Method for reducing 4-methylimidazole in caramel pigment

A technology of tetramethylimidazole and caramel coloring, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the complex production process of caramel coloring, cumbersome physical removal method operation, difficult to control reaction conditions, etc. problems, to achieve the effect of high production efficiency, optimized production process, and accelerated reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

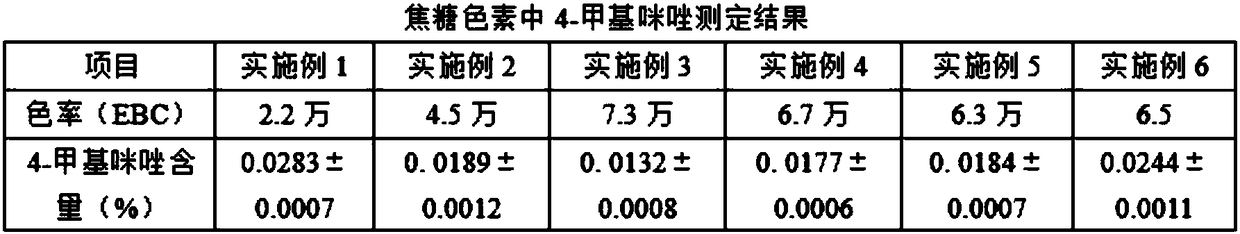

Examples

Embodiment 1

[0022] A method for reducing tetramethylimidazole in caramel pigment, the specific steps are as follows:

[0023] (1) Hydrolysis: Weigh wheat B-starch, place it in a reactor, add hydrochloric acid aqueous solution and sodium chloride, mix well, put it into a microwave reactor and radiate it for 6 minutes, take it out, cool it, add sodium hydroxide to neutralize, Filter, get filtrate, obtain wheat B-starch hydrolyzate, for subsequent use;

[0024] (2) Take wheat B-starch hydrolyzate, add deionized water, ammonium carbonate and glycine to fully mix, place the autoclave, airtight, heat up, the reaction temperature is 110 degrees, the reaction time is 50 minutes, and the reaction product is obtained. , through freeze-drying to obtain caramel coloring.

[0025] Wherein the caramel pigment is made up of the following raw materials in weight ratio: 4% glycine, 20% wheat B-starch, 1% ammonium carbonate, 0.1% hydrochloric acid aqueous solution, 10% sodium chloride, 8% sodium hydroxide...

Embodiment 2

[0027] A method for reducing tetramethylimidazole in caramel pigment, the specific steps are as follows:

[0028] (1) Hydrolysis: Weigh wheat B-starch, place it in a reactor, add hydrochloric acid aqueous solution and sodium chloride, mix well, put it into a microwave reactor and radiate it for 6 minutes, take it out, cool it, add sodium hydroxide to neutralize, Filter, get filtrate, obtain wheat B-starch hydrolyzate, for subsequent use;

[0029] (2) Take wheat B-starch hydrolyzate, add deionized water, ammonium carbonate and glycine after fully mixing, place high-pressure reactor, airtight, heat up, reaction temperature 130 degrees, reaction time 70 minutes, drop to room temperature, obtain reaction product , through freeze-drying to obtain caramel coloring.

[0030] Wherein the caramel coloring is made up of the raw material of following weight ratio: 5% glycine, 30% wheat B-starch, 3% ammonium carbonate, 0.3% hydrochloric acid aqueous solution, 13% sodium chloride, 9% sodi...

Embodiment 3

[0032] A method for reducing tetramethylimidazole in caramel pigment, the specific steps are as follows:

[0033] (1) Hydrolysis: Weigh wheat B-starch, place it in a reactor, add hydrochloric acid aqueous solution and sodium chloride, mix well, put it into a microwave reactor and radiate it for 6 minutes, take it out, cool it, add sodium hydroxide to neutralize, Filter, get filtrate, obtain wheat B-starch hydrolyzate, for subsequent use;

[0034] (2) Take the wheat B-starch hydrolyzate, add deionized water, ammonium carbonate and glycine and mix well, place the autoclave, airtight, heat up, the reaction temperature is 150 degrees, the reaction time is 90 minutes, and the reaction product is obtained. , through freeze-drying to obtain caramel coloring.

[0035] Wherein said caramel pigment is made up of the following raw materials of weight ratio: 5% glycine, 48% wheat B-starch, 6% ammonium carbonate, 0.5% hydrochloric acid aqueous solution, 10% sodium chloride, 10% sodium hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com