Device and process for purifying fried food waste oil based on continuous mode

A fried food and process technology, which is applied in the field of devices for purifying waste oil of fried food based on a continuous and uninterrupted method, can solve the problem that the acid value and peroxide value of oil are increased, the colloidal substances cannot be effectively removed, and the fried food cannot be effectively removed. Quality can not be guaranteed and other problems, to achieve the effect of reducing phospholipid content, reducing the probability of saponification, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

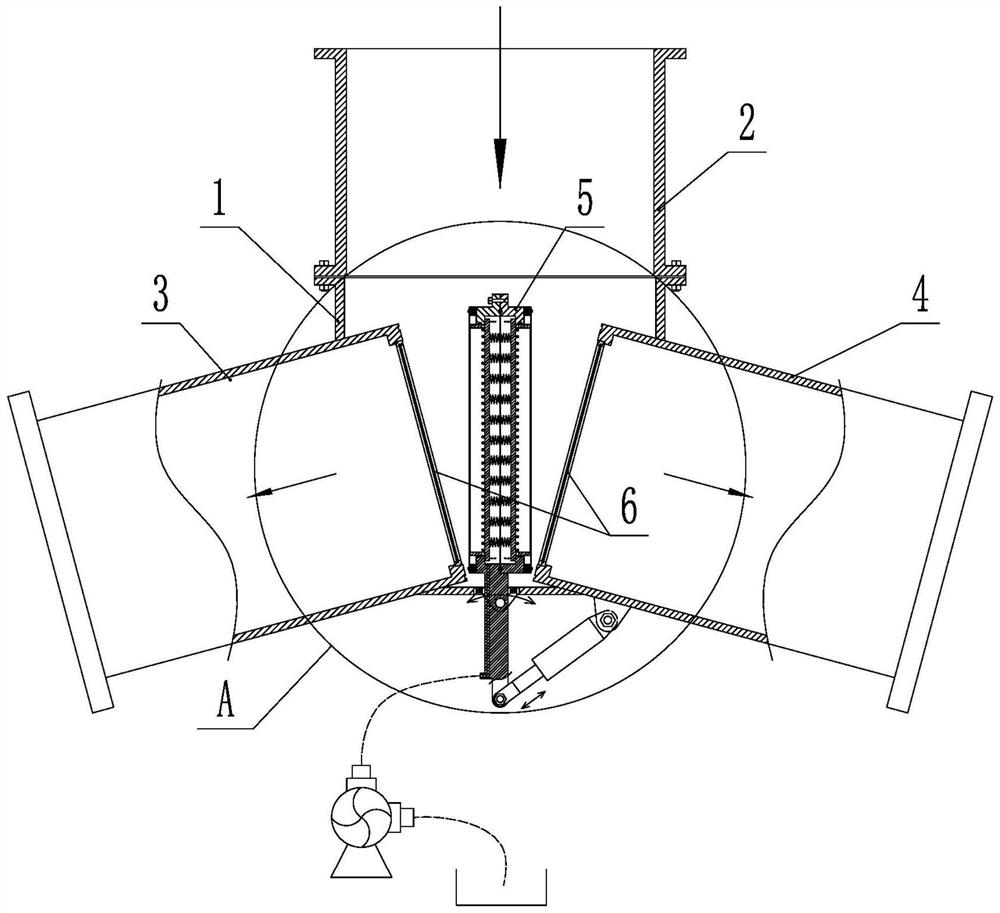

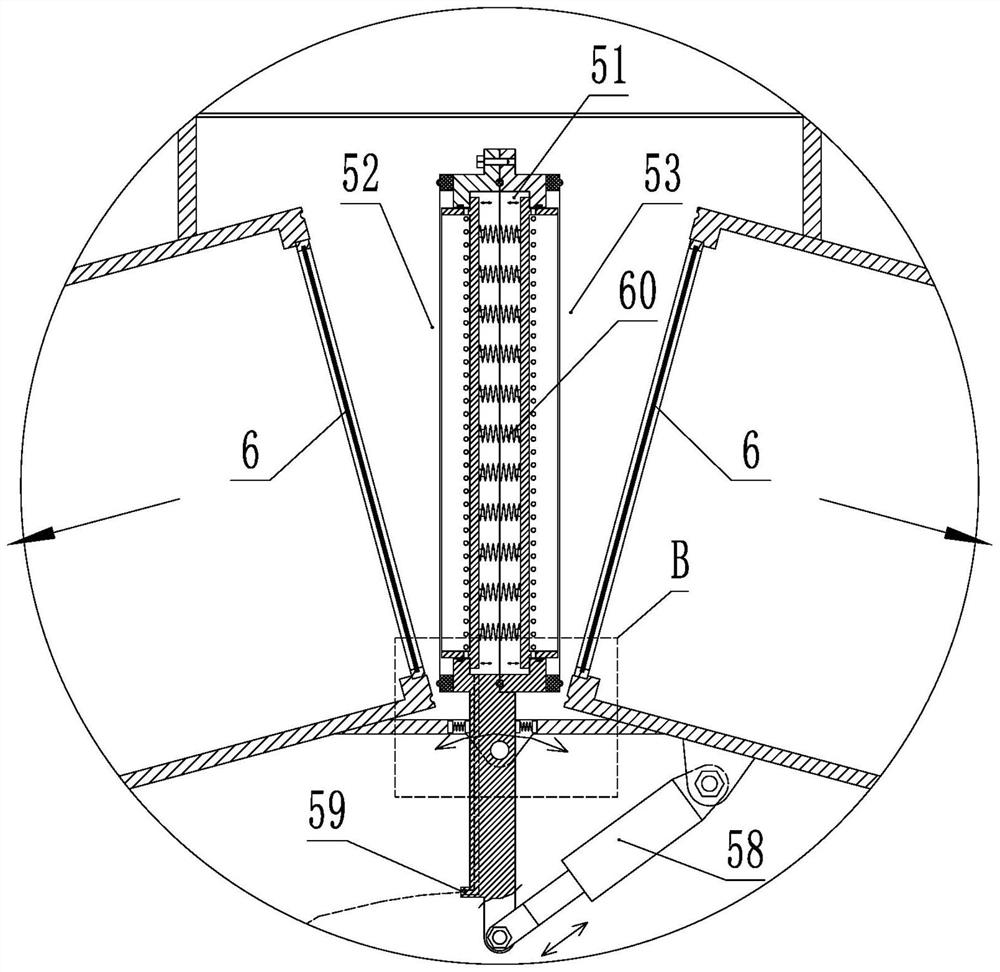

[0030] see Figure 1-Figure 4 , the embodiment of the present invention provides a device for purifying fried food waste oil based on a continuous and uninterrupted manner, comprising: a housing 1, an oil inlet pipe 2 communicating with the housing 1, a first oil outlet pipe 3, and a second oil outlet pipe 4. The reversible body 5 installed in the housing 1, and the reversing mechanism used to drive the reversible body 5; the oil inlet pipe 2, the first oil outlet pipe 3, and the second oil outlet pipe 4 are distributed in a Y shape, which can be hollow round tube.

[0031] The oil inlet end of the first oil outlet pipe 3 and the second oil outlet pipe 4 located in the housing 1 is provided with a filter device 6; it may be a filter screen.

