A kind of magnesium alloy surface zirconia base film and preparation method

A surface oxidation and magnesium alloy technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of complex zirconia film layer equipment, weak bonding of the substrate, and thermal influence of the substrate. Special equipment, excellent corrosion resistance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Magnesium alloy pretreatment: sand the magnesium alloy block with sandpaper until the surface is bright (use 200 #, 400 #, 800 #, 1000 # sandpaper in turn until the surface is bright, no obvious scratches), ultrasonic cleaning with ethanol for 10 min, dry in cold air, set aside.

[0024] (2) Configuration of hydrothermal reaction medium: ZrO (NO 3 ) 2 Anhydrous ethanol solution and pH 8 sodium hydroxide aqueous solution, ZrO (NO 3 ) 2 The volume ratio of absolute ethanol solution to NaOH aqueous solution was 8:1.

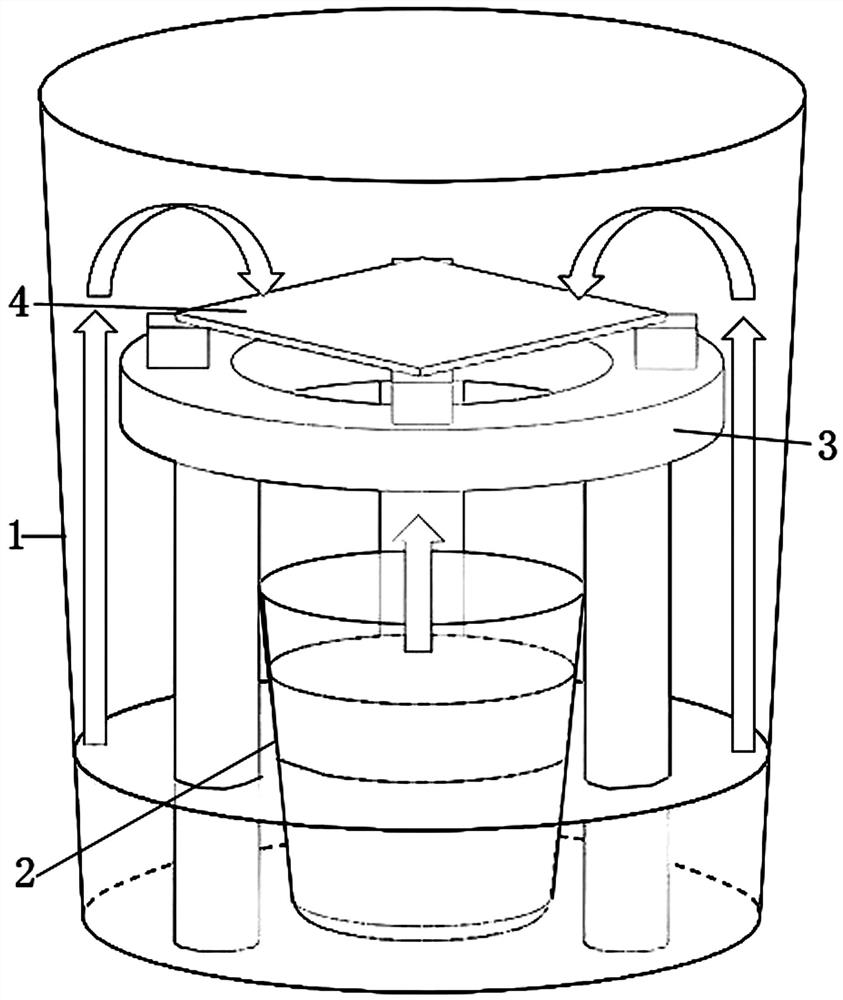

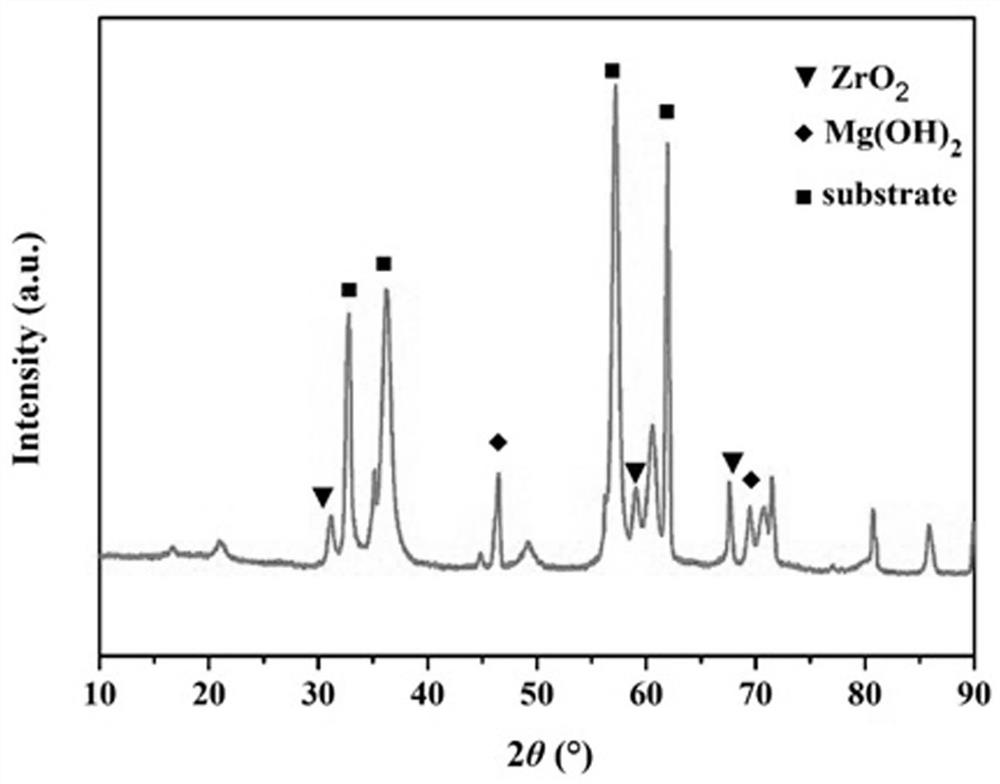

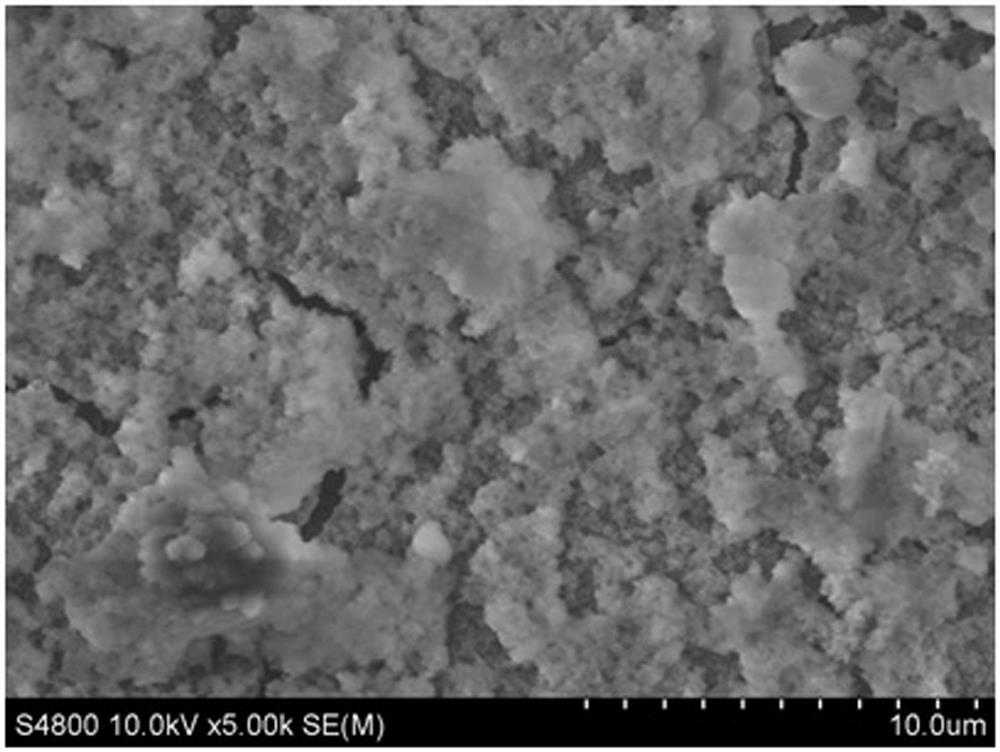

[0025] (3) Membrane layer preparation: transfer the absolute ethanol solution of zirconium oxynitrate to the inner lining of the reactor, and transfer the aqueous solution of sodium hydroxide to a small beaker. A small beaker was placed inside the reactor liner. The magnesium block was placed on the reaction support, and the reaction kettle was placed in a blast drying oven and kept at 160 °C for 8 h. After cooling, the magnesium alloy block was tak...

Embodiment 2

[0028] (1) Magnesium alloy pretreatment: The magnesium alloy block is polished with sandpaper until the surface is bright, ultrasonically cleaned with ethanol for 10 min, and dried with cold air for use.

