Patents

Literature

69 results about "Kerolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kerolite or Cerolite is a metamorphic nickel bearing phyllosilicate mineral variety of talc, can be seen as a mixture of serpentine and saponite as well. It has the formula: (Mg,Ni)₃Si₄O₁₀(OH)₂·H₂O. It is often considered as a talc variety and it was discredited 1979.

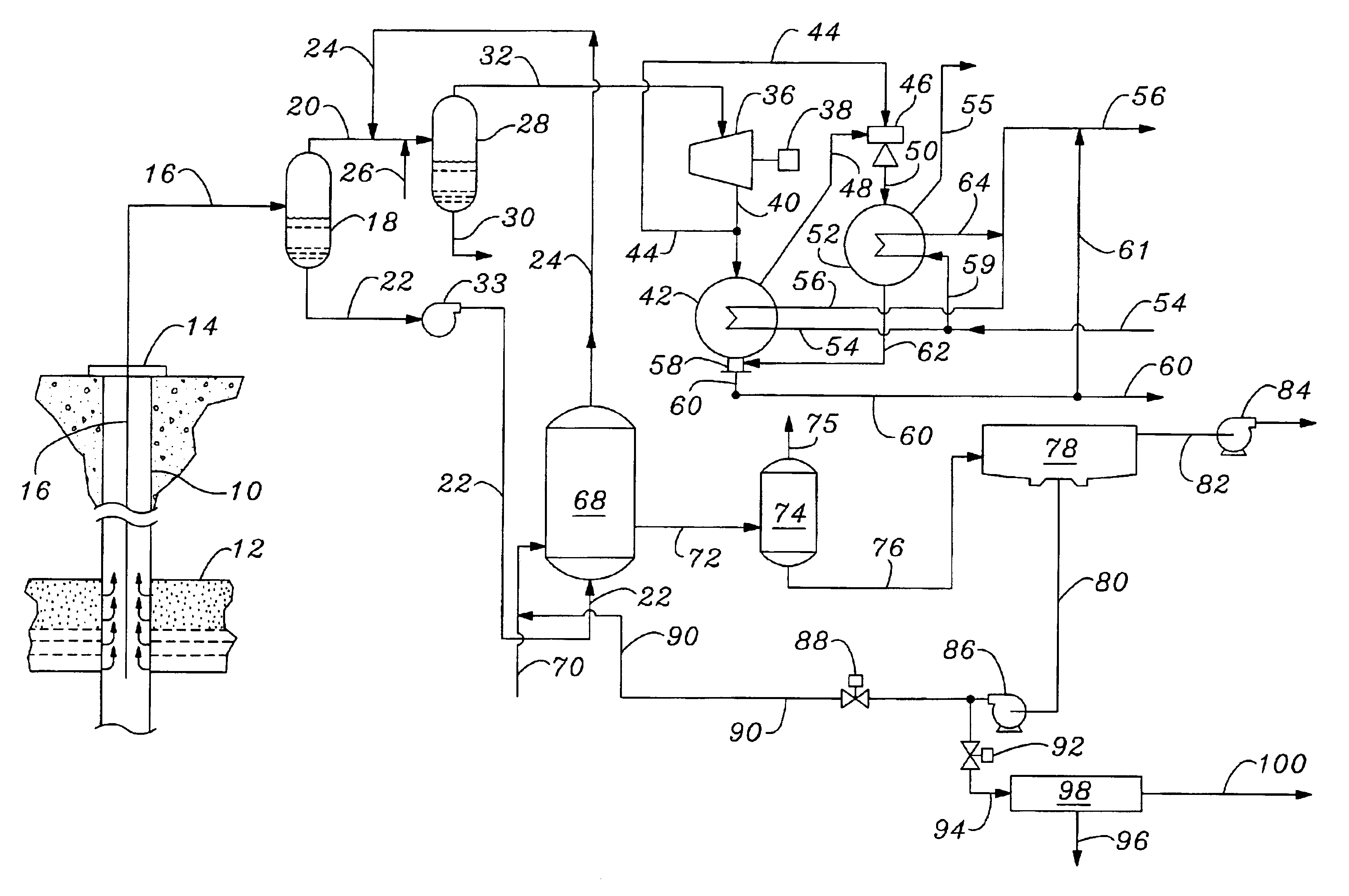

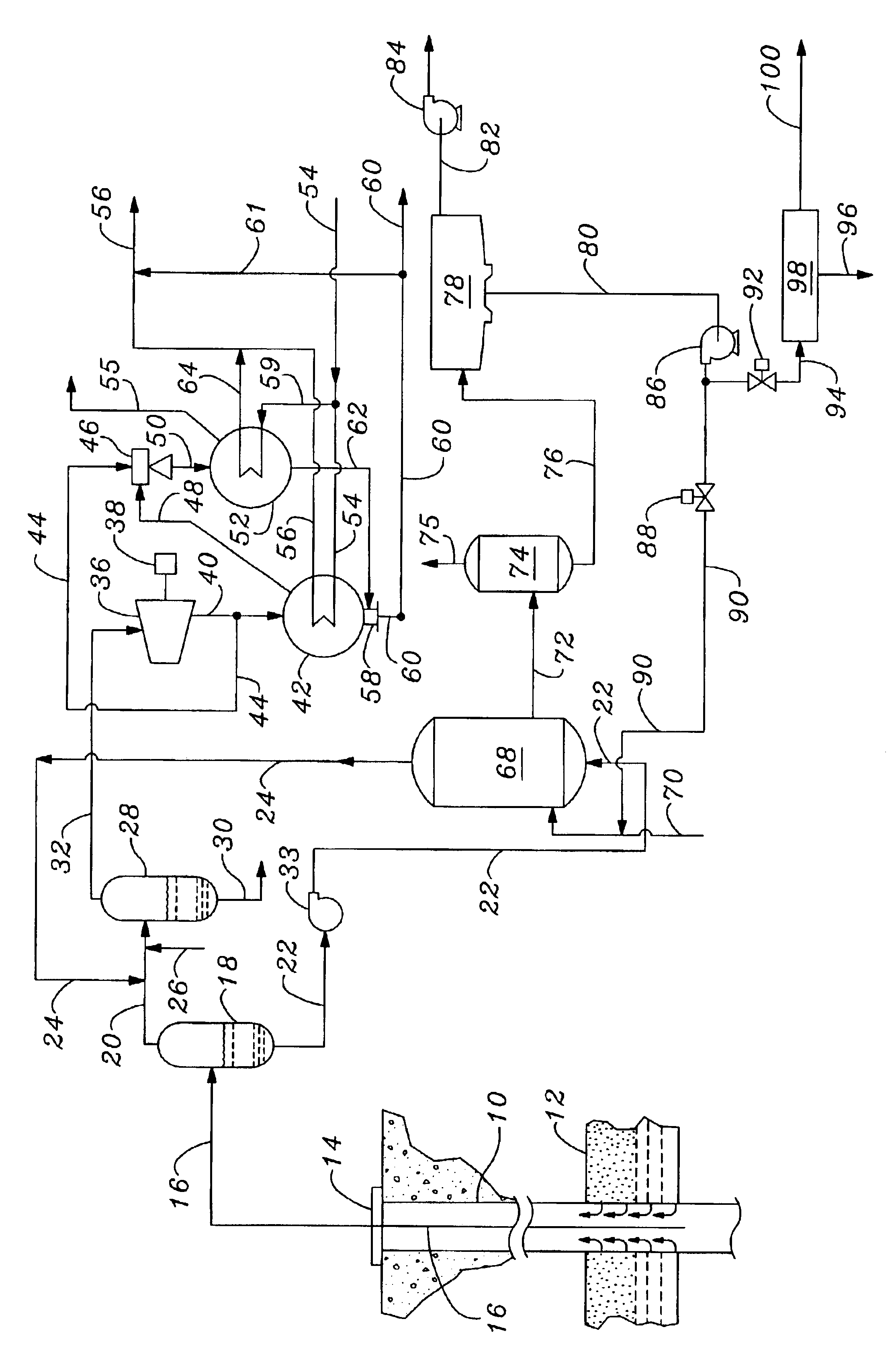

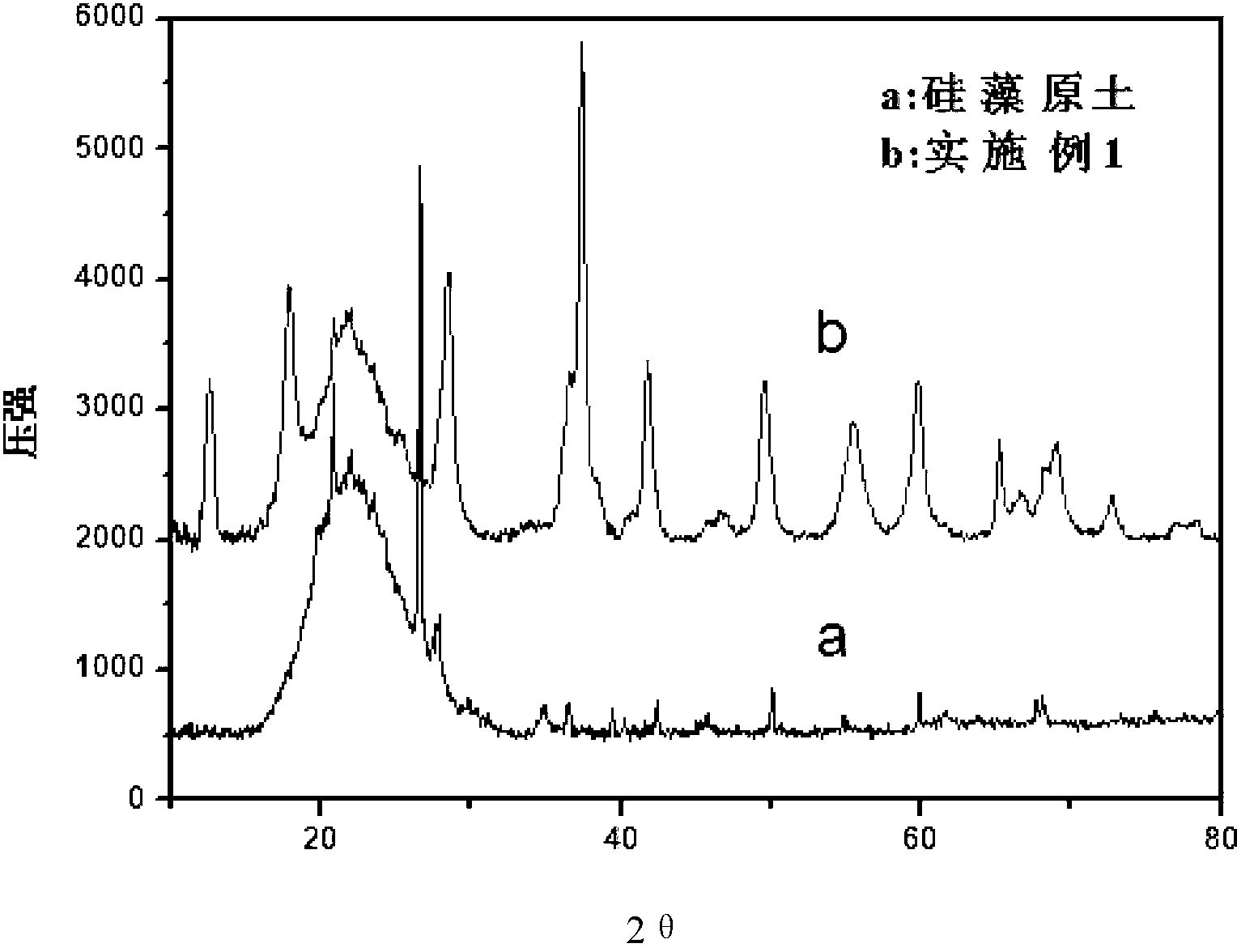

Method for synthesizing crystalline magnesium silicates from geothermal brine

Crystalline magnesium silicates are synthesized from silica-containing brines, preferably spent geothermal brines, by mixing the brine with a magnesium-containing compound, adjusting the pH of the resultant mixture between 8.0 and 14, and crystallizing the magnesium silicate from the mixture at a temperature between 50° C. and 200° C. Kerolite is preferably synthesized from brine by adjusting the pH in a range between 9.5 and 10.5 and heating the mixture to between 100° C. and 170° C. to precipitate the crystalline kerolite. The brine remaining after the crystallization step is depleted in silica and can be further processed without significant problems caused by silica scaling.

