A kind of aspergillus oryzae za109 and application thereof

A ZA109, Aspergillus oryzae technology, applied in the field of industrial microorganisms, can solve the problems of reducing the consumption rate of raw materials in the koji-making stage, lack of Aspergillus oryzae strains, and high consumption rate of raw materials, and achieve the removal of soy sauce bitterness, amylase activity and proline aminopeptide. The effect of high enzyme activity and strong growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

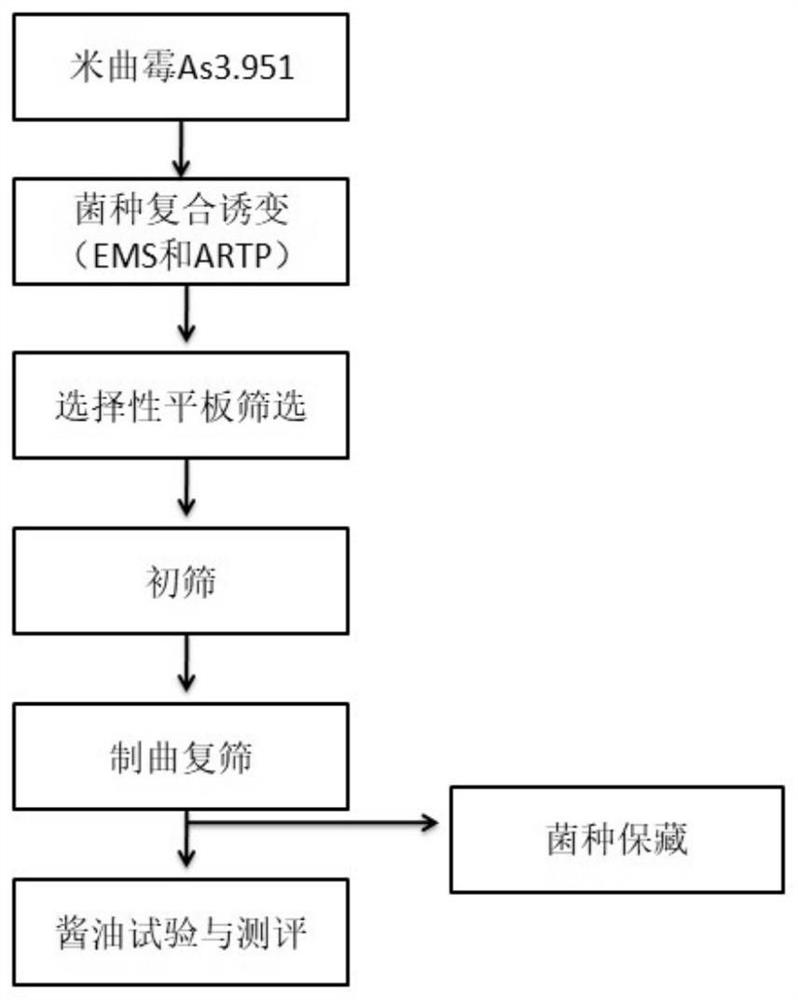

[0035] Embodiment 1 strain mutagenesis screening

[0036] 1. Separation and purification of starting strains: Separation and purification of Aspergillus oryzae As3.951, specifically, the seed liquid of Aspergillus oryzae As3.951 was evenly spread on the selective plate medium containing the substrate proline-p-nitroaniline, according to The generated yellow hydrolysis circle and the colony diameter ratio (HE value) are used to select a strain with better growth and higher vigor as the starting strain. The larger the HE value, the better the growth and vigor of the strain.

[0037] 2. Preparation of spore suspension: first inoculate the starting strain on the casein plate medium and cultivate for 72 hours, take 20 mL of sterile saline to elute the spores on the surface of the plate and transfer it to a sterile Erlenmeyer flask filled with glass beads Shake and disperse on a shaker for 20 minutes, then filter with 4 layers of sterile filter cloth, and perform gradient dilution w...

Embodiment 2

[0057] Embodiment 2 Aspergillus oryzae ZA109 genetic stability detection

[0058] Aspergillus oryzae ZA109 was continuously passaged for 8 generations on a casein slant medium, and the growth of the strains of each generation was observed, and the 1st, 4th and 8th generation slant species were used to make koji according to the method described in Example 1, and the koji spores were detected. Number, raw material consumption rate, activity of neutral protease, amylase and proline aminopeptidase. To judge its genetic stability, the results are shown in Table 4.