[0029] (2) Configuration of hydrothermal reaction medium: ZrO (NO 3 ) 2 Anhydrous ethanol solution and pH 10 sodium hydroxide aqueous solution, ZrO(NO 3 ) 2 The volume ratio of absolute ethanol solution to NaOH aqueous solution was 3:1.

[0030] (3) Membrane layer preparation: transfer the absolute ethanol solution of zirconium oxynitrate to the inner lining of the reactor, and transfer the aqueous solution of sodium hydroxide to a small beaker. A small beaker was placed inside the reactor liner. The magnesium block was placed on the reaction support, and the reaction kettle was placed in a blast drying oven for 13 h at 140 °C. After cooling, the magnesium alloy block was taken out, rinsed with deionized water, and dried at 60 °C for 6 h.

[0031] The hardness of the p...

Embodiment 3

[0033] (1) Magnesium alloy pretreatment: The magnesium alloy sheet is polished with sandpaper until the surface is bright, ultrasonically cleaned with ethanol for 10 min, and dried in cold air for use.

[0034] (2) Configuration of hydrothermal reaction medium: ZrO(NO) with 0.02 mol / L 3 ) 2 Anhydrous ethanol solution and pH 13 sodium hydroxide aqueous solution, ZrO (NO 3 ) 2 The volume ratio of absolute ethanol solution to NaOH aqueous solution was 4:1.

[0035] (3) Membrane layer preparation: transfer the absolute ethanol solution of zirconium oxynitrate to the inner lining of the reactor, and transfer the aqueous solution of sodium hydroxide to a small beaker. A small beaker was placed inside the reactor liner. The magnesium block was placed on the reaction support, and the reaction kettle was placed in a blast drying oven for 8 h at 140 °C. After cooling, the magnesium alloy block was taken out, rinsed with deionized water, and dried at 60 °C for 6 h.

[0036] The har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com