Preparation method of antibacterial self-cleaning fabric

A self-cleaning and fabric technology, applied in the field of antibacterial self-cleaning fabric preparation, can solve the problems of low self-cleaning durability, unsatisfactory light absorption range and catalytic efficiency of nano-titanium dioxide, and poor interaction, etc., and achieve the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

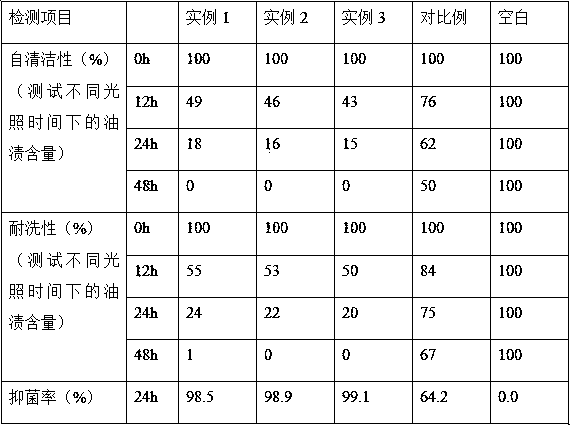

Examples

example 1

[0027] Put 20mL silver nitrate solution with a mass fraction of 25% and 30mL sodium citrate solution with a mass fraction of 20% into a one-mouth bottle, start stirring with a magnetic stirrer at a speed of 600r / min, and then add 2mL mass fraction The sodium borohydride solution with a fraction of 10% was stirred for 2 minutes and allowed to stand for 2 hours to obtain a silver seed solution; Add the above-mentioned silver crystal seed solution to deionized water, continue to add deionized water to dilute to 100mL, and obtain an activated reducing solution; cut a 15cm×15cm pure cotton fabric, soak the pure cotton fabric in the above-mentioned activated reducing solution for 2 hours, and obtain an activated reducing solution. Cotton fabric, hang the activated cotton fabric in the center of the airtight container, heat the airtight container to 200°C under the atmosphere of propylene gas, keep it warm for 4 hours, take it out, and obtain the modified cotton fabric; add 50mL of ab...

example 2

[0029] Put 22mL of silver nitrate solution with a mass fraction of 25% and 35mL of a sodium citrate solution with a mass fraction of 20% into a one-mouth bottle, start stirring with a magnetic stirrer at a speed of 650r / min, and then add 2.3mL of The sodium borohydride solution with a mass fraction of 10% was stirred for 2.5 minutes and left to stand for 2.5 hours to obtain a silver seed solution; Dissolve ammonium in deionized water and add the above-mentioned silver crystal seed solution, continue to add deionized water to dilute to 110mL to obtain an activated reducing solution; cut a 15cm×15cm pure cotton fabric, and soak the pure cotton fabric in the above activated reducing solution After 2.5 hours, the activated cotton fabric was obtained, and the activated cotton fabric was suspended in the center of the airtight container, and the airtight container was heated to 250°C under the atmosphere of propylene gas, and kept for 4.5 hours, and the modified cotton fabric was obt...

example 3

[0031] Put 25mL of silver nitrate solution with a mass fraction of 25% and 40mL of a sodium citrate solution with a mass fraction of 20% into a one-mouth bottle, start stirring with a magnetic stirrer at a speed of 700r / min, and then add 3mL of The sodium borohydride solution with a fraction of 10% was stirred for 3 minutes and allowed to stand for 3 hours to obtain a silver seed solution; 1.2 g of polyvinylpyrrolidone, 3 g of L-type ascorbic acid, and 1.5 g of cetyltrimethylammonium bromide were dissolved in Add the above-mentioned silver crystal seed solution to deionized water, continue to add deionized water to dilute to 120mL, and obtain an activated reducing solution; cut a 15cm×15cm pure cotton fabric, soak the pure cotton fabric in the above-mentioned activated reducing solution for 3 hours, and obtain an activated reducing solution. Cotton fabric, hang the activated cotton fabric in the center of the airtight container, heat the airtight container to 300°C under the at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com