Owner:UNION OIL OF CALIFORNIA

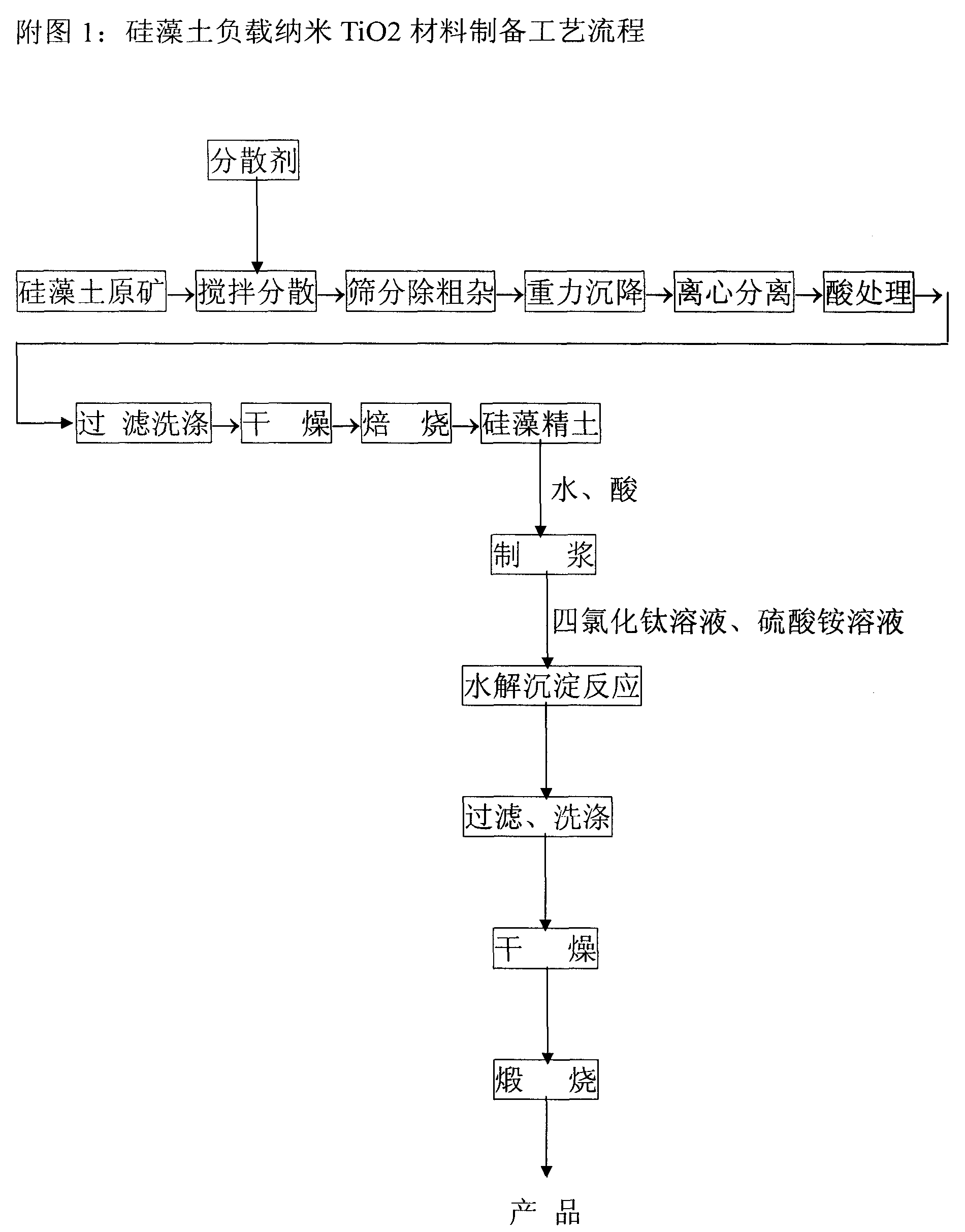

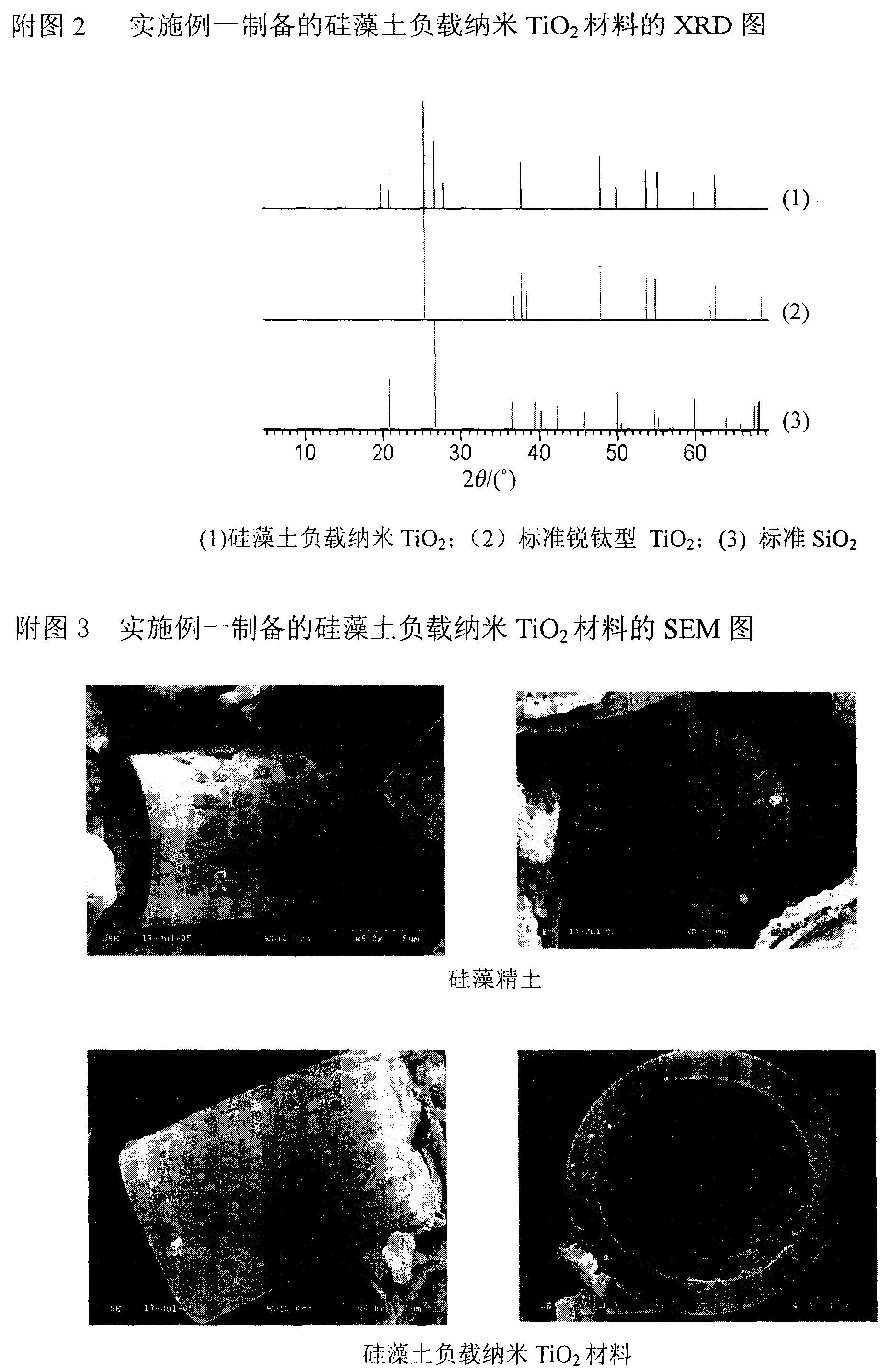

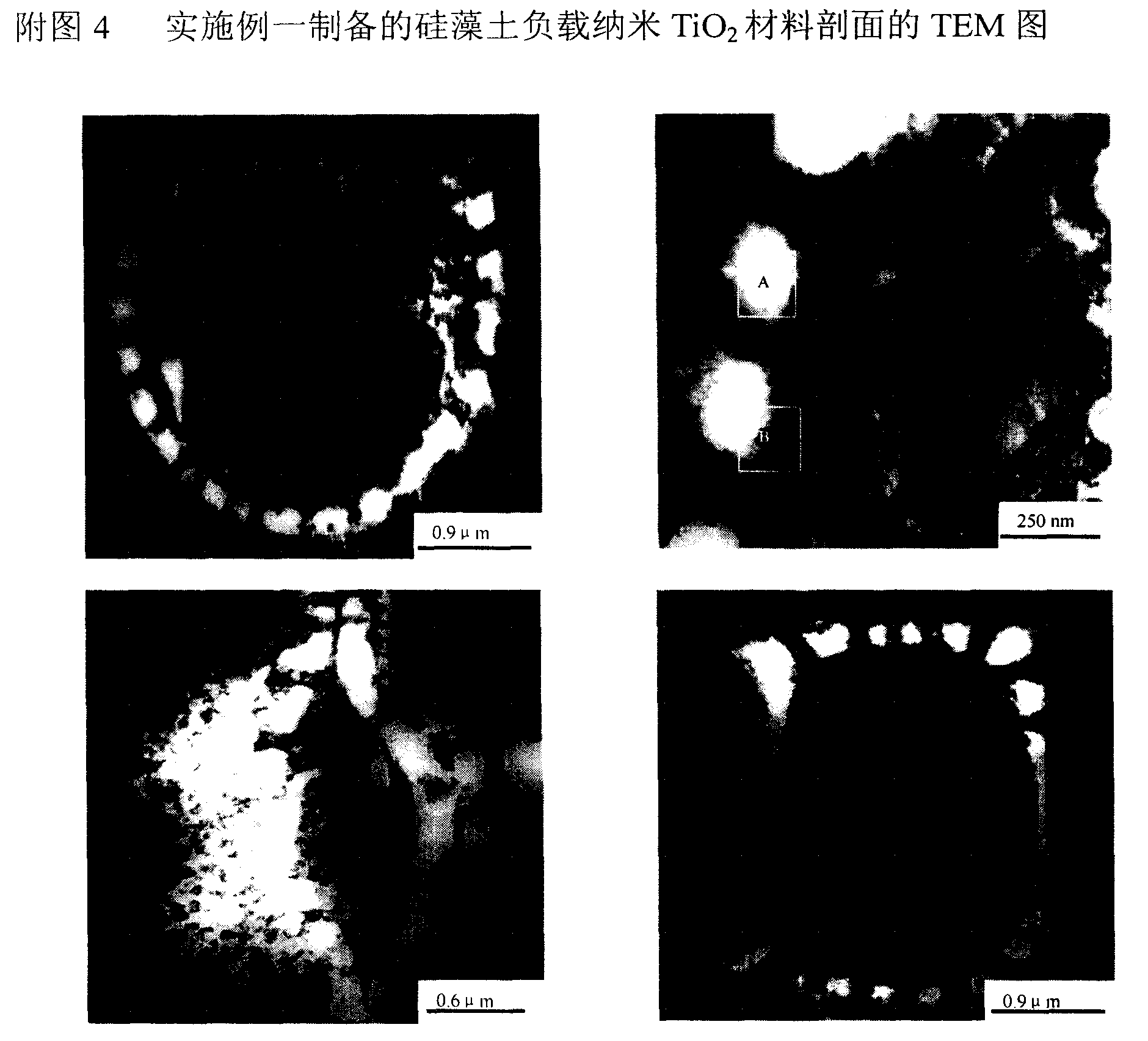

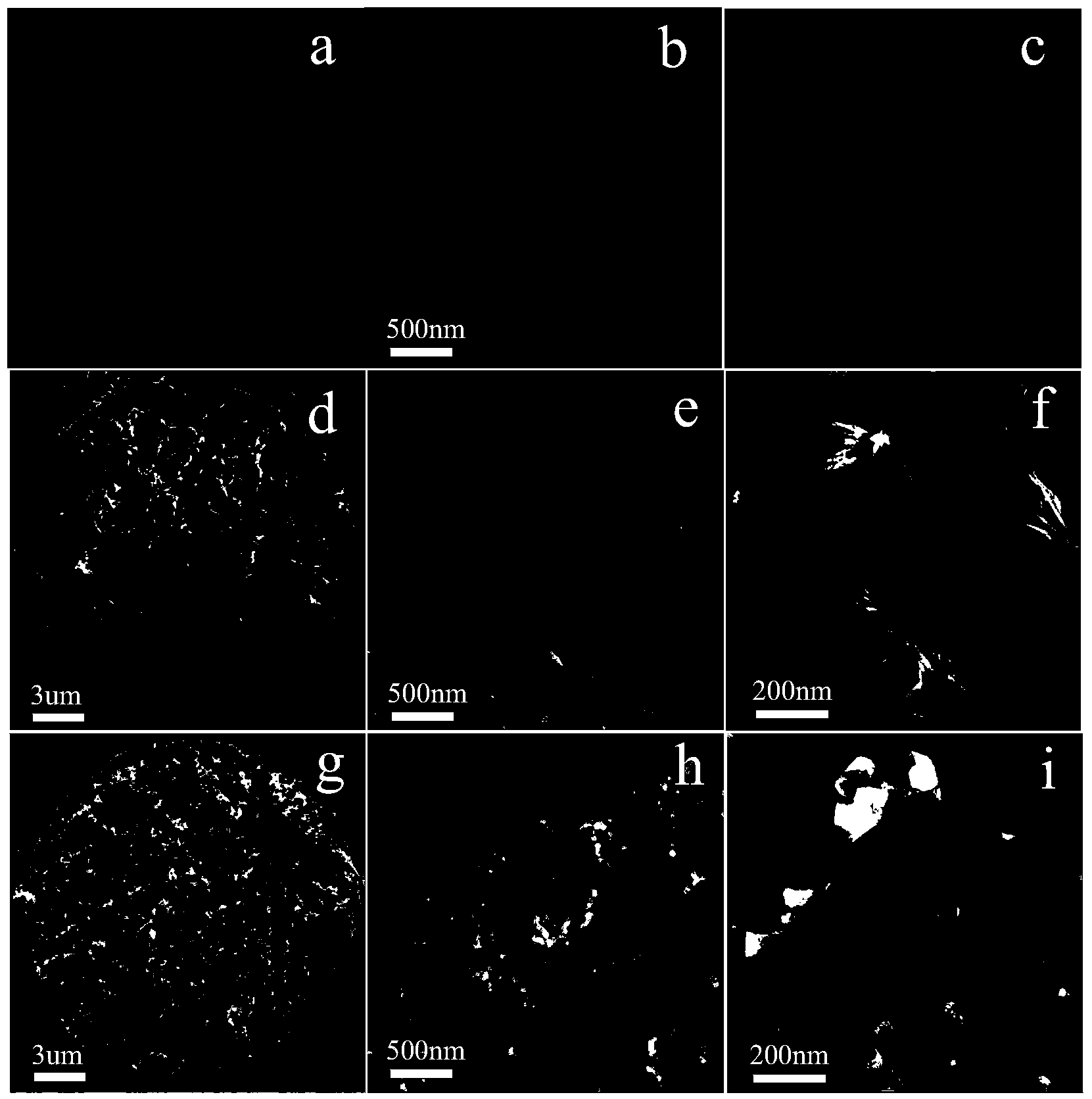

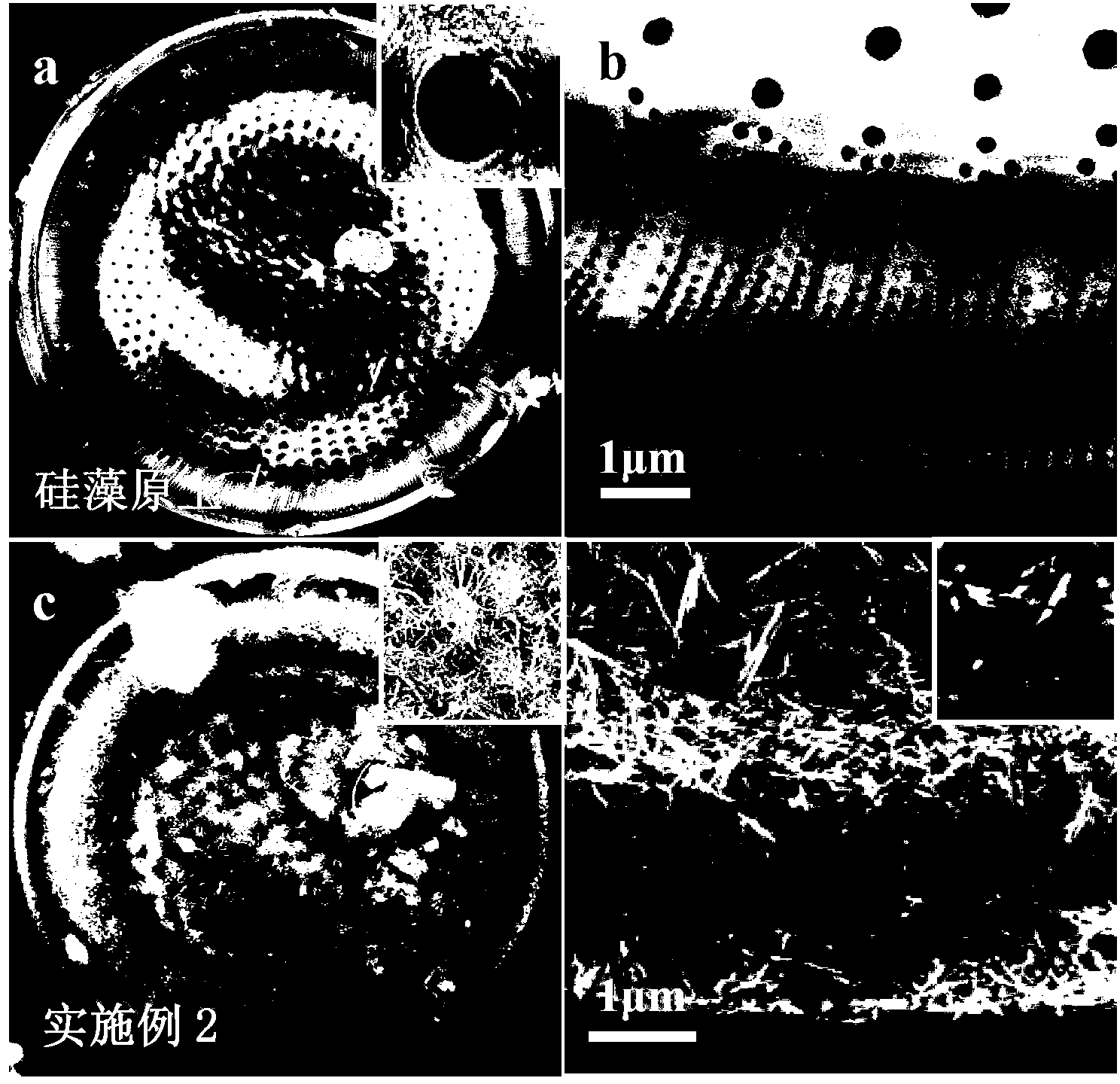

Method for producing tripolite loading nano-TIO2 material capable of being used for water and air purification

InactiveCN101195086AReduce manufacturing costGood photocatalytic effectPhysical/chemical process catalystsForeign matterDecomposition

The invention relates to a process for preparing diatom earth loading nanometer Ti2O material for purifying water and air, which belongs to the field of material process and environmental treatment. Diatom earth raw ore is filled with water and is churned and scattered, is screened, is sunken by gravity, and is eccentrically sunken, sulfuric acid is adopted to dissolve clay-type foreign matters which are left in pore passages after ores which mutually grow with diatom earth like quartz, feldspar, mica, and clay and the like and organic matters which are mixed such as grass roots and barks and the like are removed, and diatom fine soil is attained. Further, diatom fine soil is filtered, dried, and baked, and diatom fine soil after baked is filled with water, and is churned, and is filled with acid to regulate the PH value, and is filled TiCl4 solution, and is filled with ammonia sulfate solution to proceed hydrolytic decomposition deposition reaction, and product yield after the reaction is filtered, washed, dried, and baked to attain the nanometer Ti2O material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Composite porous activated carbon flue gas adsorbent and preparation method thereof

InactiveCN104437371AImprove toughnessHigh strengthOther chemical processesDispersed particle separationPorositySodium metasilicate

The invention discloses a composite porous activated carbon flue gas adsorbent which is characterized by comprising the following raw materials in parts by weight: 98-105 parts of shell activated carbon, 36-40 parts of diatomite, 2-3 parts of sodium metasilicate, 2-3 parts of rosin, 2-3 parts of VAE emulsion, 2-3 parts of polyvinyl alcohol, 1-2 parts of sodium alcohol ether sulphate, 1-2 parts of sodium citrate, 1-2 parts of gypsum residue, 2.5-3.5 parts of pulverized fuel ash, 4-5 parts of edible corn starch, 2-3 parts of lanthanum nitrate, 9-12 parts of glass fiber powder, 4-6 parts of adsorption aids and a proper amount of water. The composite porous activated carbon flue gas adsorbent disclosed by the invention is reasonable in formula, viscous matters such as polyvinyl alcohol and edible corn starch are added, the toughness and strength of the activated carbon are improved, and the service life is prolonged; and due to the addition of the adsorption aids, the adsorbent has special porosity, the contact time between gas and the adsorbent is prolonged, and the effects of inhibiting bacteria and purifying the air are achieved. Therefore, the adsorption efficiency is high, the production process is simple, and the adsorbent is suitable for industrial dry desulfurization, automobile exhaust desulfurization and daily air purification.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

