Preparation method for improving color rate of caramel by caustic sulfite method

A technology of caustic sulfite and sulfite, which is applied in the direction of chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problem that the color rate of caramel is difficult to make high, to overcome inhibition, reduce residue, and prevent product The effect of high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

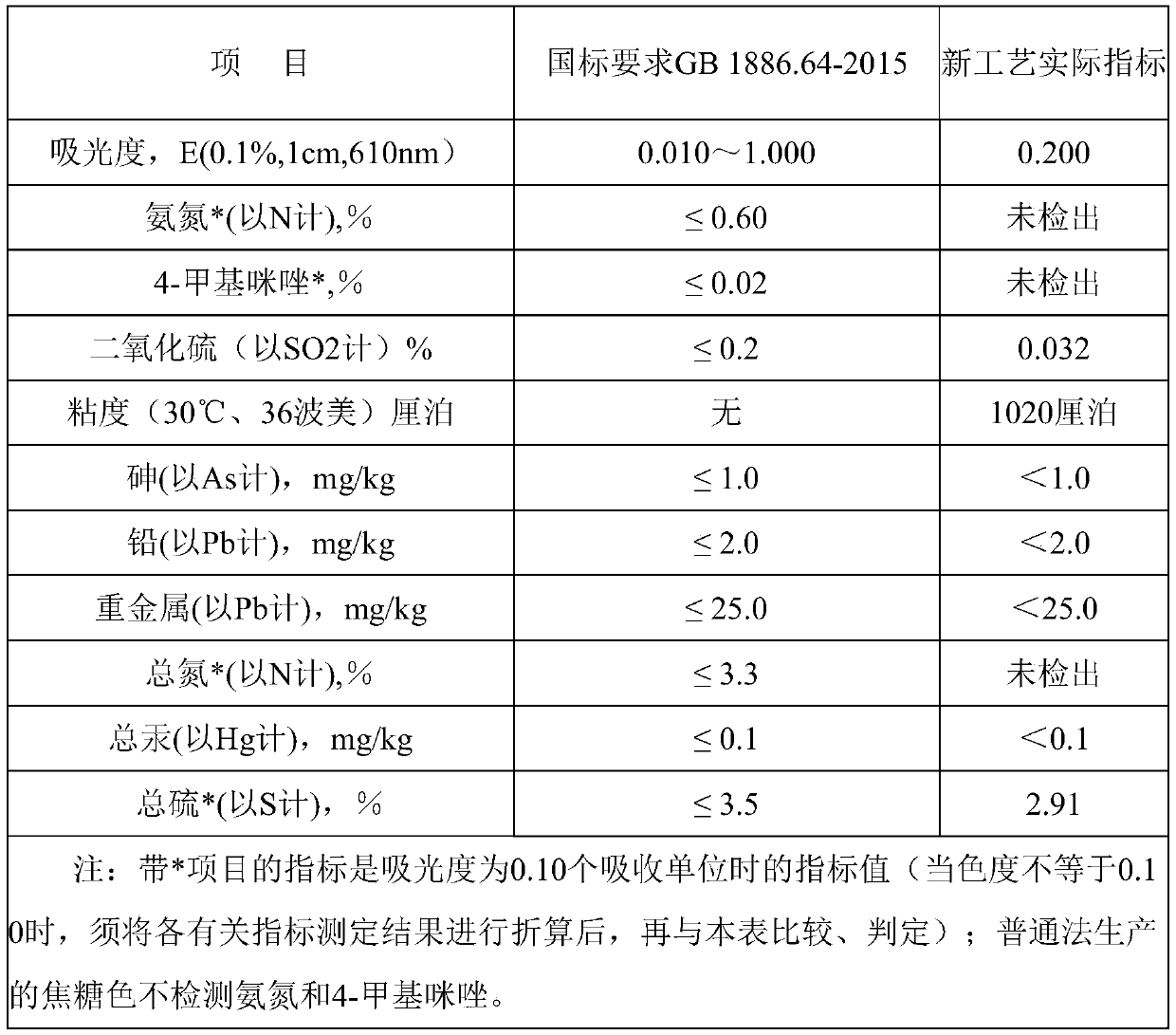

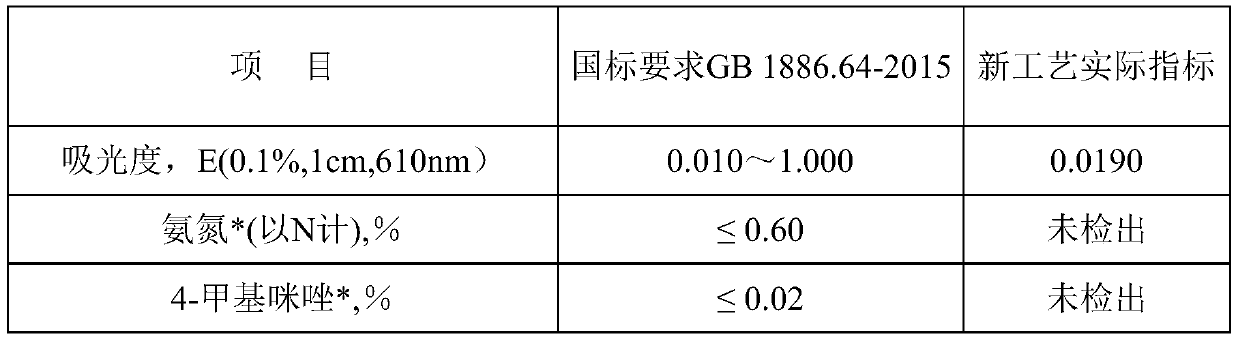

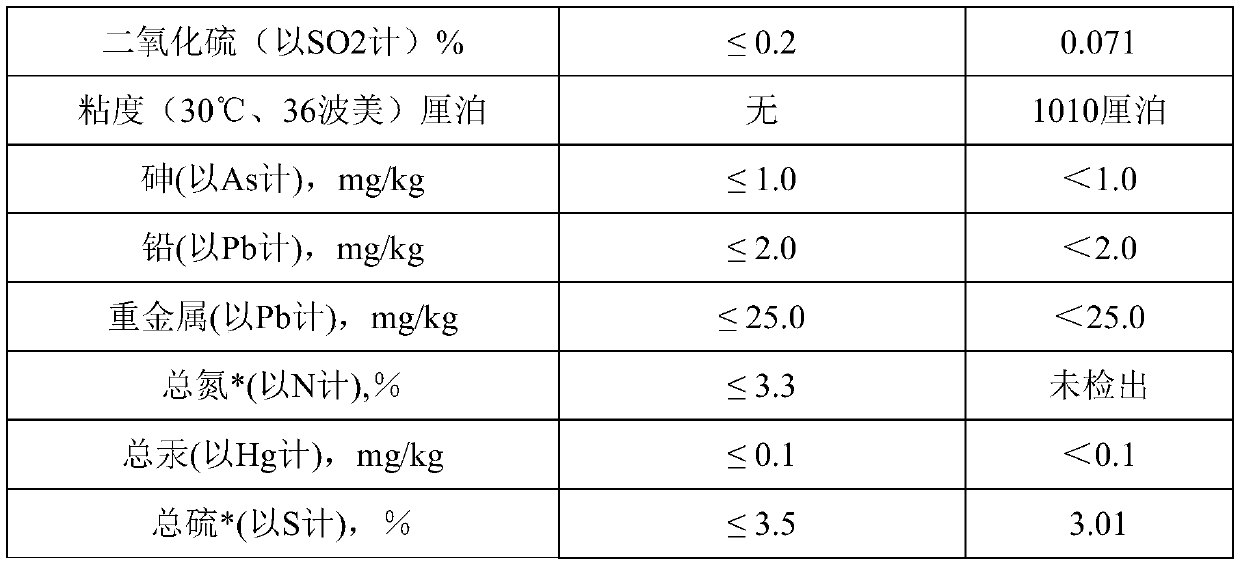

Embodiment 1

[0027] Set the production of 36Be, 50000EBC caustic acid salt method caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are the measurement indicators of caramel color), the specific steps are as follows:

[0028] 1) Raw material metering and concentration: maltose (the amount of dry matter is 6000Kg, DE value is 42%, and DE value refers to the mass percentage of reducing sugar in dry matter;) is pumped into the reaction tank, and the raw material is concentrated to dryness in the reaction tank. Basis is 65%;

[0029] 2) pressurized catalytic reaction for the first time: add 300kg (5% of the amount of maltose dry matter) sodium hyposulfite to the concentrated material, 18kg (0.3% of the amount of maltose dry matter) sodium hydroxide, heat up in the reaction tank and add Pressure reaction (the range of temperature rise is controlled at 110-130°C, and the range of pressurization is controlled at 0.1...

Embodiment 2

[0041] Set to produce 36Be, 60000EBC caustic acid salt method caramel color, the specific steps are as follows:

[0042] 1) Raw material metering and concentration: pump fructose and glucose into the reaction tank at a ratio of 1:1 (the amount of dry matter is 6000Kg, and the DE value is 97%), and the raw material is concentrated to 85% on a dry basis in the reaction tank ;

