Method for continuously generating fine gutta-percha through digestion-reextraction

A technology of eucommia gum and back-extraction liquid is applied in fertilizers made of biological waste, pharmaceutical formulations, medical preparations containing active ingredients, etc. High rate, low consumption, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

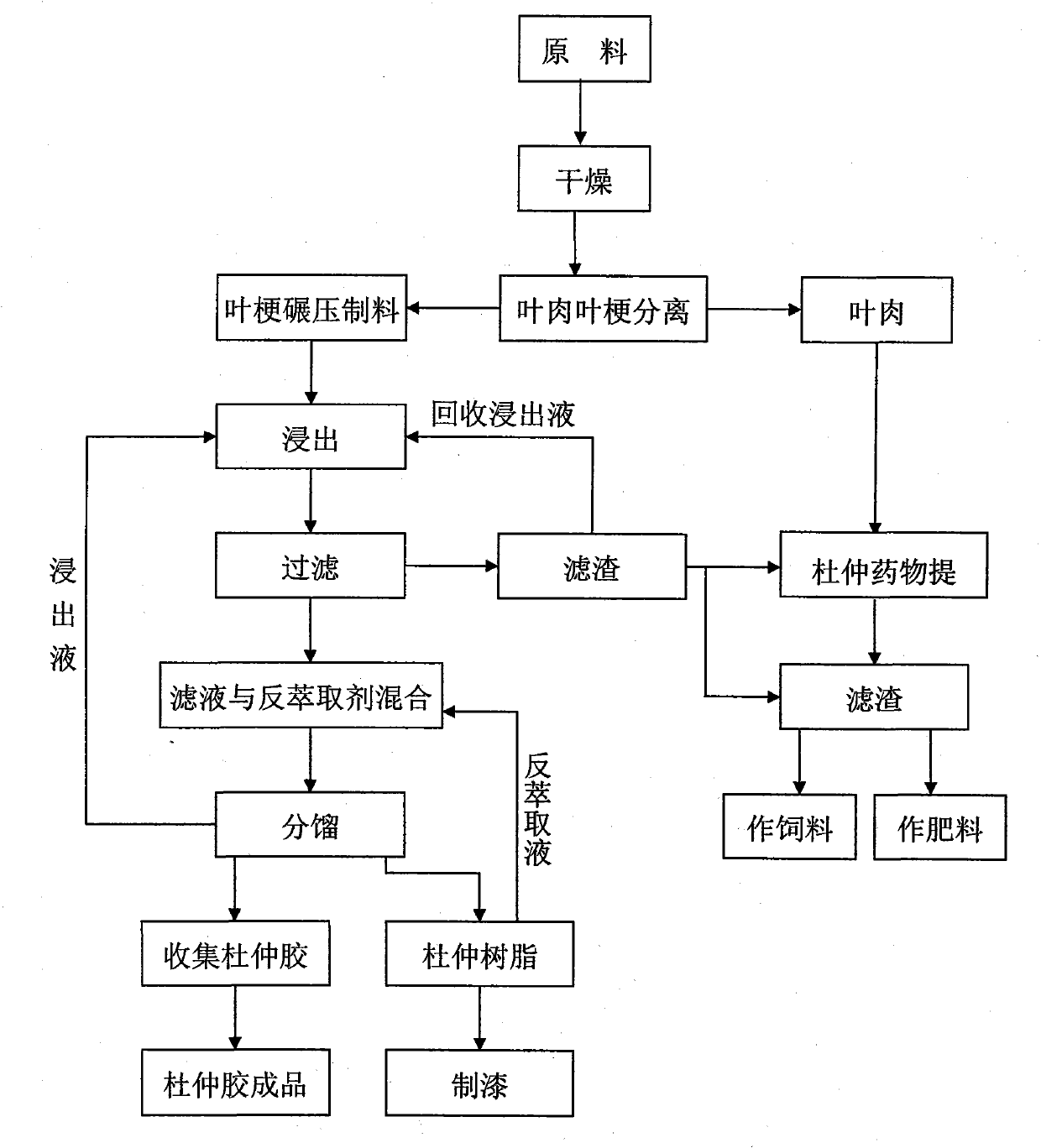

[0034] Embodiment produces Eucommia gum according to the following steps:

[0035] 1. Air-dry Eucommia leaves naturally to reduce the water content of the leaves;

[0036] 2. Put the air-dried leaves into the microwave drying through the belt conveyor to remove the remaining moisture;

[0037] 3. Transporting the dried leaves to an improved low-power axial flow fan with a blade aspect ratio of 1:10 to peel off the mesophyll and the leaf stem, and then separate the mesophyll from the leaf stem through a cyclone separator;

[0038] 4. Send the leaf stalks to the roller press with a belt conveyor. After several times of rolling, the leaf stalks form thin pieces and then cut into strips with a large noodle cutter. The strips are cut into 5mm-10mm by a shearing machine Small sections are continuously sent into the leaching tank by a belt conveyor;

[0039] 5 In a leaching tank filled with chloroform, heat the mixed material to 52°C ± 1°C, and continuously leaching for 2.5 hours u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com