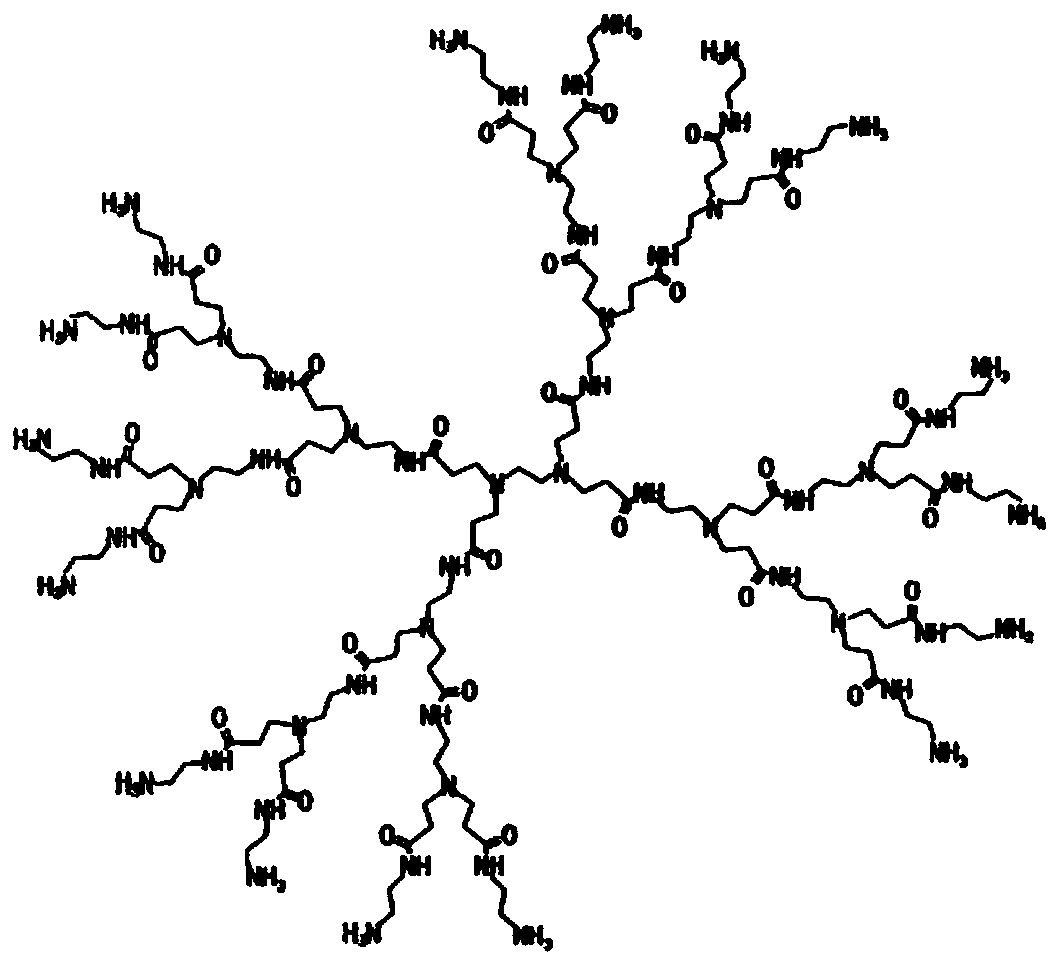

Production method of heavy metal ion adsorption type PVDF modified separation membrane

A heavy metal ion, adsorption-type technology, applied in the field of separation membranes, can solve the problems of few and difficult hyperbranched polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

