Preparation method for hollow carbon/titanium dioxide composite nano material

A technology of composite nanomaterials and titanium dioxide, which is applied in the field of preparation of hollow carbon/titanium dioxide composite nanomaterials, can solve the problems of low catalytic reaction efficiency, low utilization rate of sunlight, cumbersome operation, etc., and avoid the cumbersome removal of hard templates, Achieve economical response and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Preparation of carbon-coated silica nanomaterials Reference: Antonio B. Fuertes, et al., Chem.Commun ., 2012, 48, 6124-6126. The specific steps are:

[0016] a. Measure 40 mL of a mixture of ethanol (ethanol) and deionized water (the volume ratio of ethanol and water is 2:1), add 1.3 mL of ammonia water (NH 3 ·H 2 O), mix evenly, and stir at 30 °C for 0.5 h; measure 1.4 mL tetraethyl orthosilicate (TEOS) and add it to the above solution, after mixing, weigh 0.2 g resorcinol with an electronic balance, add After completely dissolving, add 0.3 mL formaldehyde solution with a concentration of 37 wt%, and continue to react for 24 h;

[0017] b. Put the above mixed solution into a 100 mL autoclave lined with polytetrafluoroethylene, and react at 110 °C for 24 h; , drying and other steps to obtain the required template for the preparation of the present invention—carbon-coated silica nanomaterials;

Embodiment 1

[0019] a. Use an electronic balance to accurately weigh 0.1 g of the carbon-coated silica nanomaterial prepared in the previous step, add it to 10 mL of deionized water, and ultrasonically disperse it evenly;

[0020] b. Accurately weigh 2.5 mmol titanium tetrafluoride (TiF 4 ) into 10 mL of ethanol, ultrasonically dispersed evenly, and slowly dripped drop by drop into the suspension in the previous step under the condition of stirring. In a tetrafluoroethylene-lined autoclave, react at 180 °C for 6 h;

[0021] c. After the reaction is completed, the product is taken out from the reaction kettle, and the hollow carbon / titanium dioxide composite material prepared by the present invention is obtained through steps such as centrifugation, washing, drying, and roasting under a nitrogen-protected environment.

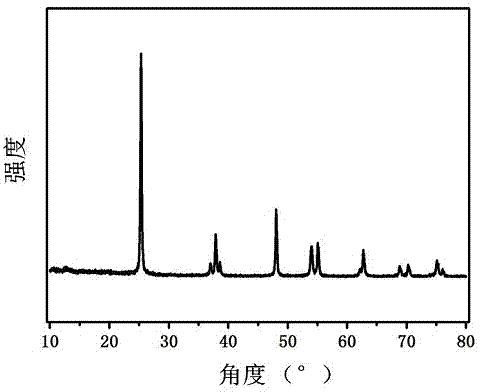

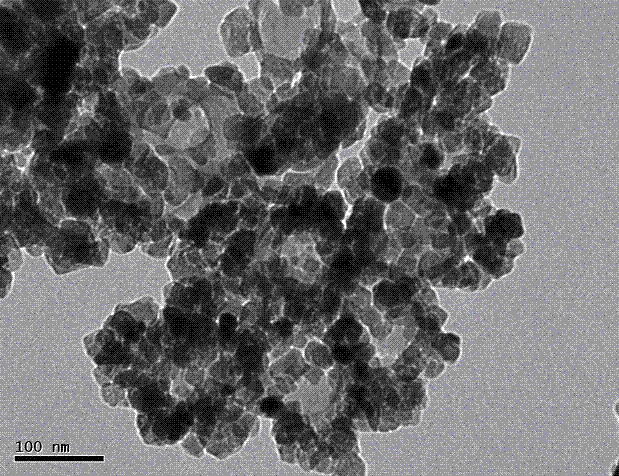

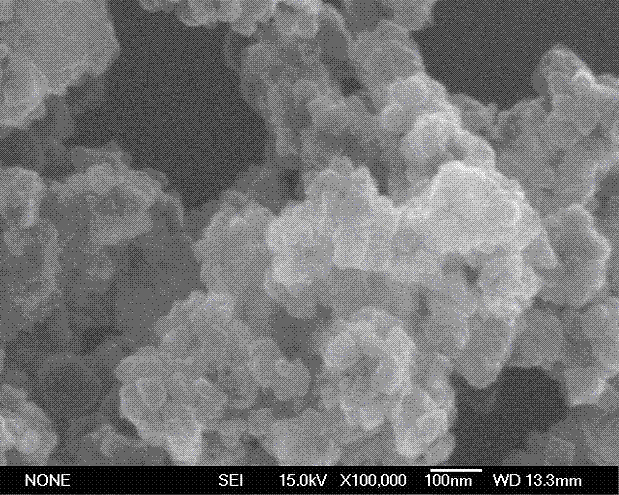

[0022] The prepared samples were characterized for their physical properties, and some of the results are shown in the accompanying drawings. The obtained material has a h...

Embodiment 2

[0024] Accurately weigh 2.5 mmol titanium tetrafluoride (TiF 4 ) into 10 mL of deionized water, ultrasonically dispersed evenly, and slowly dripped drop by drop into the suspension in the previous step under the condition of stirring. The reaction was carried out at 180 °C for 6 h in a polytetrafluoroethylene-lined autoclave.

[0025] The obtained result is quite different from Example 1, the difference is that the obtained TiO 2 Because the particles are large and uneven in shape, they cannot be evenly coated on the surface of the template.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com