Method for preparing manganese oxide nanowire by deposition on surface of natural porous diatomite

A technology of manganese oxide sodium rice noodles and porous silicon, applied in the field of materials, can solve problems such as the effect of heavy metal ion adsorption and removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

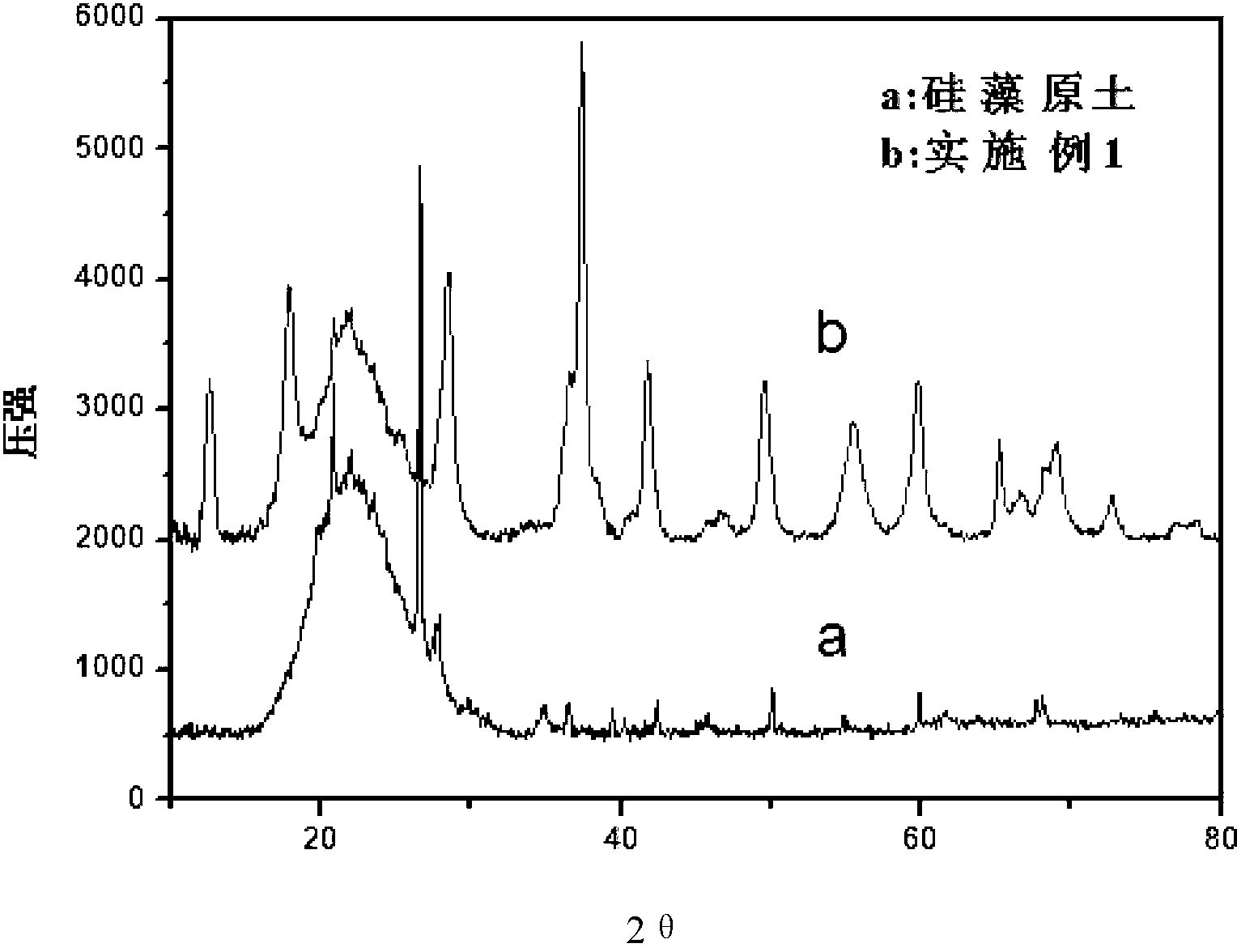

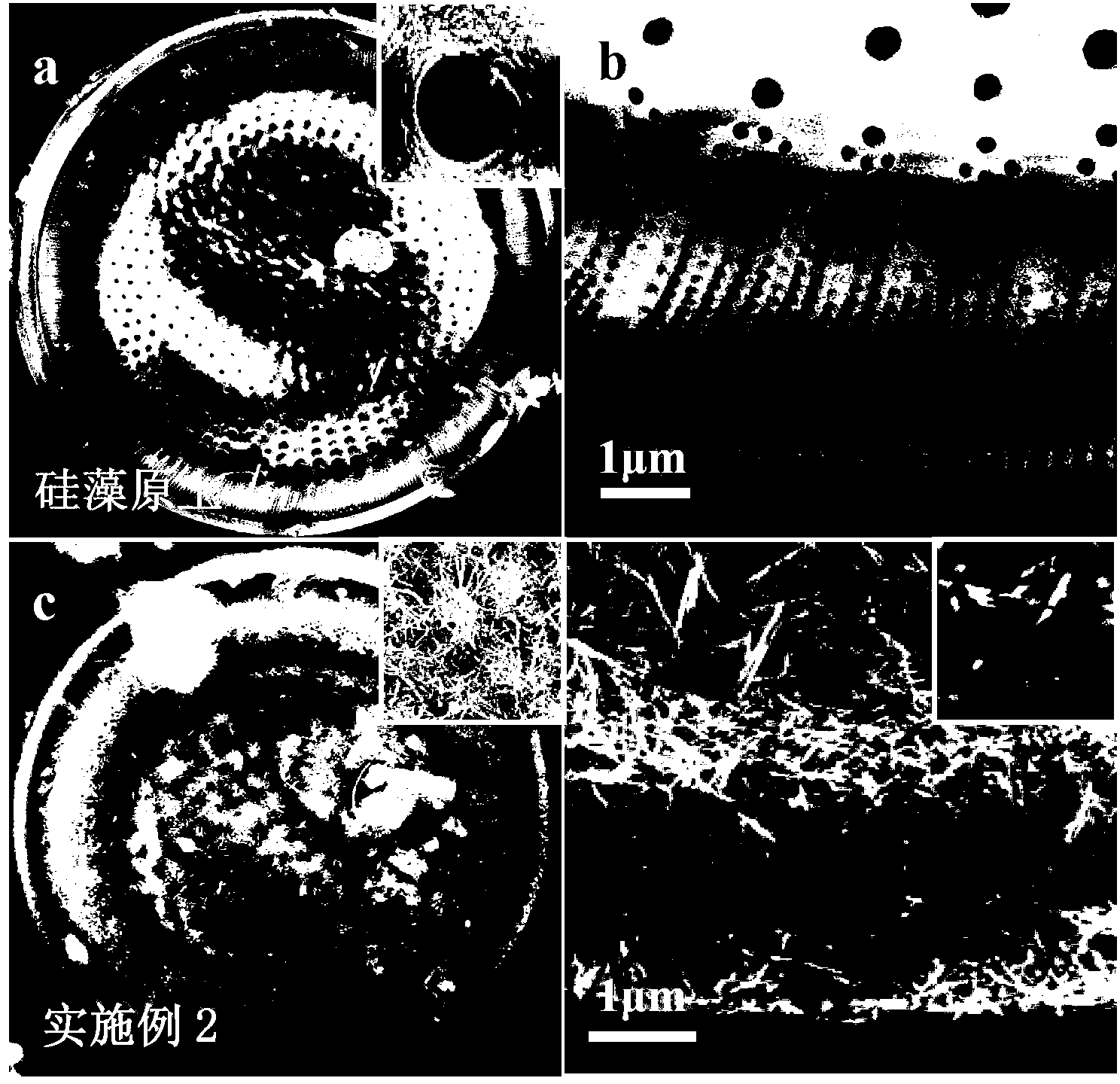

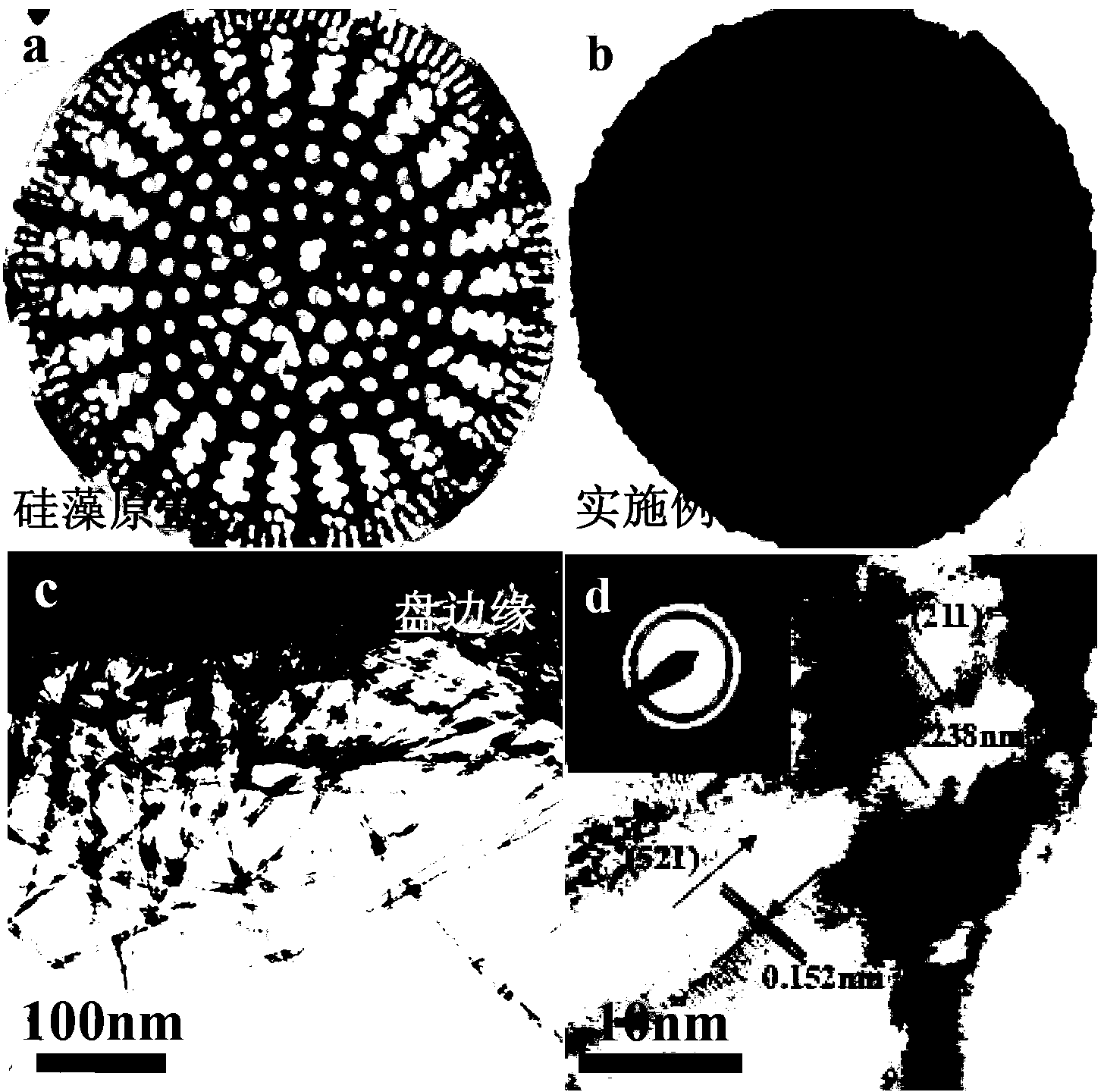

Embodiment 1

[0021] 1. Weigh 4.2g of diatomaceous earth and suspend it in 50mL of water, and place it in a constant temperature water bath and stir to form a uniform suspension.

[0022] 2. Weigh 3.7g of ammonium persulfate and add it to the diatomite suspension, stir with constant temperature magnetic force to fully impregnate it into the diatomite, add 4.424g of potassium permanganate and continue stirring to fully react and then cool to room temperature.

