A method for enhancing interfacial adhesion between organic separation membrane and support material

A support material and interface bonding technology, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as easy generation of a large amount of waste acid and alkali, unsuitable for industrialization, and high cost of waste liquid treatment. Achieve the effects of avoiding adverse effects, enhancing mechanical properties, and improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

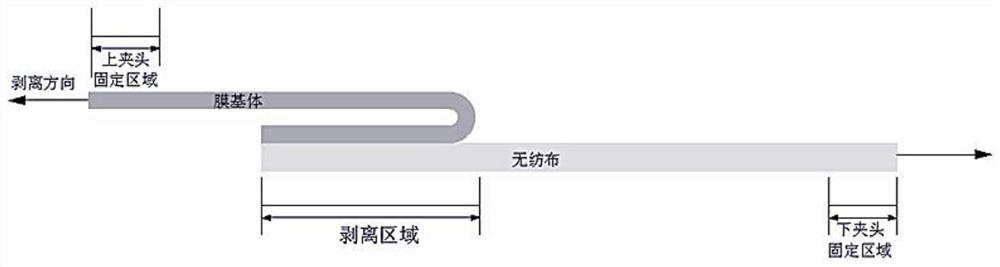

[0041] This embodiment provides a method for enhancing the interfacial adhesion between an organic separation membrane and a support material. The specific implementation steps include surface cleaning and drying of the support material (PET (polyester) non-woven fabric), surface hydroxylation treatment, surface There are four steps in modification treatment and preparation of interface-enhanced organic separation membrane, and the specific implementation steps are as follows:

[0042] Surface cleaning and drying of PET non-woven fabrics: prepare 500 mL of 15 g / L sodium hydroxide aqueous solution and 7 g / L AEO-8 aqueous solution, and mix the two solutions evenly. Immerse the PET non-woven fabric in the mixed solution for 20 minutes, take it out, rinse it with clean water, and dry it in an oven at 70°C.

