Spray processing method and spray machine for fabric dyeing and finishing

A processing method and fabric technology, applied in the field of fabric products, can solve problems such as increased dyeing and finishing thickness, difficulty in spraying, waste of dyeing and finishing auxiliaries, etc., to improve color rate and dyeing and finishing efficiency, reduce spraying difficulty, and improve uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

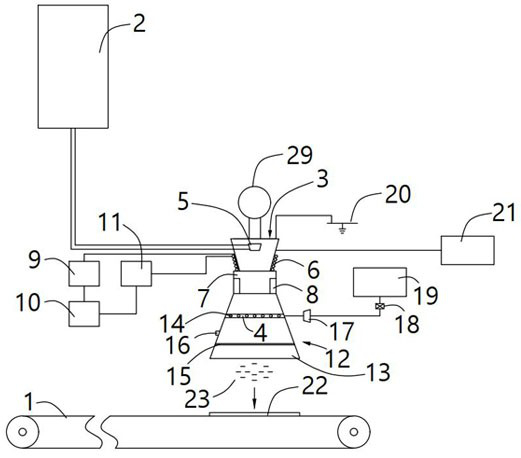

[0045] see figure 1 , the embodiment of the present invention provides a kind of technical scheme:

[0046] A spray processing method for fabric dyeing and finishing, comprising the following steps:

[0047] S1. Use gas-assisted electrostatic atomization to break the dyeing and finishing auxiliaries into electrostatically charged micron-scale first droplets;

[0048] S2. Under the combined action of air flow, gravity and electric field force, the first droplets are sprayed onto the fabric 22 as second droplets 23 after passing through the alternating cold and heat environment, so that the second droplets 23 form microscopic droplets on the fabric 22. Scale dyeing and finishing area;

[0049] Wherein, an induced electric field is formed between the second electrostatically charged droplets 23 and the fabric 22, thereby providing the electric field force in step S2.

[0050] In this embodiment, the spraying of the first droplets into the second droplets 23 on the fabric 22 af...

Embodiment 2

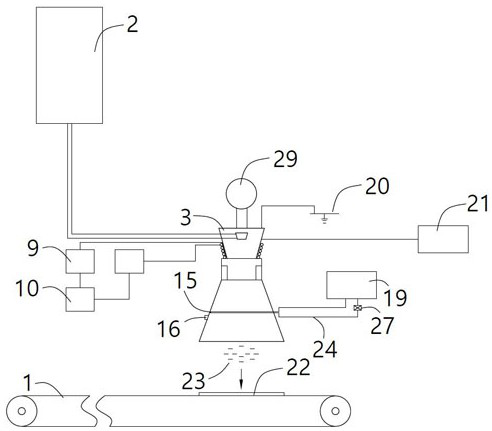

[0069] see figure 2 , the embodiment of the present invention provides a technical solution, which is basically the same as Embodiment 1, with a slight difference:

[0070] This cooling includes passing through the cooled wire mesh 15 during the spraying of the first droplets onto the fabric 22 .

[0071] Specifically, the cooling part includes a metal mesh 15 , a second liquid storage tank 19 , a circulation pump 27 and a circulation pipeline 24 . The metal mesh 15 is hollow inside and is arranged in the cover body 13 . The circulation pipeline 24 , the metal mesh 15, the circulating pump 27 and the second liquid storage tank 19 constitute a circulating loop.

[0072] In this embodiment, compared with the first embodiment, the cavity ring body 4 is replaced with a metal mesh 15, and the metal mesh 15 is hollow inside, that is, it not only has dense metal meshes, but also can pass through a circulating pump. 27 The cooling liquid (such as cold water that tends to 0 ° C) con...

Embodiment 3

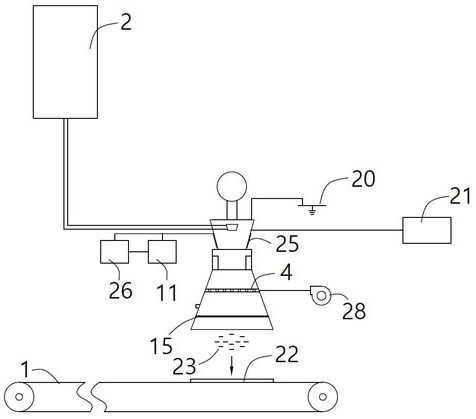

[0074] see image 3 , the embodiment of the present invention provides a technical solution, which is basically the same as Embodiment 1, with a slight difference:

[0075] Specifically, the spraying of the first droplets into the second droplets 23 on the fabric 22 after passing through the alternating cold and heat environment includes the following steps:

[0076] Atomizing the dyeing and finishing auxiliaries after cooling or cooling the dyeing and finishing auxiliaries into the first droplets;

[0077] spraying the first droplet towards the fabric 22;

[0078] In the process of spraying the first droplets to the fabric 22, hot air or heated and then atomized droplets of dyeing and finishing auxiliaries are injected. After becoming the second droplet 23, it is sieved through the metal mesh 15 and sprayed onto the fabric 22 evenly.

[0079] Specifically, the heating part includes a hot air blower 28 and a cavity ring body 4 provided in the cover body 13 and having the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com