Diatomite loaded nitrogen-doped nano titanium dioxide environment functional material

A nano-titanium dioxide and functional material technology, applied in the field of materials, can solve the problems of fragile finished products, easy agglomeration, low utilization of sunlight, etc., and achieve the effect of strong bending resistance and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

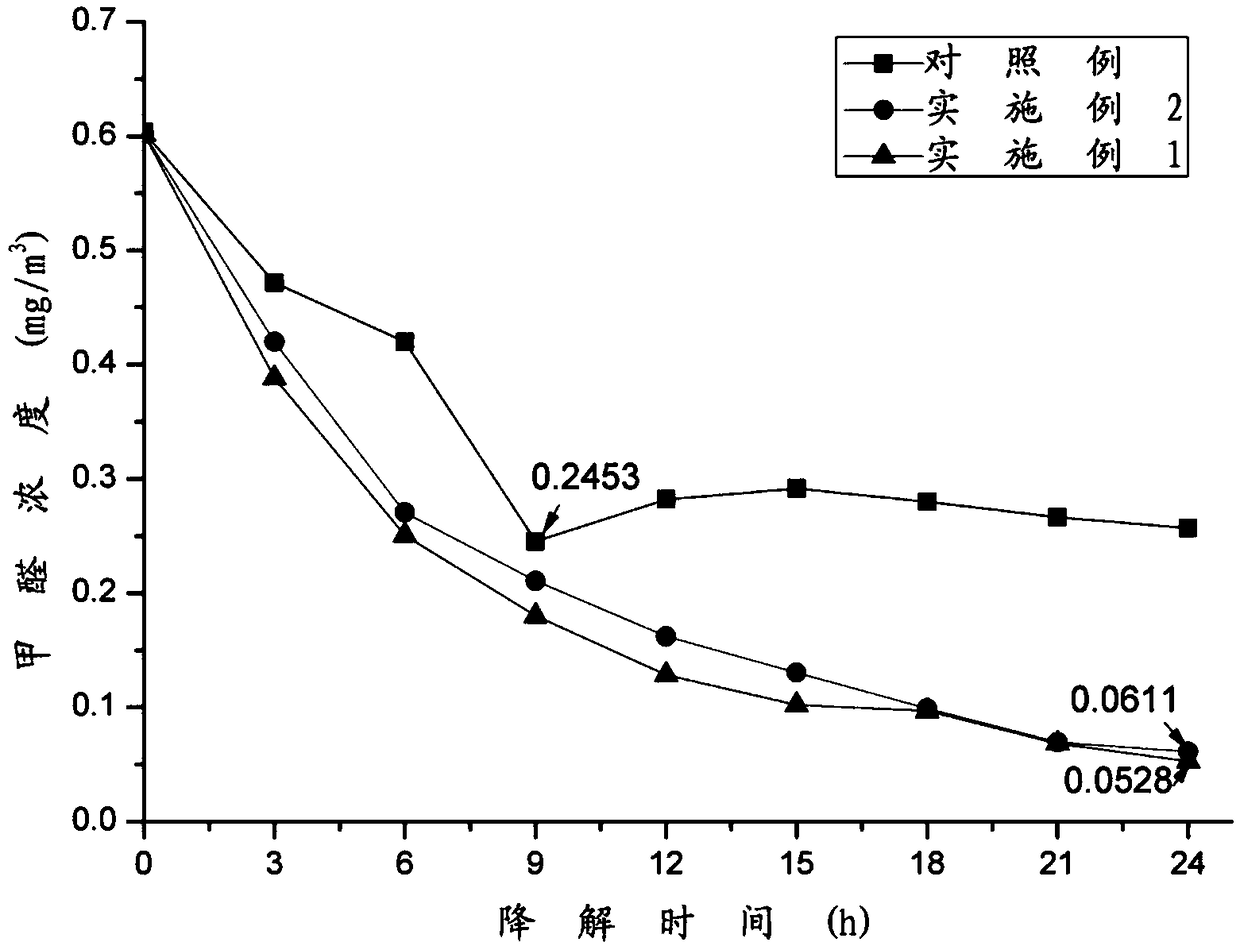

Embodiment 1

[0039] 1# Nitrogen-doped nano-TiO supported on diatomite 2 Environmental functional materials, in parts by weight, its raw materials are composed of: 35 parts of water, diatomaceous earth-loaded nitrogen-doped nano-TiO 2 50 parts, 7 parts of plant debris made from Ginkgo biloba, 3 parts of glutinous rice glue powder, 2 parts of sodium carboxymethylcellulose, 3 parts of dispersant, the dispersant specifically adopts Sokalan CP5 acrylic acid-maleic acid copolymer of BASF sodium salt.

