Preparation method and application of cross-linked resin modified by imidazole

A technology of cross-linking resin and imidazole is applied in the field of functional polymer synthesis, which can solve the problems of unsatisfactory adsorption performance of polar organic substances in water, and achieve the effects of improving adsorption performance, improving pore structure and good selective adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Preparation of precursor resin:

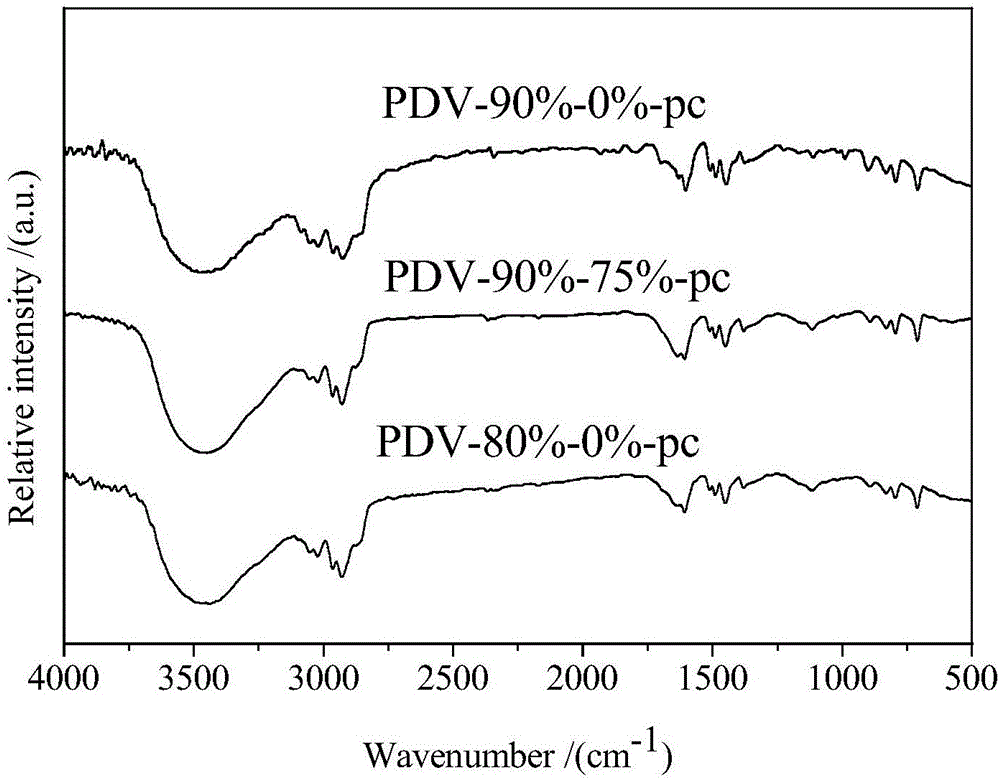

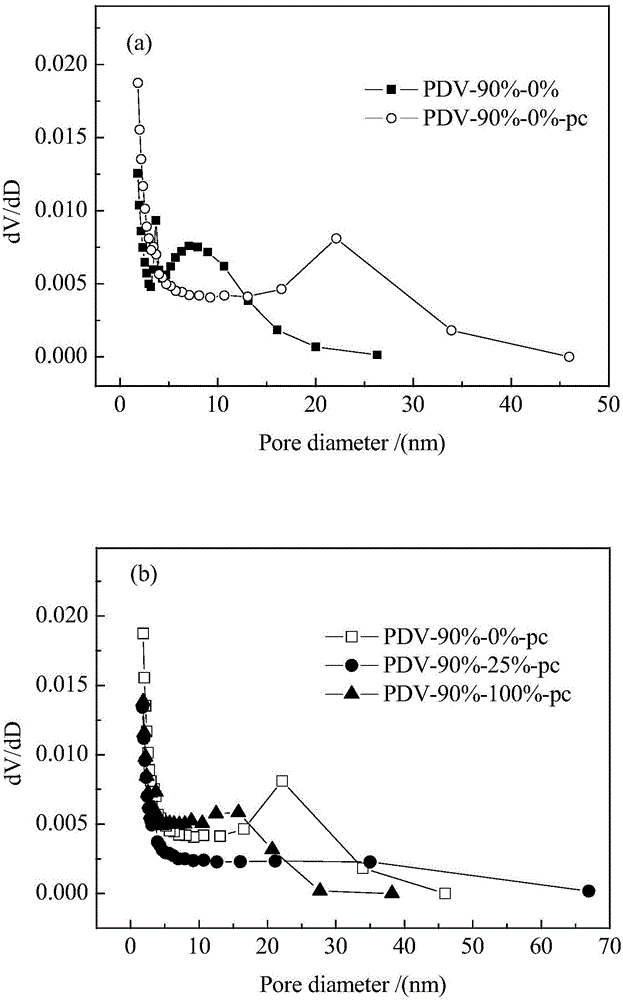

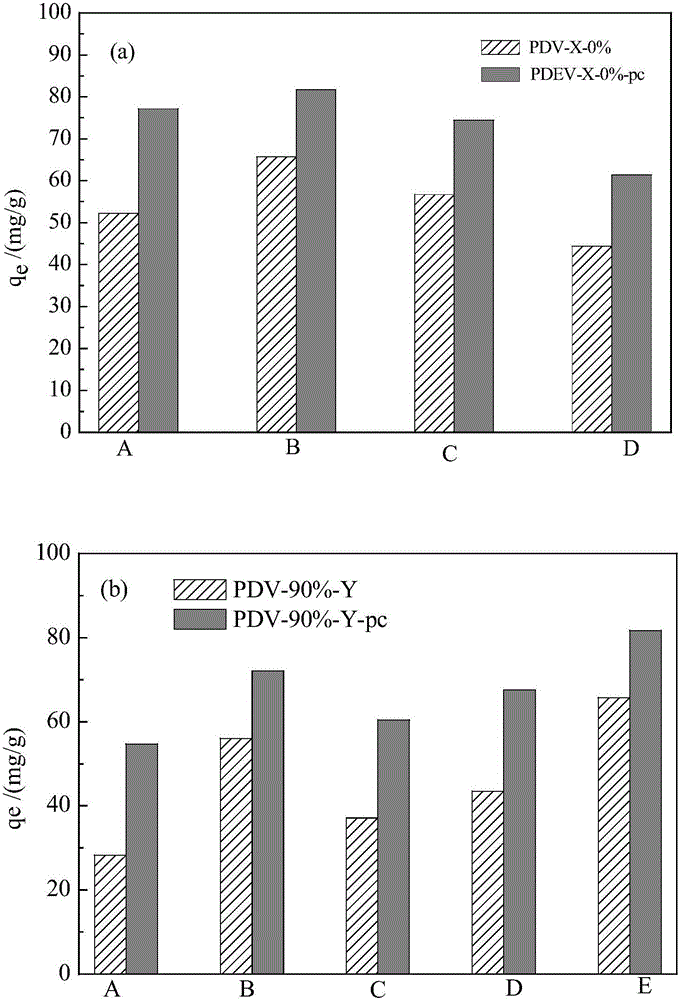

[0045] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. A mixture of 20 g of divinylbenzene (DVB) and 1-vinylimidazole (VIM), a mixed solvent of 40 g of o-xylene and benzyl alcohol, and 0.2 g of azobisisobutyronitrile (AIBN) were added. Heat to 45°C, adjust to a suitable stirring speed and stir for 30min, raise the temperature to 75°C for 3h, raise the temperature to 85°C for 3h, continue to raise the temperature to 95°C for 3h. After cooling, alternately wash the resin with absolute ethanol, hot water, and cold water until the washing solution is clear, extract it with petroleum ether in a Soxhlet extractor for 12 hours, and dry it in vacuum for 24 hours to obtain the precursor resin PDV-90%-0%, PDV-90%-25% and PDV-90%-100%.

[0046] 2) Friedel-Crafts reaction:

[0047] Add 15g of precursor resins PDV-90%-0%, PDV-90%-25% and PDV-90%-100% and 50mL 1...

Embodiment 2

[0054] 1) Preparation of precursor resin:

