Nano photocatalyst of possessing function of molecular engram, preparation method and usage

A nano-photocatalyst and molecular imprinting technology, applied in separation methods, catalyst carriers, chemical instruments and methods, etc., can solve problems such as difficulty in obtaining high degradation efficiency, high migration or recombination rate, and low rate of product desorption, and achieve Improve indoor air quality, obvious economic benefits, and improve the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

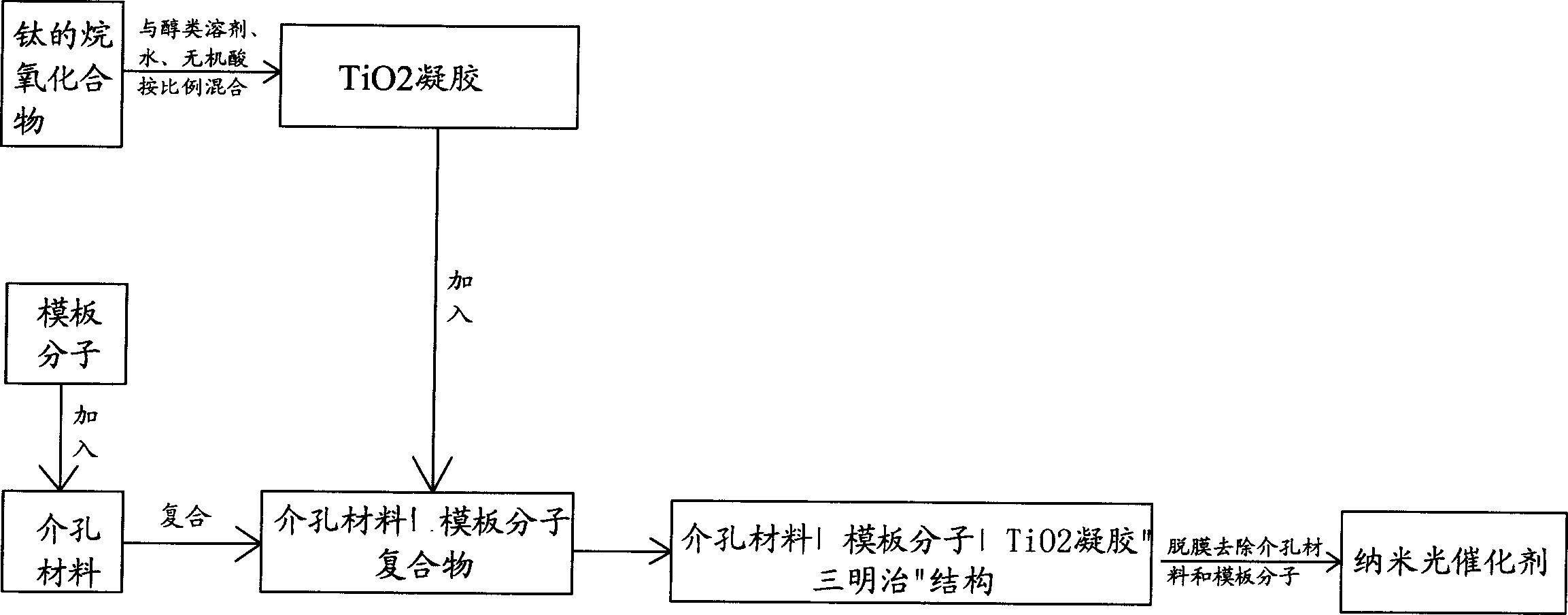

Method used

Image

Examples

Embodiment 1

[0042] (1) Formaldehyde is selected as the template molecule, and activated carbon is the mesoporous material;

[0043] (2) Adsorb formaldehyde on activated carbon to saturation, forming a complex of activated carbon|formaldehyde;

[0044] (3) With n-butyl titanate as the sol precursor, ethanol as the solvent, and protonic acid as the inhibitor, the sol-gel method is adopted, and the molar ratio of n-butyl titanate, ethanol, water, and protonic acid is 1: Mix 20:3:15 to make TiO 2 gel;

[0045] (4) the prepared TiO 2 The gel is coated on the surface of the activated carbon|formaldehyde composite prepared in (2) according to the molar ratio of n-butyl titanate:activated carbon of 1:15 to form activated carbon|formaldehyde|TiO 2 The "sandwich" structure of the gel;

[0046] (5) The "sandwich" structure obtained in (4) was calcined at 600°C for 4 hours, crushed, and activated carbon and formaldehyde were removed by demolding to form a nano-photocatalyst with specific adsorpti...

Embodiment 2

[0049] According to the step of embodiment 1, take benzene as the template molecule, activated carbon as the mesoporous material to prepare the composite of activated carbon|benzene; take n-butyl titanate as the gel precursor, follow the steps of n-butyl titanate, ethanol, water, The molar ratio of protonic acid is 1:2:10:3 mixed to prepare TiO 2 Gel; TiO 2 The gel is coated on the surface of the composite of activated carbon|benzene to form activated carbon|benzene|TiO 2 The "sandwich" structure of the gel is calcined at 350°C for 4 hours, and the activated carbon and benzene are removed by crushing and stripping to prepare a nano-photocatalyst with a specific adsorption and degradation function for benzene.

[0050] Taking formaldehyde and benzene as the target pollutants, the catalyst performance was evaluated in a continuous flow photocatalytic reaction system. The initial concentrations of formaldehyde and benzene in the system are both 10mg / m 3 , the humidity is 60%, ...

Embodiment 3

[0052] According to the steps of Example 1, take toluene as template molecule and activated carbon as mesoporous material to prepare activated carbon|toluene compound; take n-butyl titanate as gel precursor, follow n-butyl titanate, ethanol, water, The molar ratio of protonic acid is 1:5:5:8 and mixed to obtain TiO 2 Gel; according to the molar ratio of n-butyl titanate: activated carbon is 1: 2 2 The gel is coated on the surface of the composite of activated carbon|toluene to form activated carbon|toluene|TiO 2 The "sandwich" structure of the gel is calcined at 500 ° C for 4 hours, and the activated carbon and toluene are removed by crushing and defilming to prepare a nano-photocatalyst with specific adsorption and degradation functions for toluene.

[0053] Taking formaldehyde and toluene as the target pollutants, the catalyst performance was evaluated in a continuous flow photocatalytic reaction system. The initial concentrations of formaldehyde and toluene in the system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com