[0043] 2) pressurized catalytic reaction for the first time: add 1800kg potassium pyrosulfite and sodium pyrosulfite (wherein potassium pyrosulfite 900Kg), 1800kg sodium bicarbonate and sodium acetate (wherein sodium bicarbonate 1000Kg) in the concentrated material, Temperature rise and pressure reaction in the reaction tank (the range of temperature rise is controlled at 165-180°C, and the range of pressurization is controlled at 0.65-0.8Mpa), and the color rate is detected by sampling every 30 minutes. When the color rate is 0.076, the first reaction is terminated;

[0044] 3) The second atmospheric pr...

Embodiment 3

[0055] Set to produce 36Be, 50000EBC caustic acid salt method caramel color, the specific steps are as follows:

[0056] 1), Raw material metering and concentration: pump molasses, xylose and sucrose into the reaction tank according to the ratio of 1:1:1 (the amount of dry matter is 6000Kg, and the DE value is 60%), and the raw materials are concentrated to dryness in the reaction tank. 75% basis;

[0057] 2) The first pressurized catalytic reaction: add 900kg sodium bisulfite, 900kg sodium citrate, potassium hydroxide and sodium carbonate (wherein sodium citrate 600kg, potassium hydroxide 100Kg) in the concentrated material, in the reaction tank Internal heating and pressurization reaction (the range of temperature rise is controlled at 165-180°C, and the range of pressurization is controlled at 0.65-0.8Mpa), and the first reaction is terminated when the color ratio is 0.063;

[0058] 3) The second atmospheric pressure catalytic reaction: cool the material completed for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com