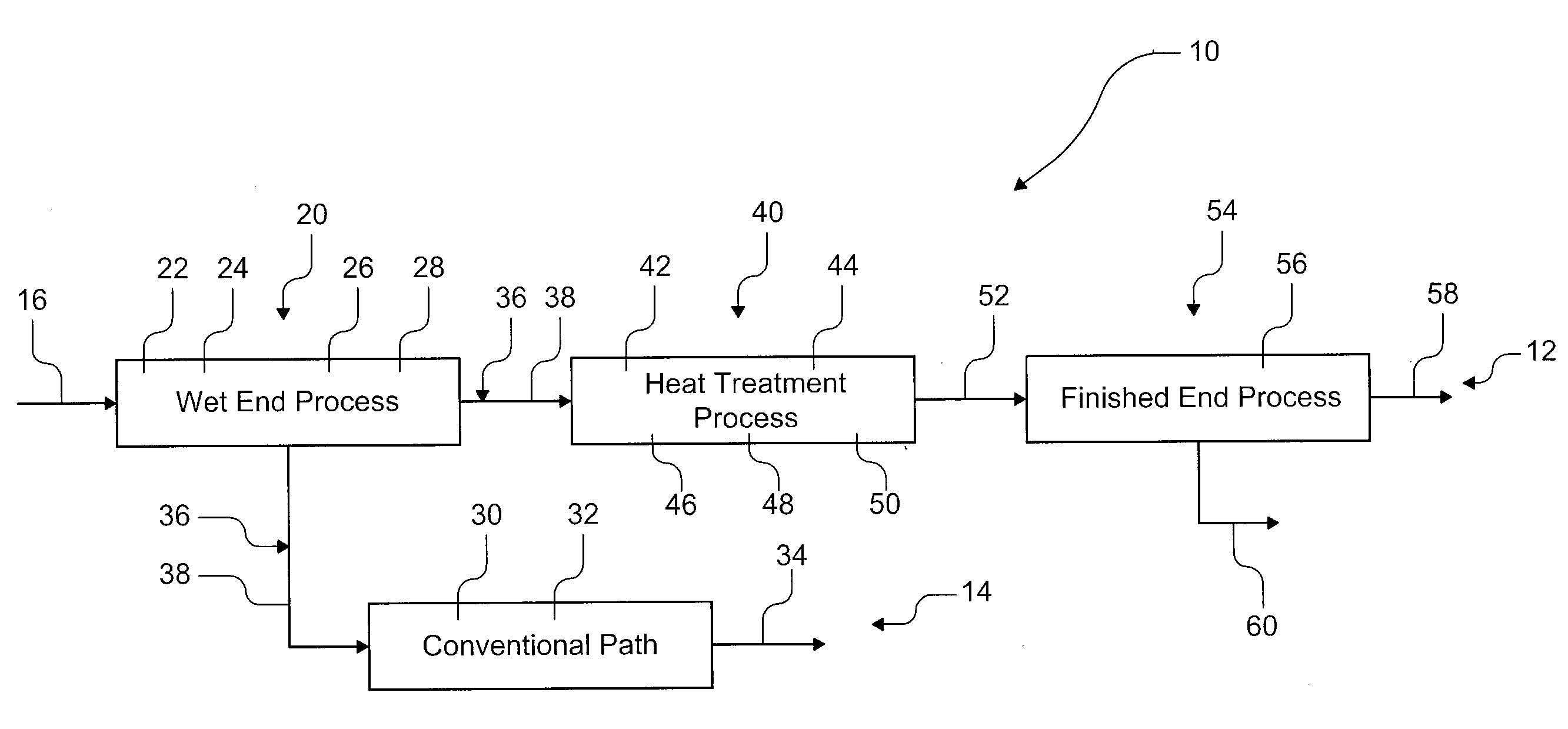

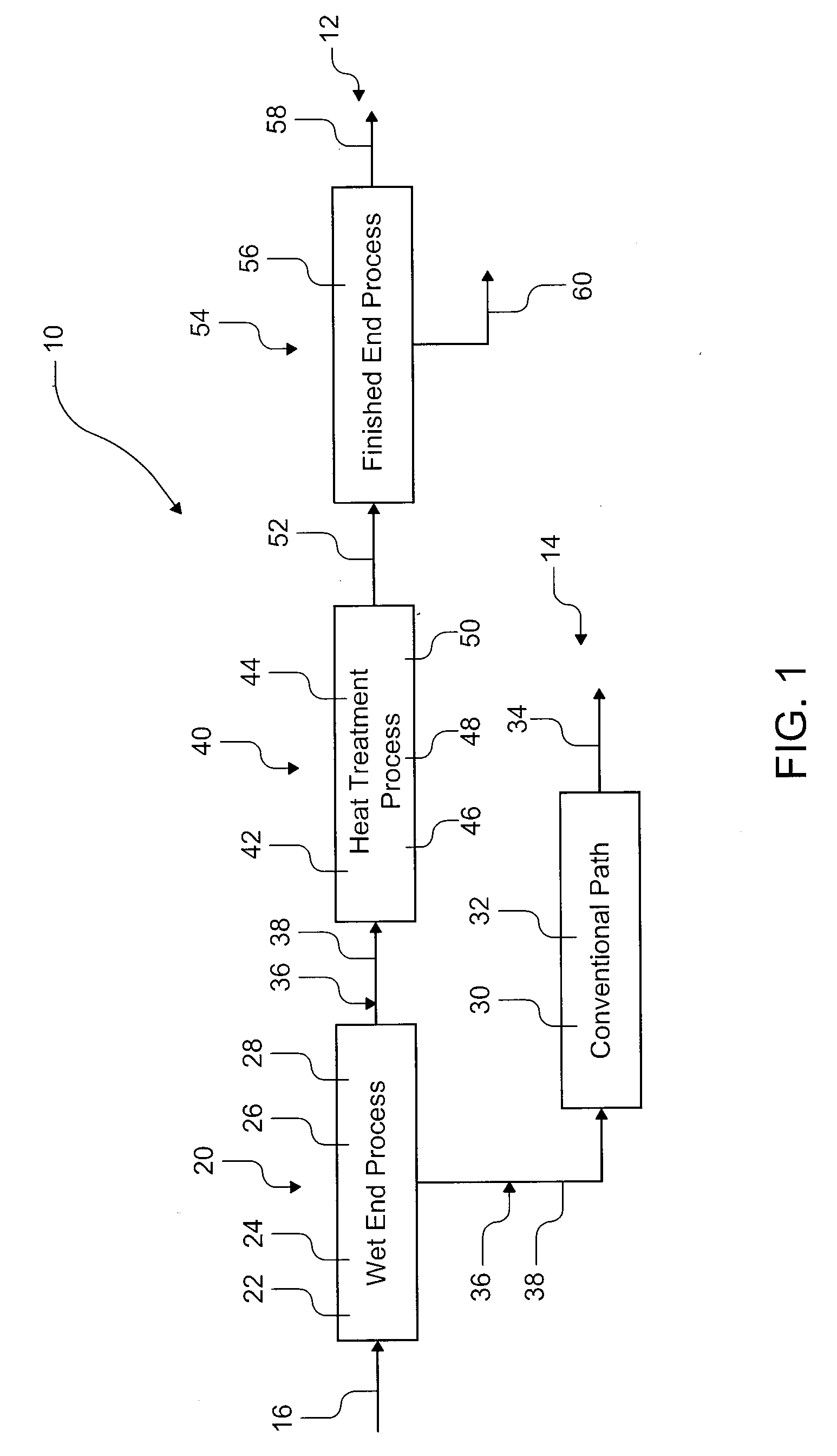

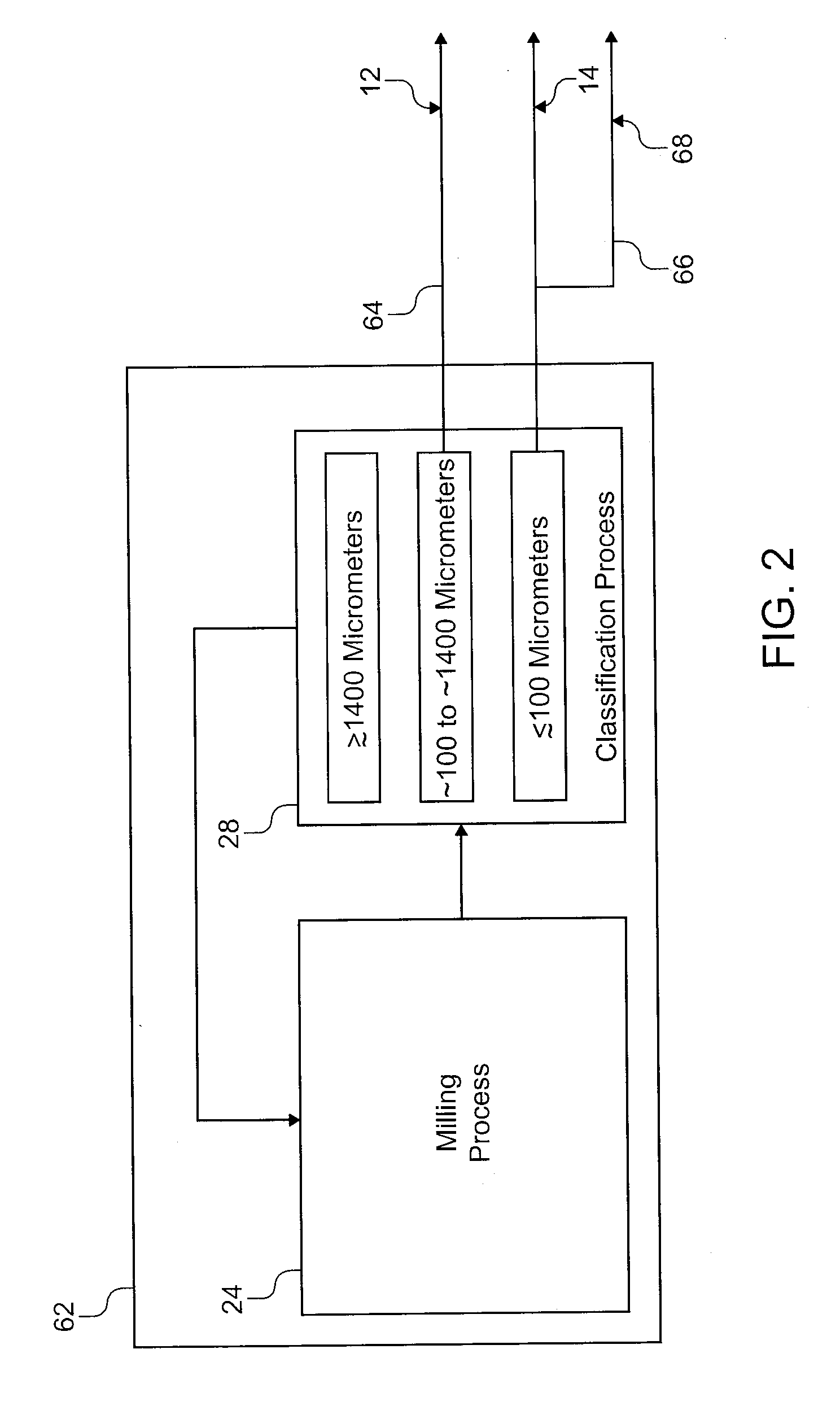

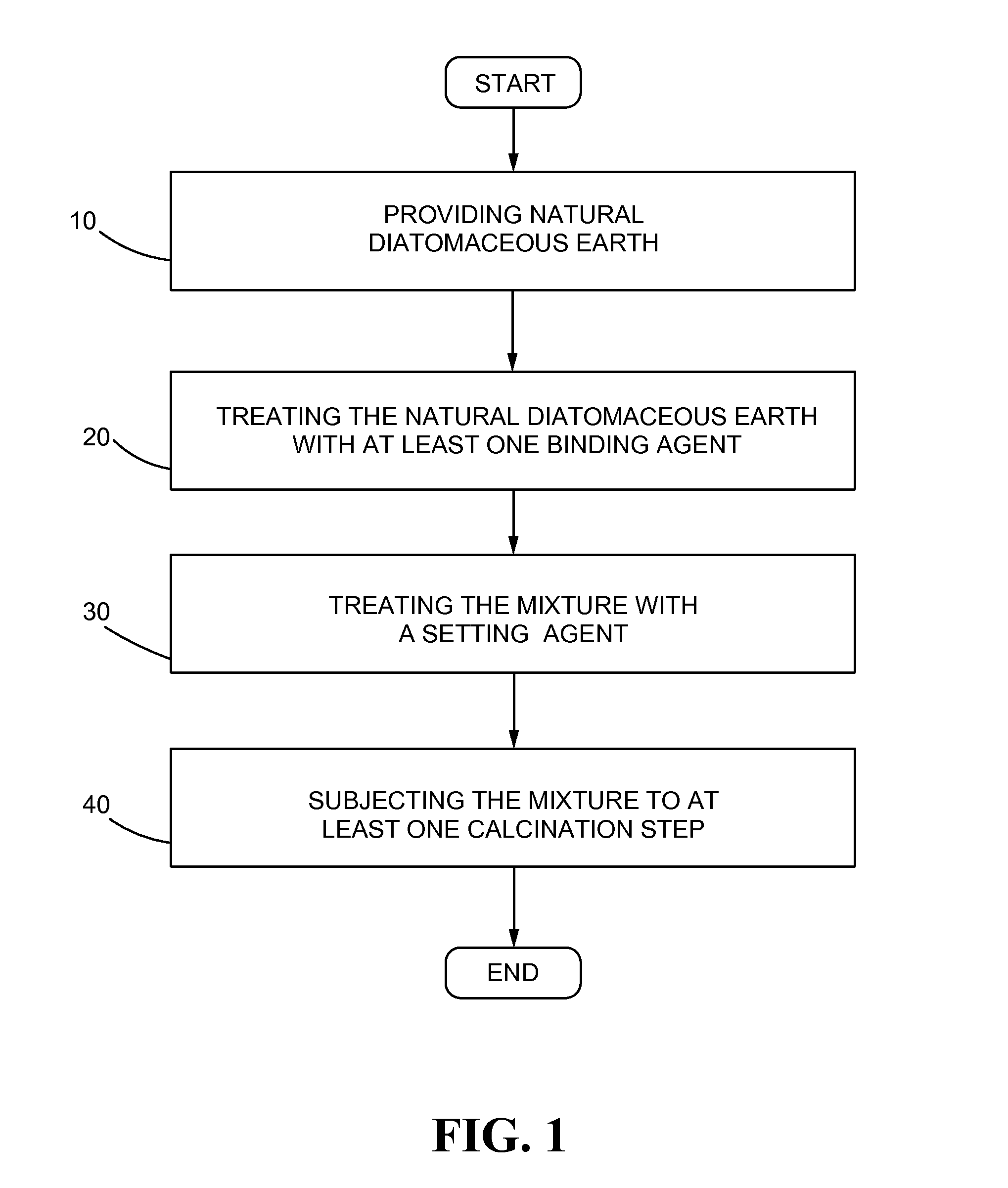

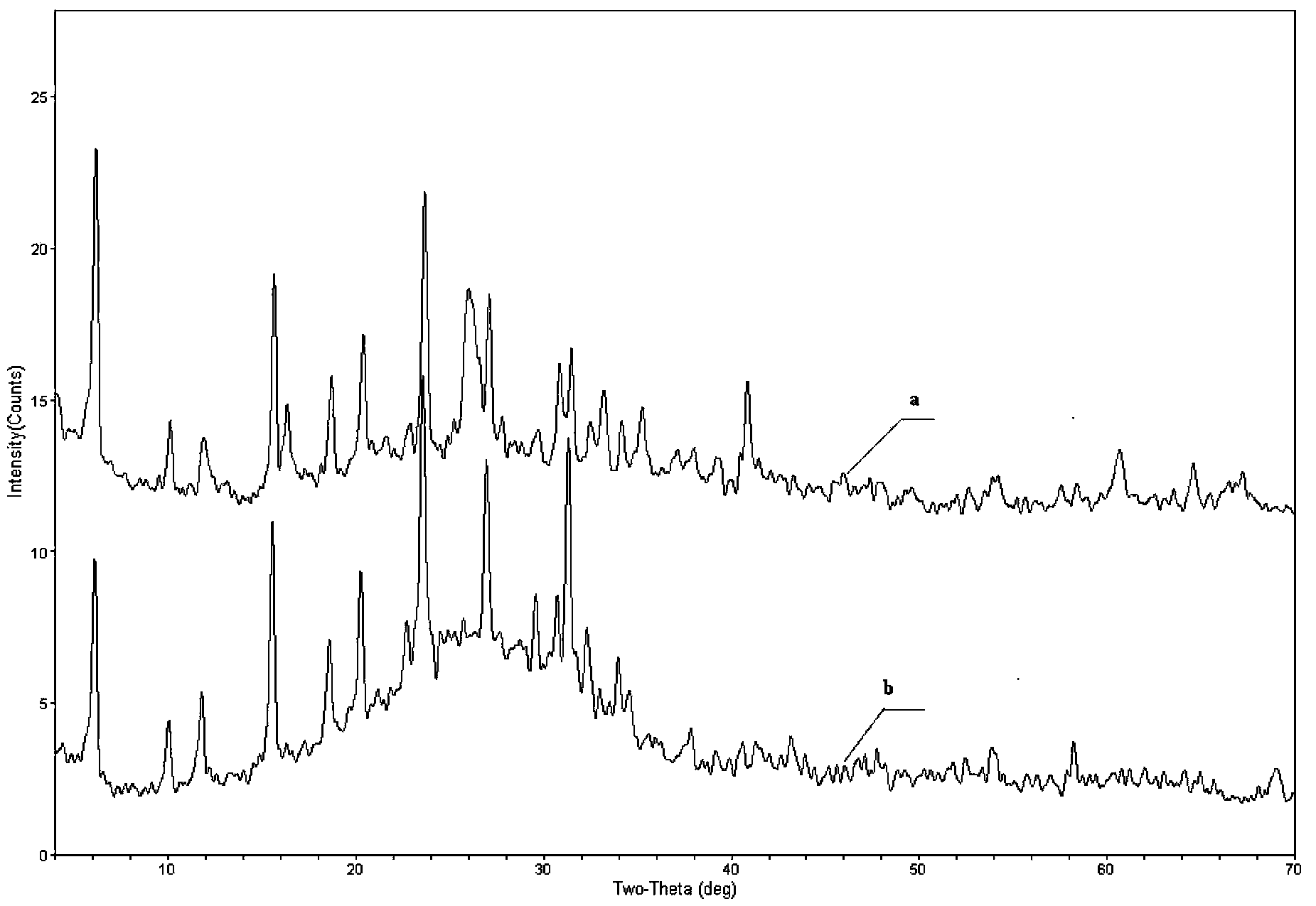

Crystalline silica-free diatomaceous earth filter aids and methods of manufacturing the same

