Electrostatic spinning directional nanofiber membrane and preparation method and application thereof

A nanofiber membrane, electrospinning technology, applied in electrospinning, fiber processing, filament/line forming and other directions, can solve the disadvantages of the application prospect of polyimide nanofiber membrane lithium battery separator, the poor porosity of fiber membrane. Uniform, uneven pore size, etc., to achieve the effect of uniform pore size, low cost, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of nanofibrous membrane with PMDA---ODA as raw material and DMPA as solvent

[0028] (1) Dissolve 0.674g ODA in 6ml DMAC, after it is completely dissolved, add 0.64g PMDA three times at low temperature. Stir mechanically at low temperature for 24 hours.

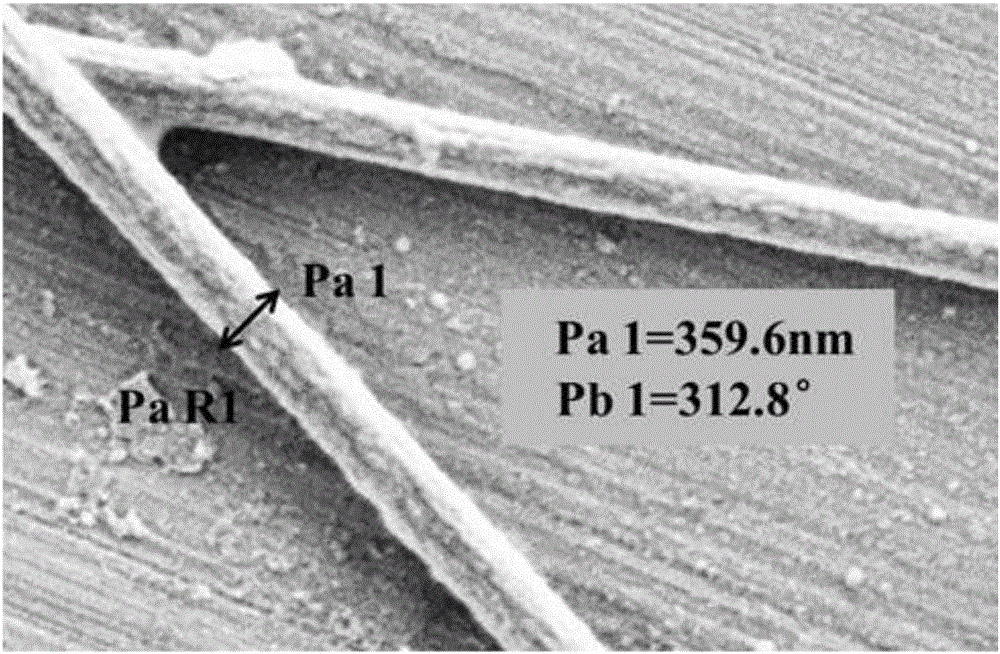

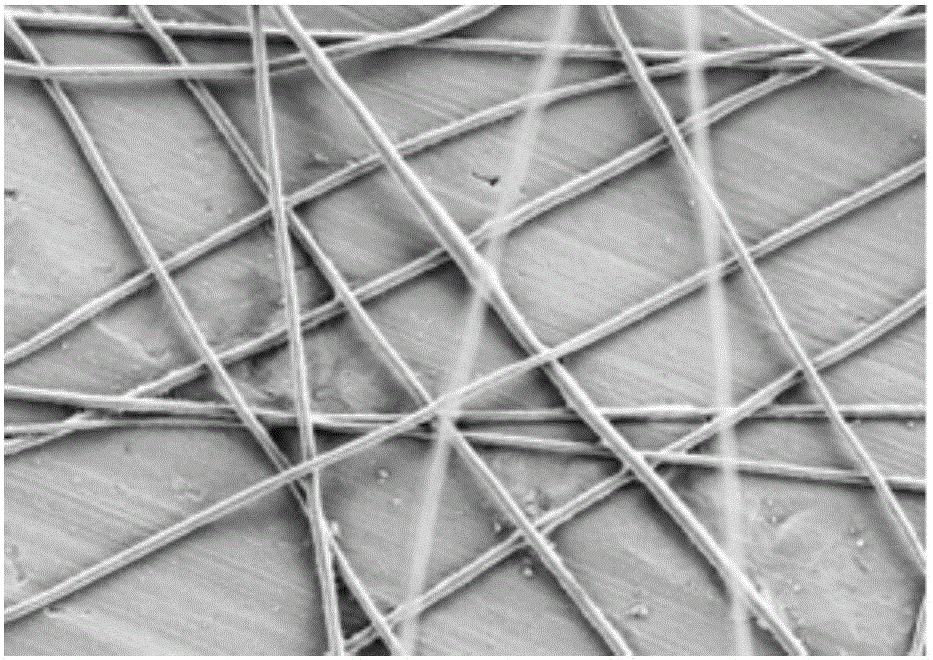

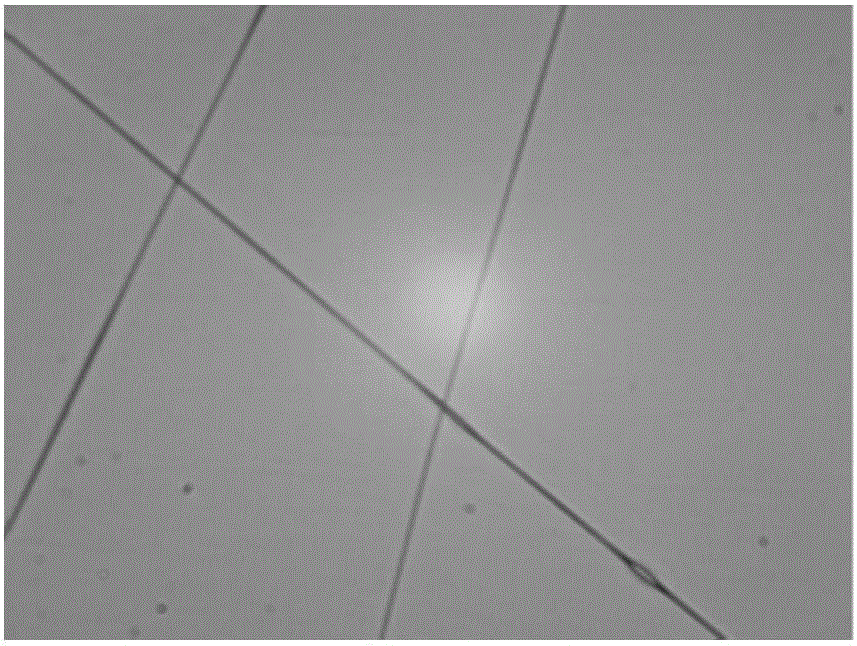

[0029] (2) Electrospinning was performed in a self-made electrospinning device, and the electrospinning parameters were: DMAC as a solvent, a spinning voltage of 18Kv, a collection distance of 12cm, and a No. 10 spinning needle. The rotation parameter of the receiving drum device: 2000r / min. The electrospinning flow rate is 0.8ml / h, and the electrospinning time is one hour.

[0030] (3) The prepared polyamic acid nanofiber membrane is imidized, and the high-temperature thermal imidization adopts the following steps: 1) Heating from room temperature to 170°C, the heating rate is about 10°C / min, and staying at 170°C for 30 minutes ; 2) Then raise the temperature to 250°C and stay for 30 minutes; 3) Rapidly...

Embodiment 2

[0032] Preparation of nanofibrous membrane with PMDA---bisphenol A (BPA) as raw material and DMPA as solvent

