Canned fish production line

A canned fish production line and technology for empty cans, which are applied in the preservation of meat/fish, dry preservation of meat/fish, food preservation, etc., can solve the problems of human operation and irregular operation, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

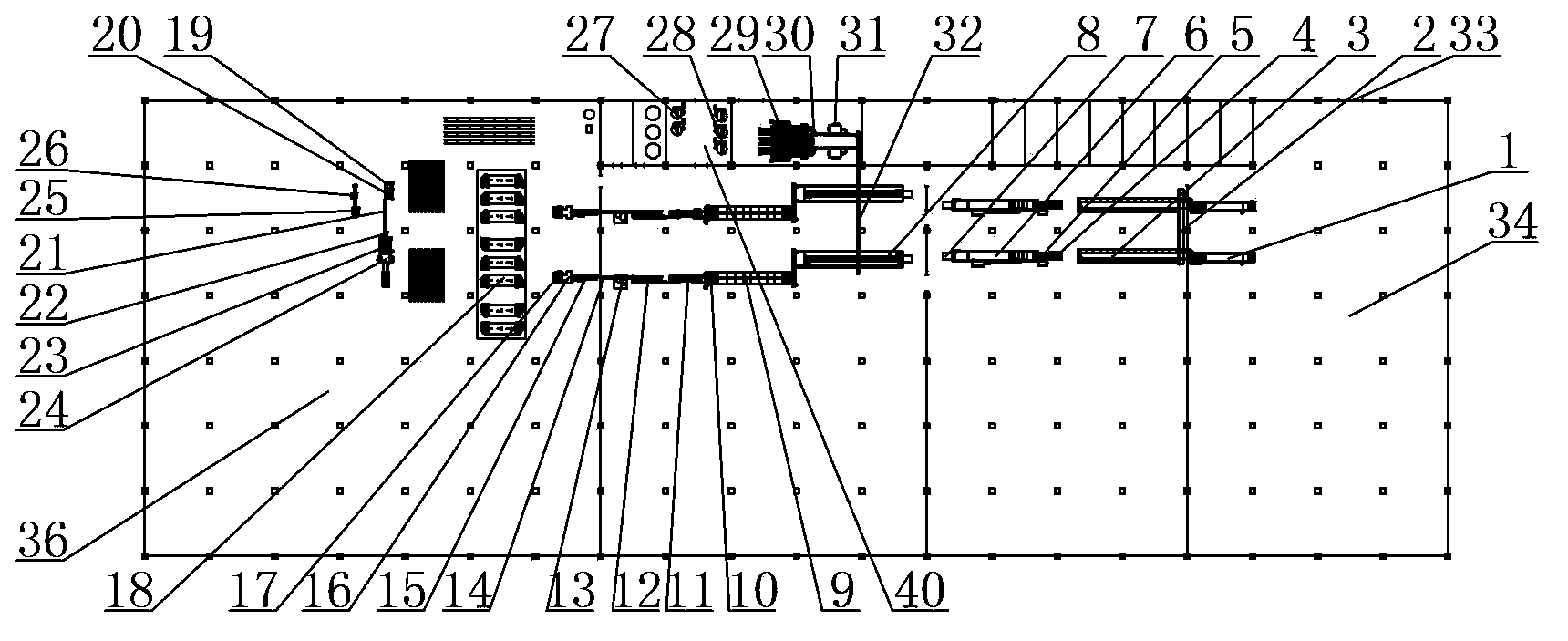

[0011] Such as figure 1 A canned fish production line shown includes a raw material channel 33 installed along the process flow, a deicing washing machine 1, a waste belt conveyor 2, a head and tail removing conveyor 3, a secondary cleaning tank 4, and a miscellaneous removal machine 5 , Salt water soaking elevator 6, material receiving workbench 7, can filling and filling conveyor 8, exhaust box 9, tank separating chain conveyor 10, tank single draining machine 11, tank adding soup machine 12, tank sealing Capping machine 13, tank inspection chute 14, tank solid tank cleaning machine 15, tank receiving platform 16, hydraulic lifting cage loading machine 17, horizontal sterilizing pot 18, horizontal lifting cage unloading machine 19, disc conveying 20, drying Machine 21, linking chain plate conveyor 22, material receiving chain plate conveyor 23, automatic hydraulic lifting stacking machine 24, labeling machine 25, coding machine 26, the canning and filling conveyor 8 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com