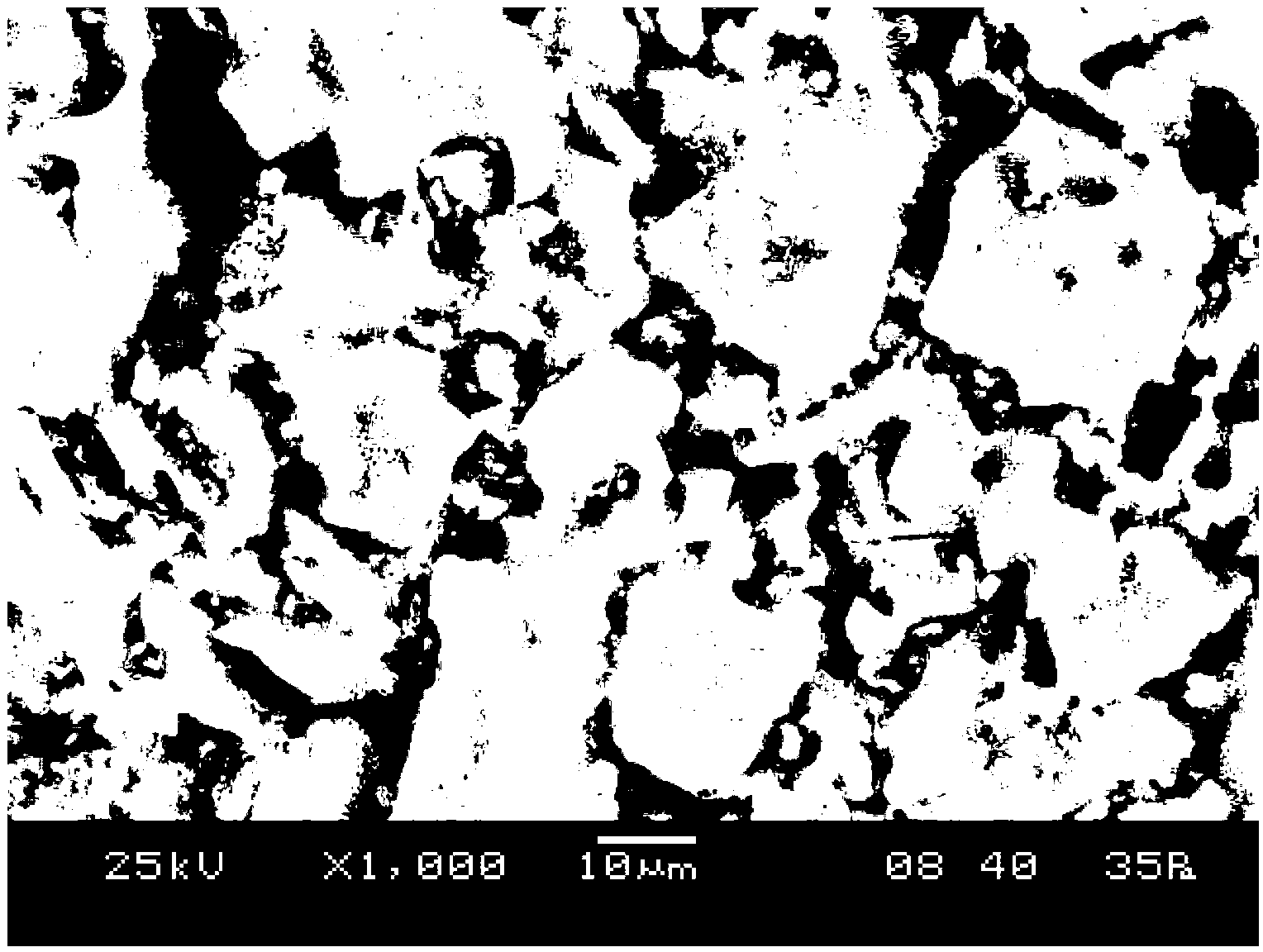

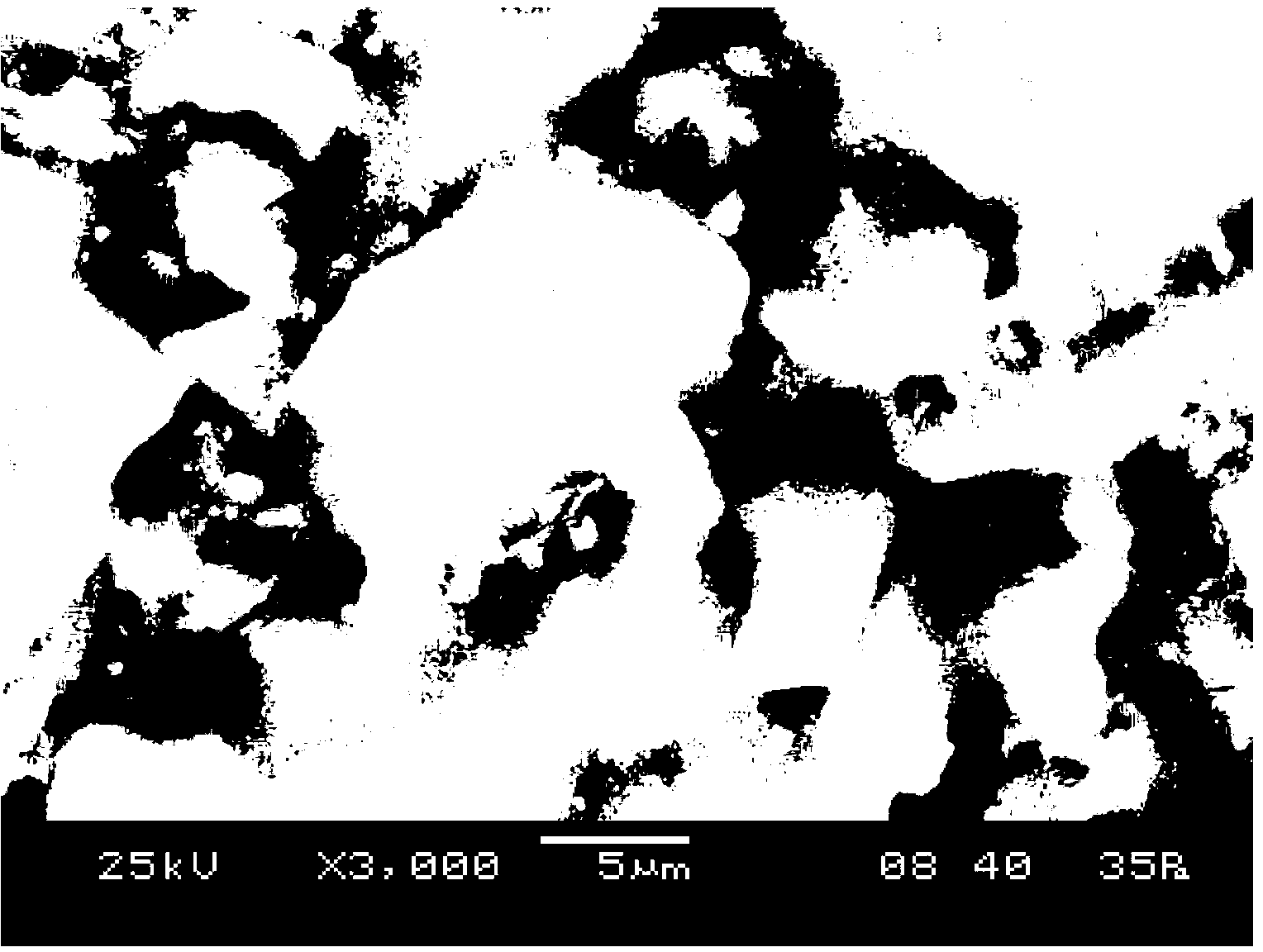

A method of producing a range of diatomaceous earth filter aids having selectable permeabilities and less than about 1 percent by weight total crystalline silica. The method includes milling diatomaceous earth ore to a size range of between about 100 micrometers and about 1400 micrometers; calcining the milled diatomaceous earth in a calciner; and milling the calcined diatomaceous earth in an adjustable milling and classification system to produce diatomaceous earth filter aids. Systems to implement such methods and compositions produced by such methods are also described.

Owner:EP MINERALS LLC

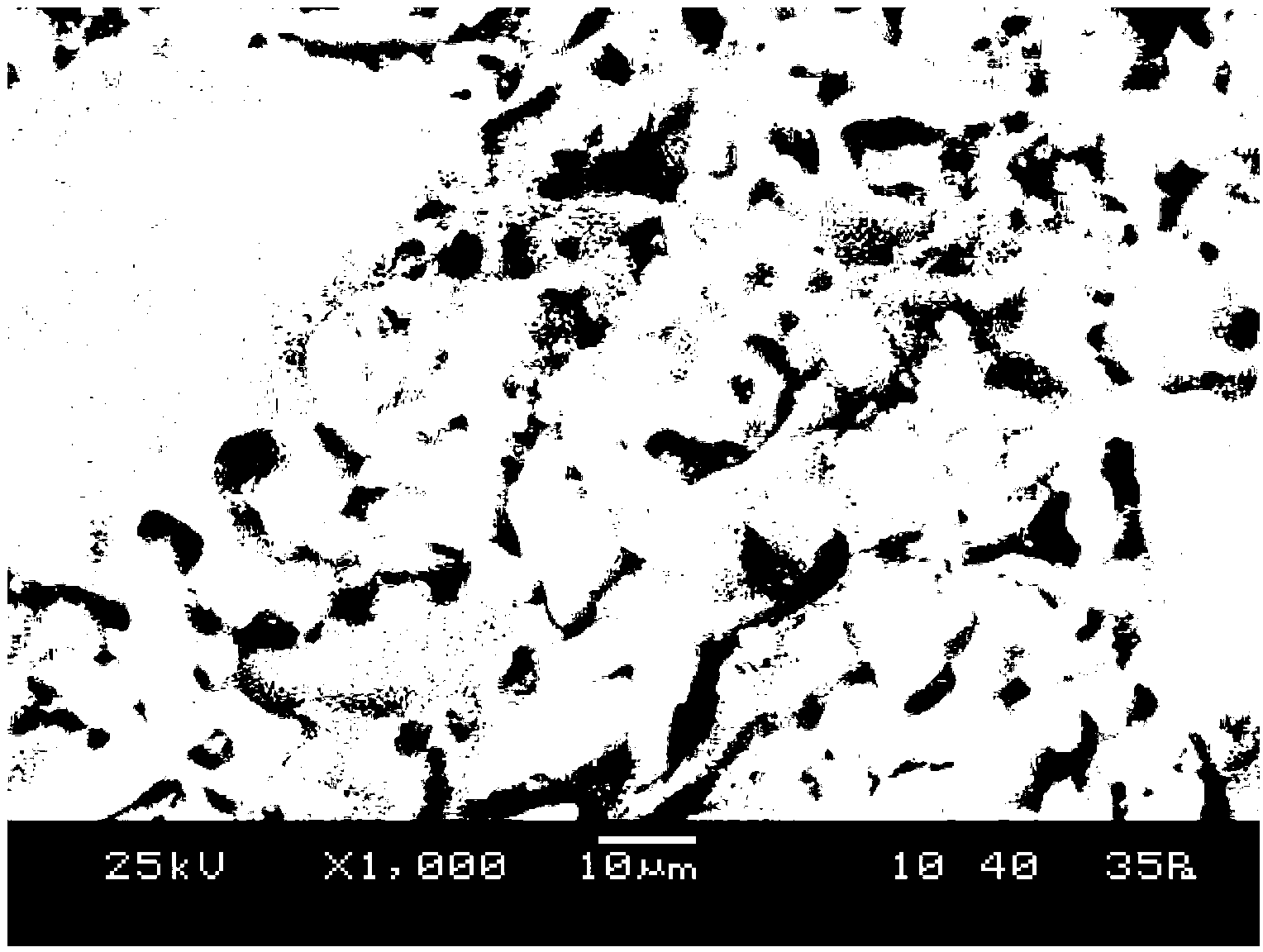

Diatomaceous Earth Filter Aid Containing a Low Crystalline Silica Content

ActiveUS20140171305A1Other chemical processesAlcoholic beverage preparationCrystallographyPotassium silicate

A diatomaceous earth product with low crystalline silica content after at least one calcination step of between about 927° C. (1700° F.) and about 1149° C. (2100° F.) is disclosed. The product comprises natural diatomaceous earth and at least one binding agent comprising potassium silicate. Further the product comprises no more than about 4.0 wt % of crystalline silica and has a permeability in the range of about 0.3 darcy to greater than about 20 darcy. A process for making such diatomaceous earth product with a low crystalline silica content is disclosed. Moreover, a diatomaceous earth filter aid comprising such a diatomaceous earth product is disclosed.

Owner:EP MINERALS LLC

Kieselguhr water-purifying agent

InactiveCN1669635ALow costImprove purification efficiencyOther chemical processesWater/sewage treatment by flocculation/precipitationAdjuvantAluminium chlorohydrate

The invention relates to a bergmeal water purification agent, which belongs to the water disposal technical fields. The water purification agent uses the medium-grade diatomite powder whose diatom content is between 60-70% as the basal body, combined with the adjuvant additive or polyacrylamide; wherein: a, the weight ratio of the component is: the adjuvant additive 13-22%, the rest is the medium-grade diatomite powder; the adjuvant additive is aluminum sulfate, ferric chloride, polychloride; b, the weight ratio of the component is: polyacrylamide 3-4ppm, the rest is the medium-grade diatomite powder.

Owner:云南银林科工贸有限公司

Hollow glass mineral agent

InactiveCN1736554AReduce manufacturing costHigh particle strengthDispersed particle separationSilicon compoundsAbsorption ratioDesiccant

The invention discloses a glazing glass mineral desiccant, the technique highlight of which is that, the glazing glass mineral desiccant comprises warp clay, sodium-hydroxide, calcium oxide, diatom earth, and high-alumina earth, and the product is prepared after milling, granulating, drying, sifting, and packing. It has a good stability, a high wet absorption ratio, and a strong intensity. And it can apply to glazing glass devices and other location needing to keep dry.

Owner:许盛英

Flame-proof filling material special for tunnel sheet pavement

ActiveCN101173105AHigh flame retardant efficiencyImprove road performanceIn situ pavingsBuilding insulationsAluminium hydroxideFilling materials

The invention relates to flame retarding type fillings, in particular to flame retarding type fillings special for a tunnel asphalt road surface. The invention is characterized in that the fillings comprises limestone powder, flame retarding substance and modified substance with the weight ratio of 100:60 to 120:70 to 150, wherein, the flame retarding substance consists of aluminium hydroxides, magnesium hydrates, boron flame retardants and synergists with the weight ratio of 100:60 to 85:4 to 15:2 to 6. The synergist is Fe oxidant, Sb2O3, MgO or MoO3. The modified substance comprises lime hydrate, diatomite and natural zeolite powder with the weight ratio of 100:60 to 80:15 to 30. The invention has the advantages of high flame retarding efficiency, nontoxic operation, effective usage for improving the properties of asphalt mixed material, etc. when being used on roads.

Owner:WUHAN MUNICIPAL CONSTR GROUP

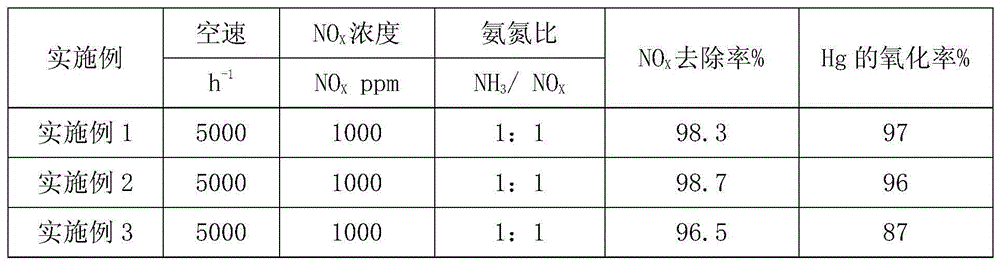

Method for preparing novel denitration catalyst

InactiveCN103252230AGood stable mechanical strengthLow costDispersed particle separationCatalyst activation/preparationSodium BentoniteCatalytic effect

The invention discloses a method for preparing a novel denitration catalyst. The method comprises the steps of: mixing 10-40wt% of attapulgite, 0.5-15wt% of bentonite, 10-35wt% of alumina powder, 40-70wt% of 4A molecular sieve, 0.5-10wt% of kieselguhr and 0.5-10wt% of assistant into powder; molding in water mediating and extruding manners and firing a carrier by a high-temperature flame; feeding ammonium metavanadate and metatungstic acid into hot water of which the temperature is not less than 85 DEG C; mixing an ethanol solution with an acid solution to form a mixing solution; adding titanate which is 5-30% of total weight of the mixing solution to the mixing solution, soaking the carrier in steeping liquor; and baking the dried carrier and preparing into the denitration catalyst. The carrier is prepared from a cheap material instead of an expensive titanium dioxide material through reasonable prescription combination; good and stable mechanical strength, 30-70% of water absorption and 20-80 m<2> / g of specific surface area of the catalyst carrier can be ensured by changing the material of the carrier; and the preparation cost can be reduced by 20-50% under the condition of keeping the catalytic effect.

Owner:姚光纯

Composite ionic adsorption material and preparation method thereof

ActiveCN103071453AIncrease swap spaceImprove exchange capacityOther chemical processesAlkali metal oxides/hydroxidesActivated carbonWater baths

The invention discloses a composite ionic adsorption material which is a spherical particle prepared by taking 80-85 parts of zeolitefine powder subjected to water bath modification by 0.8-1.0mol / L NaCl solution, 10-20 parts of medical stone fine powder, and 10-20 parts of kieselguhr fine powder as base materials, and 6 parts of activated carbon powder as a pore former and firing, wherein the diameter of the spherical particle is 2-12mm, and the pore volume of the spherical particle is 0.645-0.650 cm<3> / g. Activated zeolite is added to medical stone and kieselguhr to prepare the novel compound ionic material, and the zeolite, the medical stone and the kieselguhr jointly exert adsorption effects. The salt modified zeolite and medical stone increase an ionic exchange space and internal surface area, so that the adsorption capacity of the prepared composite adsorption material is further improved, and a better adsorption effect is achieved.

