Aqueous enzymatic camellia oil extraction method

An oil-water enzyme and process technology, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, can solve the problems of easy residual solvent, large environmental pollution and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

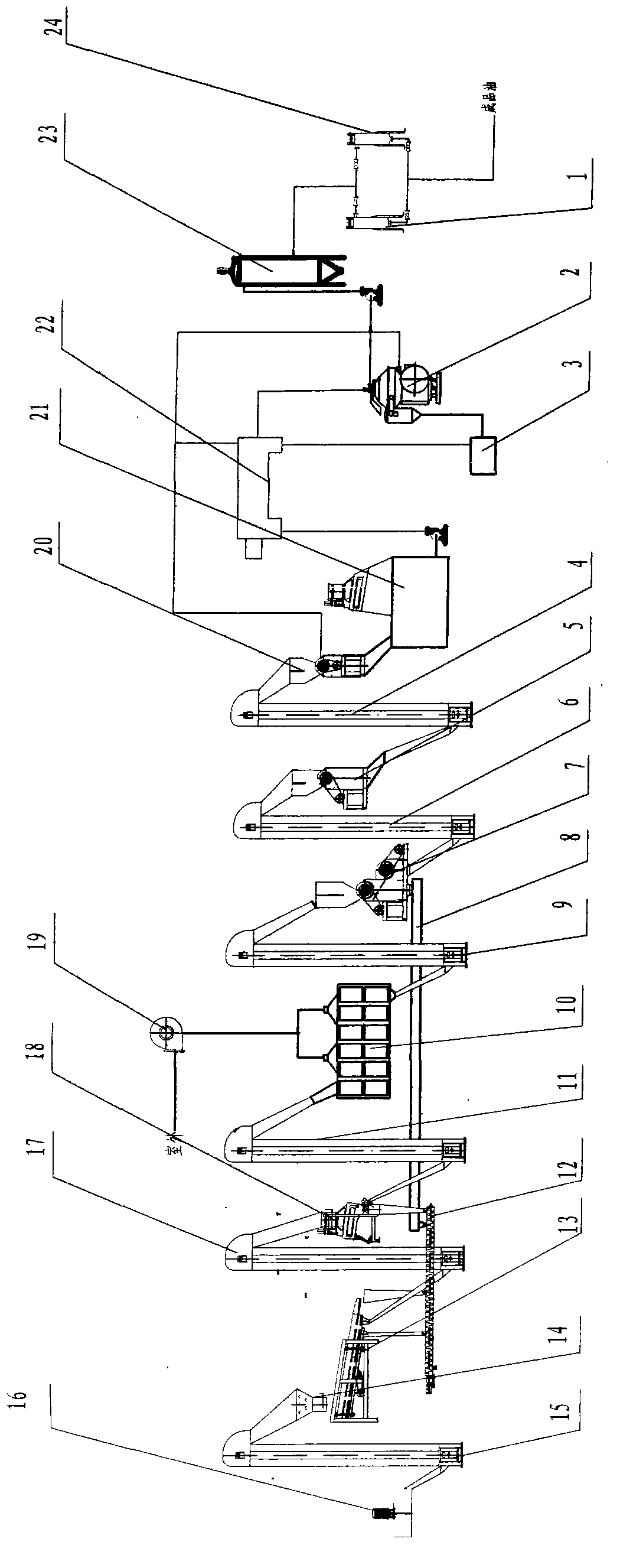

[0007] In the process involved in this project, the tea seed raw material enters the No. 6 elevator 15 through the feeder 16; it is lifted to the homogenizing hopper 14 through the No. 6 elevator 15, and is cleaned and classified by the multi-stage cleaning screen 13; the tea seed enters the No. 5 elevator 17. Transport to the stone removal machine 18 to clean up the stones and other sundries in the tea seed oil to avoid damage to subsequent equipment. After cleaning, the tea seed oil is transported to the flat dryer 10 through the No. 4 elevator 11 for drying; the water vapor is discharged to the outside through the fan 19. After the tea seed oil is dried, it is transported to the peeling machine 7 by the No. 3 elevator 9 to separate the tea seed shell; The separated sundries are transported outdoors together for treatment. The separated tea seed raw material is transported to pulverizer 5 through No. 2 hoist 6 for pulverization; the pulverized tea seed particles are transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com