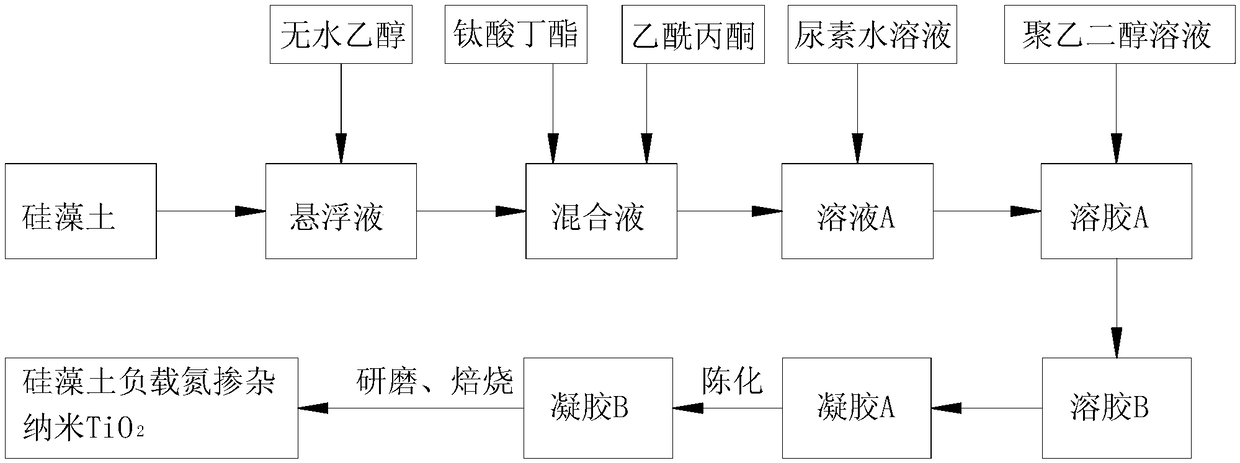

[0040] Nitrogen-doped nano-TiO supported on diatomaceous earth 2 Specifically, the following steps are used to make it, please refer to figure 1 :

[0041] First purify diatomaceous earth:

[0042] Use a 325-mesh sieve to sieve diatomite, put the diatomite under the sieve into 60wt% sulfuric acid solution, stir and wash for 2 hours; use 200W power ultrasonic treatment for 1 hour at 25°C, and wash repeatedly with distilled water to neutral; put it in a vacuum drying oven and dry it at 80°C fo...

Embodiment 2

[0052] 2# Nitrogen-doped nano-TiO loaded on diatomite 2 Environmental functional materials, in parts by weight, its raw materials are composed of: 35 parts of water, diatomaceous earth-loaded nitrogen-doped nano-TiO 2 50 parts, 5 parts of plant debris made of ginkgo leaves, 2 parts of fluorescent powder, 3 parts of glutinous rice glue powder, 2 parts of sodium carboxymethyl cellulose, 3 parts of dispersant, the dispersant is specifically acrylic acid-maleic acid copolymer Sodium salt, the phosphor specifically adopts blue-violet phosphor CaAl 2 o 4 :Eu 2+ ,Nd 3+ .

[0053] Nitrogen-doped nano-TiO supported on diatomaceous earth 2 Specifically, the following steps are used to make:

[0054] First purify diatomaceous earth:

[0055] Use a 325-mesh sieve to sieve the diatomite, put the diatomite under the sieve into 60wt% sulfuric acid solution, stir and wash for 2 hours; Properties; put it in a vacuum drying oven and dry it at 80°C for 6 hours, then put it in a muffle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com