UV light screen agent, uviorosistant fibric finishing agent and its finished fibric

An anti-ultraviolet, fabric finishing technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of affecting the hand and air permeability of fabrics, complex components, etc., to achieve excellent anti-ultraviolet performance, good affinity, and simple formulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

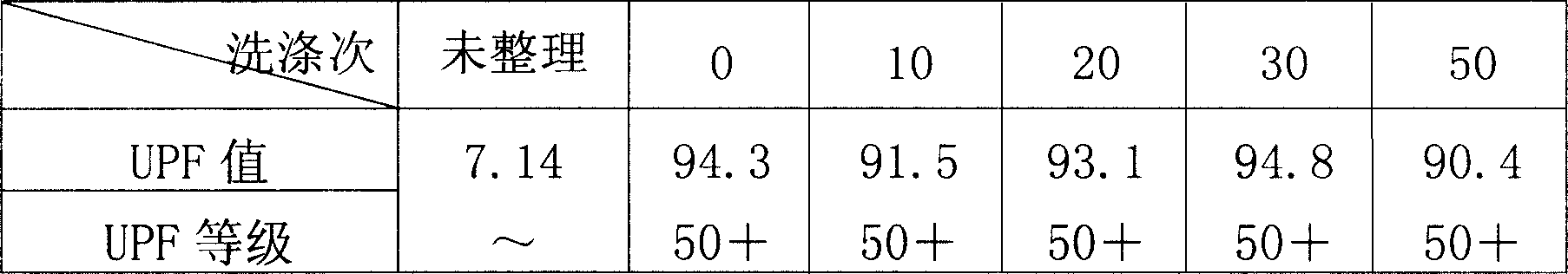

Image

Examples

Embodiment 1

[0040] Preparation of shielding agent and standard fabric finishing solution——

[0041] Add 30ml of hydrochloric acid to 865ml of water, stir evenly to make solution A; add 5ml of isopropanol to 100ml of titanium tetrachloride, stir evenly to make solution B; then slowly add solution B to In solution A, continue to stir, react for 2 hours, and age for 4 hours to obtain the water-based nano-titanium dioxide ultraviolet shielding agent, then add water at a ratio of 50.0% of the ultraviolet shielding agent, and mix evenly to obtain a standard fabric finishing solution .

Embodiment 2

[0043] Preparation of shielding agent and standard fabric finishing solution——

[0044] Add 3ml of sulfuric acid to 846ml of water and stir evenly to make solution A; add 1ml of butanediol to 150ml propyl titanate and stir evenly to make solution B; then react at 50°C to make solution A Obtain the water-based nano-titanium dioxide ultraviolet shielding agent, and then add water in the proportion of 35.0% of the ultraviolet shielding agent. All the other conditions are the same as in Example 1.

Embodiment 3

[0046] Preparation of shielding agent and standard fabric finishing solution——

[0047] Add 10ml of nitric acid to 880ml of water, stir evenly to make solution A; add 10ml of ethanol to 100ml butyl titanate, stir evenly to make solution B; the rest of the conditions are the same as in Example 2, and the described A water-based nano-titanium dioxide UV shielding agent. Then add water in the proportion of 80.0% of the ultraviolet shielding agent. All the other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com