Owner:青岛力创星碟环境工程有限公司

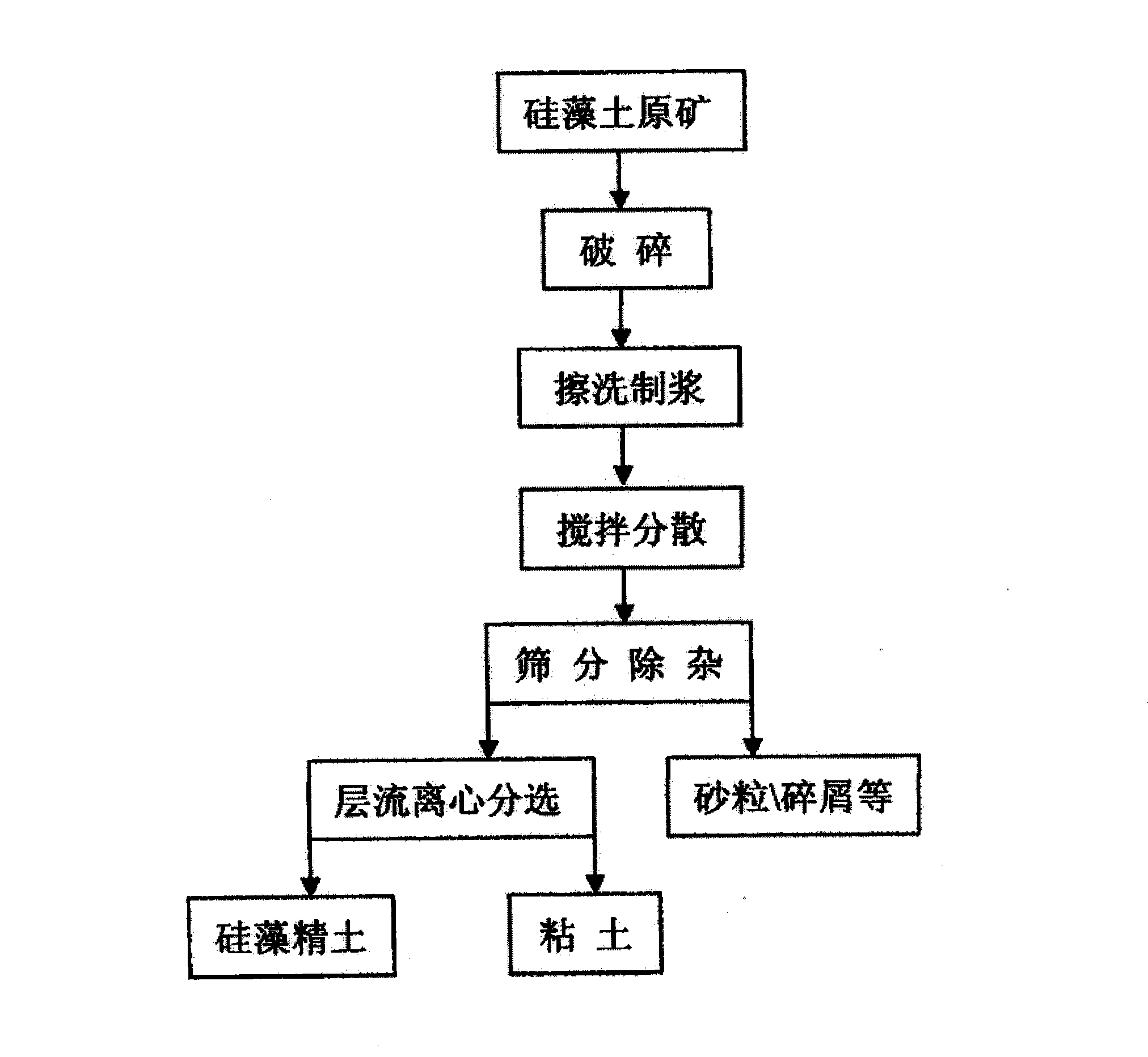

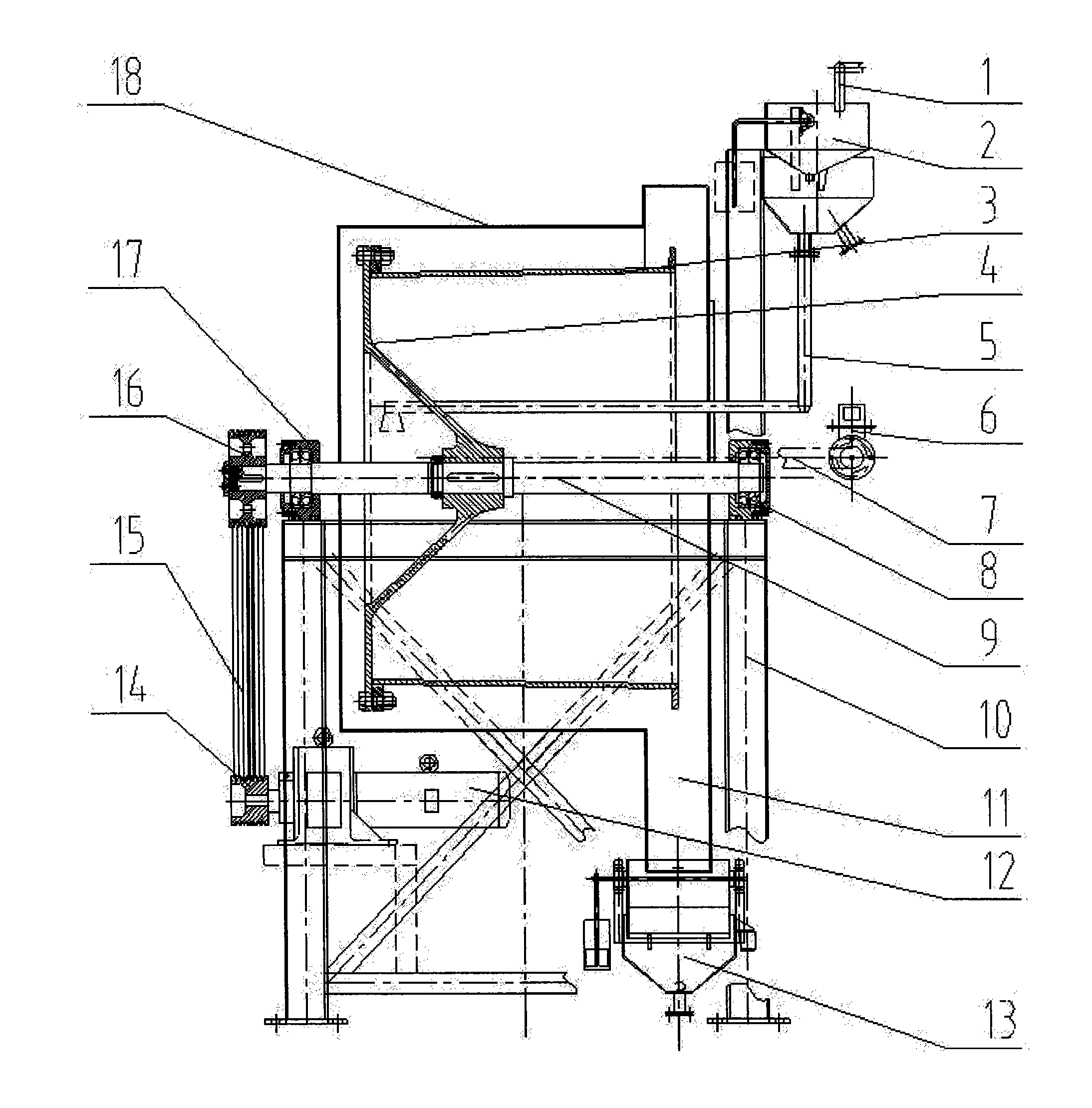

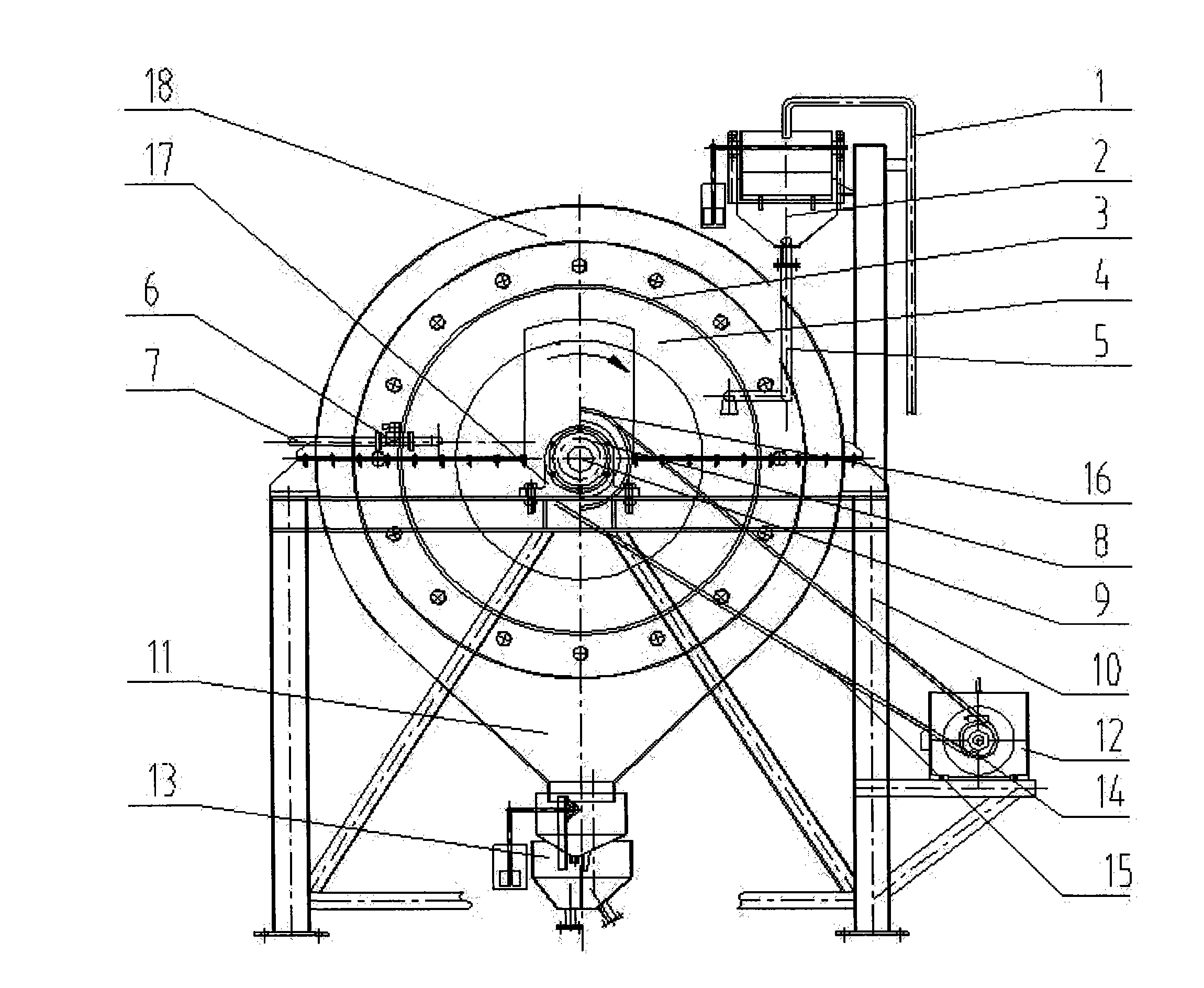

Laminar centrifugal beneficiation method for diatomite ores

ActiveCN102921532AImprove adaptabilityGood quality and stableRotary centrifugesWet separationWork cycleSlurry

The invention relates to a laminar centrifugal beneficiation method for diatomite ores, which comprises the following steps of scrubbing, slurrying, stirring, dispersing, screening, removing impurities, laminar centrifugal classifying, filtering and drying, wherein in the step of laminar centrifugal classifying, the slurry removed of sand grains and debris is fed in a laminar centrifugal separator for classifying, the technological conditions are as follows: the mass percent concentration of feeding ore slurry is 6-20%, the centrifugal separation factor is 75-900, the laminar centrifugal separator washes ore concentrate and discharges in 10-60s after 60-180s of the feeding time, and then pauses for 5-10s, then next work period starts by feeding the laminar centrifugal separator, and each work period lasts for 75-250s. According to the laminar centrifugal beneficiation method for diatomite ores, disclosed by the invention, middle-and-low grade diatomite ores can be efficiently separated, high recovery percent is achieved, and high-quality diatomite is obtained; the method has good adaptability to raw diatomite ores, the flow of the production line is short, the floor space is small, and the large-scale industrialization of beneficiation of diatomite ores is easy to achieve.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

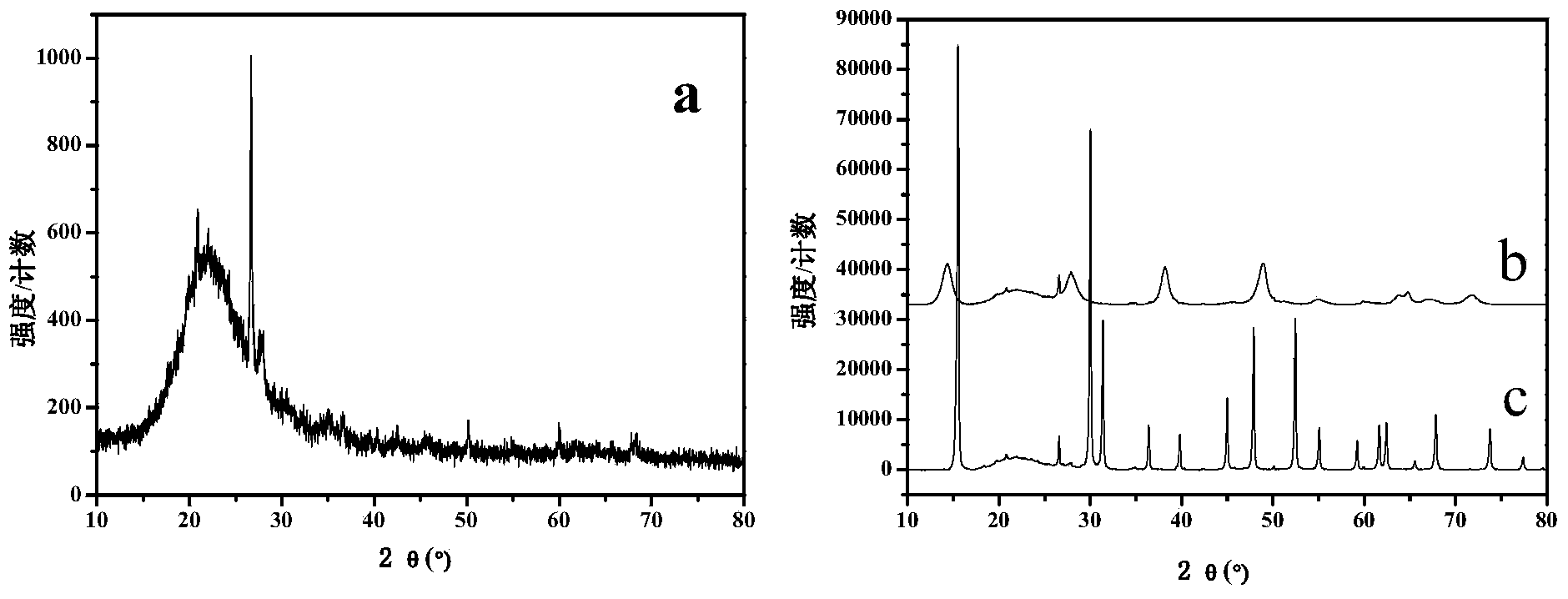

Preparation method for diatomite adsorbent chemically modified by nano gamma-Al2O3 adopting ordered structure

The invention relates to the field of materials and particularly to a preparation method for a diatomite adsorbent chemically modified by nano gamma-Al2O3 adopting an ordered structure. The preparation method comprises the following steps: adding AlCl3.6H2O into the suspension liquid of diatomite; preparing AlCl3 suspension liquid containing diatomite; preparing an ammonia water solution; dropwise adding the ammonia water solution into the AlCl3 suspension liquid containing the diatomite; adjusting the pH to be 4 and stirring continuously; adding the surfactant cetyl trimethyl ammonium bromide or sodium dodecyl benzene sulfonate into the solution; stirring for 30 min, and then adding a certain amount of urea and ammonium fluoride; transferring the solution to a reaction kettle for performing hydrothermal reaction at the temperature of 180 DEG C for 3 h, aging, cooling to room temperature, performing suction filtration, washing, and drying; performing heat treatment and cooling finally, obtaining a final sample. According to the preparation method, by coating a diatomite basic core with the nano gamma-Al2O3 adopting the ordered structure and depositing the nano gamma-Al2O3 adopting the ordered structure on the diatomite basic core through a hydrothermal method, the compound microporous adsorbent which is good in heavy metal ion adsorption performance is prepared, and can be used for adsorbing low-concentration solutions containing lead, copper and zinc metal ions, and the removal rate can reach 93% above.

