Modified diatomite and preparation method thereof

A diatomite modification technology, applied in the field of modified diatomite and its preparation, can solve the problems of MoO3 volatility and high product toxicity, lack of mercury oxidation ability, low oxidation ability, etc., to improve mechanical strength and Erosion resistance, specific surface area improvement, and oxidation ability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

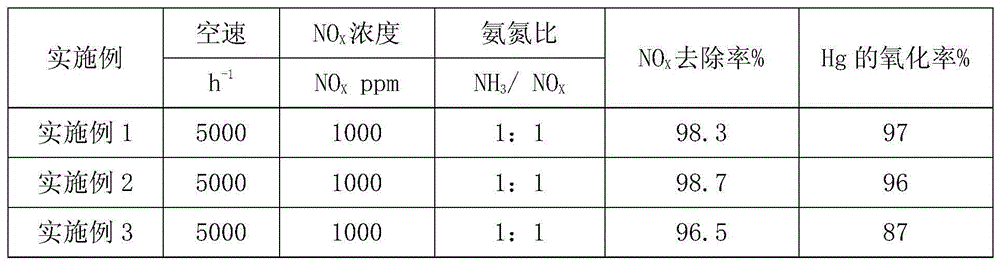

Embodiment 1

[0050] Preparation of Modified Diatomite

[0051] The commercially available diatomite is modified once with a nitric acid solution of PH=0.1, and the pre-modified diatomite is obtained by boiling, cooling, suction filtration, washing, drying, roasting, etc., and the diatomite is added to the nitric acid solution , configured into a slurry with a concentration of 50% by weight, and obtained pre-modified diatomite by boiling, cooling, suction filtration, washing, drying, and roasting. at 500°C, and the calcination time is 16h. After the calcination, the required pre-modified diatomite is obtained; the pre-modified diatomite is modified twice with ferric nitrate with a concentration of 20% by weight, and the pre-modified diatomite is The diatomite is added into the ferric nitrate solution to prepare a slurry with a mass concentration of 40%. After drying and roasting, the secondary modified diatomite is obtained. The drying temperature is 100°C, dried for 16 hours, and the calci...

Embodiment 2

[0070] Preparation of Modified Diatomite

[0071] The commercially available diatomite is modified once with a nitric acid solution of PH=0.06, and the pre-modified diatomite is obtained by boiling, cooling, suction filtration, washing, drying, roasting, etc., and the diatomite is added to the nitric acid solution , configured into a slurry with a mass concentration of 40%, and obtained pre-modified diatomite by boiling, cooling, suction filtration, washing, drying, and roasting. The boiling temperature is 85°C, the drying temperature is 95°C, and the drying temperature is 14 hours. 450°C, the calcination time is 14h, after the calcination, the required pre-modified diatomite is obtained; the pre-modified diatomite is modified twice with the mass ratio of 25% ferric nitrate, and the pre-modified silicon The diatomite is added to the ferric nitrate solution to form a slurry with a mass concentration of 40%, and then the secondary modified diatomite is obtained by drying and roa...

Embodiment 3

[0090] Preparation of Modified Diatomite

[0091] The commercially available diatomite is modified once with a nitric acid solution of PH=0.2, and the pre-modified diatomite is obtained by boiling, cooling, suction filtration, washing, drying, roasting, etc., and the diatomite is added to the nitric acid solution , configured into a slurry with a mass concentration of 45%, and obtained pre-modified diatomite by boiling, cooling, suction filtration, washing, drying, and roasting. The boiling temperature is 85°C, the drying temperature is 95°C, and the drying temperature is 13 hours. 485°C, the calcination time is 13h, and after the calcination, the required pre-modified diatomite is obtained; the pre-modified diatomite is modified twice with ferric nitrate with a mass ratio of 26%, and the pre-modified silicon The diatomaceous earth is added to the ferric nitrate solution to prepare a slurry with a mass concentration of 45%. After drying and roasting, the secondary modified dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com