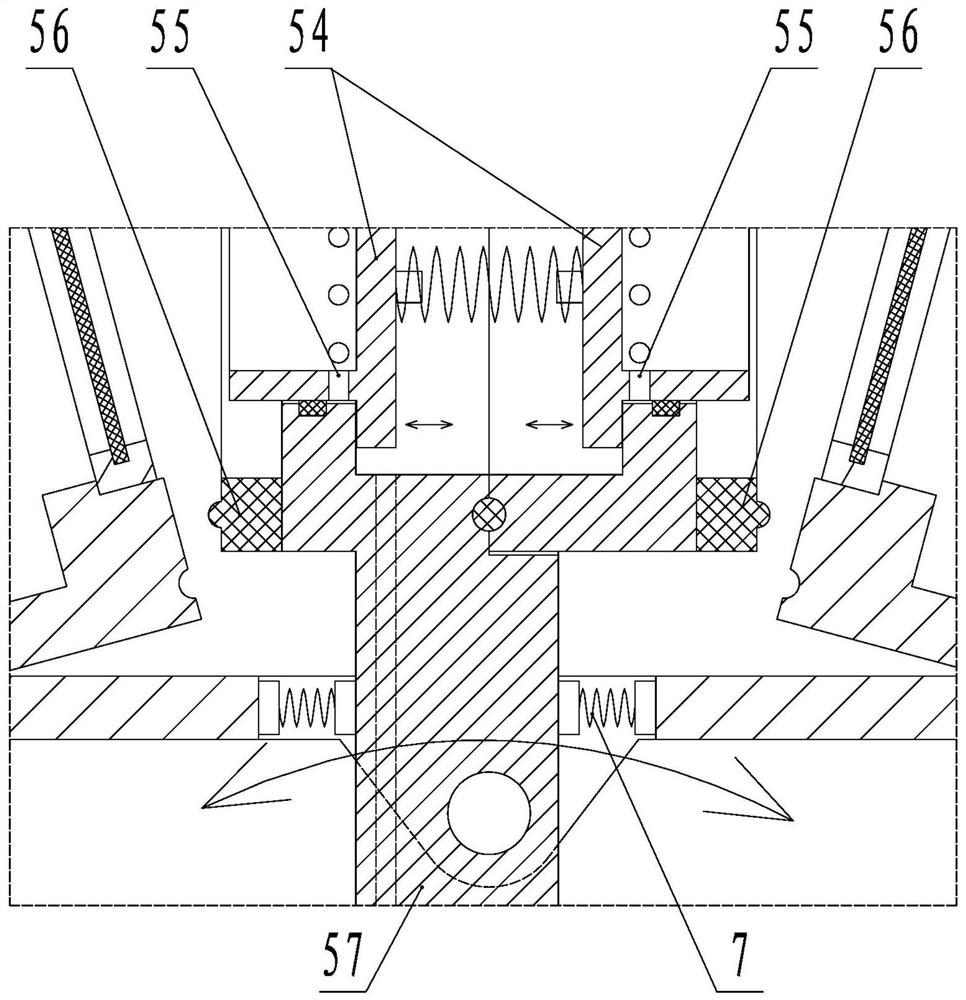

[0032] The inside of the turning body 5 is provided with an oil suction cavity 51, and the two ends are respectively provided with a first oil suction port 52 and a second oil suction port 53 connected to each other. The first oil suctio...

Embodiment 2

[0044] A process for purifying fried food waste oil based on continuous and uninterrupted mode, comprising the following steps:

[0045] S1. Preheating and acid treatment: Preheat the waste cooking oil after filtering out solid impurities to 70°C, pump it into a reaction tank for heat preservation, and add food-grade phosphoric acid accounting for 0.05% of the oil while stirring , and its concentration is 85%, to obtain acid-treated mixed oil;

[0046] S2. Rapid cooling and coagulation impurity treatment: quickly lower the acid-treated mixed oil after S1 treatment to 30°C, and then add food-grade lye with a concentration of 20% to it according to the acid value to be lowered, and the reaction time is 8 minutes. Coagulate the impurities to form a group of flocculent impurities, and obtain the alkali-treated mixed oil;

[0047] S3. Continuous and uninterrupted purification treatment: pump the alkali-treated mixed oil liquid after S2 treatment into the oil inlet pipe, and then c...

Embodiment 3

[0049] A process for purifying fried food waste oil based on continuous and uninterrupted mode, comprising the following steps:

[0050] S1. Preheating and acid treatment: Preheat the waste cooking oil after filtering out solid impurities to 75°C, pump it into a reaction tank for heat preservation, and add food-grade phosphoric acid accounting for 0.12% of the oil while stirring , and its concentration is 85%, to obtain acid-treated mixed oil;

[0051] S2. Rapid cooling and coagulation impurity treatment: quickly lower the acid-treated mixed oil after S1 treatment to 35°C, and then add food-grade lye with a concentration of 22% to it according to the acid value to be lowered, and the reaction time is 12 minutes. Coagulate the impurities to form a group of flocculent impurities, and obtain the alkali-treated mixed oil;

[0052] S3. Continuous and uninterrupted purification treatment: pump the alkali-treated mixed oil liquid after S2 treatment into the oil inlet pipe, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com