Owner:BEIJING UNIV OF TECH

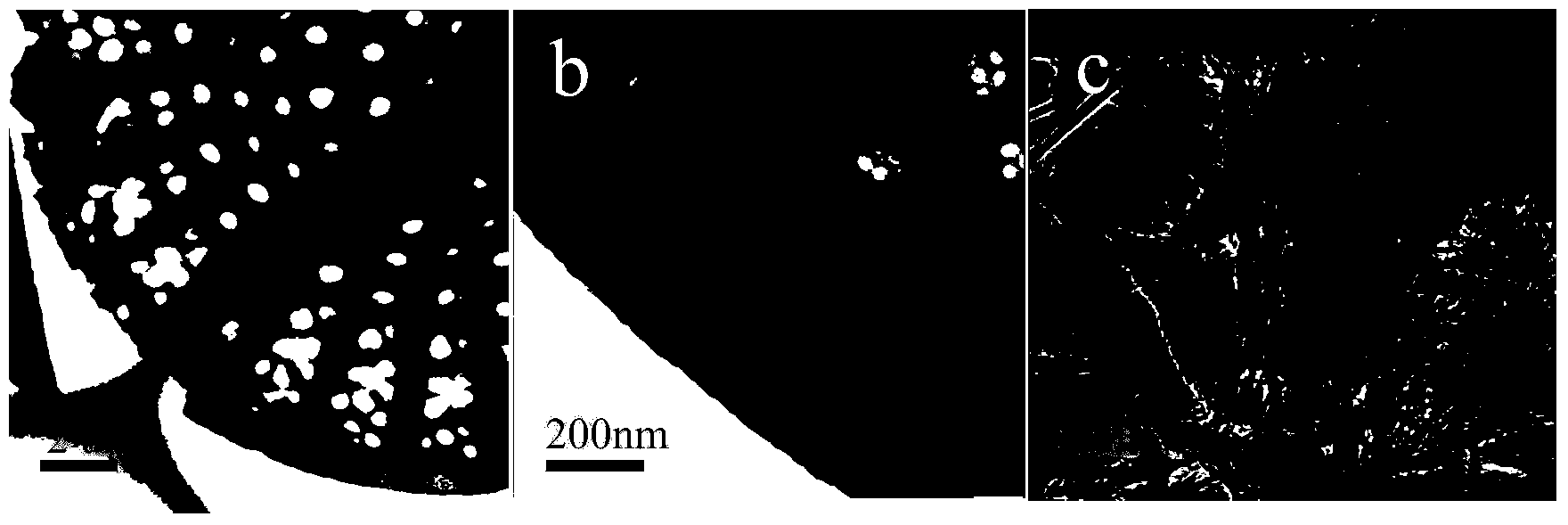

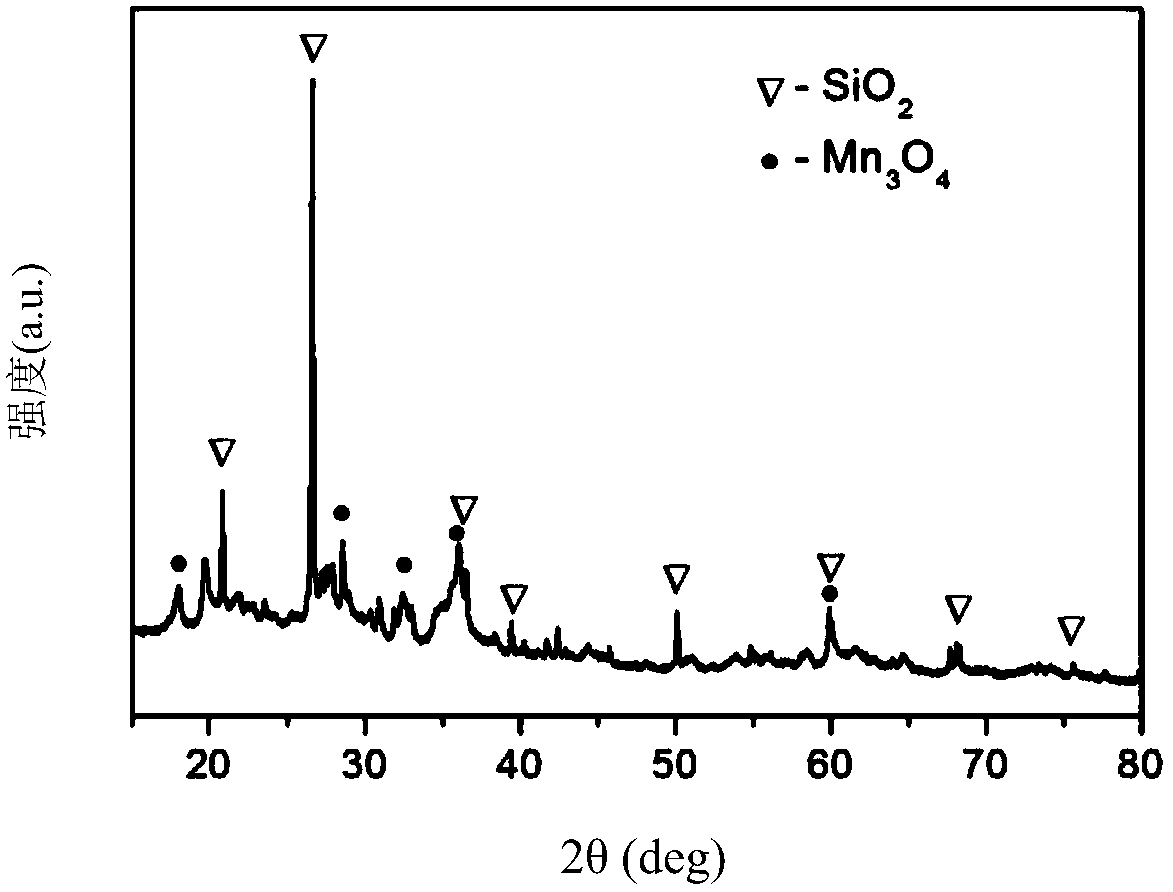

Modified diatomite and preparation method thereof

InactiveCN104415763AImprove oxidation capacityHigh specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCrystallographyPerovskite

The present invention provides a modified diatomite and a preparation method thereof. The modified diatomite preparation steps comprise: pre-modifying diatomite with a nitric acid solution, carrying out secondary modification on the pre-modified diatomite with a ferric nitrate solution, and carrying out air flow dispersion mixing on a perovskite substance and the obtained diatomite to obtain the finally-modified diatomite. According to the present invention, the specific surface area of the modified diatomite is substantially improved.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH

Preparation method for magnesium alloy cast paint

InactiveCN101342570AReduced hot cracking tendencyImprove insulation effectFoundry mouldsFoundry coresWrinkle skinPhosphoric acid

The present invention relates to a method for preparing magnesium casting coating; 0.7 percent of paligorskite clay that is configured with 17 percent of water is milled for 3 hours to be made into solution A; secondly 5 percent of talcum powder, 3 percent of diatomite, 0.5 percent of KBF4 and 1 percent of aluminium phosphate are put into a spherical mill, and is respectively mixed with solution A, 3 percent of silica sol and 67.6 percent of water to be milled for 3 hours to obtain the magnesium alloy metal-typed casting coating; metal mould is heated to be about 200 DEG C, and then is sprayed with a layer of magnesium alloy casting coating on the surface, and is dried finally. The method of the present invention has the advantages of strong heat preservation, flame retardant performance, sticking performance and coating performance, favorable suspension performance and less heat fracture of the casting piece. Oxidation is prevented, so the surface is bright and smooth and is free from oxidized wrinkle.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

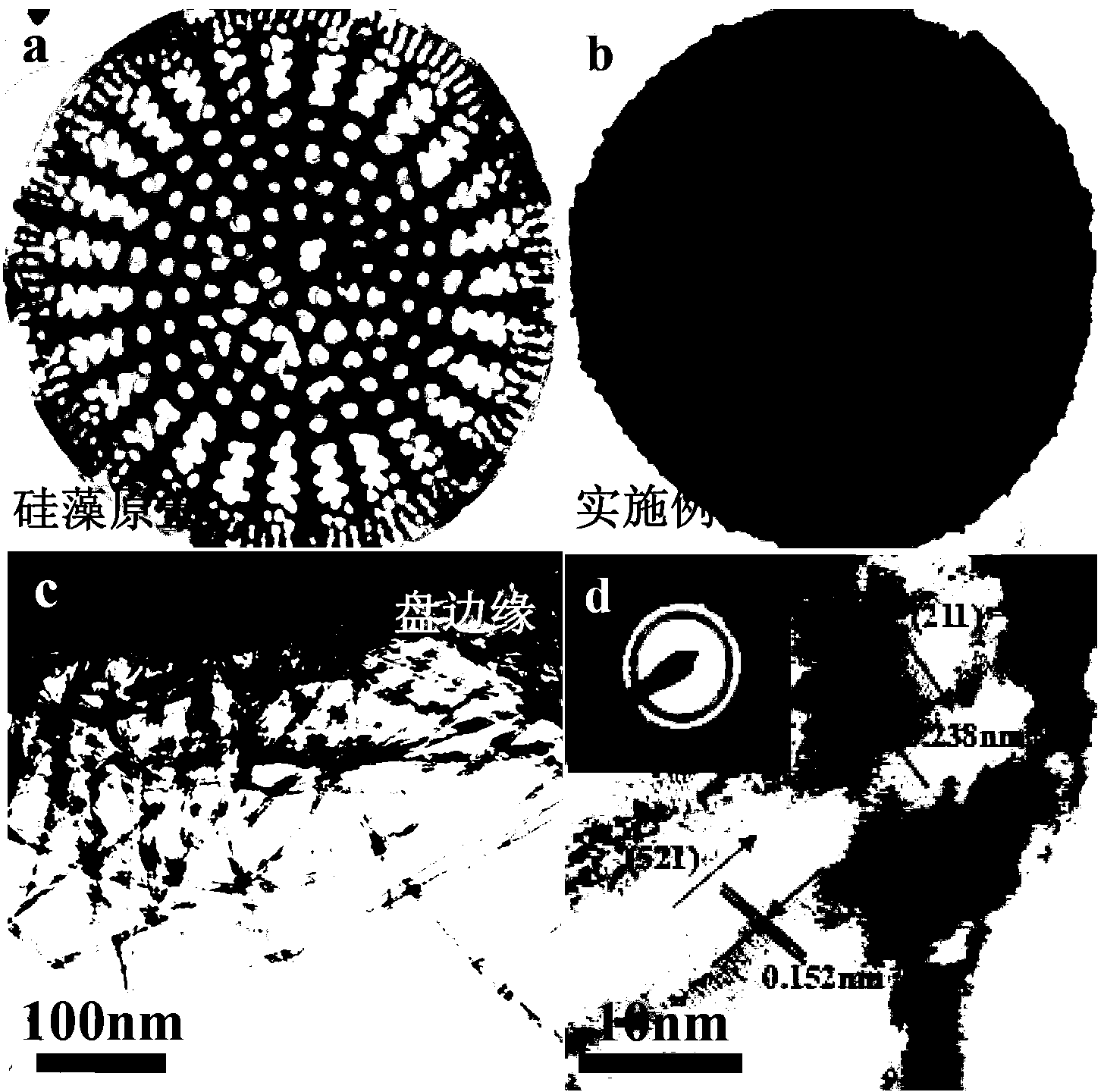

Method for preparing manganese oxide nanowire by deposition on surface of natural porous diatomite

InactiveCN103182293AImprove adsorption capacityGood adsorption of heavy metal anionsOther chemical processesAlkali metal oxides/hydroxidesWater bathsRoom temperature

The invention discloses a method for preparing a manganese oxide nanowire by deposition on the surface of natural porous diatomite. The method is characterized by comprising the following steps: 1, weighing a diatomite powder body, placing the diatomite powder body into a beaker filled with water, placing the beaker into a water bath pond, and stirring to prepare a diatomite suspension solution; 2, weighing ammonium persulfate (NH4)2S2O8, placing ammonium persulfate (NH4)2S2O8 into the diatomite suspension solution, magnetically stirring for more than 30 min, fully impregnating into the diatomite, weighing KMnO4, placing KMnO4 into a mortar, fully grinding, dissolving in water, dripping into the diatomite suspension solution, continuing to stir for more than 30 min, and cooling to the room temperature; and 3, transferring the solution into a reaction kettle for water bath / hydrothermal reaction at the temperature of 50-160 DEG C, ageing, cooling to the room temperature, washing by de-ionized water and absolute ethanol for multiple times, and drying to obtain a final sample. According to the method, the adsorption efficiency of a composite material on heavy metal ions is improved; and the method is low in production cost, simple in operation process and easy for industrial production.

Owner:BEIJING UNIV OF TECH

Activated carbon diatomite particles capable of rapid purification of flue gas and preparation method thereof

InactiveCN104475050AHigh desulfurization precisionQuick purificationOther chemical processesDispersed particle separationPorositySilicon dioxide

The invention discloses activated carbon diatomite particles capable of rapid purification of flue gas, and is characterized in that the activated carbon diatomite particles are prepared from the following raw materials in parts by weight: 105-110 parts of wooden activated carbon, 35-40 parts of diatomite, 1-2 parts of tripotassium citrate, 4-6 parts of expanded perlite, 3-5 parts of ammonium chloride, 2-3 parts of zirconium silicate, 6-9 parts of nano kaolin, 4-6 parts of nano silica, 3-5 parts of copper sulfate, 1-2 parts of rosin-polythylene oxide ester, 3-5 parts of methyldiethanolamine, 4-6 parts of an adsorption auxiliary agent, and a proper amount of water. The formula is reasonable; with addition of nano kaolin and expanded perlite, much surface pores exist, and the porosity is high; with addition of methyldiethanolamine, the activated carbon diatomite particles have a flue gas rapid purifying effect; with addition of the adsorption auxiliary agent, the activated carbon diatomite particles have special porousness, and prolong the contact time with gas; and activated carbon can quickly adsorb various solutes and free gases, and is high in activity, high in desulfurization precision, and suitable for industrial dry desulfurization, automobile tail gas desulfurization, daily air purification and the like.

Owner:ANHUI PHOENIX INT CO LTD

Compound adsorbent for water treatment

InactiveCN105664881AWide variety of sourcesLow costOther chemical processesSpecific water treatment objectivesFiberSodium Bentonite

The invention discloses a composite adsorbent for water treatment. According to the mass percentage, the raw materials include 64-82% of bentonite, 4-10% of bagasse, 3-5% of fly ash, 1-2% of alginic acid fiber, Polyvinyl alcohol 0.15-0.5%, potassium carbonate 1-2%, diatomaceous earth 3-4.8%, zeolite powder 0.5-1%, nano titanium dioxide 0.35-0.7% and water 5-10%. The invention has the characteristics of wide source of raw materials and low cost, and each raw material will not pollute the environment. The present invention uses bentonite and diatomite as main raw materials, by adding polyvinyl alcohol with strong binding force, bagasse, fly ash, alginic acid fiber with strong adsorption, potassium carbonate with antibacterial effect, nano-titanium dioxide, etc. It is obtained by mixing auxiliary raw materials, has good binding force, antibacterial property, adsorption property and long-lasting effect, and can be widely used in water treatment.

Owner:HANGZHOU DIANZI UNIV

Preparation method of catalyst for improving yield of diesel oil produced by catalytic cracking

ActiveCN104275205AImprove pore structureWell-developed pore structureMolecular sieve catalystsMicrosphereRare earth

The invention discloses a preparation method of a catalyst for improving the yield of diesel oil produced by catalytic cracking. The preparation method comprises the following steps: with a mixture of kaolin and diatomite subjected to acid treatment as a raw material, adding chemical water, structural auxiliaries, a dispersing agent and / or a reinforcing agent into the mixture, and performing mixed pulping and spraying to obtain microspheres; roasting the sprayed microspheres, mixing the roasted microspheres with a guiding agent, sodium silicate and sodium hydroxide in a certain ratio, and performing a crystallization reaction under hydrothermal conditions, thereby obtaining a crystallization product with a pore structure and excellent abrasion resistance and with a 20%-30% NaY molecular sieve, wherein the crystallization product, namely the in-situ crystallized microspheres, can be taken as a precursor for preparing the catalytic cracking catalyst; and exchanging the in-situ crystallized microspheres with ammonium salt and rare earth to obtain the catalytic cracking catalyst for improving the yield of diesel oil.

Owner:PETROCHINA CO LTD

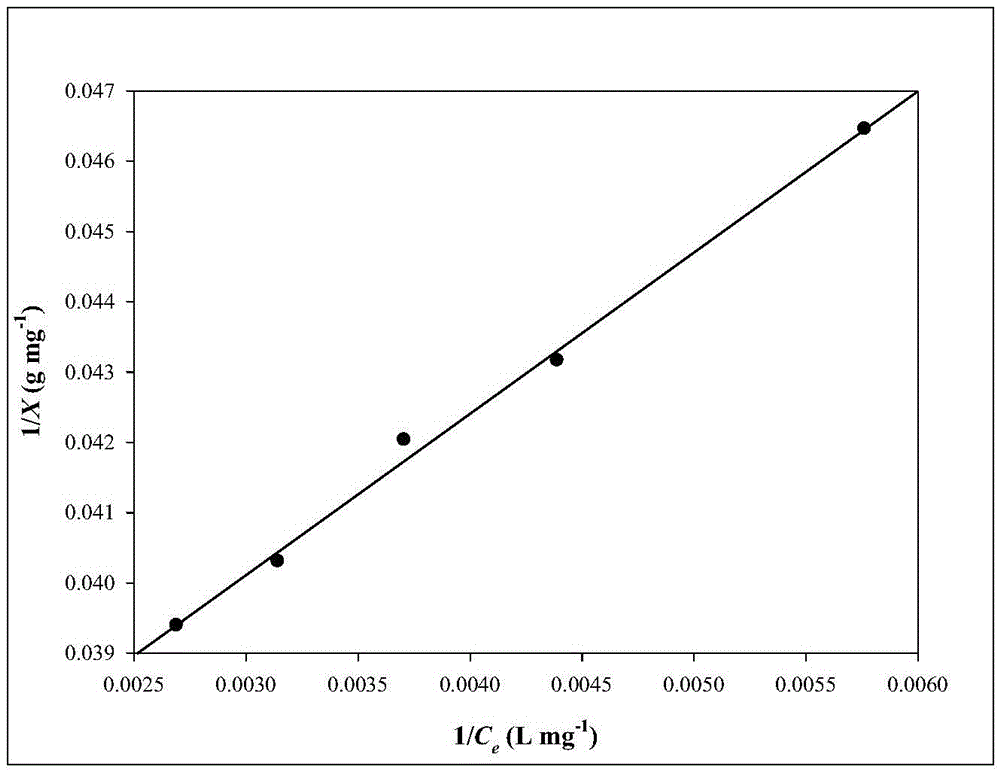

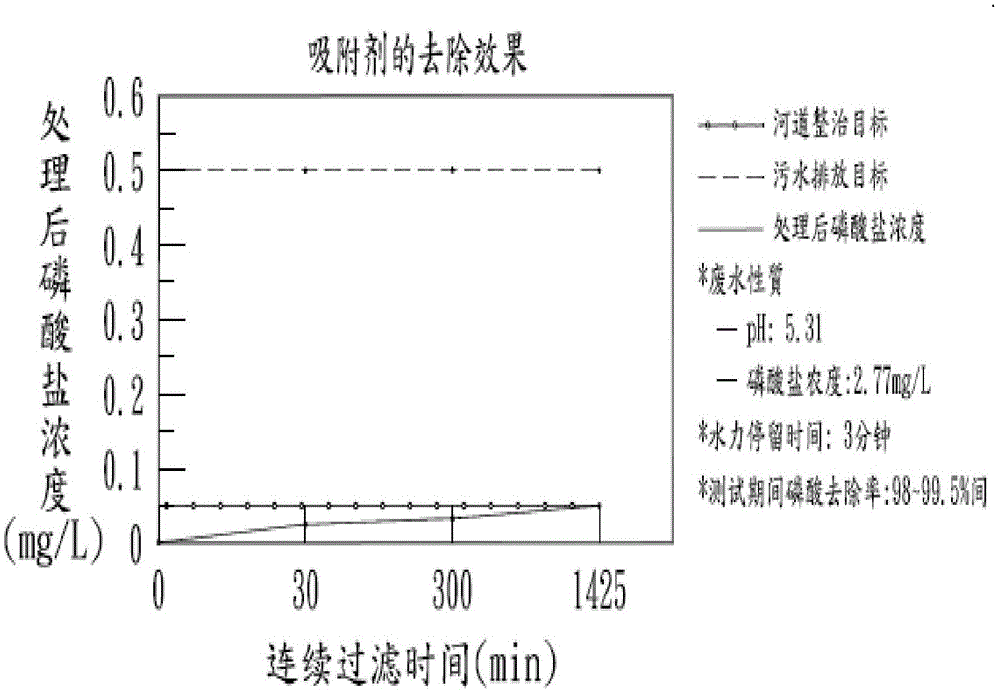

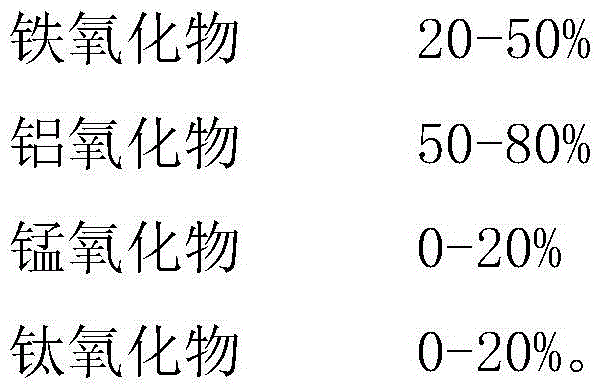

Phosphate adsorbent capable of being repeatedly used and preparation method thereof

InactiveCN105582881AReduce use costHigh porosityOther chemical processesAluminium silicatesSorbentSilicon oxide

The invention belongs to the technical field of sewage treatment and particularly relates to a phosphate adsorbent capable of being repeatedly used and a preparation method thereof. According to the adsorbent, a porous carrier serves as a core, and the surface of the carrier is coated with a metallic oxide layer. The weight of the metallic oxide layer accounts for 3-25% of the total weight of the adsorbent. The porous carrier is one or a combination of silicon oxide, aluminum oxide, manganese oxide, zeolite, activated carbon and diatomite. The metallic oxide layer is prepared from, by weight, 20-50% of iron oxide, 50-80% of alumina, 0-20% of manganite and 0-20% of titanic oxide. The prepared phosphate adsorbent can be repeatedly used, use cost is greatly reduced, the adsorption capacity of the phosphate adsorbent is high, use is convenient, the removal rate of phosphate in sewage reaches 98% or above, and adsorption efficiency is high.

