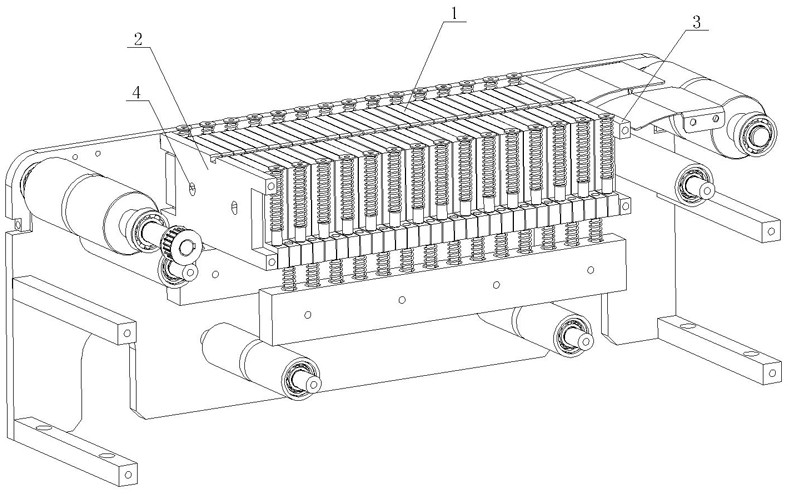

Upper and outsole press-fit workbench

A technology for shoe uppers and platform brackets, which is applied to footwear, bonding shoe parts, shoe-making machinery, etc., can solve the problems of long lamination time, cumbersomeness, cost, etc., and achieves high lamination support strength, guarantees lamination quality, The effect of short pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

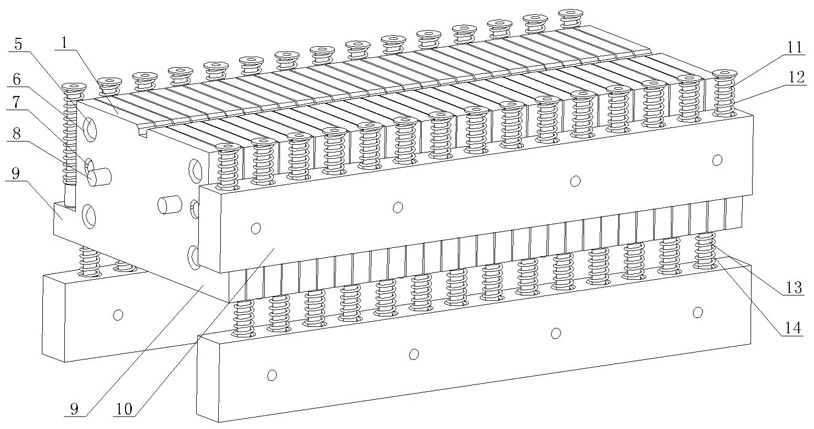

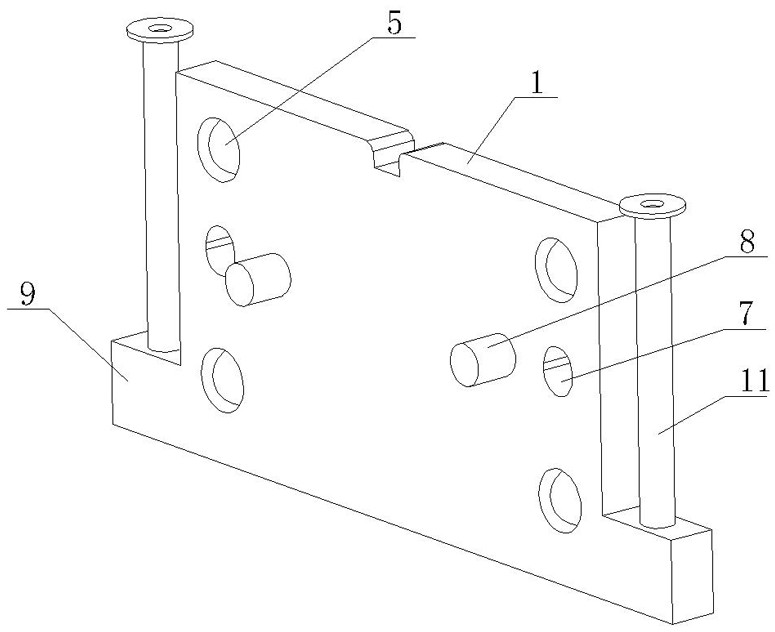

[0018] As shown in the figure, the shoe upper and outsole pressing workbench of the present invention includes a platform support and a floating block group arranged on the platform support. The floating block group is composed of twenty-nine floating blocks 1 arranged longitudinally. The thickness of the floating block 1 is 6mm, and the adjacent floating blocks 1 move up and down relative to each other. The floating block 1 is supported by springs, and the corresponding springs of the two adjacent floating blocks are staggered up and down, that is, some of them float. The block is correspondingly provided with two springs 12 on its left and right sides, and the springs 12 are sleeved on the vertical guide rod 11, and the vertical guide rod 11 is fixedly installed on the left and right sides of the floating block, and other floating blocks are correspondingly installed There are two springs 14, and the springs 14 are sleeved on the vertical guide rod 13, and the vertical guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com