Processing method for antioxidant fen-flavor peanut oil

A processing method and technology of peanut oil, applied in the direction of producing fat, edible oil/fat, fat oil/fat production, etc., can solve problems such as short storage period, and achieve the effects of less phospholipid content, less quality change, and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

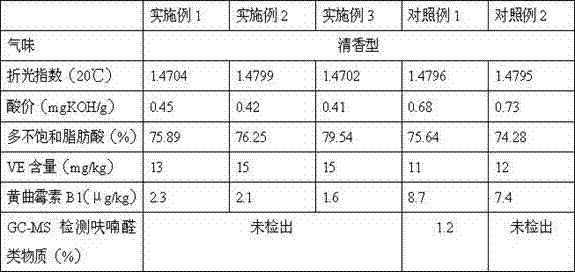

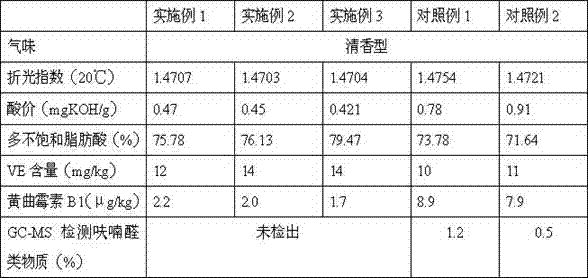

Examples

Embodiment 1

[0021] The first step is to remove the red skin of the peanuts, and after crushing, use microwave treatment to make the moisture content 2wt%, the microwave power is 1000KW, and the temperature in the microwave heater is 120°C;

[0022] In the second step, the ground peanuts obtained in the first step are added to a twin-screw oil press for pressing at a pressing temperature of 10°C and a screw speed of 15 rpm to obtain crude oil;

[0023] In the 3rd step, the crude oil obtained in the 2nd step is successively filtered through a leaf filter and a ceramic membrane filter with an average pore size of 0.1 μm, and then an acid solution of 1 wt% of the crude oil quality is added to the filtered oil, and the acid solution is Be the aqueous solution of acetic acid, concentration is 1wt%, after stirring for 20min, remove water layer, and wash oil layer through water;

[0024] In step 4, the peanut oil obtained in step 3 is cooled to 2°C, left for 1 day, and solids are filtered out at ...

Embodiment 2

[0028] Step 1, remove the red skin of the peanuts, and after crushing, use microwave treatment to make the moisture content 3wt%, the microwave power is 1200KW, and the temperature in the microwave heater is 140°C;

[0029] In the second step, the ground peanuts obtained in the first step are added to a twin-screw oil press for pressing, the pressing temperature is 25°C, and the screw speed is 20 rpm to obtain crude oil;

[0030] In the 3rd step, the crude oil obtained in the 2nd step is successively filtered through a leaf filter and a ceramic membrane filter with an average pore size of 0.5 μm, and then an acid solution of 3wt% of the crude oil quality is added to the filtered oil, and the acid solution It is an aqueous solution of acetic acid with a concentration of 3wt%. After stirring for 20-40 minutes, remove the water layer and wash the oil layer with water;

[0031] In step 4, the peanut oil obtained in step 3 is cooled to 5°C, left for 3 days, and solids are filtered ...

Embodiment 3

[0035] The first step is to remove the red skin of the peanuts, and after crushing, use microwave treatment to make the moisture content 2wt%, the microwave power is 1100KW, and the temperature in the microwave heater is 130°C;

[0036] In the second step, the peanut powder obtained in the first step is added to a twin-screw oil press for pressing at a pressing temperature of 15°C and a screw speed of 18 rpm to obtain crude oil;

[0037] In the 3rd step, the crude oil obtained in the 2nd step is successively filtered through a leaf filter and a ceramic membrane filter with an average pore size of 0.2 μm, and then an acid solution of 2wt% of the crude oil quality is added to the filtered oil, and the acid solution is Be the aqueous solution of acetic acid, concentration is 2wt%, after stirring for 30min, remove water layer, and wash oil layer through water;

[0038] In step 4, the peanut oil obtained in step 3 is cooled to 3°C, left for 2 days, and solids are filtered out at lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com