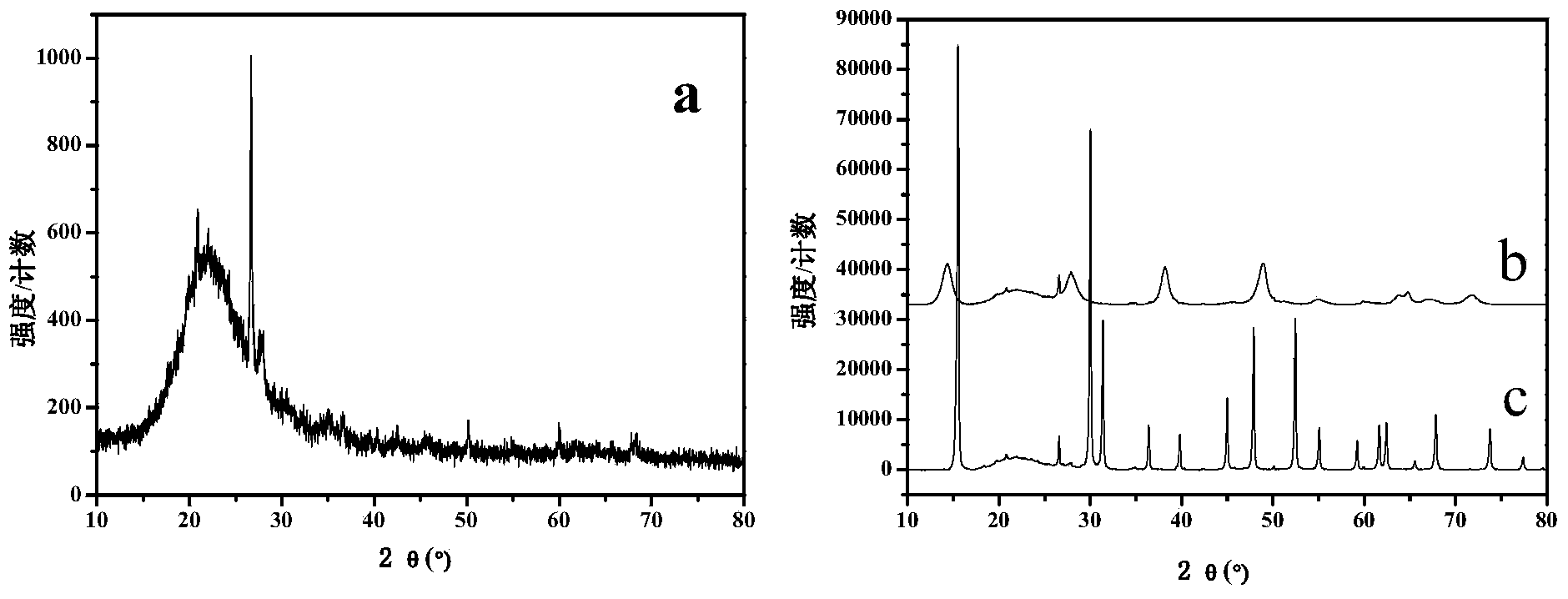

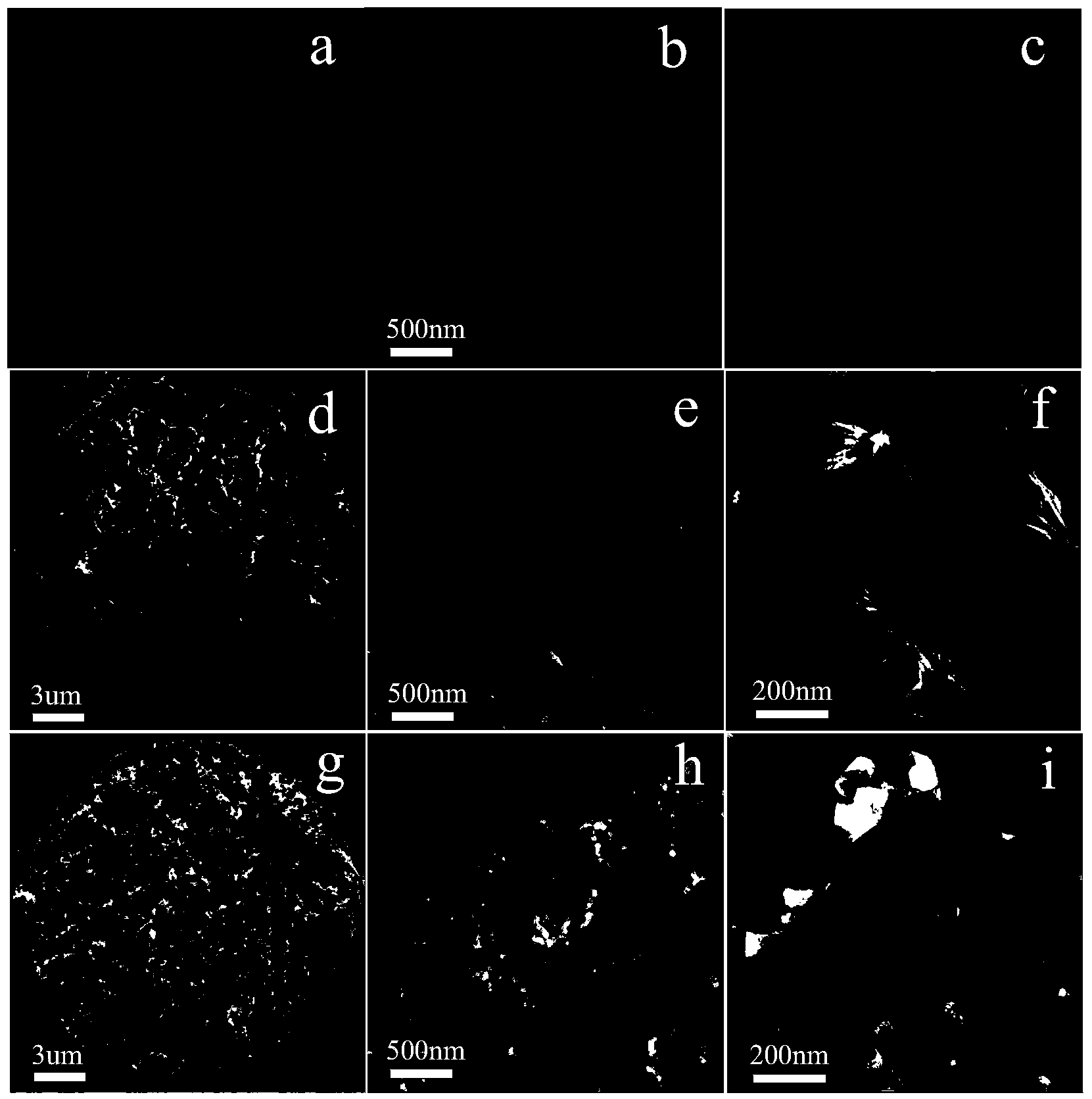

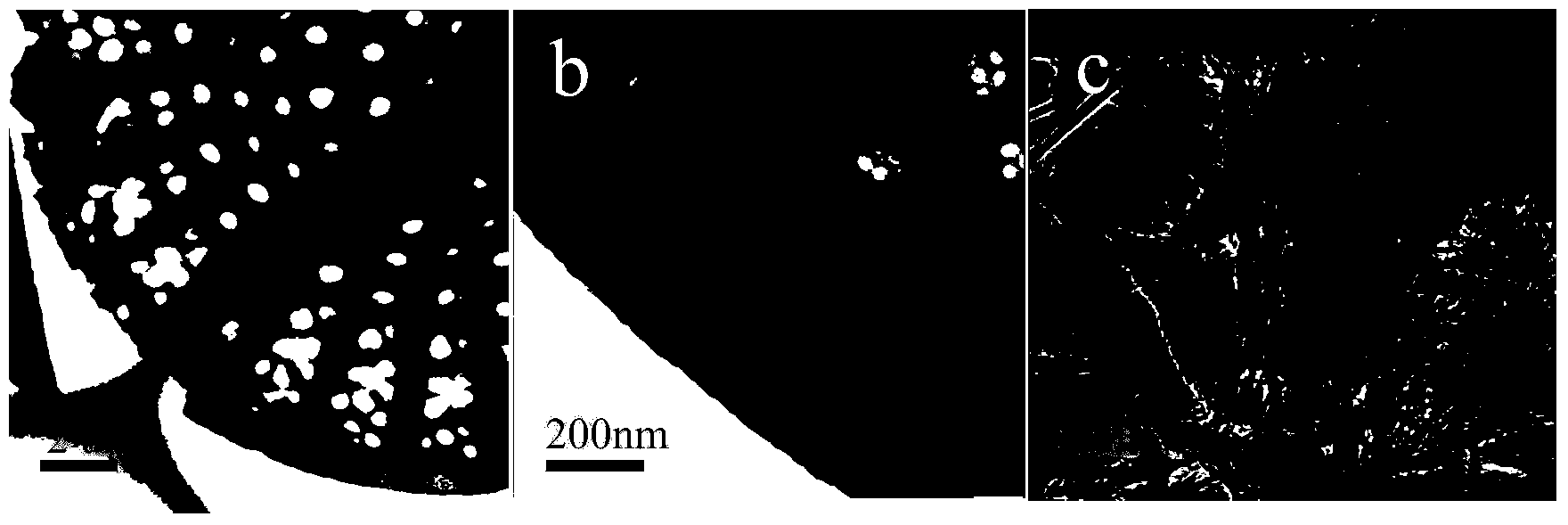

Preparation method for diatomite adsorbent chemically modified by nano gamma-Al2O3 adopting ordered structure

A technology of ordered structure and chemical modification, applied in the field of materials, can solve the problems of reduced adsorption effect of heavy metal ions, low specific surface area, limited adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In the first step, 1.8 g of diatomite was weighed and dissolved in a beaker filled with 30 ml of deionized water, and the beaker was placed in a constant temperature water bath and stirred for 30 minutes to obtain a suspension of diatomite.

[0020] In the second step, accurately weigh 4.828g AlCl 3 ﹒ 6H 2 O was added to the suspension of diatomite, stirred with constant temperature magnetic force for 3h and fully immersed on the diatomite to prepare AlCl containing diatomite 3 suspension.

[0021] The third step is to prepare 2mol / L ammonia solution and add the above AlCl 3 In the suspension, adjust the pH to 4 and continue stirring for 30 min.

