A kind of method preparing potassium periodate

A technology of potassium iodate and potassium hydrogen iodate, which is applied in the direction of iodine oxygen compounds, can solve the problems of long operating hours, long working hours, and low efficiency, and achieve low equipment requirements, easy industrialization, and simple and safe preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

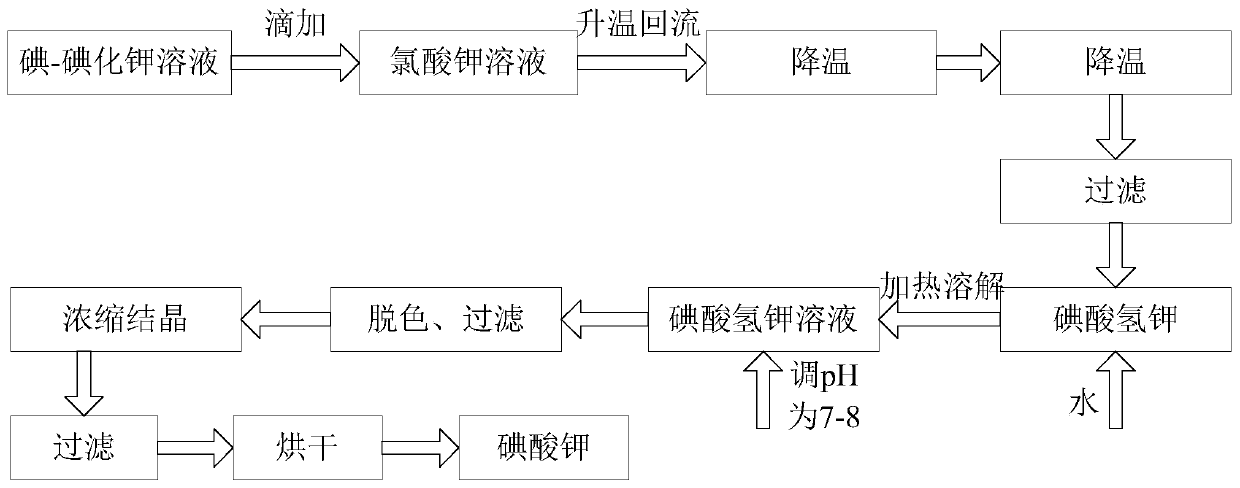

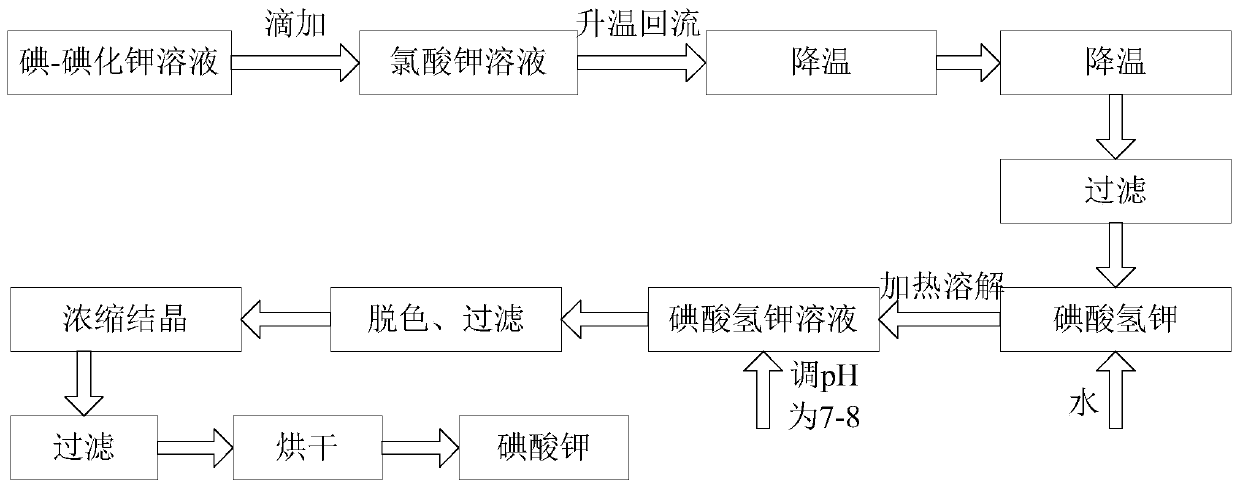

Method used

Image

Examples

preparation example Construction

[0033] a) Preparation of iodine-potassium iodide solution:

[0034] Dissolve crude iodine in potassium iodide solution to prepare iodine-potassium iodide solution;

[0035] b) Preparation of potassium hydrogen iodate:

[0036] Drop the iodine-potassium iodide solution prepared in step a) into the mixed solution of potassium chlorate and concentrated hydrochloric acid to obtain a potassium hydrogen iodate solution;

[0037] c) Preparation of potassium iodate:

[0038] The pH value of the potassium hydrogen iodate solution prepared in step b) is adjusted to 7-8 with potassium hydroxide, and potassium iodate is obtained by decolorization, crystallization, filtration and drying.

[0039] The above technical scheme uses crude iodine to prepare the iodine-potassium iodide solution, which solves the problem that the direct feeding of crude iodine cannot accurately measure the iodine content; the feeding method of dissolving and adding iodine is adopted to improve the solid iodine feeding. Chlo...

Embodiment 1

[0056] Preparation of iodine-potassium iodide solution:

[0057] Dissolve crude iodine in potassium iodide solution to prepare iodine-potassium iodide solution;

[0058] The molar ratio of crude iodine to potassium iodide solution is 1:1; the mass concentration of potassium iodide in the potassium iodide solution is 40%.

[0059] Preparation of potassium hydrogen iodate:

[0060] b1) After adding potassium chlorate to the water and mixing uniformly, then adding concentrated hydrochloric acid, and heating the temperature of the solution to 80°C after mixing uniformly to obtain a mixed solution of potassium chlorate and concentrated hydrochloric acid;

[0061] b2) Add dropwise the iodine-potassium iodide solution obtained in step a) to the mixed solution of potassium chlorate and concentrated hydrochloric acid obtained in step a). After the dropwise addition is completed, heat the temperature to 100°C and reflux for 1 hour. After cooling to room temperature, filter Obtain potassium hydro...

Embodiment 2

[0069] Preparation of iodine-potassium iodide solution:

[0070] Dissolve crude iodine in potassium iodide solution to prepare iodine-potassium iodide solution;

[0071] The molar ratio of crude iodine to potassium iodide solution is 1.5:1; the mass concentration of potassium iodide in the potassium iodide solution is 60%.

[0072] Preparation of potassium hydrogen iodate:

[0073] b1) After adding potassium chlorate to the water and mixing uniformly, add concentrated hydrochloric acid, and after mixing uniformly, heat the temperature of the solution to 95°C to obtain a mixed solution of potassium chlorate and concentrated hydrochloric acid;

[0074] b2) Add dropwise the iodine-potassium iodide solution obtained in step a) to the mixed solution of potassium chlorate and concentrated hydrochloric acid obtained in step a). After the dropwise addition is completed, heat the temperature to 100°C and reflux for 1 hour. After cooling to room temperature, filter Obtain potassium hydrogen ioda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com