High-dryness squeezing method for sludge

A high-dry, sludge technology, applied in the direction of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of increasing dehydration time, high moisture content of mud cake, reducing production, etc., to achieve crushing Short time, good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

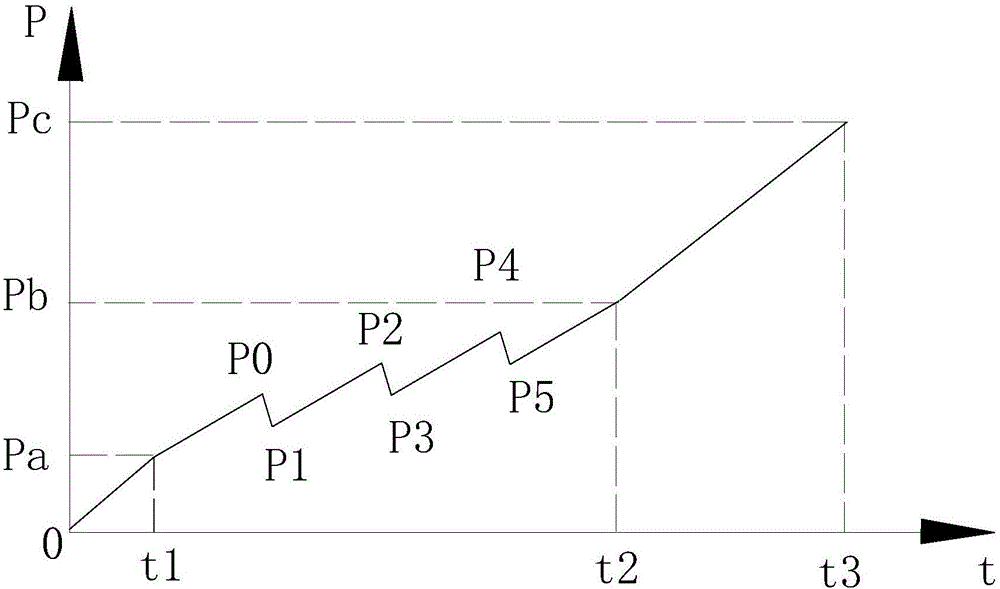

[0008] like figure 1 As shown, a sludge high-dry pressing method, this method uses a filter press to perform high-dry dehydration on the mud obtained after the sludge modification treatment, and the pressure value P applied by the filter press increases linearly with time t After the wave changes again, it increases linearly. The pressure value P of the filter press of the present invention increases linearly first, and part of the water in the sludge is quickly pressed out. At this time, the water content on the outer surface of the mud cake is low, but the water content inside the mud cake is still very high; at this time The fluctuating change of the pressure value P causes the sludge to be periodically compacted and relaxed, which is beneficial to the separation and extrusion of the sludge, capillary water, and interstitial water, so that the moisture content of the inner and outer surfaces of the mud cake tends to be consistent; the final pressure value P then changes li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com