Preparation method of silane functionalized graphene aerogel material

An aerogel and functionalized technology, applied in the field of aerogel, can solve the problem of less research on the regulation and preparation of three-dimensional graphene pore size and surface properties, lack of inter-lamellar interaction mode and effective control and amplification of interface properties. Preparation and application prospects and other issues, to achieve the effect of non-toxic and pollution-free preparation process, improved mechanical properties, simple and safe preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

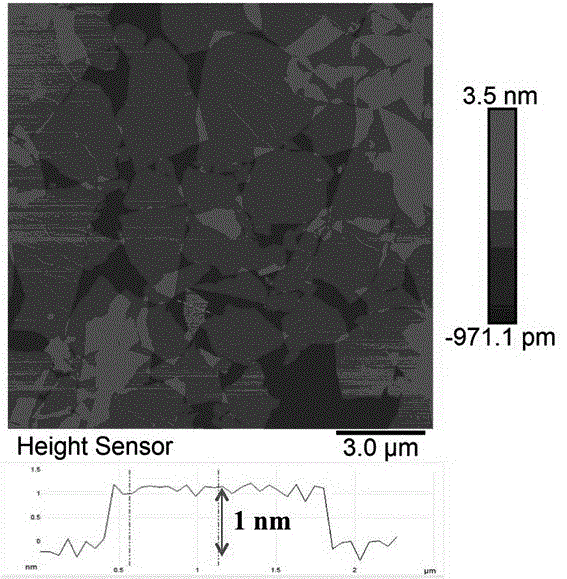

[0024] Disperse GO evenly in deionized water, configure 10 mL of 1 mg / mL GO aqueous solution, add ammonia water, adjust pH = 12, stir and mix evenly at room temperature for 10 min, then add 10 mg of γ-glycidyl etheroxypropyl trimethoxysilane KH560 , and stirred evenly for 10 minutes, then raised the temperature to 60° C. and maintained for 24 hours to obtain a functionalized graphene hydrogel. The hydrogel was added to ethanol and dialyzed for 24 hours, and then freeze-dried at -50°C with a vacuum of 10 Pa for 48 hours to prepare functionalized graphene airgel 1.

Embodiment 2

[0026] Disperse GO evenly in deionized water, configure 10mL of 2mg / mL GO aqueous solution, add NaOH, adjust pH=12, stir and mix evenly at room temperature for 5min, then add 400mg of γ-(methacryloyloxy)propyltrimethoxy base silane KH570, and stirred evenly for 5 minutes, then raised the temperature to 80°C and kept for 12 hours to prepare functionalized graphene hydrogel. The hydrogel was dialyzed with water for 6 hours, and then freeze-dried at -50°C with a vacuum of 5 Pa for 48 hours to prepare functionalized graphene airgel 2.

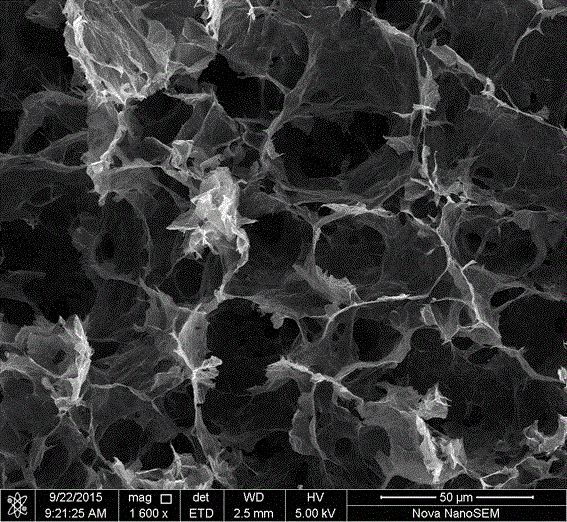

[0027] The SEM image of the silane (KH570) functionalized graphene airgel 2 prepared in Example 2, its internal structure is interlinked, foldable and other characteristics such as figure 2 shown.

Embodiment 3

[0029] Disperse GO evenly in deionized water, configure 10mL of 5mg / mL GO aqueous solution, add HI, adjust pH=1, stir and mix at room temperature for 20min, add 2.5mg of tridecafluorooctyltrimethoxysilane, and stir well After 20 minutes, the temperature was raised to 120°C and kept for 4 hours to obtain a functionalized graphene hydrogel. The hydrogel was dialyzed with water for 1 h, and then freeze-dried at -50° C. and vacuum at 0.3 Pa for 48 h to prepare silane-functionalized graphene airgel 3 .

[0030] The silane functionalized graphene airgel 3 prepared in embodiment 3 has superhydrophobicity such as image 3 As shown, the left figure is the graphene airgel 3 processed by tridecafluorooctyltrimethoxysilane prepared in Example 3, and the right figure is the untreated graphene airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com