Method for preparing titanate, titanic acid and titanium dioxide

A technology of titanate and titanic acid, applied in the direction of titanium dioxide, alkali metal titanate, chemical instruments and methods, etc., can solve the problems of difficult recovery of nano-photocatalysts, low tap density of nano-materials, lack of nano-material electrodes, etc. , to achieve the effect of easy large-scale industrial production, easy control of process parameters and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

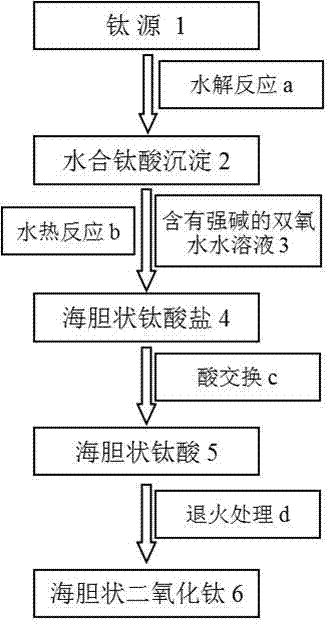

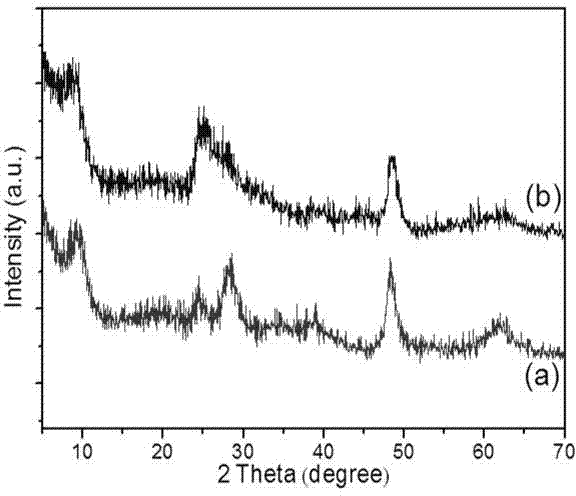

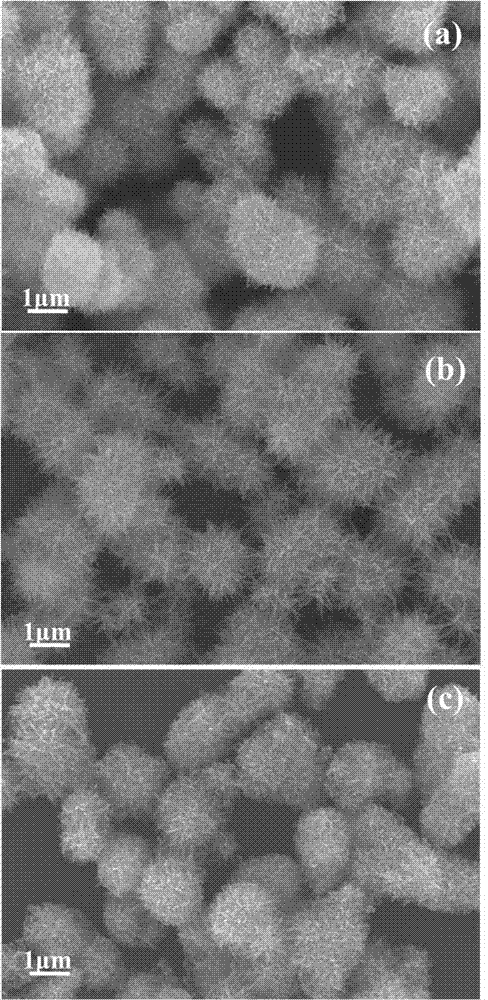

[0050] Please refer to figure 1 , under stirring conditions, disperse 0.5 g of titanium sulfate in 50 ml of deionized water, hydrolyze at room temperature to form hydrated titanic acid precipitate, centrifuge the above hydrated titanic acid precipitate, wash with 50 ml of deionized water three times, and centrifuge to obtain Hydrated titanic acid precipitates after washing. The hydrated titanic acid precipitate after washing was dispersed in 40 ml of an aqueous solution with a concentration of sodium hydroxide of 1 mole per liter and a concentration of hydrogen peroxide of 2%. After stirring for 1 hour, the mixed solution was transferred to a hydrothermal kettle, heated to 150° C., and kept at a constant temperature for 12 hours to prepare sea urchin-like sodium titanate with nano-micro hierarchical structure. The sea urchin-like sodium titanate solid was transferred to a beaker, ultrasonically dispersed, washed 5 times with deionized water, and centrifuged. Then add 0.01 mo...

Embodiment 2

[0059] Please refer to figure 1 , under stirring conditions, disperse 0.5 g of titanium sulfate in 50 ml of deionized water, hydrolyze at room temperature to form hydrated titanic acid precipitate, centrifuge the above hydrated titanic acid precipitate, wash with 50 ml of deionized water three times, and centrifuge to obtain Hydrated titanic acid precipitates after washing. The hydrated titanic acid precipitate after washing was dispersed in 40 ml of an aqueous solution with a concentration of sodium hydroxide of 1 mole per liter and a concentration of hydrogen peroxide of 2%. After stirring for 1 hour, the mixed solution was transferred to a hydrothermal kettle, heated to 150° C., and kept at a constant temperature for 12 hours to prepare sea urchin-like sodium titanate with nano-micro hierarchical structure. The sea urchin-like sodium titanate solid was transferred to a beaker, ultrasonically dispersed, washed 3 times with deionized water, and centrifuged. Then add 0.01 mo...

Embodiment 3

[0061] Please refer to figure 1 , under stirring conditions, disperse 1 gram of titanium sulfate in 50 ml of deionized water, hydrolyze at room temperature to form hydrated titanic acid precipitate, centrifuge the above hydrated titanic acid precipitate, wash with 50 ml of deionized water for 5 times, and centrifuge to obtain Hydrated titanic acid precipitates after washing. The hydrated titanic acid precipitate after washing was dispersed in 40 ml of an aqueous solution with a potassium hydroxide concentration of 2 moles per liter and a hydrogen peroxide concentration of 6%. After stirring for 1 hour, the mixed solution was transferred to a hydrothermal kettle, heated to 150° C., and kept at a constant temperature for 12 hours to prepare sea urchin-like potassium titanate with nano-micro hierarchical structure. The urchin-like potassium titanate solid was transferred to a beaker, ultrasonically dispersed, washed 5 times with deionized water, and centrifuged. Then add 0.1 mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com