Low temperature oil preparation and protein in oil-bearing materials preparation method

An oil protein, low temperature technology, applied in the protein composition of vegetable seeds, protein food components, fat oil/fat production, etc., can solve the problems of protein denaturation, deepening of crude oil color, high phospholipid content, and high water absorption. and oil absorption, no chemical contamination or residue, low crude fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

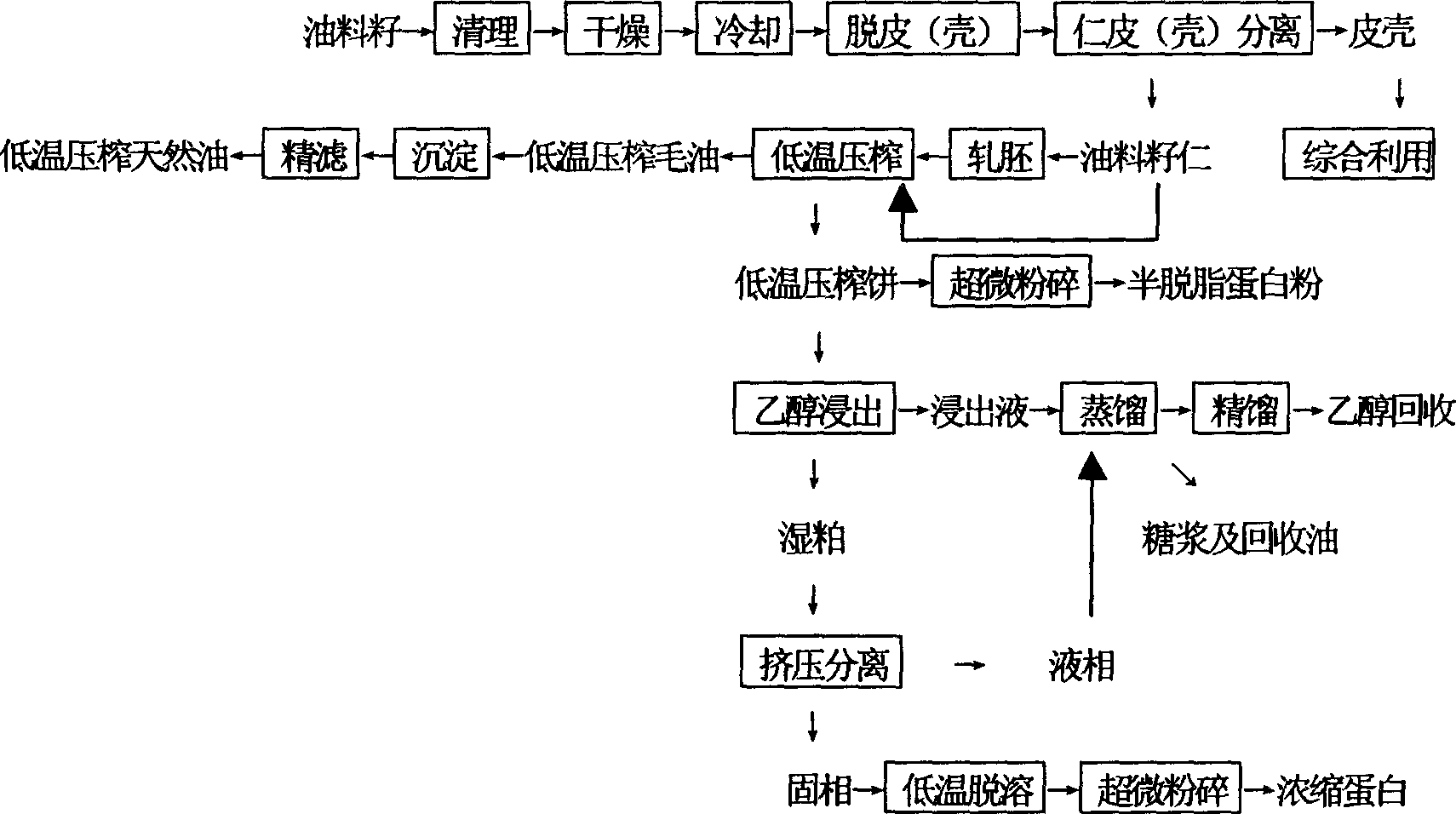

[0013] see figure 1 , a low-temperature oil production method of peanut kernels and oil protein preparation method, the specific steps are: the oil is peanut kernels, after the raw materials are cleaned, the water is dried to 4%; after cooling to ambient temperature (20°C-30°C ), carry out peeling treatment, take off the red coat, and the peeling rate is above 90%, then separate the kernel and skin to obtain oilseed kernels (peanut kernels) with a skin rate of 2%, and the red coat (husk) is separately processed Comprehensive utilization; low-temperature pressing of peanut kernels without rolling or after rolling, using low-temperature oil pressing equipment at an input temperature of 50°C to obtain low-temperature pressed crude oil and low-temperature pressed cake; the crude oil is precipitated 1. After fine filtration, the low-temperature pressed natural oil (peanut oil) is obtained; the low-temperature pressed cake is directly subjected to superfine pulverization processing ...

Embodiment 2

[0016] A low-temperature oil production method of sunflower seeds and oil-seed protein production method, the specific steps are: after cleaning the raw materials of sunflower seeds, drying the water to 5%; cooling to ambient temperature (20°C-30°C), and removing Shell treatment, the shelling rate is above 90%, and then separate the kernels and shells to obtain oilseed kernels with a shell content of 3%, and the shells will be comprehensively utilized; the sunflower kernels are used without rolling or after rolling The low-temperature oil pressing equipment performs low-temperature pressing under the condition of the input temperature of 40°C to obtain low-temperature pressed crude oil and low-temperature pressed cake; the crude oil is processed by precipitation and fine filtration to obtain low-temperature pressed sunflower oil; low-temperature pressed cake Using ethanol leaching, first leaching with ethanol with a concentration of 95%, and then leaching with ethanol with a co...

Embodiment 3

[0018] A low-temperature soybean oil production method and oil-seed protein production method, the specific steps are: the oil is soybean, the raw material is cleaned, and the moisture is dried to 5%; after cooling to ambient temperature (20°C-30°C), carry out Peeling treatment, the peeling rate is above 90%, and then the kernels and skins are separated to obtain soybean kernels with a skin content of 1%, and the soybean hulls are used for comprehensive utilization; the soybean kernels are not rolled or after rolling, and the oil is pressed at low temperature The equipment carries out low-temperature pressing under the condition of the input temperature of 30°C to obtain low-temperature pressed crude oil and low-temperature pressed cake; the crude oil is processed by precipitation and fine filtration to obtain low-temperature pressed soybean oil; the low-temperature pressed cake is used The crushing equipment directly carries out superfine crushing processing to obtain semi-def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com