Heat-resistant poly(butylenes succinate) and preparation method thereof

A technology of polybutylene succinate and succinic acid, which is applied in the field of polymer materials, can solve the problems of small improvement of heat resistance, large amount of nucleating agent added, complicated process, etc., so as to improve the heat resistance. , the effect of high molecular weight and simple polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

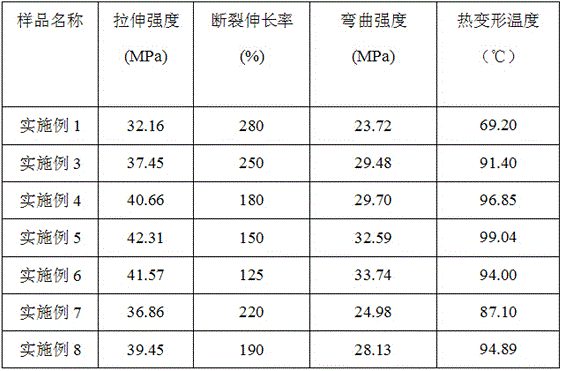

Examples

Embodiment 1

[0026] Add 6.86Kg succinic acid and 7.32Kg 1,4-butanediol into the reaction kettle, stir evenly to carry out esterification reaction, control the temperature at 230~250°C, wait until the water output reaches 90% of the theoretical water output, and the esterified product is transparent The reaction was complete upon clarification. Add 28g of tetrabutyl titanate dropwise to the esterified product to start polycondensation, the pre-shrinkage vacuum degree is 2000~5000Pa, and the final polycondensation vacuum degree is 20~300Pa. The temperature is controlled at 230~260°C until the stirring current stops rising, the polycondensation stage is completed, and a white polymer is obtained. The number average molecular weight measured by GPC test method is 47,300, and the molecular weight distribution is 1.98.

Embodiment 2

[0028] Add 6.86Kg succinic acid and 7.32Kg 1,4-butanediol into the reaction kettle, stir evenly to carry out esterification reaction, control the temperature at 230~250°C, wait until the water output reaches 90% of the theoretical water output, and the esterified product is transparent The reaction was complete upon clarification. Add 28g of tetrabutyl titanate dropwise to the esterified product, add 600g of inorganic nucleating agent talc powder, and start polycondensation. The vacuum degree of pre-shrinkage is 2000~5000Pa, and the vacuum degree of final polycondensation is 20~300Pa. The temperature is controlled at 230~260°C until the stirring current stops rising, the polycondensation stage is completed, and a white polymer is obtained. The number average molecular weight measured by GPC test method is 69,800, and the molecular weight distribution is 1.96. Wherein, the molar ratio of the hydroxyl group to the carboxyl group of the polymerized monomer is 1.4, and the theore...

Embodiment 3

[0032] Add 6.86Kg succinic acid and 7.32Kg 1,4-butanediol into the reaction kettle, stir evenly to carry out esterification reaction, control the temperature at 230~250°C, wait until the water output reaches 90% of the theoretical water output, and the esterified product is transparent The reaction was complete upon clarification. Add 28g of tetrabutyl titanate dropwise to the esterified product, add 600g of inorganic nucleating agent talc powder, and start polycondensation. The vacuum degree of pre-shrinkage is 2000~5000Pa, and the vacuum degree of final polycondensation is 20~300Pa. The temperature is controlled at 230~260°C. When the stirring current reaches a certain value, the reaction is terminated and a white polymer is obtained. The number average molecular weight measured by GPC test method is 18,900, and the molecular weight distribution is 1.62. Wherein, the molar ratio of the hydroxyl group to the carboxyl group of the polymerized monomer is 1.4, and the theoretic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com