Synthetic method for high-performance liquid-phase chromatography column packing materials

A technology of high performance liquid chromatography and synthesis method, which is applied in the field of synthesis of high performance liquid chromatography column packing material TiO2/MWCNTs, can solve the problems of limited application of metal oxide packing, complex surface properties, tailing of chromatographic peaks, etc. The effect of short cycle, low cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

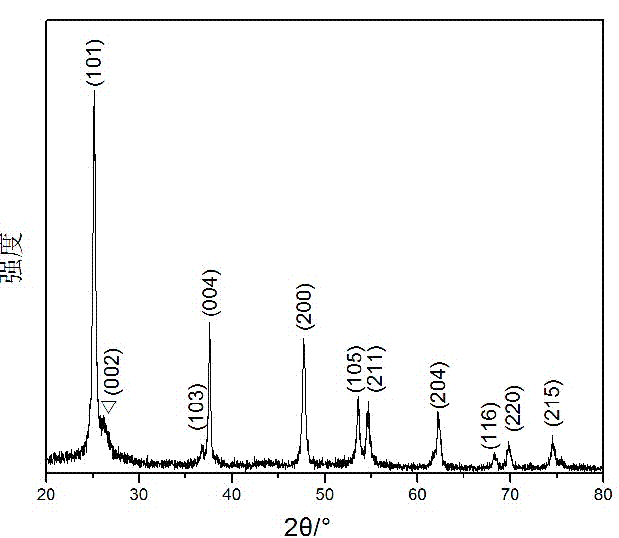

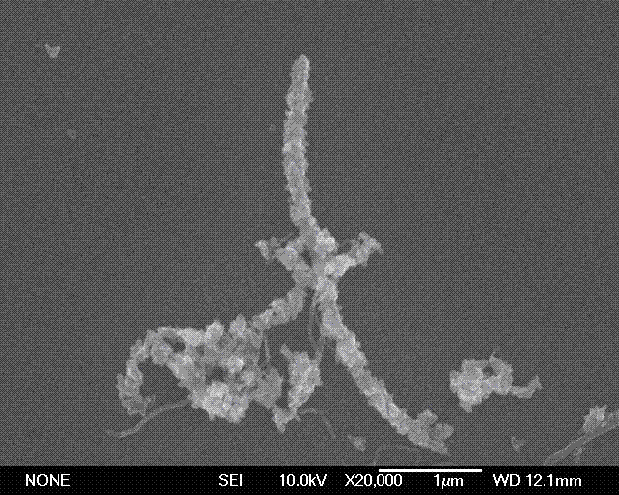

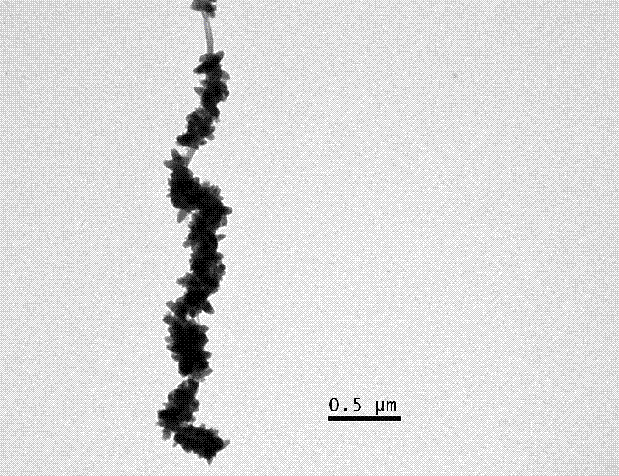

Examples

Embodiment 1

[0023] Concrete preparation steps:

[0024] a. Weigh 0.025 g MWCNTs with an electronic balance and add to 40 mL 0.08 mol / L TiF 4 aqueous solution, and ultrasonic for 30 min to make it evenly mixed;

[0025] b. Transfer the above solution into a self-made sealed bag, and place it in the irradiation area under the electron accelerator for irradiation, with an irradiation dose of 280 kGy;

[0026] c. Transfer the irradiated solution into a 200 mL beaker, seal it with parafilm and put it in an oven at 60 °C for 20 h;

[0027] d. wash the reaction product with water and ethanol successively;

[0028] e. Put the washed product in a vacuum oven at 60 °C for 6 h to obtain TiO 2 / MWCNTs composite filling material.

Embodiment 2

[0030] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is: weigh 0.050 g MWCNTs.

Embodiment 3

[0032] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is: weigh 0.075 g MWCNTs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com