Preparation method of catalyst for improving yield of diesel oil produced by catalytic cracking

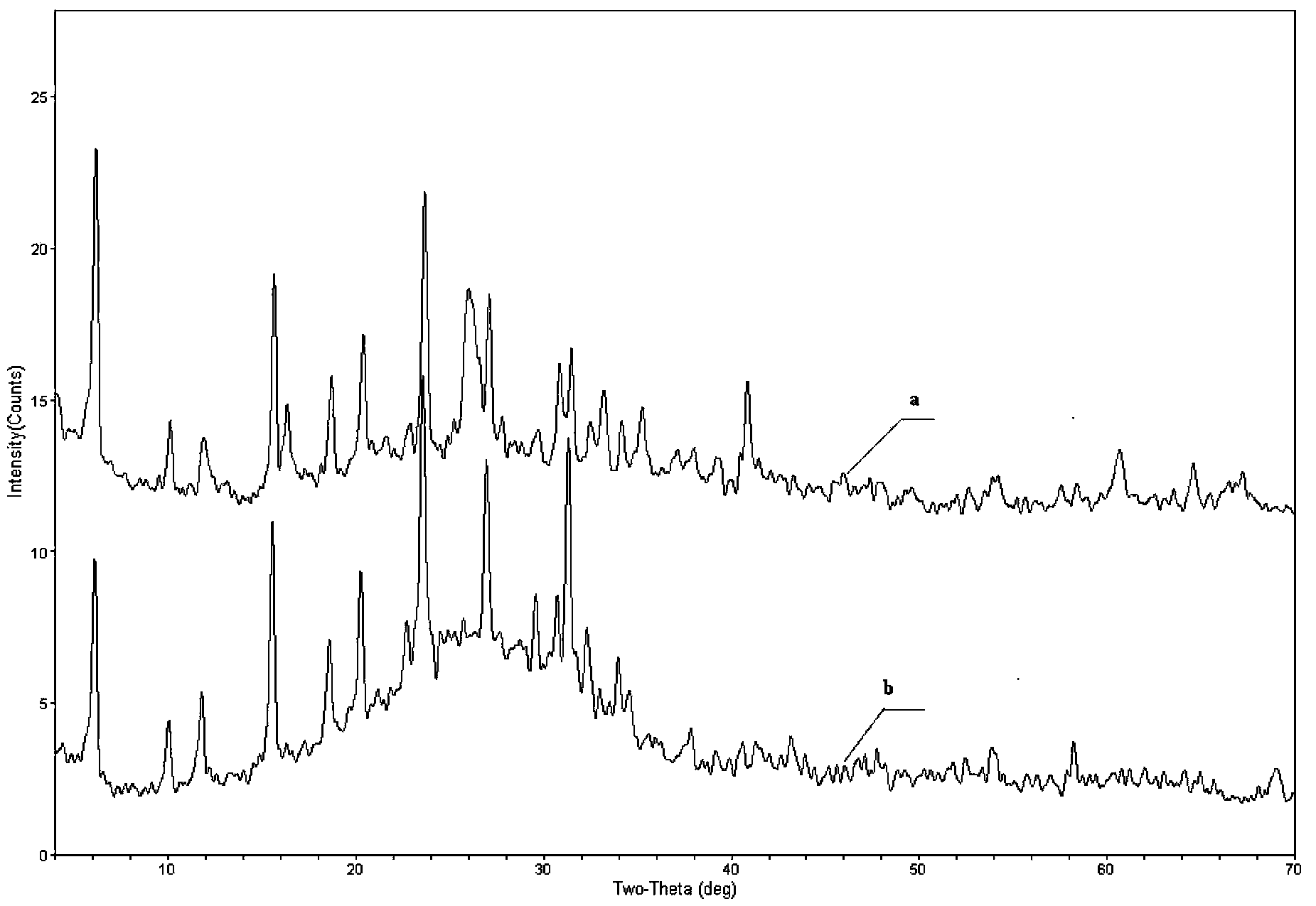

A catalytic cracking diesel oil and catalytic cracking technology, which is applied in the field of in-situ crystallization catalytic cracking catalyst and its preparation, can solve the problems of non-environmental protection, strength, complex process, etc., and achieve a rich specific surface, good pore structure, and small crystal grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Mix the phosphoric acid solution with an acid concentration of 0.75mol / L and diatomaceous earth, and then treat it at 50°C and pH 4.2 for 10 minutes, filter, wash, and dry, and then add 2000g of kaolin (calcium base), acid-treated 950 grams of diatomaceous earth (calcium base), 4% sodium silicate, 8% zinc nitrate as a structural aid, and chemical water were prepared to form a mixed slurry with a solid content of 46%, and spray-dried to obtain 2225g of spray particles with a particle size of 20-110μm Microsphere TS1.

[0047] A part of TS1 spray soil balls was roasted at 925°C for 2.6h to obtain roasted microspheres TM1, and the other part was roasted at 650°C for 2.8h to obtain roasted microspheres TP1, and then 200g of TM1 and 300g of TP1 were mixed and sodium silicate, The directing agent, sodium hydroxide solution, and chemical water are used for in-situ crystallization reaction to obtain the crystallized product J1.

Embodiment 2

[0049] Mix sulfuric acid solution with an acid concentration of 3mol / L and diatomite at 90°C for 15 minutes, and control the pH value at 3.5. 900 g of soil (calcium base), 6% of aluminum sol, 0.5% of magnesium nitrate as a structural aid, and chemical water were prepared to form a mixed slurry with a solid content of 32%, and spray-dried to obtain 1130 g of spray microspheres TS2 with a particle size of 20-110 μm .

[0050] The TS2 spray soil balls were calcined at 990°C for 1.5h to obtain the calcined microspheres TM2. Add 800g of TM2 to sodium silicate, directing agent, sodium hydroxide solution, and chemical water to carry out in-situ crystallization reaction to obtain the crystallized product J2.

Embodiment 3

[0052] Mix the acetic acid solution with an acid concentration of 5mol / L and diatomite and treat it at 75°C and pH 3.8 for 45 minutes. 1200g (calcium base), 6% sodium silicate, 2% lanthanum nitrate as a structural aid, and chemical water to prepare a mixed slurry with a solid content of 40%, and spray drying to obtain 1582g of spray microspheres TS3 with a particle size of 20-110 μm .

[0053] A part of TS3 was calcined at 920°C for 2.5h to obtain calcined microspheres TM3, and the other part was calcined at 730°C for 2.8h to obtain calcined microspheres TP3, then 150g TM3 and 750g TP3 were added to sodium silicate, directing agent, hydroxide Sodium solution and chemical water are used for in-situ crystallization reaction to obtain the crystallized product J3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com