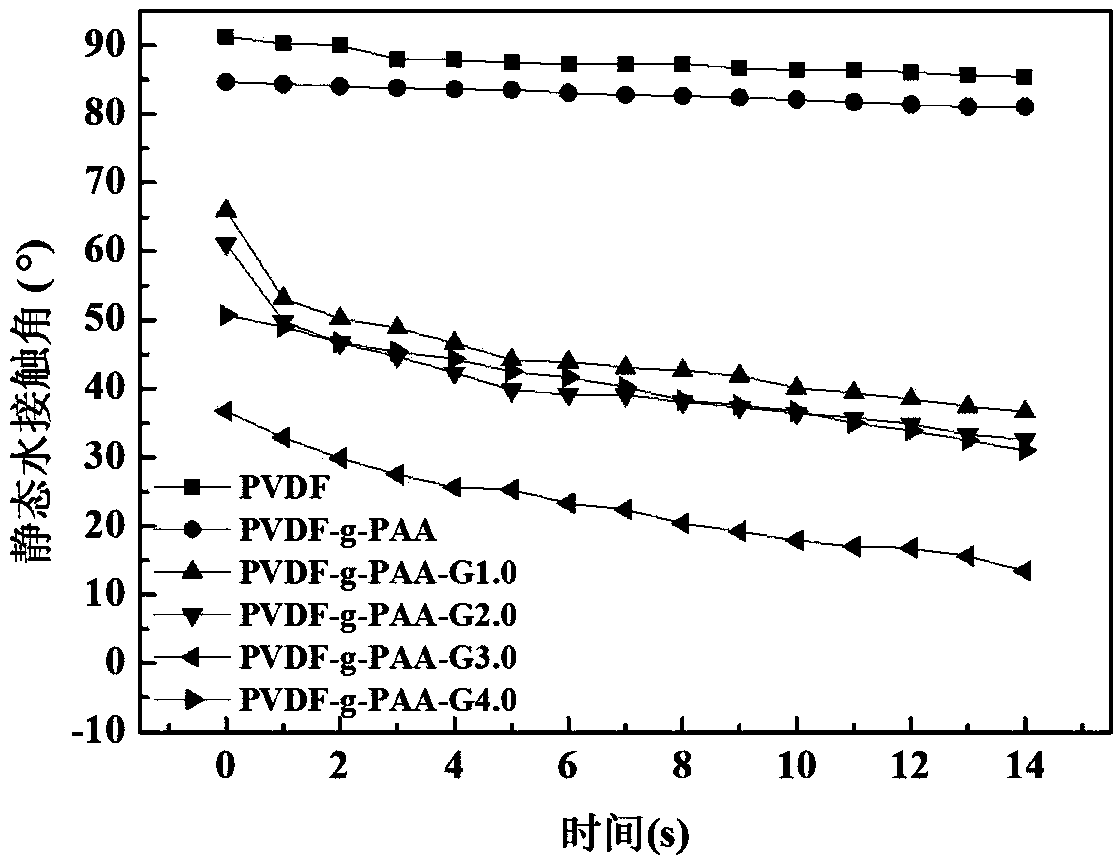

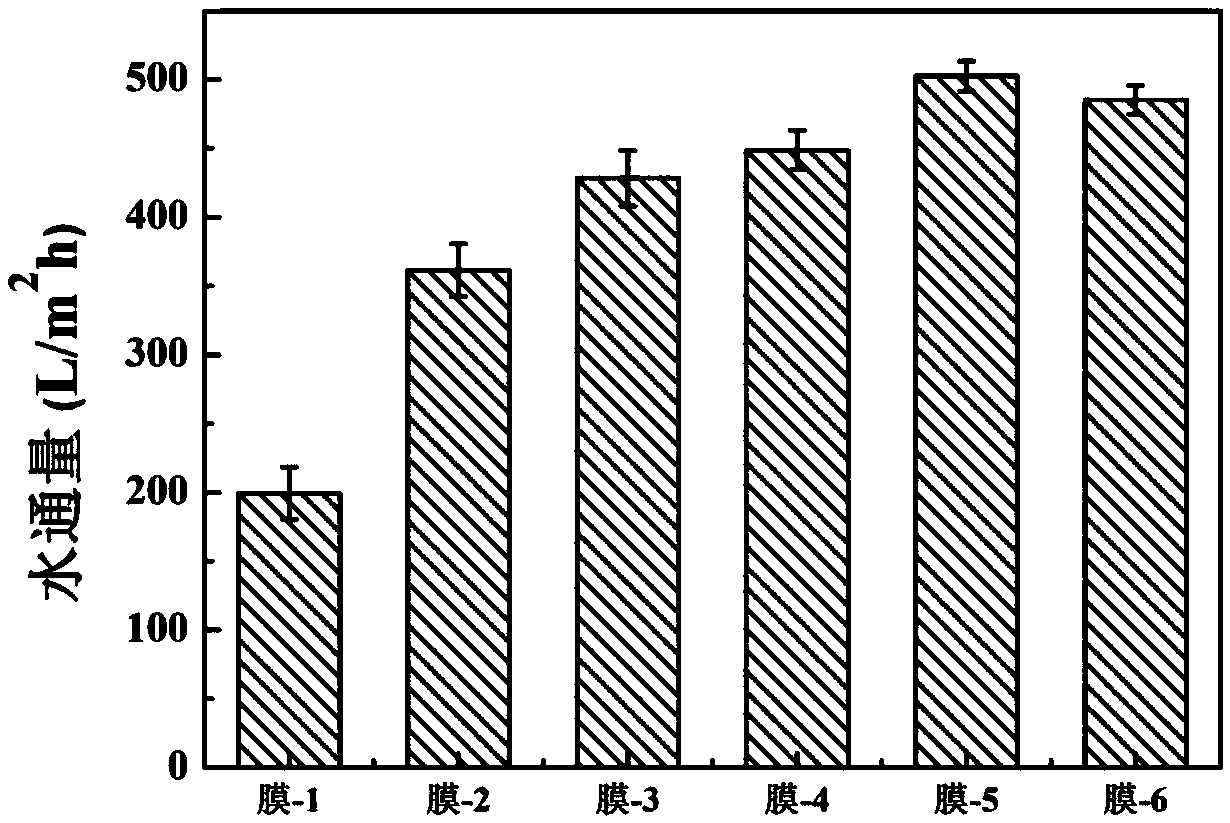

[0073] Example 1 Preparation of Heavy Metal Ion Adsorption Type PVDF Modified Separation Membrane PVDF-g-PAA-Gn PAMAM Membrane

[0074] (1) Pretreatment of PVDF powder. Weigh 25g of potassium hydroxide to prepare a 2.5mol / L potassium hydroxide solution, quickly add 20g of PVDF powder into the potassium hydroxide solution in a water bath at 60°C, and control the ratio of PVDF powder and potassium hydroxide solution to 20g:150 -300mL, at the same time quickly pour 4mL of absolute ethanol and stir for 10min, then filter with suction, wash with a large amount of deionized water for more than 3 times, and dry the final product for later use. Take 5g of the treated PVDF powder and place it in 100mL N-N dimethylformamide (DMF), and dissolve it with nitrogen gas at 60°C. After the PVDF powder is dissolved, continue to pass nitrogen gas for 5min, then add 10g of acrylic acid (AA) and 0.1g of bismuth After nitrogen bisisobutyronitrile (AIBN) was passed through nitrogen for 15 minutes, ...

Embodiment 2

[0083] Example 2: Preparation of Heavy Metal Ion Adsorption Type PVDF Modified Separation Membrane PVDF-g-PAA-Gn PAMAM Membrane (1) Pretreatment of PVDF powder. Weigh 30g of potassium hydroxide to prepare a 3mol / L sodium hydroxide solution, quickly add 30g of PVDF powder into the sodium hydroxide solution in a 70°C water bath, and at the same time quickly pour 6mL of absolute ethanol into it and stir for 20min before suction filtration. and washed with a large amount