Nickel catalyst for grease hydrogenation and preparation method thereof

A nickel catalyst, oil hydrogenation technology, applied in fatty acid hydrogenation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of chemical and filtering performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

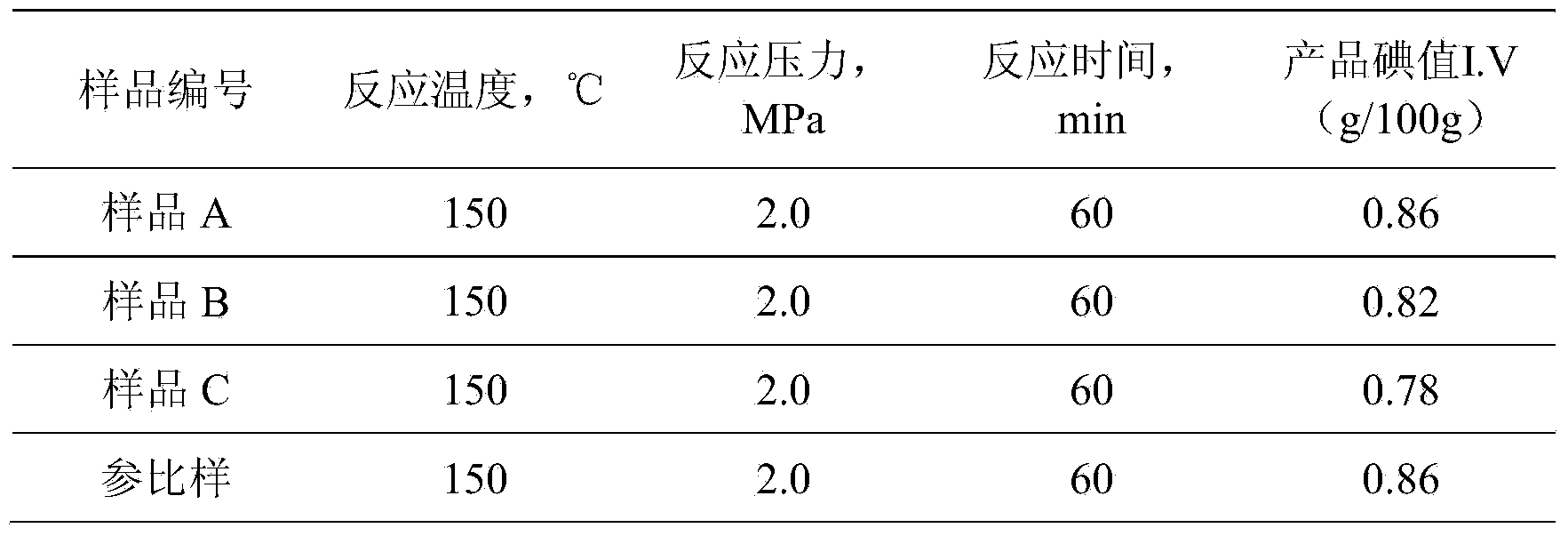

Examples

Embodiment 1

[0017] Weigh 200g of ethyl orthosilicate, add 200g of deionized water under magnetic stirring at room temperature, and hydrolyze for 1.5h; dissolve 8g of ethyl titanate in 60g of absolute ethanol, add 50g of deionized water while stirring, and hydrolyze for 0.5h. Add the ethyl titanate solution dropwise to the tetraethyl orthosilicate solution, then heat the mixed solution to 85°C to remove the alcohol for 6 hours, and add 60ml of 0.1mol / L sulfuric acid solution. Put the above solution into the reaction kettle and raise the temperature to 170°C for crystallization, the crystallization time is 48h. The obtained white powder was washed to neutral, dried, and calcined at 500° C. for 4 hours. The obtained powder was ground and passed through a 100-mesh sieve to obtain a catalyst carrier.

[0018] Prepare 0.5mol / L Ni(NO 3 ) 2 ·6H 2 O aqueous solution 100ml; prepare 1.0mol / L Na 2 CO 3 Aqueous solution 1L, as alkaline precipitant solution; Weigh 22g carrier, 1.0gMo(NO 3 ) 3 .5...

Embodiment 2

[0021] Prepare 0.5mol / L Ni(NO 3 ) 2 ·6H 2 O aqueous solution 100ml; prepare 1.0mol / L Na 2 CO 3 Aqueous solution 1L, as alkaline precipitant solution; Take by weighing 15.5g carrier (synthetic steps are as described in Example 1), 2.0gMo(NO 3 ) 3 .5H 2 O mixed with 70ml of deionized water to obtain a carrier suspension; pour the carrier suspension into the reactor, move it into a constant temperature water bath at 70°C, slowly add the nickel salt solution and the alkaline precipitant solution dropwise, and the alkaline precipitant The dosage is based on controlling the pH of the endpoint solution to be 8.5. After the dropwise addition was completed, the mixture was aged at 70° C. for 3 hours. After cooling to room temperature, filter with suction, wash with deionized water until there is no acid ion, dry the filter cake at 100°C for 2 hours, and crush it to below 150 mesh.

[0022] Take 0.5g of the above fine powder and put it into the reduction reactor, and pass N at 5...

Embodiment 3

[0024] Prepare 0.5mol / L NiCl 2 ·6H 2 O aqueous solution 100ml; prepare 1.0mol / L NaHCO 3 Aqueous solution 1L, as alkaline precipitant solution; Take by weighing 12.5g carrier (synthetic steps are as described in Example 1), 2.0gMo(NO 3 ) 3 .5H 2 O mixed with 70ml of deionized water to obtain a carrier suspension; pour the carrier suspension into the reactor, move it into a constant temperature water bath at 70°C, slowly add the nickel salt solution and the alkaline precipitant solution dropwise, and the alkaline precipitant The dosage is based on controlling the pH of the end point solution to be 7.5. After the dropwise addition was completed, the mixture was aged at 70° C. for 3 hours. After cooling to room temperature, filter with suction, wash with deionized water until there is no acid ion, dry the filter cake at 100°C for 2 hours, and crush it to below 150 mesh.

[0025] Take 0.5g of the above fine powder and put it into the reduction reactor, and pass N at 500°C 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com