Forming method and device of anisotropic neodymium iron boron bonded permanent magnet

An anisotropic and bonded magnet technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of difficult control of explosion parameters and poor safety of explosive explosion molding, so as to shorten the production cycle and avoid Difficulty in fabrication, effects of improved density and magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

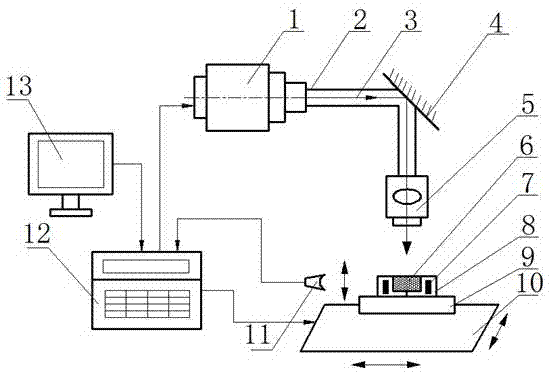

[0026] Example: uniformly mix anisotropic NdFeB magnetic powder with 0.5wt% binder and 0.15wt% curing agent, then put it into a split mold 8 with an inner diameter of φ4mm and a height of 5mm, and vibrate while loading Real, and at the same time apply a 1.2T magnetic field treatment, heating to a temperature of 110°C with a resistor 7. The parameters of the laser pulse beam 3 are that the spot diameter is φ4mm, the wavelength is 532nm, the pulse width is 8ns, and the energy of the laser pulse is 200mJ. After the above-mentioned laser-induced shock wave punching, after cooling in the split mold 8 for 45min, a φ4mm ×4mm anisotropic bonded NdFeB magnet, the magnet properties are: remanence Br=0.725T (Tesla), intrinsic coercive force jHc=689KA / m, maximum energy product (BH) max=85KJ / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com