[0055]Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. Add 20g of a mixture of divinylbenzene (DVB) and 2-methyl-1-vinylimidazole (MVIM); 60.0g of a mixed solvent of o-xylene and benzyl alcohol, and 0.2g of azobisisobutyronitrile (AIBN). Heat to 45°C, adjust to an appropriate stirring speed and stir for 30 minutes, raise the temperature to 68°C for 5 hours, raise the temperature to 78°C for 5 hours, and continue to heat up to 90°C for 5 hours. After cooling, alternately wash the resin with absolute ethanol, hot water, and cold water until the washing solution is clear, extract it with petroleum ether in a Soxhlet extractor for 12 hours, and dry it in vacuum for 24 hours to obtain the precursor resin PDMV-95%-20%, PDMV-85%-50% and PDMV-70%-80%.

[0056] 2) Friedel-Crafts reaction:

[0057] Add 15g of precursor resins PDMV-95%-20%, PDMV-85%-50% and PD...

Embodiment 3

[0064] 1) Preparation of precursor resin:

[0065] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. A mixture of 20 g of divinylbenzene (DVB) and 2-ethyl-1-vinylimidazole (EVIM), a mixed solvent of 20.0 g of o-xylene and benzyl alcohol, and 0.2 g of azobisisobutyronitrile (AIBN) were added. Heat to 45°C, adjust to an appropriate stirring speed and stir for 30 minutes, raise the temperature to 68°C for 5 hours, raise the temperature to 78°C for 5 hours, and continue to heat up to 90°C for 5 hours. After cooling, alternately wash the resin with absolute ethanol, hot water, and cold water until the washing liquid is clear, extract it with petroleum ether in a Soxhlet extractor for 12 hours, and dry it in vacuum for 24 hours to obtain the precursor resin PDEV-90%-90%, PDEV-80%-60% and PDEV-70%-30%.

[0066] 2) Friedel-Crafts reaction:

[0067] Add 15g of precursor resins PDEV-90%-90%, PDEV-80%-60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com