of deionized water for more than 5 times, and the finally obtained product was dried for later use. Take 11g of the treated PVDF powder and place it in 120mL N-N dimethylformamide (DMF), dissolve it with nitrogen gas at 70°C, and continue nitrogen gas flow for 15min after the PVDF powder is dissolved, then add 15g of acrylic acid (AA) and 0.3g of bismuth Nitrogen gas was passed through nitrogen bisisobutyronitrile (AIBN) for 25 minutes, continued to stir for 12 hours, then suction filtered, washed with deionized w...

Embodiment 3

[0091] Example 3 Preparation of Heavy Metal Ion Adsorption Type PVDF Modified Separation Membrane PVDF-g-PAA-Gn PAMAM Membrane

[0092](1) Pretreatment of PVDF powder. Weigh 28g of potassium hydroxide to prepare a 2.8mol / L potassium hydroxide solution, quickly add 25g of PVDF powder into the potassium hydroxide solution in a water bath at 65°C, and at the same time quickly pour 5mL of absolute ethanol and stir for 15min before pumping Filter, and wash with a large amount of deionized water more than 4 times, and finally the product obtained is dried for later use. Take 8g of the treated PVDF powder and put it in 110mL N-N dimethylformamide (DMF), and dissolve it under nitrogen gas at 65°C. After the PVDF powder is dissolved, continue to pass nitrogen gas for 10min, then add 12g of acrylic acid (AA) and 0.2g of bismuth Nitrogen was passed through nitrogen bisisobutyronitrile (AIBN) for 20 minutes, continued to stir for 12 hours, then suction filtered, washed with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com