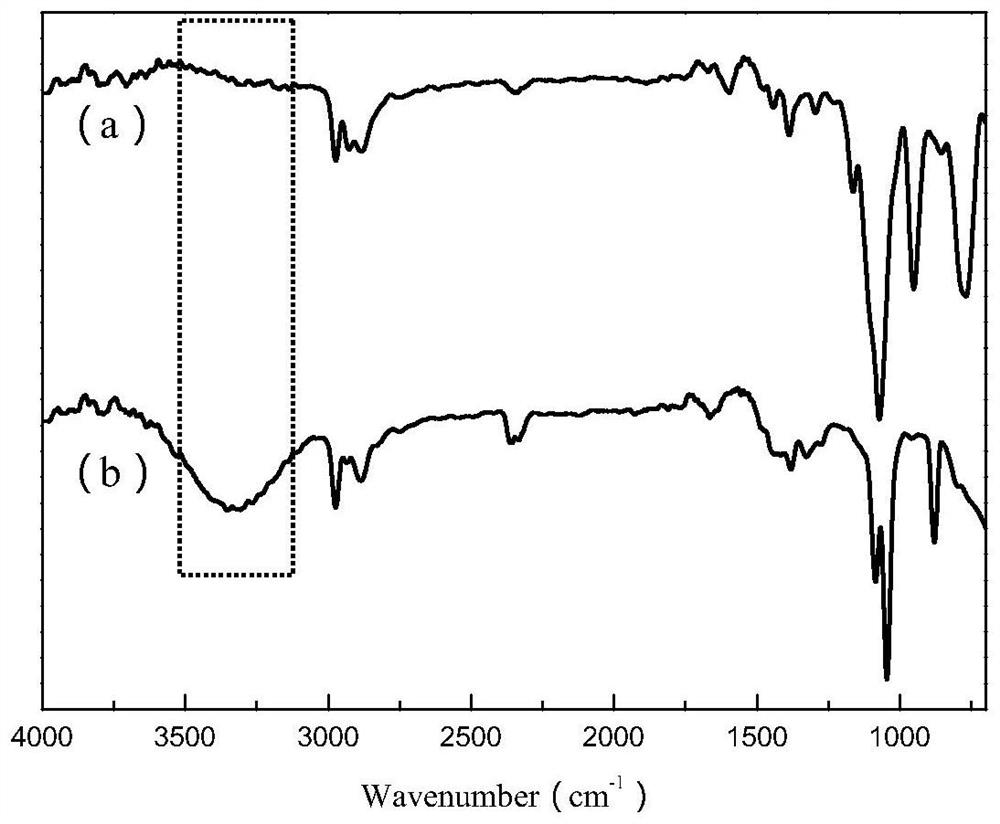

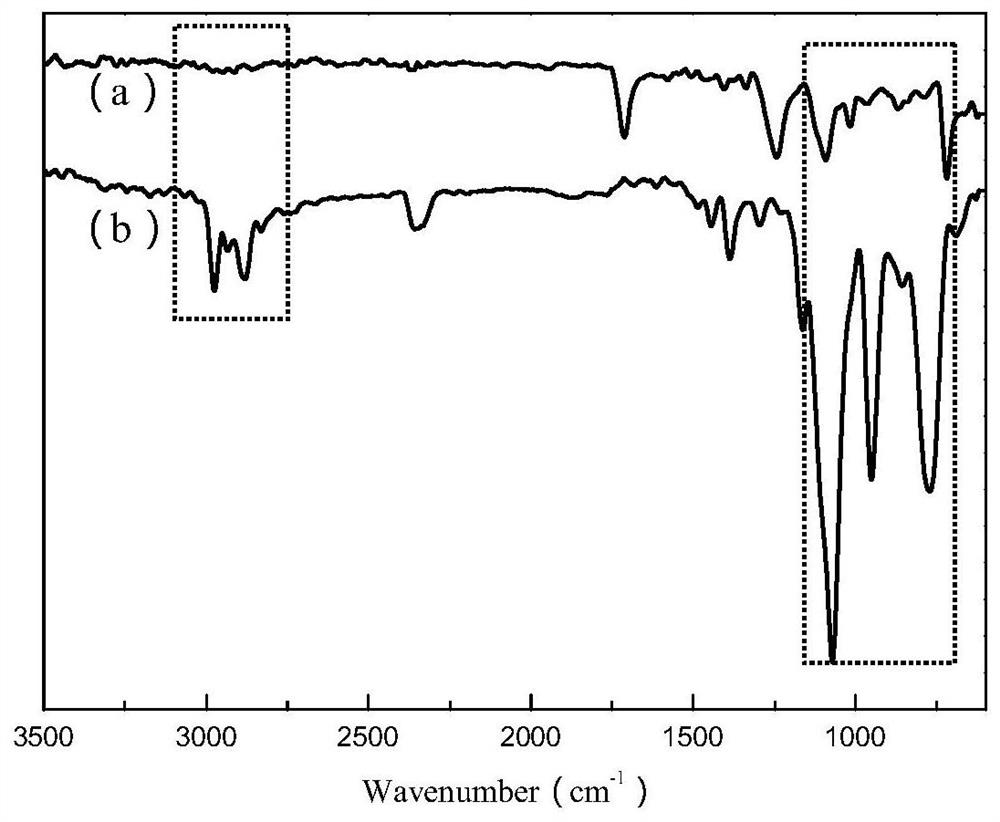

[0043] Surface-rich hydroxylation treatment: soak the dried PET non-woven fabric in 200g / L sodium hydroxide aqueous solution for 30 minutes, take it out and rinse the surface ...

Embodiment 2

[0059] This embodiment provides a method for enhancing the interfacial adhesion between an organic separation membrane and a support material. The specific implementation steps include surface cleaning and drying of the support material (PET (polyester) non-woven fabric), surface hydroxylation treatment, surface There are four steps in modification treatment and preparation of interface-enhanced organic separation membrane, and the specific implementation steps are as follows:

[0060] Surface cleaning and drying of PET non-woven fabrics: prepare 500 mL of 15 g / L sodium hydroxide aqueous solution and 7 g / L AEO-8 aqueous solution, and mix the two solutions evenly. Immerse the PET non-woven fabric in the mixed solution for 20 minutes, take it out, rinse it with clean water, and dry it in an oven at 70°C.

[0061] Surface-rich hydroxylation treatment: soak the dried PET non-woven fabric in 200g / L sodium hydroxide aqueous solution for 30 minutes, take it out and rinse the surface ...

Embodiment 3

[0066] This embodiment provides a method for enhancing the interfacial adhesion between an organic separation membrane and a support material. The specific implementation steps include surface cleaning and drying of the support material (PET (polyester) non-woven fabric), surface hydroxylation treatment, surface There are four steps in modification treatment and preparation of interface-enhanced organic separation membrane, and the specific implementation steps are as follows:

[0067] Surface cleaning and drying of PET non-woven fabrics: prepare 500 mL of 15 g / L sodium hydroxide aqueous solution and 7 g / L AEO-8 aqueous solution, and mix the two solutions evenly. Immerse the PET non-woven fabric in the mixed solution for 20 minutes, take it out, rinse it with clean water, and dry it in an oven at 70°C.

[0068] Surface-rich hydroxylation treatment: soak the dried PET non-woven fabric in 200g / L sodium hydroxide aqueous solution for 30 minutes, take it out and rinse the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com