Hydrolysis-resistant PC/PBT alloy material and preparation method thereof

An alloy material and hydrolysis-resistant technology, applied in the field of engineering plastics, can solve the problems of decreased mechanical properties and chemical resistance of alloy materials, decreased mechanical strength of alloy materials, decreased relative molecular weight, etc., so as to improve hydrolysis resistance and mechanical strength, Enhanced weatherability, good chemical and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

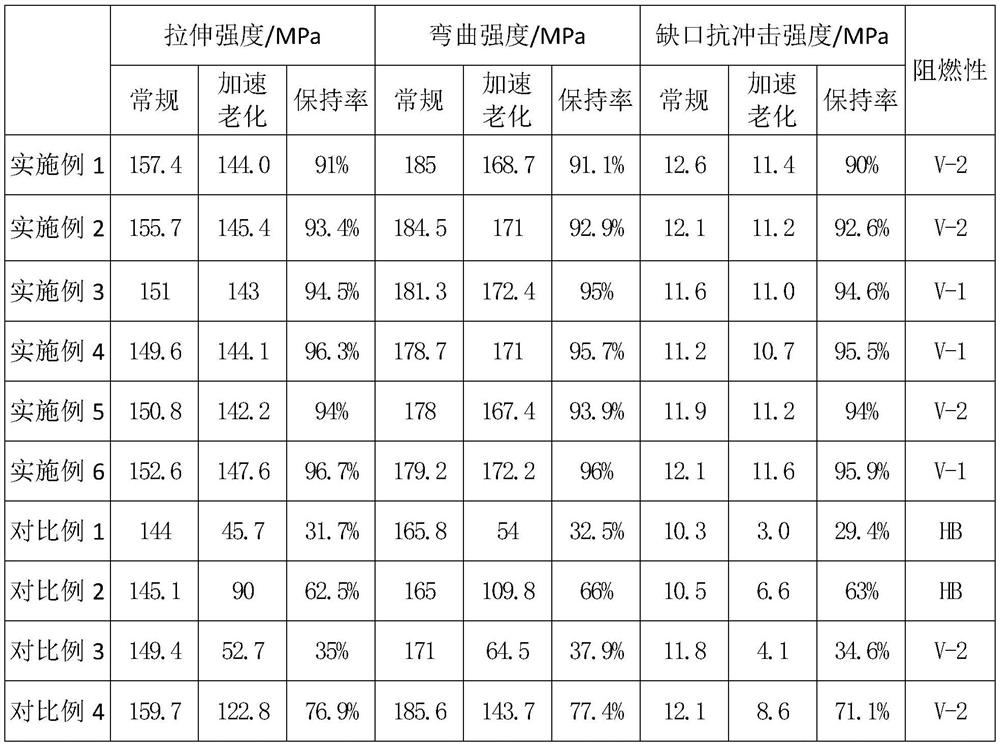

Examples

Embodiment 1

[0044] This embodiment discloses a hydrolysis-resistant PC / PBT alloy material, including the following raw material components in weight percentages:

[0045] PC resin 40.4%;

[0046] PBT resin 35.3%;

[0047] Glass fiber 20.7%;

[0048] Hydrolysis resistance agent 0.5%;

[0049] Transesterification inhibitor 0.2%;

[0050] Heat stabilizer 0.1%;

[0051] Other additives 3%.

[0052] The preparation method is as follows:

[0053] S1. Dry PC resin, PBT resin and glass fiber at 80-120°C for 20 minutes respectively;

[0054] S2. Mix the dried PC resin, PBT resin, transesterification inhibitor, hydrolysis resistance agent, heat stabilizer and other additives evenly to obtain a mixed raw material;

[0055] S3. The above-mentioned mixed raw materials are fed from the main feeding port of the twin-screw extruder, and the glass fiber is fed from the side feeding port of the twin-screw extruder, and then cooled, dried, and pelletized to obtain PC / PBT alloy material.

[0056] in:...

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is:

[0063] PC resin 35.2%;

[0064] PBT resin 30.1%;

[0065] Glass fiber 30.2%;

[0066] Anti-hydrolysis agent 1%;

[0067] Transesterification inhibitor 0.4%;

[0068] Heat stabilizer 0.5%;

[0069] Other additives 3%.

Embodiment 3

[0071] PC resin 35.2%;

[0072] PBT resin 30.1%;

[0073] Glass fiber 30.2%;

[0074] Anti-hydrolysis agent 1%;

[0075] Transesterification inhibitor 0.6%;

[0076] Heat stabilizer 0.5%;

[0077] Other additives 3%.

[0078] Wherein, the glass fiber is E-CR glass fiber; the hydrolysis-resistant agent is phenyl glycidyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com