Owner:钱中明

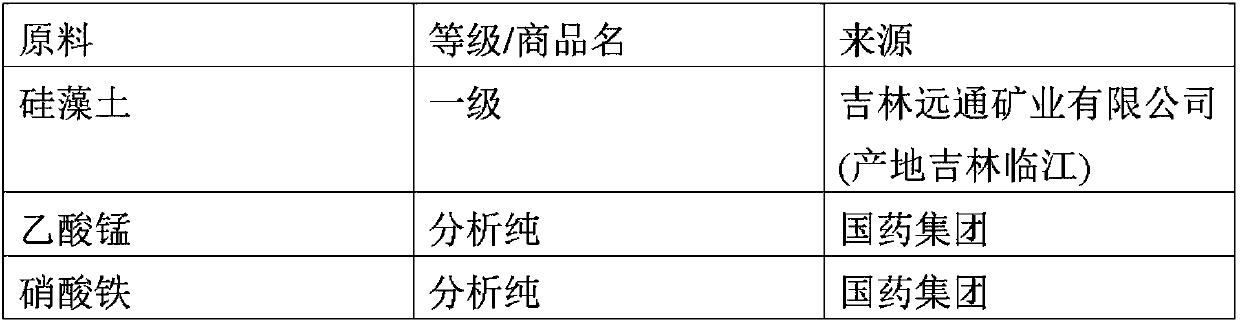

Catalyst for decomposing ozone, and preparation method of catalyst

ActiveCN107649145AEnhanced ability to decomposeEasy to makeGas treatmentDispersed particle separationMANGANESE ACETATEAcetic acid

The invention discloses a catalyst for decomposing ozone, and a preparation method of the catalyst. The catalyst is prepared from diatomaceous earth and Fe-doped manganese oxide loaded on the diatomaceous earth, wherein the mass of Mn element in the manganese oxide accounts for 2-10% of the total mass of the catalyst. The preparation method of the catalyst comprises the following steps: (1) soaking the diatomaceous earth into a mixed solution of manganese acetate and iron salt, and enabling the diatomaceous earth to be evenly dispersed in the solution, wherein the adding amount of the diatomaceous earth is 25-200g / L; (2) separating the diatomaceous earth out from the solution, drying and then calcining to obtain the catalyst.

Owner:NORTHEASTERN UNIV

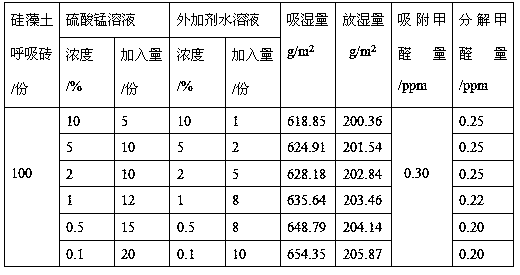

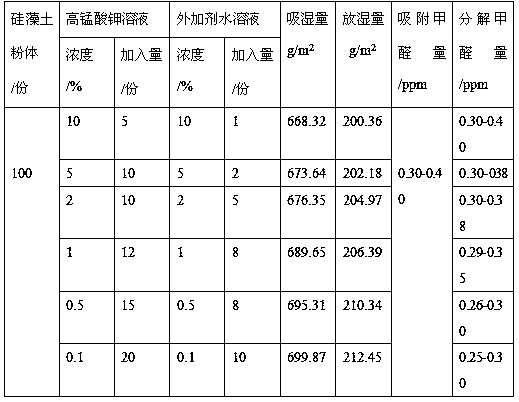

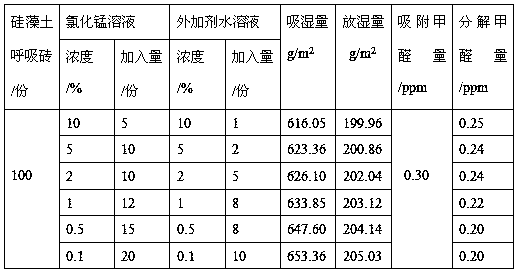

Preparation method for diatomite loaded birnessite type manganese dioxide

The invention discloses a preparation method for diatomite loaded birnessite type manganese dioxide, and relates to a preparation method for manganese dioxide. The preparation method is characterizedin that a manganese salt and an additive are prepared into a uniform aqueous solution; diatomite and a product thereof are soaked into an aqueous solution of the manganese salt and the additive, and drying and / or forming treatment is performed; the diatomite loaded birnessite type manganese dioxide is prepared from 5-20 parts of a manganese salt solution, 1-10 parts of an additive aqueous solutionand 100 parts of diatomite and a product thereof, wherein manganese salt is prepared from potassium permanganate, manganese chloride and manganese sulfate, and concentration of the manganese salt is0.1-10.0%; concentration of the additive aqueous solution is 0.1-10.0%; and the diatomite and the product thereof are prepared from diatomite powder and a diatomite breathing brick; the loaded birnessite type manganese dioxide diatomite is prepared. Birnessite type manganese dioxide is loaded onto the diatomite and the product thereof, and moisture absorption of diatomite and formaldehyde adsorption are organically combined with formaldehyde decomposition and regeneration of birnessite type manganese dioxide, so that indoor air is efficiently purified.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Preparation method for magnesium alloy cast paint

InactiveCN101342571AReduced hot cracking tendencyImprove insulation effectFoundry mouldsFoundry coresWrinkle skinBoric acid

The present invention relates to a method for preparing the magnesium casting coating; 0.8 percent paligorskite clay that is configured with 17 percent of water is milled for 3 hours to be made into solution A; secondly 3 percent of talcum powder, 4 percent of diatomite, 0.6 percent of NH4BF4 and 3 percent of boric acid are put into a spherical mill, and is respectively mixed with solution A, 4 percent of silica sol and 67.6 of percent water to be milled for 3 hours to obtain the magnesium alloy metal-typed casting coating; metal mould is heated to be about 200 DEG C, and then is sprayed with a layer of magnesium alloy casting coating on the surface, and is dried finally. The method of the present invention has the advantages of strong heat preservation, flame retardant performance, sticking performance and coating performance, favorable suspension performance and less heat fracture of the casting piece. Oxidation is prevented, so the surface is bright and smooth and is free from oxidized wrinkle.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

Novel easily collapsible precoated sand and preparation method thereof

InactiveCN104841863AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresCross-linkUltimate tensile strength

The invention discloses novel easily collapsible precoated sand, which is characterized by being made of the following raw materials in parts by weight: 4 to 6 parts of thermoplastic phenolic resin, 1 to 2 parts of polyformaldehyde, 1 to 1.5 parts of cross-linking agent TAC, 2.5 to 3 parts of water, 0.8 to 1.2 parts of urotropine, 80 to 90 parts of silica sand, 3 to 5 parts of molybdenum disulfide, 8 to 11 parts of kieselguhr, 0.4 to 0.7 parts of calcium peroxide, 0.25 to 0.35 parts of calcium stearate and 5 to 7 parts of synergists. The synergists made by a special process are added, so liquidity, breathability, heat dispersion and strength of the precoated sand are enhanced, and the surface is compact and is not easy to crack and deform; the components for enhancing the liquidity and breathability, including the molybdenum disulfide, the kieselguhr and the like, and the collapsing components including the calcium peroxide and the like are also added, and the polyformaldehyde and the thermoplastic phenolic resin are mixed to increase product strength, so the made precoated sand is high temperature resistant, easily collapsible, small in sand burning possibility, free of shell mould delamination, good in thermal conductivity and liquidity, and is smooth in casting surface.

Owner:MAANSHAN HENGYI MACHINERY MFG

Uneasily-disintegrated mixed active carbon desulfurizing agent and preparation method thereof

InactiveCN104437366AHigh strengthNot easy to disintegrateOther chemical processesDispersed particle separationPorositySodium Bentonite

The invention discloses an uneasily-disintegrated mixed active carbon desulfurizing agent and a preparation method thereof. The uneasily-disintegrated mixed active carbon desulfurizing agent is characterized by being prepared from the following raw materials in parts by weight: 90-100 parts of active carbon, 40-50 parts of diatomite, 2.5-4 parts of zinc oxide, 6-8 parts of nano bentonite, 1-2 parts of sodium alcohol ether sulphate, 3-5 parts of anthracite, 3-5 parts of limestone powder, 3-4 parts of copper sulfate, 3-4 parts of silica sol, 2.5-4 parts of propyl acetate emulsion, 2-4 parts of ammonium hydrogen carbonate, 0.5-0.8 part of potassium sorbate, 4-6 parts of an adsorption auxiliary agent and a proper amount of water. According to the uneasily-disintegrated mixed active carbon desulfurizing agent, zinc oxide, limestone and the like are added into active carbon so that the desulfurizing efficiency is enhanced; viscous matters including the silica sol, the propyl acetate emulsion and the like are added so that the strength of the active carbon is increased, and a product is not easy to disintegrate and is firm and durable; the adsorption auxiliary agent is added and has the special porosity so that the contact time between gas and the adsorption auxiliary agent is prolonged, and furthermore, the effects of inhibiting bacteria and purifying air are realized; and the uneasily-disintegrated mixed active carbon desulfurizing agent is suitable for industrial desulfurization, is also suitable for treating automobile tail gas with a good effect.

Owner:ANHUI PHOENIX INT CO LTD

Composite absorbent material for waste gas treatment

InactiveCN105536718AStrong adsorptionBoth adsorption andOther chemical processesDispersed particle separationSodium BentoniteAbsorbent material

The invention discloses a composite absorbent material for waste gas treatment. The composite absorbent material is prepared from a carrier, a functional component and a catalytic component, wherein the carrier is prepared from a mixture of bentonite and kieselguhr, activated carbon, zeolite, attapulgite, a mixture of wood chips, sawdust and crop straws, CMC (Carboxy Methylated Cellulose) and the like; the functional component is prepared from ferrous sulfate, potassium permanganate, and potassium sulfate / magnesium chloride; the catalytic component is prepared from nano-water and ferric oxide, and nanometer titania; the composite absorbent material disclosed by the invention has the advantages of good adsorbing effect, low cost, and simple preparation.

Owner:山东永辰环境科技有限公司

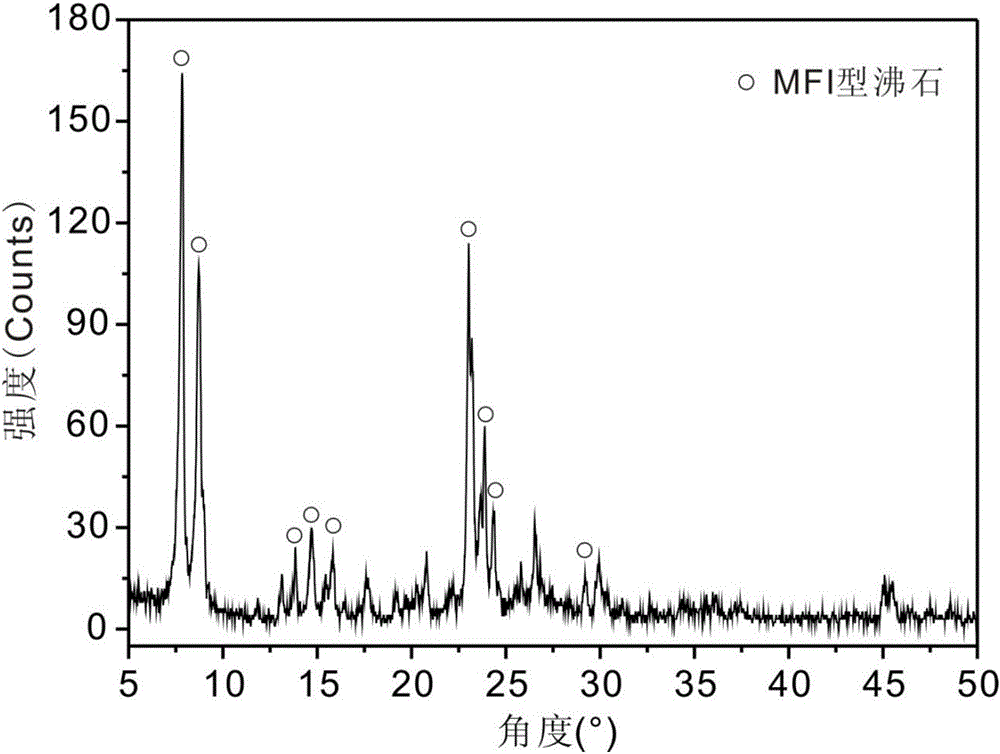

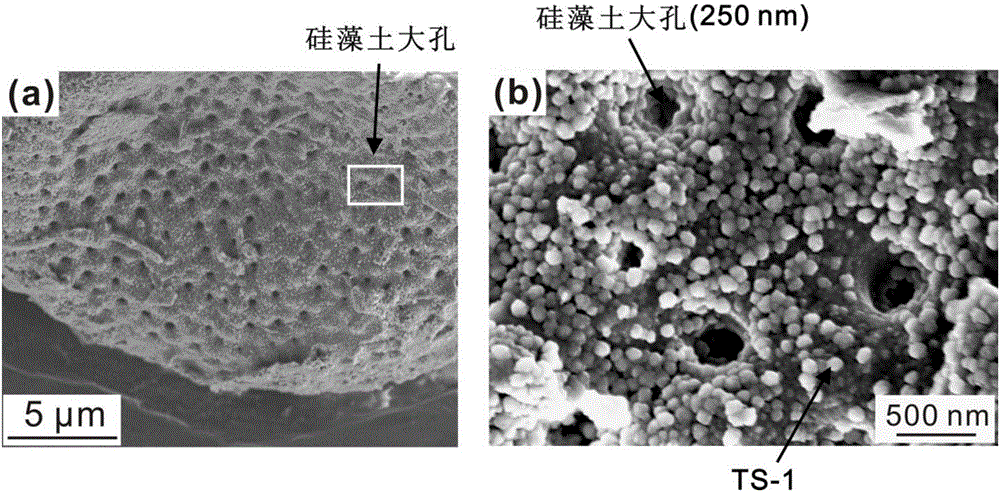

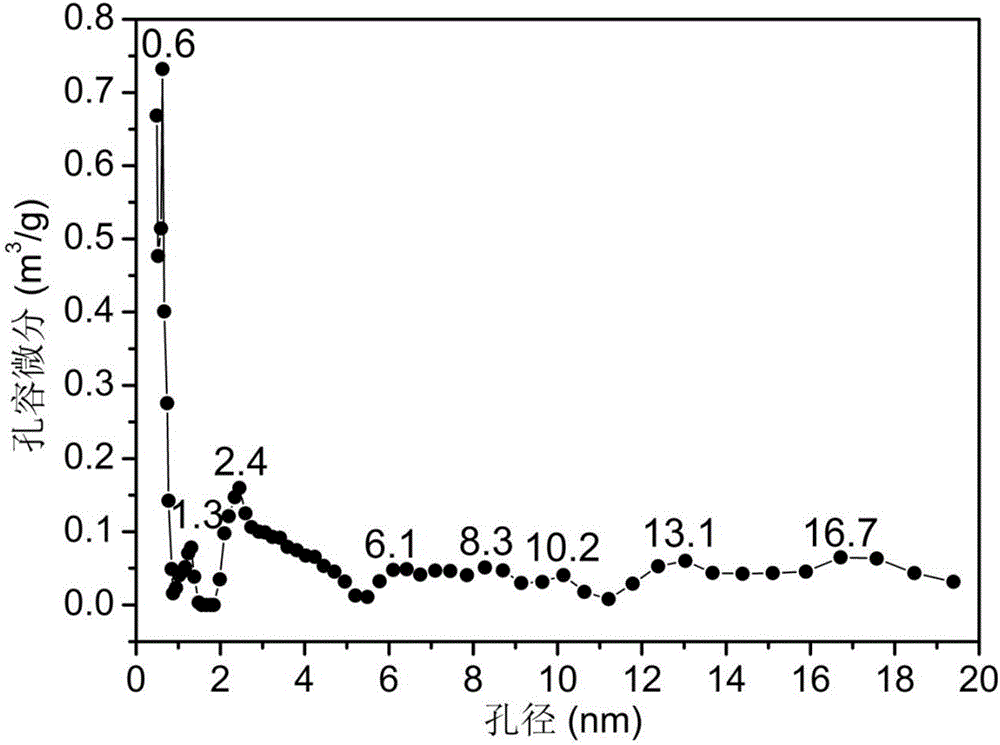

Diatomite/nano TS-1 titanium silicalite composite material with hierarchical porous structure and preparation method of diatomite/nano TS-1 titanium silicalite composite material

InactiveCN106268936ALarge specific surface areaHigh total pore volumeMolecular sieve catalystsCatalyst activation/preparationTitaniumNucleation

The invention discloses a diatomite / nano TS-1 titanium silicalite composite material with a hierarchical porous structure and a preparation method of the diatomite / nano TS-1 titanium silicalite composite material. By adoption of the cheap diatomite as a carrier, nano TS-1 titanium silicalite is uniformly loaded on the surface of the diatomite by means of electrical property inversion, adsorption, nucleation and crystallization to obtain the diatomite / nano TS-1 titanium silicalite composite material with a hierarchical porous structure having macropores / mesopores / micropores, and the composite materials is large in specific surface area and total pore volume. By loading of the nano TS-1 titanium silicalite on the surface of the diatomite, problems of single pore structure and low specific surface area of the diatomite can be solved, the obtained composite materials is excellent in photocatalytic degradation of organic pollutants such as crystal violet, and application value of the diatomite in the field of catalysis is increased. In addition, the preparation method of the diatomite / nano TS-1 titanium silicalite composite material has advantages of technical simplicity and feasibility, low cost, low energy consumption and low pollution and has a promising industrial application prospect.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Hydrogen-sulfide-removed modified active carbon and preparation method thereof

InactiveCN103566876ABig gapImprove adsorption capacityOther chemical processesDispersed particle separationCopper oxideSilicon dioxide

The invention relates to hydrogen-sulfide-removed modified active carbon, which is prepared from the following raw materials in parts by weight: 110 to 120 parts of active carbon, 15 to 20 parts of copper sulfate, 8 to 10 parts of zeolite, 8 to 10 parts of diatomite, 5 to 7 parts of active aluminum oxide, 20 to 25 parts of orange peel, 2 to 4 parts of nanometer silicon dioxide, 3 to 5 parts of copper oxide superfine powder, 4 to 5 parts of modified diatomite and an appropriate amount of water. The copper sulfate is used for modifying the active carbon, so that hydrogen sulfide can be rapidly removed; due to use of zeolite, modified diatomite, active aluminum dioxide, copper oxide superfine powder and the like, the effects of rapidly desulphurizing, absorbing bacteria and deodorizing can be realized; and since the orange peel is used as a material of the active carbon, the produced active carbon has a large pore size, high adsorption capability and reduced cost, is suitable for the livestock farm and can be used for purifying automobile exhaust.