[0059] Table 4 Aspergillus oryzae ZA109 subculture quality analysis of koji making

[0060] strain name Spore count Raw material consumption rate Neutral protease activity Amylase activity proline aminopeptidase activity As3.951 1.00 1.00 1.00 1.00 1.00 1st generation 0.91 0.84 1.26 1.23 1.24 4th generation 0.93 0.89 1.25 1.21 1.22 8th generation 0.92 0.88 1.29...

Embodiment 3

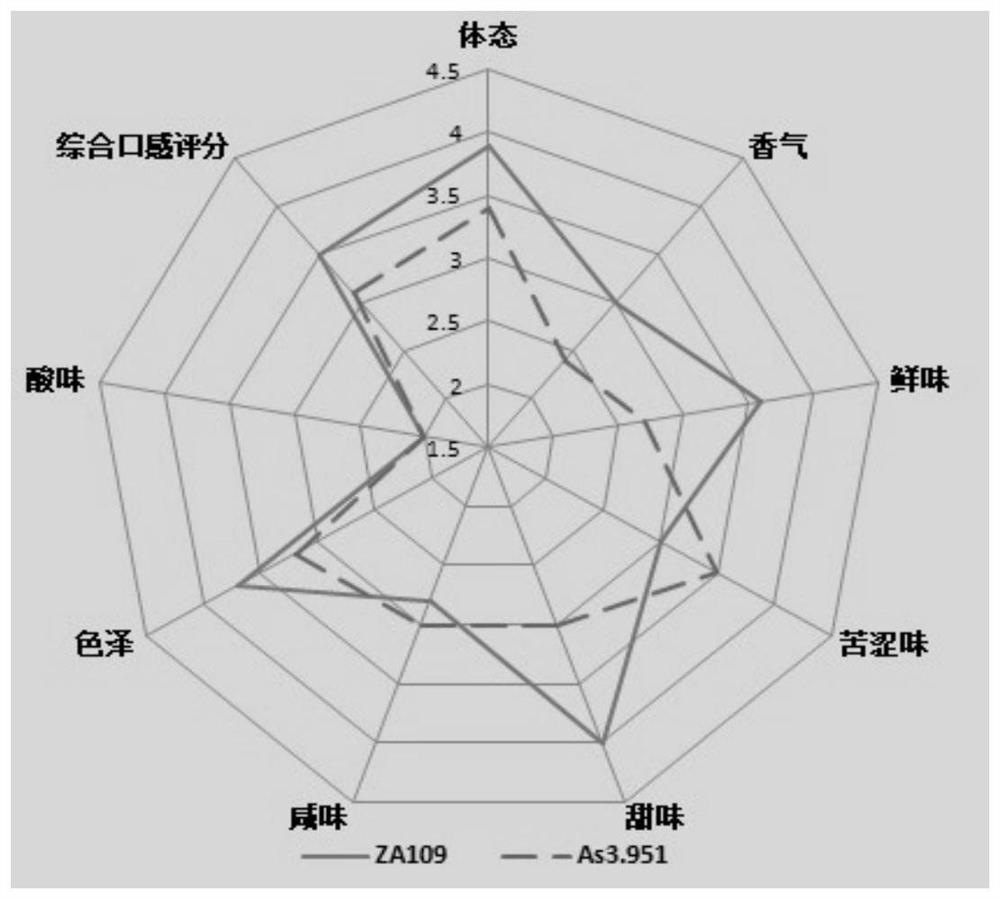

[0063] The soy sauce fermentation verification of embodiment 3 Aspergillus oryzae ZA109

[0064] The new strain ZA109 screened by mutagenesis and the starting strain As3.951 were used in the production of soy sauce simultaneously. After the koji making was finished, the relevant enzyme activities were sampled and tested, and the crude oil indicators were tested after the fermentation. The results are shown in Table 5 and Table 6. Heat the crude oil and call 10 professional appraisers for sensory evaluation. Evaluation indicators for sensory evaluation include body shape, aroma, umami, bitterness, sweetness, saltiness, color, sourness and comprehensive taste. The evaluation results are shown in Table 7 and figure 1 shown.

[0065] Table 5 Comparison of koji-making quality between Aspergillus oryzae As3.951 and Aspergillus oryzae ZA109

[0066]

[0067]

[0068] Table 6 Comparison of the quality of crude oil fermented by Aspergillus oryzae As3.951 and Aspergillus oryzae...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com