[0033] (1) Dissolve 0.65g of BPA in 6ml of DMAC. After it is completely dissolved, add 0.64g of PMDA in three times at low temperature. Stir mechanically at low temperature for 24 hours.

[0034] (2) Electrospinning was performed in a self-made electrospinning device, and the electrospinning parameters were: DMAC as a solvent, a spinning voltage of 18Kv, a collection distance of 12cm, and a No. 10 spinning needle. The rotation parameter of the receiving drum device: 2000r / min. The electrospinning flow rate is 0.8ml / h, and the electrospinning time is one hour.

[0035] (3) The prepared polyamic acid nanofiber membrane is imidized, and the high-temperature thermal imidization adopts the following steps: 1) Heating from room temperature to 170°C, the heating rate is about 10°C / min, and staying at 170°C for 30 minutes ; 2) Then raise the temperature to 250°C and stay f...

Embodiment 3

[0037] Preparation of nanofibrous membrane with PMDA---BPA as raw material and DMF as solvent

[0038] (1) Dissolve 0.65g of BPA in 6ml of DMF, after it is completely dissolved, add 0.64g of PMDA in three times at low temperature. Stir mechanically at low temperature for 24 hours.

[0039] (2) Electrospinning was performed in a self-made electrospinning device, and the electrospinning parameters were: DMF as a solvent, a spinning voltage of 18Kv, a collection distance of 12cm, and a No. 10 spinning needle. The rotation parameter of the receiving drum device: 2000r / min. The electrospinning flow rate is 0.8ml / h, and the electrospinning time is one hour.

[0040] (3) The prepared polyamic acid nanofiber membrane is imidized, and the high-temperature thermal imidization adopts the following steps: 1) Heating from room temperature to 170°C, the heating rate is about 10°C / min, and staying at 170°C for 30 minutes ; 2) Then raise the temperature to 250°C and stay for 30 minutes; 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com