Owner:BENGBU HUAFANG FILTER

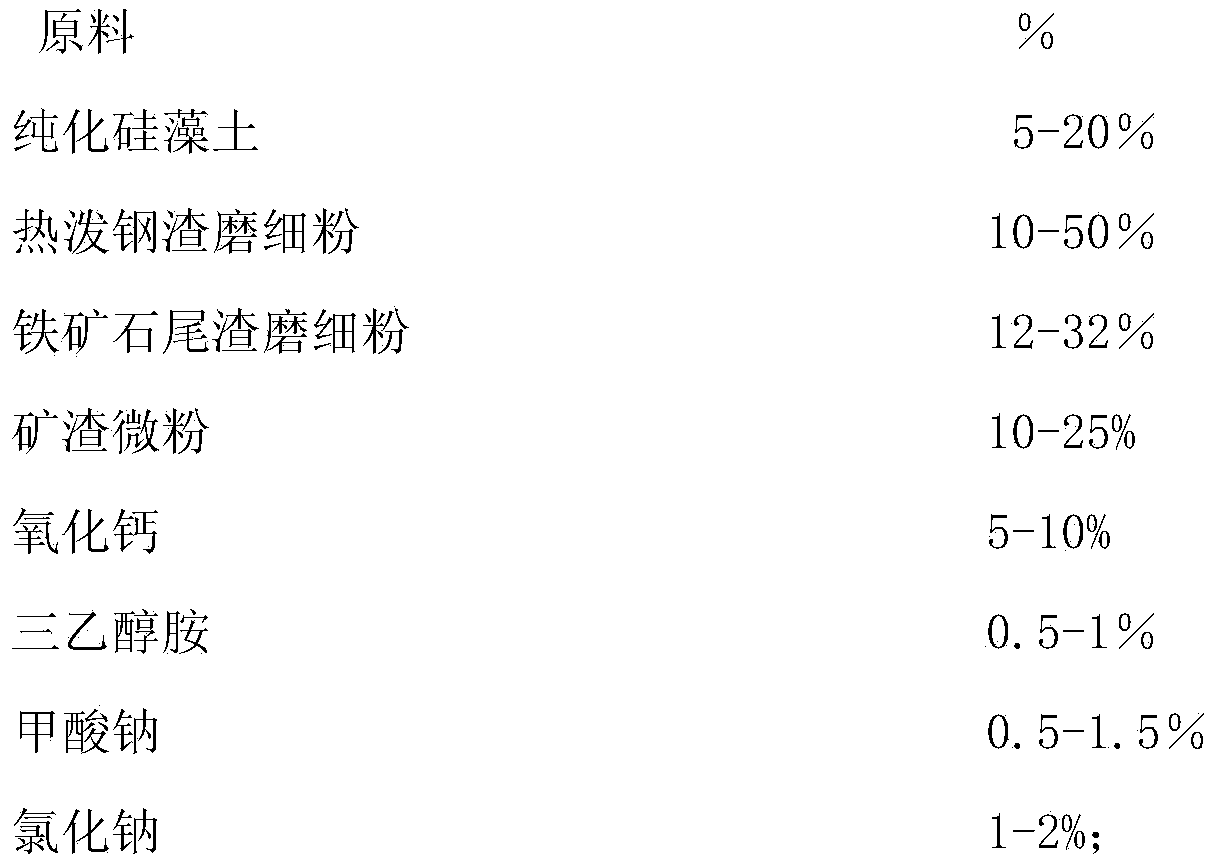

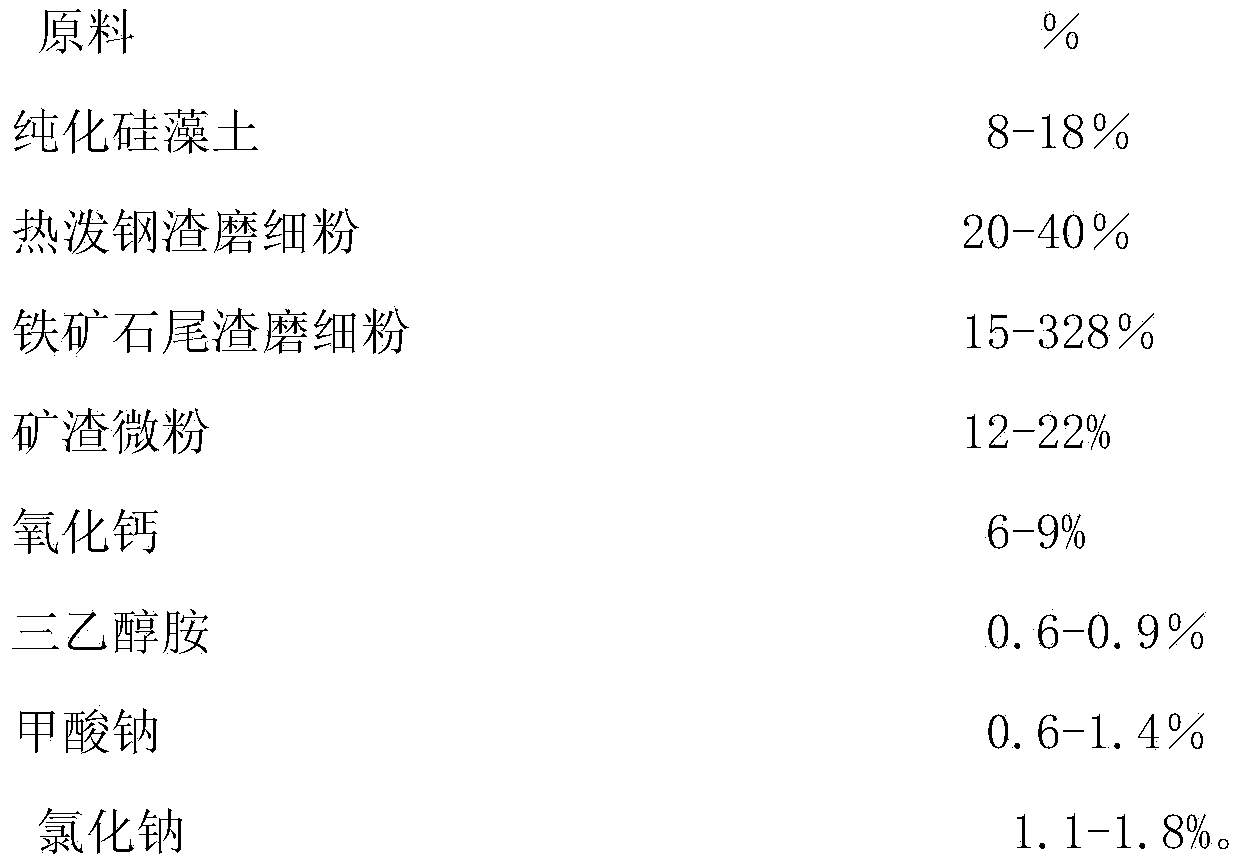

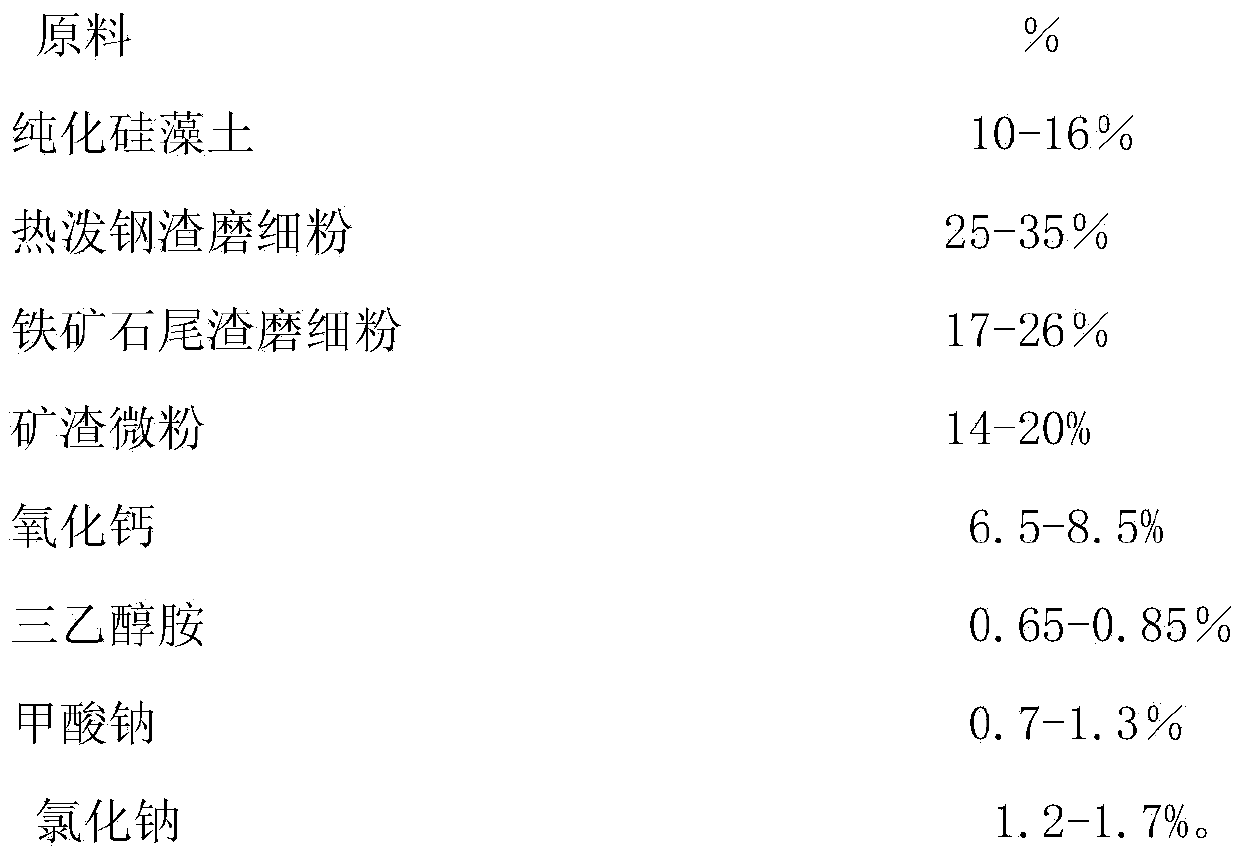

Contaminated soil consolidation remediator and preparation method

The invention discloses a contaminated soil consolidation remediator and a preparation method. The remediator is composed of purified infusorial earth, hot splashing steel slag pulverized powder, iron ore tailing pulverized powder, superfine slag powder, calcium oxide, triethanolamine, sodium formate and sodium chloride according to a certain proportion. The method includes the steps that A, steel slag, the purified infusorial earth and iron ore tailings are soaked respectively through hydrochloric acid, and the treated steel slag, infusorial earth and iron ore tailings are mixed so as to obtain a mixture A; B, the steel slag, the infusorial earth and the iron ore tailings are levigated respectively through a ball mill; C, the superfine slag powder, the calcium oxide, the triethanolamine, the sodium formate and the sodium chloride are mixed sequentially or randomly so as to obtain a mixture B; and D, the mixture A and the mixture B are added into a sealed three-axis agitator to be agitated, mixing is performed after film laminating and packaging, and the soil consolidation remediator is obtained. According to the contaminated soil consolidation remediator, the formula is easy to prepare; operation is easy and convenient; the treatment effect is good; the production cost is low; secondary soil contamination is avoided.

Owner:HUBEI JBM ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

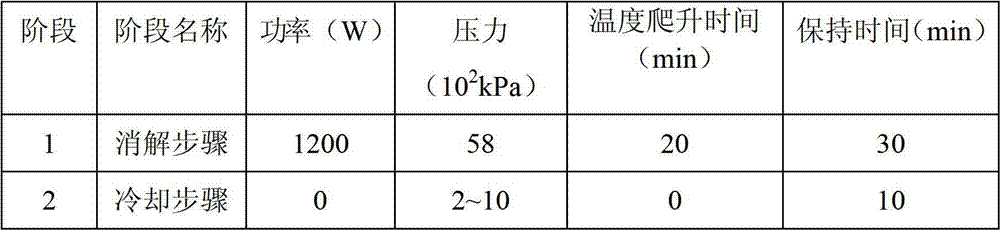

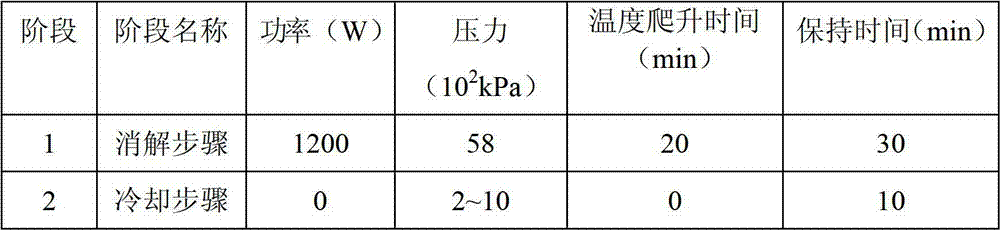

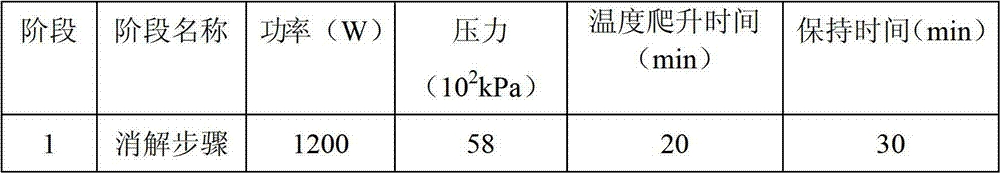

Method for determining nickel content in nickel-chromium-aluminum coated diatomite

InactiveCN102735794AImprove accuracyDetermination is accurate and reliableChemical analysis using titrationPreparing sample for investigationElement analysisMaterial resources

The invention belongs to a nickel-chromium-aluminum coated diatomite element analysis technology, and relates to a method for determining nickel content in nickel-chromium-aluminum coated diatomite. According to the method, 5-10 mL of hydrochloric acid, 1-5 mL of nitric acid and 5-10 drops of hydrofluoric acid are adopted to treat (metal-inorganic non-metal powder) nickel-chromium-aluminum coated diatomite, such that problems of large use amounts of reagents for dissolving the sample, difficult dissolving of the sample, incomplete dissolving of the sample, and the like in the prior art are solved. With the present invention, a classical chemical method-dimethylglyoxime-EDTA volumetric method is adopted to determine the nickel content in the nickel-chromium-aluminum coated diatomite, and an appropriate standard substance is adopted as a control so as to improve accuracy of analytical measurement; the study results show that the established method for determining the nickel content in the nickel-chromium-aluminum coated diatomite is accurate and reliable, and can meet requirements of research and production; and the method of the present invention has characteristics of rapidness, easy operation, manpower saving and material resource saving.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A kind of diatomite calcium plastic composite board

A diatomite calcium plastic composite board and a production method thereof, the main points of which are that it includes the following components: PVC resin, heavy calcium carbonate, nanoscale heavy calcium carbonate, plasticizer, diatomite, straw Flour or wood flour, heat stabilizer, stearic acid, polyethylene wax, paraffin wax; after mixing and drying the above components in a certain proportion, extrude the plate structure through the extruder according to the mold, and then vacuum shape and cut , Sanding the bottom surface and the surface, the surrounding mortise and deep processing of the surface can become the finished floor. The present invention adds a small amount of nano-scale heavy calcium carbonate and diatomite to fully fill between the large particles of heavy calcium carbonate, thereby forming a complete package for PVC resin particles and increasing the specific surface area. Its reactivity increases; its hardness is high and its plasticity is strong; the nanoparticles in the nanocomposite material can prevent the formation of crystals, therefore, it can greatly reduce the weight and improve the thermal conductivity.

Owner:吉林爱尔得板材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com