[0022] In the fourth step, weigh 0.107 g of sodium dodecylbenzene sulfonate and add it to the above solution, stir for 30 min, then add 2.67 g of urea, and stir for 1 h.

[0023] In the fifth step, the solution is transferred to a reaction kettle for 180°C hydrothermal reaction for 3 hours for aging, after cooling to room...

Embodiment 2

[0025] In the first step, 2.2 g of diatomite was weighed and dissolved in a beaker filled with 50 ml of deionized water, and the beaker was placed in a constant temperature water bath and stirred for 30 minutes to obtain a suspension of diatomite.

[0026] In the second step, accurately weigh 5.634g AlCl 3 ﹒ 6H 2 O was added to the suspension of diatomite, stirred with constant temperature magnetic force for 3h and fully immersed on the diatomite to prepare AlCl containing diatomite 3 suspension.

[0027] The third step is to prepare 3mol / L ammonia solution and add the above AlCl 3 In the suspension, adjust the pH to 4 and continue stirring for 30 min.

[0028] In the fourth step, weigh 0.191 g of sodium dodecylbenzenesulfonate and add it to the above solution, stir for 30 min, then add 4.06 g of urea, and stir for 1 h.

[0029] The fifth step is to transfer the solution to the reaction kettle for 3 hours of hydrothermal reaction at 180°C for aging, after cooling to room ...

Embodiment 3

[0031] In the first step, 1.0 g of diatomite was weighed and dissolved in a beaker filled with 30 ml of deionized water, and the beaker was placed in a constant temperature water bath and stirred for 30 minutes to obtain a suspension of diatomite.

[0032] In the second step, accurately weigh 2.272g AlCl 3 ﹒ 6H 2 O was added to the suspension of diatomite, stirred with constant temperature magnetic force for 3h and fully immersed on the diatomite to prepare AlCl containing diatomite 3 suspension.

[0033] The third step is to prepare 1mol / L ammonia solution and add the above AlCl 3 In the suspension, adjust the pH to 4 and continue stirring for 30 min.

[0034] Step 4: Weigh 0.036 g of sodium dodecylbenzenesulfonate and add it to the above solution, stir for 30 min, add 2.16 g of urea and 0.3704 g of ammonium fluoride, and stir for 1 h.

[0035] In the fifth step, the solution is transferred to a reaction kettle for 180°C hydrothermal reaction for 3 hours for aging, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com