[0023] 3. Transfer the solution to a reactor at 90°C for 12 hours in a water bath for aging, cool to room temperature, wash with deionized water and absolute ethanol several times, and dry.

Embodiment 2

[0025] 1. Weigh 4.2g of diatomaceous earth and suspend it in 50mL of water, and place it in a constant temperature water bath and stir to form a uniform suspension.

[0026] 2. Weigh 4.146g of ammonium persulfate and add it to the diatomite suspension, stir with constant temperature magnetic force to fully impregnate the diatomite, then add 4.957g of potassium permanganate and continue stirring at constant temperature for one hour to fully react and then cool to room temperature.

[0027] 3. Transfer the solution to a reactor in a water bath at 50°C for 24 hours for aging, cool to room temperature, wash with deionized water and absolute ethanol several times, and dry.

Embodiment 3

[0029] 1. Weigh 4.2g of diatomaceous earth and suspend it in 50mL of water, and place it in a constant temperature water bath and stir to form a uniform suspension.

[0030] 2. Weigh 3.06g of ammonium persulfate and add it to the diatomite suspension, stir it with a constant temperature magnetic force to fully impregnate it into the diatomite, then add 3.66g of potassium permanganate and continue stirring at a constant temperature for one and a half hours to fully react and then cool to room temperature .

[0031] 3. Transfer the solution to a reaction kettle for 16 hours in a water bath at 120°C for aging, cool to room temperature, wash with deionized water and absolute ethanol several times, and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com