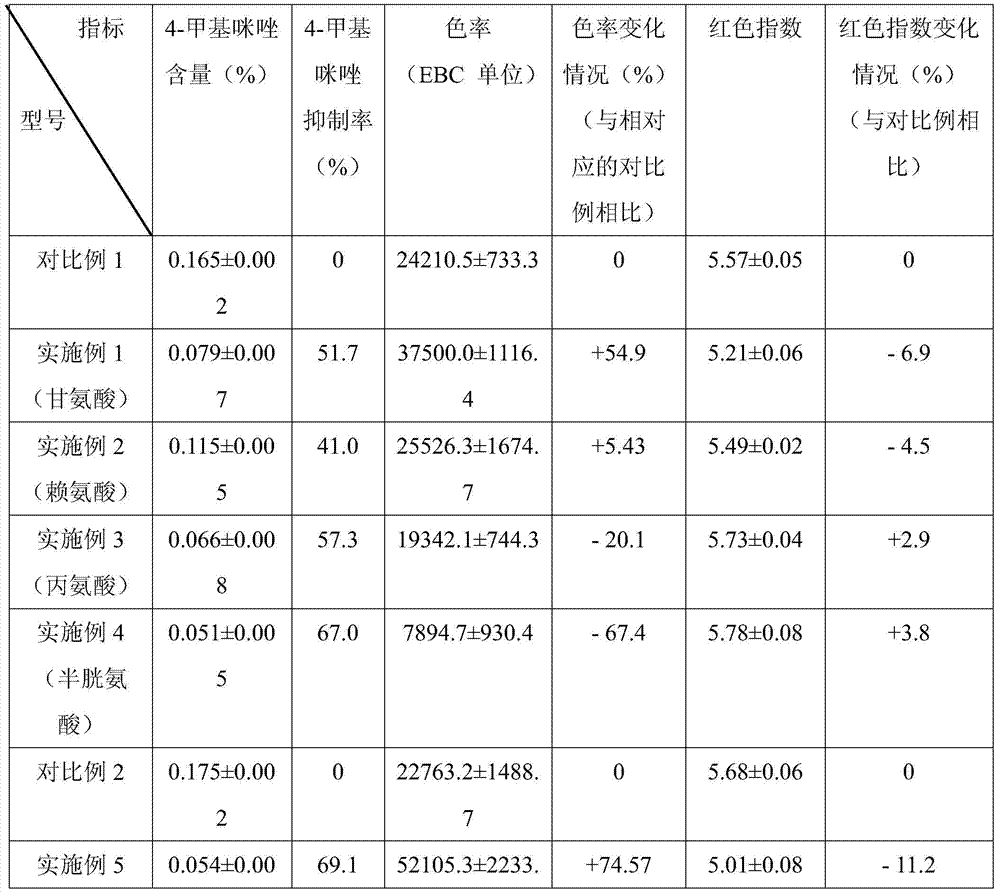

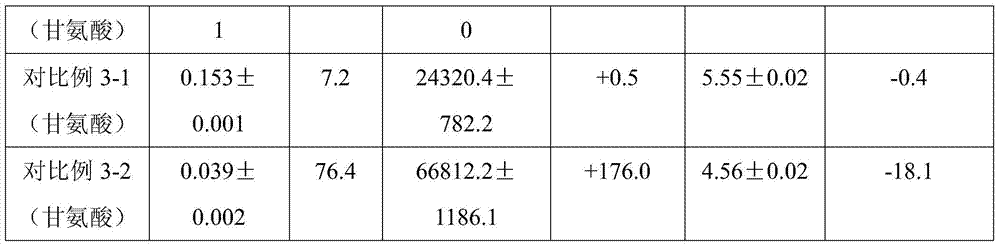

Embodiment 1

[0031] Glucose and water are mixed to prepare a glucose solution with a concentration of 50% (w / v). 4 + Amount and the mass meter of sugar liquid dry matter) add ammoniacal liquor (the aqueous solution containing 25%~28% (mass %) of ammonia, the following cases are all equal) as catalyst, simultaneously press sugar liquid 6% (with the quality of glycine and Glycine is added in proportion to the mass meter of sugar liquid dry matter), fully dissolved, and stirred evenly. Rapidly raise the temperature of the reaction solution (that is, control the heating rate to 3-4°C / min) to 140°C, and control the temperature to 140±2°C for 60 minutes. After the reaction, rapidly cool down (complete the cooling within 5 minutes) to below 50°C. The above reaction solution was concentrated in vacuum (at 40°C) to a viscous liquid (33-38°Bé, the same below), and freeze-dried to obtain solid caramel pigment powder.

[0032] Remarks: Glycine is added at a ratio of 6% of the sugar solution (based o...

Embodiment 2

[0034] Glucose and water are mixed to prepare a glucose solution with a concentration of 50% (w / v). 4 + The ratio of the amount and the mass of sugar liquid dry matter) is added ammoniacal liquor as catalyst, simultaneously adds lysine in the ratio of sugar liquid 3% (in the mass meter of the quality of lysine and sugar liquid dry matter), fully dissolves, Stir well. Rapidly raise the temperature of the reaction solution to 140°C, control the temperature at 140±2°C and react for 60 minutes. After the reaction, quickly cool down to below 50°C, concentrate the above reaction solution in vacuum (at 40°C) to a viscous liquid, and freeze-dry to obtain Solid caramel coloring powder.

Embodiment 3

[0036] Glucose and water are mixed, and the glucose solution that is prepared into concentration is 50% (w / v), and above-mentioned sugar solution is transferred to reaction kettle, by the quality 6% of sugar solution (in NH 4 +The ratio of the amount and the mass of the sugar liquid dry matter) is added as a catalyst, and at the same time, alanine is added in a ratio of 6% of the sugar liquid quality (in terms of the quality of alanine and the mass of the sugar liquid dry matter), fully dissolved , stir evenly, quickly raise the temperature of the reaction solution to 140°C, control the temperature at 140±2°C for 60 minutes, after the reaction, quickly cool down to below 50°C, concentrate the above reaction solution in vacuum (at 40°C) to a viscous liquid, Freeze drying to obtain solid caramel powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com