Method for determining nickel content in nickel-chromium-aluminum coated diatomite

A technology of diatomite-coated and nickel content, which is applied in the field of nickel-chromium-aluminum-coated diatomite element analysis, can solve the problems of incomplete dissolution of nickel-chromium-aluminum-coated diatomite samples, long sample dissolution time, and long analysis cycle. Achieve the effect of rapid measurement, accurate and reliable method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

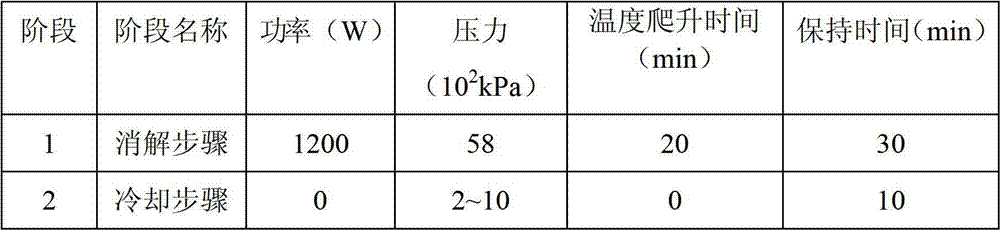

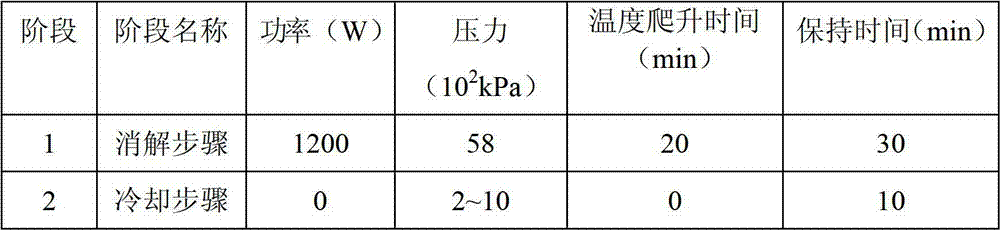

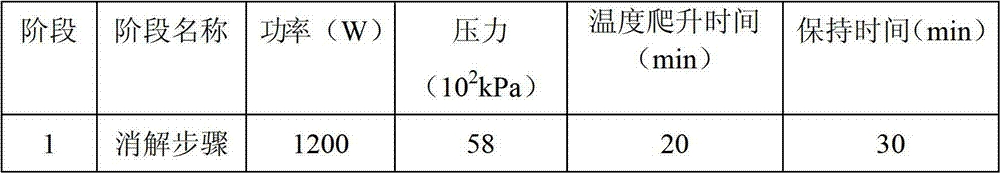

[0050] Microwave digestion was used to dissolve the samples, and the working conditions of the microwave digestion instrument (Anton paar multiwave3000) were as follows:

[0051] Table 1 Microwave digestion conditions and acid dosage

[0052]

[0053] (1) The reagents used in the determination process are as follows:

[0054] (1.1), citric acid solution: 500g / L;

[0055] (1.2) Ammonia buffer solution: Weigh 67g of ammonium chloride, add 570mL of ammonia water, dilute to 1000mL with water, and mix well;

[0056] (1.3), 10gL ethanol solution of dimethylglyoxime solution: dissolve 5g dimethylglyoxime in 500mL ethanol;

[0057] (1.4) Nickel standard solution with a mass fraction not less than 99.9%: 1.00mg / mL, weigh 1.0000g, put it in a 300mL beaker, add 20mL nitric acid 1+1, heat to dissolve. Add 50mL of water and boil to remove nitrogen oxides. Cool to room temperature, transfer to a 1000mL volumetric flask, dilute with water to the mark, and shake well;

[0058] (1.5), ED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com