A kind of preparation method of bauxite positive flotation tailings pressure filtration separation filter cloth

A technology of bauxite and filter cloth, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problem of high floating content in filtrate, single filter press filter cloth material and manufacturing process, refractory tailings two The need for secondary dehydration and other problems, to achieve the effect of short pressing time and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

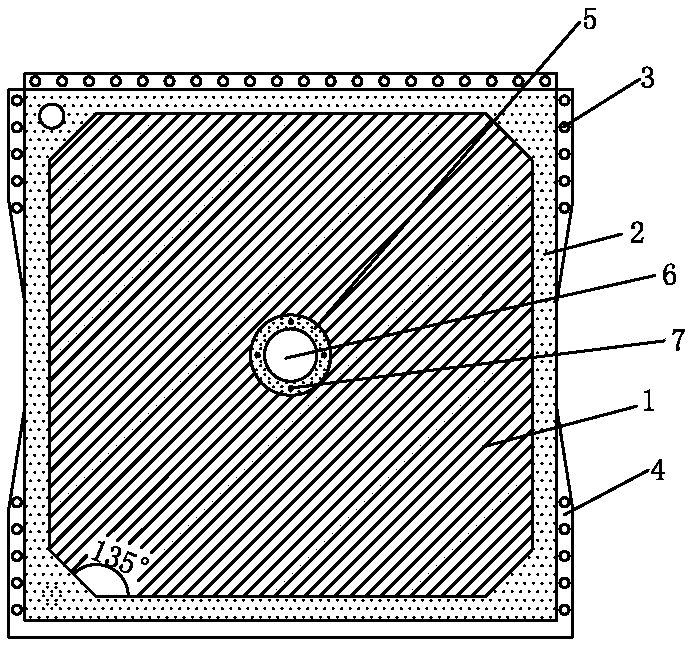

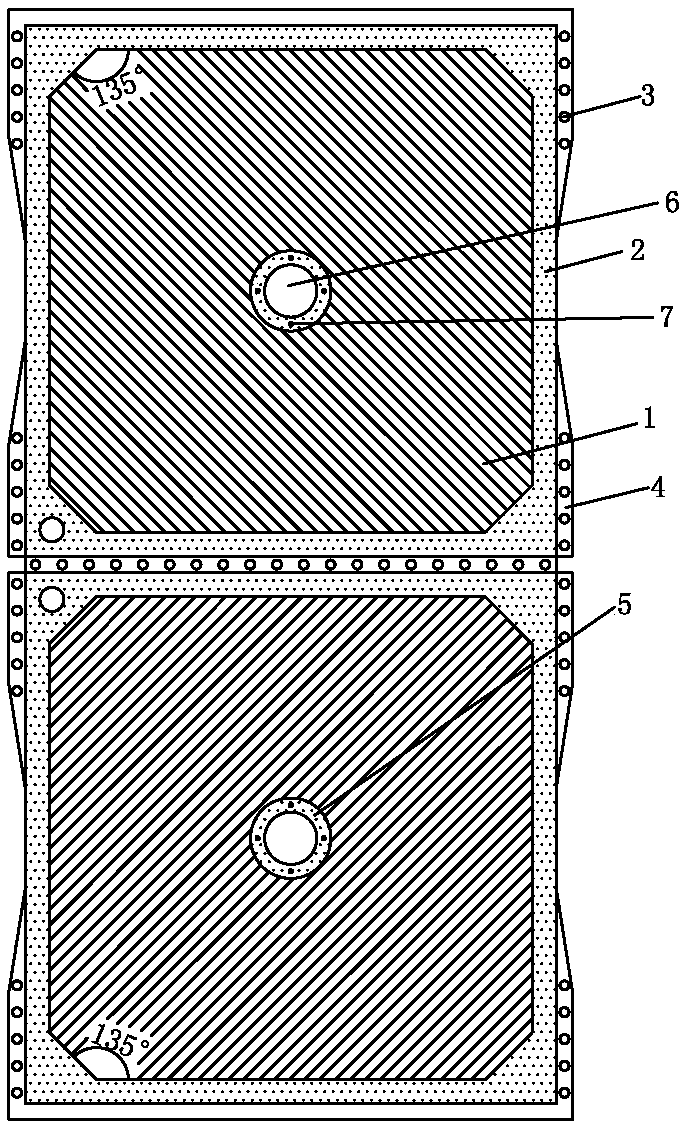

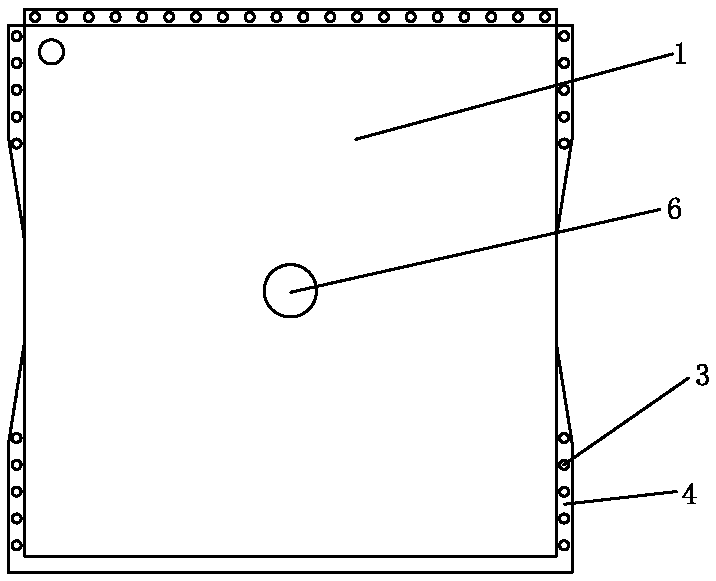

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Depend on Figure 1-Figure 4 Given, the specific steps of the manufacturing method of the bauxite positive flotation tailings press filtration separation filter cloth of the present invention are: the first layer is a polypropylene multifilament plain filter cloth 1, the second layer is a non-woven filter cloth 2, The first layer is a square, and there are fixed sides 4 extending horizontally outward on the upper, lower and left and right sides of the square, and there are symmetrical trapezoidal grooves in the center of the fixed sides on the left and right sides, and the upper side on the outer side of the upper side. There are fixed holes 3 evenly distributed on the fixed sides and the fixed sides on the left and right sides. The center of the square has a circular central hole 6. The second layer is placed on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com